See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

Avery Dennison label and packaging materials North America has expanded its portfolio of Forest Stewardship Council (FSC)-certified products, which now totals more than 500 products. Avery Dennison...

June 25 2019

Avery Dennison label and packaging materials North America has expanded its portfolio of Forest Stewardship Council (FSC)-certified products, which now totals more than 500 products. Avery Dennison says this is the largest in the industry.

The number of FSC products will continue to increase as the company works to meet its aggressive sustainability sourcing goal: to source 100 percent certified claim paper products by the year 2025, 70 percent of which must be FSC-certified. To date, 84 percent of all paper facestocks offered by Avery Dennison in North America are certified, and of that, 78 percent are FSC-certified.

‘As an industry leader, Avery Dennison has worked hard to add to our FSC-certified portfolio, growing from 150 products in 2016 to more than 500 products today,’ said Tina Hart, vice president, marketing, Avery Dennison label and packaging materials. ‘No one has more FSC-certified products in the industry today than Avery Dennison. We offer more than four times the number of FSC-certified products than our competition and plan to source 100 percent certified paper five years before they do.’

FSC is the standard for sustainable forestry practices. To achieve FSC-certification, products must come from well-managed sources that provide environmental, social and economic benefits. Avery Dennison also partners with the Rainforest Alliance, which works directly with forest stakeholders to create sustainable management plans and improve market opportunities for these small landowners.

‘We work hand-in-hand every day to help converters and brand owners in markets such as food, wine and spirits, and dairy reach their sustainability goals,’ said Sarah Sanzo, product compliance and sustainability manager at Avery Dennison. ‘The demand from consumers for accountability has never been greater, so we must continue to lead the way in making our industry more sustainable.’

French RIP software specialist Caldera has announced a range of new technologies and product updates to be showcased at this year’s ITMA. The company will be exhibiting a new version of Texti...

June 25 2019

French RIP software specialist Caldera has announced a range of new technologies and product updates to be showcased at this year’s ITMA. The company will be exhibiting a new version of TextilePro, its production suite for textile printing, along with developments in the SportsFactory E2E web-to-workflow solution and Kit Builder custom clothing designer software, and will be demonstrating automation via Nexio. ITMA will take place in Barcelona, between 20 and 26 June, and Caldera will be in booth H3-B105.

With the release of Version 12.1, TextilePro now features a range of new additions that focus on improving processing speeds and providing a more intuitive user experience.New textile enhancements includes RotationBoost, which saves time on the rotation of huge raster files, making the Caldera rotation algorithm 30% faster than its competitors and Caldera Snapshots, for backing up the installation folder and restoring previously saved backups.

Exclusively for CalderaCare users, CalderaJobs can ensure exact color reproduction of old jobs by archiving and re-importing jobs, CxF/4 spot color libraries import allows to reproduce D65/10 degrees spot colors, and the latest version also incorporates InkPerformer V3, which can lead to ink savings of up to 30%.

Caldera SportsFactory is a comprehensive solution which offers bespoke workflow building to enable users to create their ideal E2E digital workflow. After debuting at FESPA in 2018, the suite delivers capability in project assessment and scoping, inventory of deliverables, planning and budgeting. By working together with strategic partners, Caldera has implemented standardized digital printing set-ups tailored to provide color management, workflow and bi-directional business data between brands and in-house or external print contractors. This results in a comprehensive solution, from the E-commerce storefront to the print file creation and transfer, and color management functions.

Kit Builder is a new fully-customizable clothing designer software that allows customers to design garments with a range of options specified by the provider – including colors, logos, text and embellishments. The result is faster design times, increased sales and fewer production mistakes.

Also on show at Caldera’s ITMA stand will be Nexio – a program that connects the Caldera RIP with third party programs to increase the number automated sequences in the workflow. Production times are reduced, along with errors and costs, while JDF job reports allow for production performance analysis which can fuel operational development and enhance profitability.

According to Sébastien Hanssens, VP Marketing, Operations and IT, “Caldera already has an important number of key customers who specialize in textile printing, and the number continues to grow. We work with producers of sportswear, team uniforms, fashion and home décor, and we will continue to develop products and projects for this important sector of the market.”

Caldera will also be highlighting the recently-launched CalderaCare at ITMA. This is a new customer service agreement that gives clients access to routine maintenance and technical support, along with software updates and enhancements. The scheme offers one, two or three-year contracts and is open to all users of Caldera RIP products. The aim of the subscription is to give users the peace of mind that comes with knowing they have someone to turn to when software issues arise. Commenting on its launch, Sébastien Hanssens said, “CalderaCare is one of our most important initiatives. Providing the best possible support to our users shows our commitment to the customer experience.”

Kornit Digital, a worldwide market leader in digital textile printing technology, announced Kornit Konnect, its new cloud-based, mobile workflow software platform that enables businesses to maximis...

June 25 2019

Kornit Digital, a worldwide market leader in digital textile printing technology, announced Kornit Konnect, its new cloud-based, mobile workflow software platform that enables businesses to maximise productivity of their digital printing solutions. This is the first phase in Kornit’s implementation of its industry vision of textile design, decoration and production being fuelled by data-driven insights and performance metrics.

In its first phase, the Kornit Konnect enables businesses to monitor production, analyse insights and manage their fleet, in order to eliminate blind spots. It includes a fleet management dashboard, data driven benchmarks, actual production costs, and cost structures per job, making it easy for businesses to learn more, react faster and perform better.

Future phases and releases of the Kornit Konnect will enable deeper insights and actions as it comes to optimising production management and enabling a seamless software workflow environment for businesses of all sizes.

“While businesses need to deliver high-quality faster than ever to maintain customer loyalty, they are also challenged to maximise their efficiency and productivity,” said Omer Kulka, VP Marketing at Kornit Digital. “Konnect empowers these businesses to make better-informed production decisions and act on them, with greater visibility and control over their operations. We have a revolutionary vision for this cloud-based platform and have plans to frequently add new modules and features that customers can leverage for long-term business success.

www.kornit.com

Once a year usually around November, signwriters from all over New Zealand are joined by Australians, and one or two Americans and the odd European, to participate in the annual brushfest known as ...

June 25 2019

Once a year usually around November, signwriters from all over New Zealand are joined by Australians, and one or two Americans and the odd European, to participate in the annual brushfest known as ‘Letterheads’.

At these events artisans and craftspeople from the various disciplines of signmaking congregate to share their wealth of knowledge with anyone who is prepared to watch, listen, learn or experiment. It is in this way that an appreciation for the traditional craft of signmaking is passed on from the elder statesmen to the present practitioners to ensure that these arts and crafts are not lost to the digital age, and to this end all people with an artistic mind, an artistic hope or an artistic skill are welcome to register and attend.

Letterheads this year sees another first – Our first time in Taupo located on the shore of the caldera of the now extinct Taupo Volcano, and arguably the adventure capital of North Island New Zealand, known for its trout fishing, hot springs, winter ski fields, geothermal valleys and the famous Huka Falls near the head of the mighty Waikato River.

Our host, Bevan Weal, is a traditionally trained sign craftsman and well known in the Taupo district not only for his work but also his involvement with motocross and community involvement in general having even participated in a charity boxing match (which he won!)

Bevan had hoped to be hosting us in his new premises but the delays in building consents and approvals mean that we’ll be meeting in his Ashwood Avenue premises and while Bevan’s workshop is quite large, he will only be accepting 70 registrations for this year’s event, wanting to concentrate on a quality experience for all participants.

So if you are planning to attend please don’t leave it until the last minute as you’ll end up being disappointed.

Register here.

SAi, the leading provider of software solutions for the signmaking, digital printing and CNC machining industries, has announced that it has established a new business entity in Australia. SA...

June 25 2019

SAi, the leading provider of software solutions for the signmaking, digital printing and CNC machining industries, has announced that it has established a new business entity in Australia. SA International Pty Ltd, based in Sydney, New South Wales, will support the company’s growing network of resellers and customers across both Australia and New Zealand.

Currently already supporting around 30 resellers that serve an increasing number of customers across Australasia, the facility will strengthen SAi’s ability to meet its expanding operations, while demonstrating its commitment to customers’ growth and success.

The introduction of a local team will also further facilitate training opportunities with product specialists for both new and existing customers, as well as resellers, ensuring that Flexi and EnRoute users make the most of their software.

“Australia is a growing market for our software solutions, particularly in the woodworking and kitchen cabinet segments,” explains Sarit Tichon, Senior Vice President of Worldwide Sales, SAi. “Strategically, it makes sense for us to open a new business division here.”

The resident Director of SA International Pty Ltd will be Gregory Will from Penguin Management, an Australian-based company which specializes in the management of local business operations for overseas companies.

“I am delighted to be working with a company that provides its customers with such revolutionary solutions and expert advice,” comments Will. “I look forward to helping SAi establish its Australian division and anticipate a very exciting time ahead as SA International Pty Ltd goes from strength-to-strength.”

SAi is headquartered in the United States and has other offices in Belgium, Brazil, China and Japan.

Xante' has announced the EnVite Multi-Media Digital Press, its newest innovative digital press designed for the demanding stationery and specialty printing markets. Stationery stores serve customer...

June 25 2019

Xante' has announced the EnVite Multi-Media Digital Press, its newest innovative digital press designed for the demanding stationery and specialty printing markets. Stationery stores serve customers who have very high standards and so does Xante', said Robert Ross, President and CEO. The EnVite delivers extremely high-quality, fast and fully automated prints on specialty media and does so at a very affordable price.

The EnVite produces stunning 4800 dpi colour quality on an extensive range of media types and sizes. Well-suited to fast production of invitations, envelopes, stationery, business cards and greeting cards, EnVite boasts speeds of up to 3,500 full-colour, fully-addressed A7-size envelopes per hour and media sizes from 3.5x3.5 up to 13x49. The digital press includes the Enterprise SP, a radical new design high-speed feed system that fits comfortably in the limited floor space of stationery stores. With the EnVite, stationery stores will be able to print on a wide range of media including vellum, linen, sueded, pearlised, and foil-lined envelopes. EnVite print markets include small poster printing, menus, postcards and so much more.

Powered by Xante's iQueue workflow software, the EnVite provides stationery stores with rich personalisation and customisation tools to satisfy any requirement.

We designed a product that greatly expands the capability of the typical stationery shop, said Mark Priede, Xante's Vice-President of Global Sales and Marketing. The extensive variable data printing tools included at no extra charge in iQueue make each print job unique and personalised. Customers can bring their own designs or use any of iQueue's more that 1,000 free design templates and specialty fonts. EnVite and our iQueue workflow software make outstanding personalised print jobs incredibly easy.

The Xante' EnVite Multi-Media Digital Press is available immediately direct from Xante' or its reseller partners around the globe.

X-Rite Incorporated and Pantone LLC, global leaders in color science and technology, announce the new i1Pro 3 Plus, a spectral colour measurement solution specifically designed for imaging, print, ...

June 25 2019

X-Rite Incorporated and Pantone LLC, global leaders in color science and technology, announce the new i1Pro 3 Plus, a spectral colour measurement solution specifically designed for imaging, print, and textile professionals who need advanced calibration and color profiling capabilities to support today’s wide-format and industrial printing applications. The i1Pro 3 Plus has been optimised for digital printing on a range of materials and surfaces, including ceramics, textiles, glass, metal, wood, vinyl, plastics, thin films, cardboard, paper, and more. Commercial, wide-format, grand-format, packaging, and industrial printers can now create ICC profiles for almost any substrate and calibrate print production devices for the highest level of colour accuracy.

As more industries turn to digital printing, customers are putting greater emphasis on achieving accurate and repeatable colour. To do this, production print equipment needs to be linearized and profiled for each substrate in order to monitor colour output. Current profiling solutions are limited in their ability to measure textured, rough, or uneven surfaces and cannot accommodate various material thicknesses. Many devices do not have the resolution required to ensure the highest colour quality when printing detailed patterns, metallic effects, or photography images. This leads to costly colour errors and rework which impacts a printer’s bottom line.

“The i1Pro 3 Plus builds on the success of the i1 Family and removes the variability to create accurate ICC profiles on the widest range of materials,” said Ray Cheydleur, Printing and Imaging Product Portfolio Manager, X-Rite. “Wide- and grand-format users and industrial material printers will see immediate value by incorporating the affordable i1Pro 3 Plus into their prepress and production workflows, resulting in more accurate and repeatable color, a reduction of waste, and an increased return on investment.”

A long-term X-Rite partner, EFI (Electronics For Imaging), also sees the great potential of this latest i1 Family member. “We are delighted to support X-Rite’s newly announced i1Pro 3 Plus measurement device within our latest Fiery technologies at ITMA 2019. Due to the nature of digital textile production, this large-aperture device is an excellent fit with our latest single pass EFI BOLT high-speed textile printer. For both colour management and quality control, this device will allow our customers to produce accurate colour much more easily,” said John Henze, Vice President of Sales and Marketing, EFI Fiery.

New in the i1Pro 3 Plus:

- Larger aperture of 8mm to support new materials and substrates used in digital printing applications.

- New polarisation (measurement condition M3) filter that reduces specular highlights and shadows on fabrics and ceramics. It provides “better blacks” and richer colours on rough surfaces and glossy medias, like canvas prints and fine art photo papers.

- Simultaneously measure M0, M1 and M2 in a single pass to account for optical brighteners so prepress and print operators can quickly predict how colours printed on optically brightened substrates will look under different lighting conditions.

- Longer ruler for measuring the wider charts used in grand-format printing. The ruler includes an ISO-compliant white backer and removable magnetic strips on the top and sides for holding samples in place while measuring.

- New LED illuminant that improves device reliability. The i1Pr o3 Plus allows for four measurement conditions (ISO 13655 M0; M1: D50; M2: UV Excluded, M3 Polarised).

- Now supports transmission scanning for backlit film and materials used in signage.

- Measures high brightness, up to 5K NITs for ultra-bright displays.

“We are used to seeing bumpy shadow measurements from unpolarised devices on glossy textured medias like canvas. With the new polarisation feature in the i1Pro 3 Plus, our M3 measurements are dramatically smoother in the shadows - perfect in fact,” commented Scott Martin, Founder, Onsight, a leading workflow consultant for print, prepress, design and photography.

New X-Rite iO Table

In addition, X-Rite announces a new i1iO Automated Scanning Table that supports the i1Pro 3 Plus. This hands-free test chart reader offers automated color profiling on a variety of substrates with reduced risk of colour measurement errors. It is ideal for photographers, designers, and printers who want to speed up and automate the measurement process and eliminate manual strip reading.

The new i1iO table can be used with a variety of industrial materials including textiles, ceramics, corrugated, etc. and supports materials up to 33mm thick, with the optional z-axis spacer. It also supports transparencies and backlit materials.

Avery Dennison today introduced the new Avery Dennison MPI 3300 Easy Apply™ Series for a variety of short-term indoor and outdoor applications that require fast and consistent application of ...

June 18 2019

Avery Dennison today introduced the new Avery Dennison MPI 3300 Easy Apply™ Series for a variety of short-term indoor and outdoor applications that require fast and consistent application of the graphic to the substrate.

A premium grade monomeric calendered film with clear permanent and grey (opaque) removable adhesives, the MPI 3300 Easy Apply™ Series is a line extension to the company’s popular MPI 3300 StaFlat™ Series of promotional films. With this new introduction, the widened MPI 3300 portfolio is best suited for promotional and point-of-sale advertising, short-term signage, exhibition graphics as well as real estate signage.

“What makes this series stand out is the significant increase in productivity during the installation of graphics provided by Avery Dennison’s Easy Apply™ technology,” said Jordan Leach, senior business manager for Avery Dennison Graphics Solutions in Australia and New Zealand. “Busy graphics professionals will welcome its excellent installation performance.”

The film has a durability of up to three years and the combined MPI 3300 portfolio is available in clear and opaque grey, permanent and removable adhesives in roll sizes of 1.37m x 50m and 1.52m x 50m. Available in gloss white MPI 3300 Permanent Easy Apply™ and MPI 3302 Grey Removable Easy Apply™, wrap installers can expect the same high quality print performance with extra application versatility.

As with all Avery Dennison graphic films, the MPI 3300 Series has undergone extensive and comprehensive testing and is backed by the company’s long-established Integrated Component System (ICS) Warranty Program.

For more information on the MPI 3300 Easy Apply™ Series, please click here.

Roland DG Australia, a leading manufacturer of wide format inkjet printers and 3D devices, today announced new EOFY special offers for the award-winning TrueVIS VG Series Printer Cutters and the LE...

June 18 2019

Roland DG Australia, a leading manufacturer of wide format inkjet printers and 3D devices, today announced new EOFY special offers for the award-winning TrueVIS VG Series Printer Cutters and the LEF Series Benchtop UV Printers.

Get unbeatable colour, image quality, and non-stop productivity for less with these incredible deals on the award-winning TrueVIS VG Series printer cutters. Don’t miss out on this limited time offer that includes printer, take up unit, and a set of ink.

Save up to $4,000** on an LEF Series Benchtop UV Printer

Take advantage of the countless product customisation possibilities of the LEF Series, including direct printing onto electronics, giftware, leather items, décor, promotional goods and so much more. These specials include printer and BOFA extraction unit.

Click below for more details.

Roland DG EOFY

Alfex Laser has announced their EOFY 2019 specials. And when you see the deals you'll realise there's never been a better time to invest in state-of-the-art laser engraving technology. ...

June 17 2019

Alfex Laser has announced their EOFY 2019 specials. And when you see the deals you'll realise there's never been a better time to invest in state-of-the-art laser engraving technology.

Simply click on the link below to take advantage of incredible savings on the leading range of Laser engravers in the market. Why not chat with the team at Alfex Laser to learn about the amazing opportunities that exist with laser engraving technology.

Alfex Laser EOFY 2019

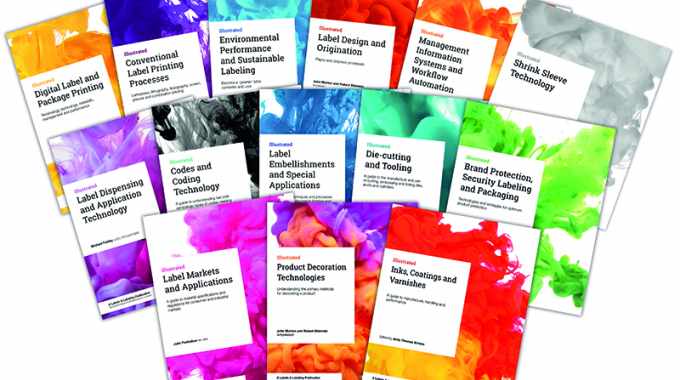

Visitors to the 40th anniversary edition of Labelexpo Europe, the world’s biggest label and package printing industry trade show, will be able to deepen their technical knowledge of flexible ...

June 11 2019

Visitors to the 40th anniversary edition of Labelexpo Europe, the world’s biggest label and package printing industry trade show, will be able to deepen their technical knowledge of flexible packaging and self-adhesive labels with the introduction of dedicated expert-led master classes and a workshop. These bring the number of in-depth technical learning programs to four – the show’s most extensive educational schedule to date.

Led by the Label Academy, the industry’s global training one-stop shop, the new master class and workshop will run simultaneously as half-day sessions on Thursday September 26, from 9am. The new Flexible Packaging master class will be hosted by Label Academy founder Mike Fairley alongside other leading experts and aims to equip label converters looking to enter or expand their production into flexible packaging with the essential technical knowledge required. This includes substrates, design and origination, printing and converting. Participants will learn how ink components interact with drying and curing technologies, and with packaging line demands. Current legislation, including ink migration, will also be addressed.

The new Self-Adhesive Label Materials workshop will be hosted by Labels & Labeling and Labelexpo’s strategic director Andy Thomas-Emans, alongside other experts in the field of self-adhesive label substrates. Participants will learn how self-adhesive laminates are made; the importance of materials and the need for different adhesives; why different laminate constructions are needed, their usage and how to identify them; and use of different self-adhesive test methods. The workshop also provides an insight into the correct methods for handling and storage of unprinted and printed laminates, and management of material waste.

Lisa Milburn, managing director of Labelexpo Global Series, said: ‘We are delighted to offer our most extensive educational schedule yet, with the addition of two new expert-led programs at Labelexpo Europe’s 40th anniversary edition. The show is known for being the place where visitors can top up their in-depth knowledge of the latest technical developments driving progress and see it in action on site.

‘Flexible packaging has an annual global rate of around five percent – one of the highest across all printing sectors. The dedicated master class will give label converters a valuable insight into its potential, and they can build on this knowledge by watching live digital and flexo press line demonstrations in the Flexible Packaging Arena. Self-adhesive labels continue to be Europe’s dominant label technology, so it’s vital that those involved in label production keep their knowledge fresh and relevant by taking advantage of this specialist workshop.’

A host of high-profile specialists are lined up to present at the learning programs. They include Alex Knott, senior technical service and development scientist at Dow Chemical Company and winner of the 2018 Label Industry Global Award for individual achievement, who will present on release liner substrates, and Christopher Ellison, Finat president and managing director of OPM (Labels and Packaging) Group, who will be among the presenters at the Flexible Packaging master class.

Back by popular demand are two more master classes taking place at Labelexpo Europe 2019: Digital Label and Package Printing, and Inks, Coatings & Varnishes. Both will run on September 27. The digital printing master class will be hosted by Mike Fairley and leading experts from the fields of materials, pre-press printing and finishing technology. The inks and coatings master class is led by Andy Thomas-Emans and offers participants the opportunity to learn how inks, top and barrier coatings, primers and varnishes are being adapted and applied to modern narrow-web converting operations.

Places on the master classes cost €695 (including the relevant Label Academy text book), while workshop places are €595. In either case, bookings include refreshments and lunch. Places are limited, so early booking is encouraged.

Mactac announces the launch of three new innovative and unique protective overlaminates for product packaging applications. Designed to give product-packaging labels added protection a...

June 11 2019

Mactac announces the launch of three new innovative and unique protective overlaminates for product packaging applications.

Designed to give product-packaging labels added protection as well as dramatic appearances and superior shelf appeal, the new overlaminates are ideal for packaging applications in markets such as health and beauty, household goods and food packaging.

Featuring highly creative brand-enhancing finishes, the new products include:

LTC01275 – a 0.7-mil matte clear soft touch overlaminate that adds a soft feeling and luxurious impression to packaging labels. Features a high clarity acrylic adhesive, a 50# white glassine liner and high scratch resistance to protect and maintain the clean look of the label.

LTCREVI901A – a 0.75-mil multilayered holographic overlaminate that changes colour depending on the viewing angle. Features a clear polyester film that gives a metallic tone without metal, an acrylic adhesive and a 50# white glassine liner.

LTCFR1125-25 – a 1.0-mil clear matte top-coated overlaminate that offers labels a subtle flat and soft finished appearance. Features a clear polyester film with an acrylic adhesive and a 50# white glassine liner.

“As the need to influence consumer purchasing decisions has increased, so has the importance of eye-catching packaging,” said Kim Hensley, marketing manager, Mactac Performance Adhesives. “Packaging labels are not just a source of information, they reflect a brand’s image and enhance consumer perception of a product’s quality. The unique soft touch, color change and matte finish characteristics of these overlaminates creates a rich appeal and differentiates a product from the rest, drawing and attracting customers.”

Mactac overlaminates serve two important functions – added protection and visual appeal. The new overlaminates were formulated to ensure a brand’s graphics remain in tact for the lifetime of the product-packaging label and elevate a label’s finished appearance and aesthetic qualities to enhance brand image and create outstanding shelf appeal.

The overlaminates were originally developed by Mactac’s parent company, LINTEC Corporation, which provides a wide range of pressure-sensitive papers and films to produce labels and seals for a variety of applications, such as food labelling, consumer electronics and automotive identification. They are known for their superior ability to provide resistance against chemicals, water and abrasion to help avoid loss of label legibility.

Glass fabrication specialist OSG will showcase its innovative new ScreeneX glass-embedded digital display solutions at this year’s UITP. Developed by OSG’s expert in-house ...

June 10 2019

Glass fabrication specialist OSG will showcase its innovative new ScreeneX glass-embedded digital display solutions at this year’s UITP.

Developed by OSG’s expert in-house R&D team, ScreeneX’s cutting-edge technology makes the most of valuable, but unutilised, real estate in transport and retail – namely glass windows, doors and partitions.

The ultra-slim digital displays are embedded into standard glass units transforming these areas into information and signage solutions for communicating with passengers. The surface of each side of the screen is as smooth and clear as conventional glass, so it does not impact aesthetics or safety.

Among the innovations on display will be the TRN 21-21T dual-sided partition which combines a digital display on one side and a touchscreen interface on the other. Seamless integration with existing passenger information systems ensures operators and manufacturers can plug-and-play with ease.

The dual-sided partition has already been soundly tested in a successful pilot with Bombardier and Deutche Bahn in Germany, Kinkisharyo in USA and is set to change the standard in the on-board passenger information world.

Other products on show include the TRN 38-LED. This dual-sided product was created especially for vehicle side windows. The external side features a new slim LED sign, while the internal one has a widescreen LCD for displaying passenger information.

ScreeneX technology can even be used for divided frame windows on buses and trains. A non-opening unit is fitted to the upper part of the window, which gives all the benefits of digital signage without the need to replace the entire window should an issue arise.

As well as public transportation vehicles themselves, ScreeneX’s high performance displays are also the perfect fit for rail and bus terminals, stations and platforms. Every display is built to the highest quality standards, as well as being highly resilient to vibration, changes in temperature and humidity, and vandalism, to make them the reliable choice for these challenging environments.

www.screenex-tech.com

Avery Dennison Graphics Solutions has announced the opening of its annual Wrap Like A King Challenge. This year’s vehicle wrap competition will run June 3 through Aug. 30, 2019, and it will a...

June 10 2019

Avery Dennison Graphics Solutions has announced the opening of its annual Wrap Like A King Challenge. This year’s vehicle wrap competition will run June 3 through Aug. 30, 2019, and it will again include Regional Wrap Kings, Continental Wrap Kings and the crowning of the prestigious “King of the Wrap World.”

Wrap installers from 53 countries across the world are invited to submit commercial, full print or color change wrap projects to be judged for the chance to win thousands of dollars in prizes. The prize packages for 2019 are worth a combined total of over $30,000, available to Regional Wrap Kings, Continent Wrap Kings and the “King of the Wrap World.” In 2018, more than 200 installers entered the challenge.

“We’ve been expanding the Wrap Like A King Challenge to new regions across the globe over the past two years, with the newest addition of South Africa for this year’s competition. We’re also introducing the ‘People’s Choice Award’ which allows the public to vote for their favorite project. This new award will provide additional and well-deserved recognition for our valued customers,” said Bill Podojil, vice president, Graphics Solutions North America. “We’re astonished at the level of creativity and talent with each passing year, and we anticipate the submissions for the 2019 challenge to surpass our expectations.”

Participating nations make up 13 geographic regions across the United States, Canada, Europe, Australia, New Zealand, Japan, South Korea and South Africa. Wrap installers in these regions will submit projects featuring Avery Dennison Supreme Wrapping™ Film, the Conform Chrome series, the ColorFlow™ Series, MPI 1105 Supercast Digital film or a combination of car wrap films to be evaluated against their regional peers by a panel of judges.

The 13 Regional Wrap Kings will win nearly $2,000 worth of personalized marketing materials, Avery Dennison product, SEMA passes and more. They will then go on to battle for royalty on their continents: North America, Europe, North Asia and Australia/New Zealand. The overall winner will be chosen by the judges as the best in show and crowned the “King of the Wrap World” at the 2019 SEMA Show, Nov. 5-8 in Las Vegas, Nevada.

Industry experts from around the globe will use their wealth of experience to narrow down the field, picking the most beautiful, technically challenging or otherwise most impressive wraps to move on in each round of the Challenge.

The 2019 Judges Panel:

- Justin Pate – The Wrap Institute, Global

Pate is an Avery Dennison-certified installer/instructor in the United States with over 20 years of experience. He leads the Avery Dennison North America hands-on car wrap workshop and certification program and is co-owner of The Wrap Institute.

- Myles Kovacs – DUB® Magazine, USA

Kovacs is the president and co-founder of DUB® Magazine, a U.S.-based magazine that focuses on the urban custom car culture and celebrities and their vehicles. He has been in the auto industry for 25 years.

- Yianni Charalambous – Yiannimize, UK

Charalambous is the owner of Yiannimize, a wrap shop in London catering to celebrities and high-end clientele. He has an incredible social following, with more than 1.3 million YouTube subscribers.

- Eddy Speelman – Speelman Graphic Applications, Europe

Speelman is the owner of Speelman Graphic Applications and has been an Avery Dennison trainer for 15 years. He has been part of the wrapping industry for decades, and he specializes in color change applications, paint protection and window tinting.

- Molly Waters – Avery Dennison Graphics Solutions, North America

Waters is a senior technical specialist in North America with over 19 years of industry experience. She often travels all over the country visiting sign and wrap shops and talking with customers about the car wrap industry. She also frequently contributes to the Avery Dennison blog.

- Peter Wright – Avery Dennison Graphics Solutions, Australia/New Zealand

Wright is a technical marketing manager and works with the ’industry’s leading installers, teaching vehicle wrapping workshops and promoting the industry. With strong expertise in leading vehicle wrapping workshops, he has trained more than 2,000 people from Australia, New Zealand and ASEAN countries.

- Sarel Krüger – Avery Dennison Graphics Solutions, South Africa

Krüger joined the Avery team in 2011 after working in the signage industry for nearly 10 years. His experience ranges from equipment and software, to the manufacturing of signage and graphics, vehicle wrapping and, ultimately, the supplying of material.

- Frank Marquart – Avery Dennison Graphics Solutions, Europe

Marquart is a technical marketing manager, digital print media, in Europe and actively participates in product development and relationship management with printer OEMs.

The four continent winners will receive a four-night stay in Las Vegas for the 2019 SEMA Show, where the “King of the Wrap World” will be announced. The $3,200 prize pack for continent winners also includes personalised Wrap Like A King swag, $500 in gift vouchers, a Race Ramp product and a variety of promotional and marketing tools for the winner’s wrap shop. The “King of the Wrap World” grand prize package is worth almost $5,000, with additional gift vouchers and exposure via the Avery Dennison website and web advertisements.

www.wraplikeaking.com

Epson has purchased shares in venture company Cross Compass Ltd. and has begun a partnership focusing on artificial intelligence (AI). Cross Compass, established in 2015, sees artifici...

June 04 2019

Epson has purchased shares in venture company Cross Compass Ltd. and has begun a partnership focusing on artificial intelligence (AI).

Cross Compass, established in 2015, sees artificial intelligence as a next-generation core technology. It uses deep learning techniques to analyse data, provide AI consulting services, and develops and provides algorithms and neural networks. Cross Compass has earned a particularly strong reputation among its customers in the manufacturing industry.

Cross Compass also provides Manufacturing-IX (M-IX), an integrated development environment (IDE) for the manufacturing industry that enables easy implementation of AI without requiring AI expertise.

Epson, as stated in its Epson 25 Corporate Vision, seeks to transform the future of manufacturing by strengthening its business infrastructure as a manufacturing company, driving advances and efficiency improvements in manufacturing and production control, and innovating manufacturing processes. The development, application, and implementation of AI are seen as critical for achieving this vision.

By forging capital and business ties with Cross Compass, Epson seeks to combine the unique technologies of both companies to achieve business synergies that will drive manufacturing process innovations and advances in product intelligence.

Follow Epson on social media:

Facebook: @EpsonAustralia

Twitter: @EpsonAust

Instagram: @EpsonAust

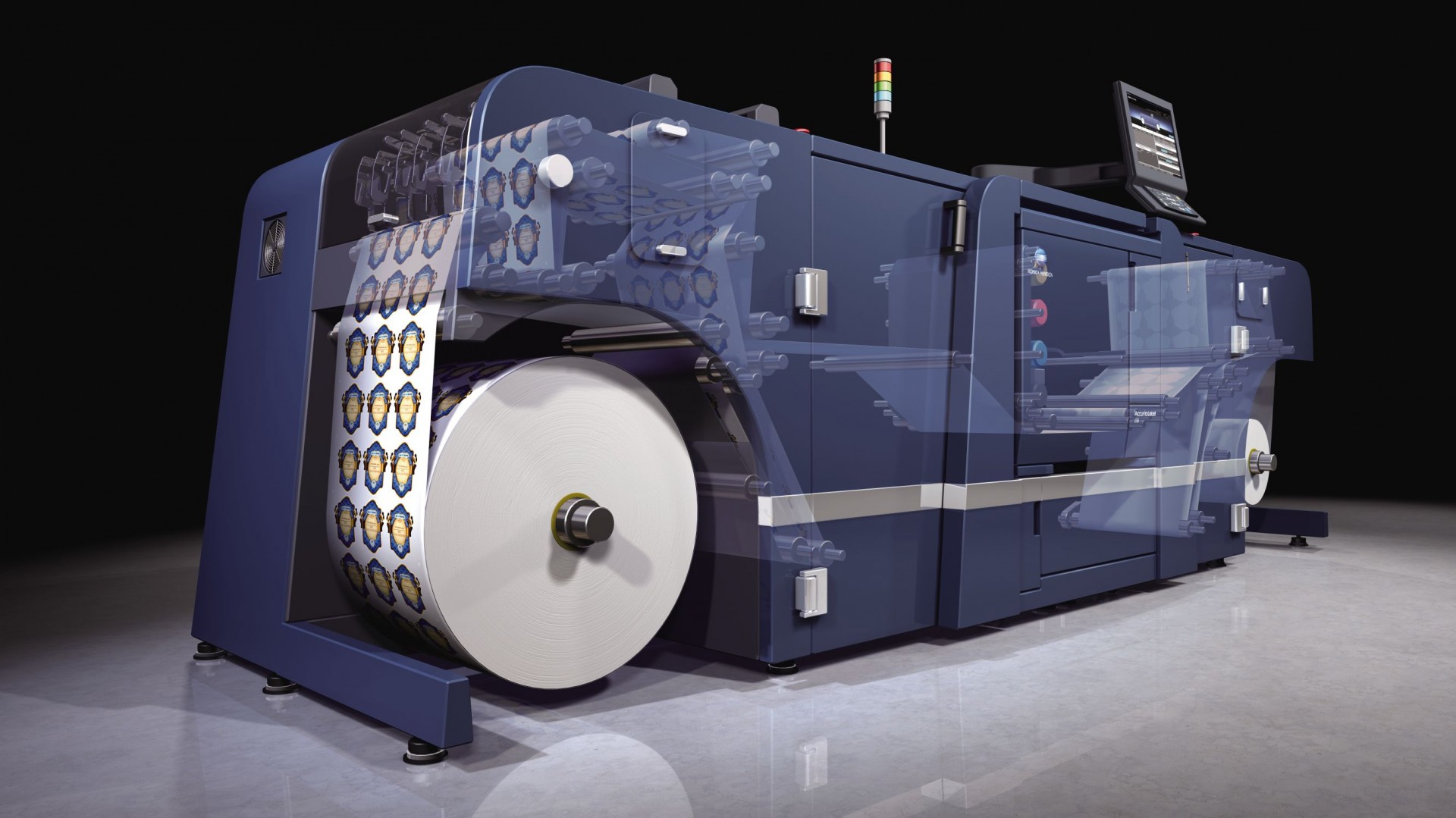

Konica Minolta has launched AccurioLabel 230, the latest version in its digital toner press portfolio. AccurioLabel 230 builds on the AccurioLabel 190 press and is claimed to bring num...

June 04 2019

Konica Minolta has launched AccurioLabel 230, the latest version in its digital toner press portfolio.

AccurioLabel 230 builds on the AccurioLabel 190 press and is claimed to bring numerous benefits for customers including productivity, flexibility and stability. It has been built on the established Konica Minolta AccurioPress engine. It is targeted at small- and mid-range segments and is suitable for label printers, print providers, brand owners, packaging companies and commercial printers.

Enhancements available with the 4-color Konica Minolta AccurioLabel 230 include:

- Increased speed, at 23.4m/min and representing up to a 147 percent increase, with most coated/uncoated papers, PP and PET media now able to be printed at full speed;

- Productivity, with continuous highest quality 1200 x 1200 dpi print runs of up to 1000 meters able to be achieved without the need for recalibration; the time taken between jobs has also been eliminated, increasing productivity further;

- Overprinting, allowing printing of pre-printed media, for example overprinting of flexo white pre-printed on clear PP labels; and

- More accurate print registration, with a built-in speed detector for media feeding also cutting paper wastage.

Jon Pritchard, Industrial Print business unit leader at Konica Minolta Business Solutions (UK), explained: ‘With over 350 installations of the predecessor to the AccurioLabel 230, the core technology is proven worldwide. The AccurioLabel 230 is a robust and simple to operate/maintain concept that makes for the perfect entry-level digital label press, with productivity and print quality performance to match and exceed presses over three times the cost.

‘This is truly the most capable CYMK digital label press in the market, when considering performance and investment. Printers looking at entering the digital label market no longer have to compromise on media width, speed or quality. Whilst the AccurioLabel 230 has the price tag of an entry-level press, its performance and flexibility allow it to compete with the long-standing digital label presses in the market. If automation is required then the fully integrated inline semi rotary label finishing solution gives ultimate productivity advantage. The AccurioLabel 230 is the true no compromise entry-level label press.’

Shipments have already started for the new AccurioLabel 230 digital label press, which has been developed and manufactured in Europe with Danish firm Grafisk Maskinfabrik (GM).

AccurioLabel 230 will be officially shown in public for the first time at Labelexpo Europe 2019.

At the opening of Océ Australia’s high-tech Customer Experience Centre, Océ took the opportunity to formally introduce the new Océ Arizona 1300 series flatbed UV printer ...

June 04 2019

At the opening of Océ Australia’s high-tech Customer Experience Centre, Océ took the opportunity to formally introduce the new Océ Arizona 1300 series flatbed UV printer to a gathering of Océ customers and industry professionals.

The new addition to the award-winning Océ Arizona range was one of the highlights at FESPA earlier this month, and guests at the new Centre’s launch found it equally impressive.

The latest in the popular and proven Arizona range, the 1300 series is designed for the high-productivity mid-volume wide-format and digital print markets. It delivers innovations in print speed, ease of use and curing technology which Product Manager Garry Muratore says will allow print service providers to do more, do it smarter…and do it now.

“The Océ Arizona 1300 series is a great choice for print service providers in the sign and display graphics industry who want to really lift productivity, versatility and quality,” Muratore said today.

“Today’s print buyer is not only discerning in terms of quality, but also creative, driving a new wave of innovative print products on an almost limitless range of media and substrates. This is where the Arizona 1300 series delivers in spades.”

This affordable machine features productive print modes which can easily expand capacity and throughput for small to mid-range businesses who currently need more speed and quality than their lower-end or older printers can deliver, or who are looking to expand their product range and increase output.

“The new Océ Arizona 1300 series answers the two biggest challenges faced by print service providers today – the need to boost productivity, and the need to diversify their application portfolio to take advantage of new business opportunities,” Muratore explains.

According to Muratore, operators will immediately notice the difference on both scores, with outstanding speed and ‘mind-blowing’ application latitude.

“The Océ Arizona 1300 stands out in its market segment as an easy-to-use, mid-range workhorse which not only delivers exceptional productivity, consistent prints and reliable performance, but uncompromised quality,” he says, adding that the range appeals particularly to print service providers interested in high-end applications like photography or fine art reproductions.

“Optional light magenta, light cyan, varnish and Océ’s brightest white ink ever, plus enhanced screening come standard and, because all our new LED inks are Greenguard Gold certified, the prints can be used anywhere, even in schools and hospitals,” Muratore says.

Like other Arizona models, the 1300 series also supports Océ Touchstone, so printers can easily create textured prints, both transparent and opaque, which Muratore says will ‘delight’ customers. “And, all these options – additional ink channels, roll media option and static suppression upgrade kit that makes for static and trouble-free printing on hard plastic materials like acrylic, polycarbonate and styrene – can be retrofitted, helping future-proof your business,” he adds.

Versatility is also a key, with the Arizona 1300 range easily able to produce flawless imaging to a wide range of media including odd shaped, heavy, smooth or pre-cut media, and even unusual substrates like canvas, glass or wood – a must for print service providers who want to build their business by expanding their product offering to create valuable new revenue streams.

This is married with a range of other innovative features, including an intuitive user interface which makes short work of designing even the most complex, multi-layered projects and allows operators to easily make last-minute adjustments at the printer, such as nesting, batching of complex jobs, step and repeat, mirroring and re-assignment of print modes.

Integrated Océ Arizona Xpert self-learning technology enhances this ease of use, enabling the machine to learn from what its operators do and then remember the ‘recipe’ to produce consistent, flawless results, time and time again.

“And, importantly, this range is fast,” Muratore adds. “All Arizona 1300 models deliver sharp, high-key prints at speeds of up to 53m2/hour. And productivity is boosted even further by innovations like Océ’s ‘instant-on’ capability, a new LED curing system which requires no warm up so the printer is always ready when you are.”

Rounding out the package is reliable performance, backed by the Océ Automated Maintenance System which allows hands-free printhead maintenance to restore nozzle function in seconds, and support from both Océ remote service and Océ Australia’s extensive national service and support team.

Australian businesses can choose from three GT models (Océ Arizona 1340 GT, 1360 GT, 1380 GT) with a flatbed print area of 1.25m x 2.5m, or three larger 2.5m x 3.08m XT models (Océ Arizona 1340 XT, 1360 XT, 1380 XT).

Customers invited to the opening of the CEC in Melbourne were first to see the new series in action, with an Arizona 1380GT installed at the Centre, but the range is already taking off with Muratore saying Océ expects to place several units in the field in coming months.

www.oce.com.au

Well over 100 guests were treated to an outstanding experience last night when they became the first in the country to explore Océ Australia’s expansive new Customer Experience Centre ...

June 04 2019

Well over 100 guests were treated to an outstanding experience last night when they became the first in the country to explore Océ Australia’s expansive new Customer Experience Centre at its head office facility in Clayton.

The impressive facility, which the company says has been designed to ‘inspire the world of print, to print the world’, takes up most of the ground floor of the building which has been transformed to showcase an inspirational product range while providing a ‘best in class’ customer experience.

Craig Nethercott, Océ Australia’s Managing Director, was clearly delighted with the realisation of his vision as he welcomed guests to the new facility, saying the launch event represented the culmination of a long and exciting period of planning and development, and a company-wide commitment to building stronger customer relationships.

The result of these endeavours is an open, welcoming and innovative space that reinforces the Australian arm of the Netherlands-based print leader at the forefront of its global network – but was designed with just one person in mind: the Océ customer.

“Océ’s vision is to ‘inspire the world of print, to print the world’ – and in this Customer Experience Centre we are bringing the very best print technology to our world-leading print service providers right here in Australia, so that they can explore the possibilities for their own businesses,” Nethercott said.

Using a range of flexible and rigid media, the team illustrated the versatility and superiority of their products, producing a diverse array of applications on the spot, while more were on show in what Nethercott calls the ‘Ideas Lab’ – a space packed full of inspirational applications designed to get print service providers thinking ‘outside the box’.

“In an increasingly competitive market, innovation is important for two reasons,” he said. “Firstly, it gives you a point of difference – something to take to new prospects and a reason to go back to your existing customers. Secondly, it adds value, allowing you to improve profitability with higher-margin products.”

Those high-value products are very much in evidence in the new Centre. The glass entry doors feature printed decals and lead directly into the Ideas Lab’s, which is dominated by a floor-to-ceiling, seductively tactile, faux-brick wall created using Océ’s dimensional Touchstone print technology.

Available only on Océ Arizona printers, this technology has made a major impression recently at local and international shows, including winning a prestigious European Digital Press Association (EDP) Award at FESPA recently.

Printed coffee cup holders and ceramic tile coasters adorn a range of print-topped tables and even a printed canvas ottoman, bathed in the glow from a lamp with a printed shade. Vibrant posters produced on the Océ ColorWave printer using a number of different media provide a practical illustration of the different effects which can be achieved.

The unrivalled media versatility of Océ’s printer range is further demonstrated in the CEC’s showpiece – a multi-media printed wall featuring everything from acrylics and MDF, to glass and ceramic tiles, display boards and corrugated iron. The company has even printed a pair of thongs and an electric guitar to demonstrate the potential.

And it’s not all about wide-format. Océ’s innovative continuous feed and sheet fed inkjet presses haven’t been forgotten, with plenty of applications created on these devices also showcased at the facility.

“The Ideas Lab is central to the concept of this Customer Experience Centre – it demonstrates in practice how ideas and inspiration can be translated into a profitable reality using Océ technology,” Nethercott says.

“Here, our technical experts will push our products to the limit to create exciting new applications, and our customers can come to gather ideas, see our technology in action, and talk to product specialists about how it can create new opportunities for their businesses.”

In an adjacent, glass-panelled area, vistors could see the company’s range of market-leading machines from both the Display Graphics (DG) and Technical Document Systems (TDS) ranges in action – and what a line up it was.

Headed by the flagship Océ Colorado 1640 roll-to-roll printer featuring the company’s revolutionary UVgel technology and an Océ Arizona 1380 model from its recently-released 1300 range it also features a ProCut digital cutting system – all powered by ONYX end-to-end PDF workflow software and ProCut digital workflow and cut preparation software, and integrated Océ Arizona Xpert self-learning technology. ColorWave and PlotWave printers, for both display graphics and architectural, engineering and construction applications, were also on show.

Importantly, visitors to the CEC can also see straight into the company’s new, open plan office area where the full Océ Australia team is on hand to meet, greet and support customers – something Nethercott says is vital to building the kind of strong, long-term partnerships on which the company prides itself.

“This new CEC is at the heart of our headquarters, providing us with an unique opportunity to connect with our customers,” he says, indicating that the team is planning regular events and is also keen to welcome customers and prospects to meet there at any time by appointment, for what he calls the ‘full Océ experience’.

“We believe Océ is quite unique in the market, in that we understand that it’s not just about the product – it’s about what our brand means, the experience we create for and with our customers, and the vision we share, for our business and for theirs.

“Above all, it’s about the relationships we build. We want our customers to come here and explore new opportunities, but also to connect with as many of our people as possible, from operations and logistics, to our service personnel, the customer service team who are our first point of contact for sales and service calls, to our marketing team, finance and HR experts.

“We want our customers to get to know us – all of us – just as we like to get to know them, and their businesses, so that we can genuinely partner with them in their future success.”

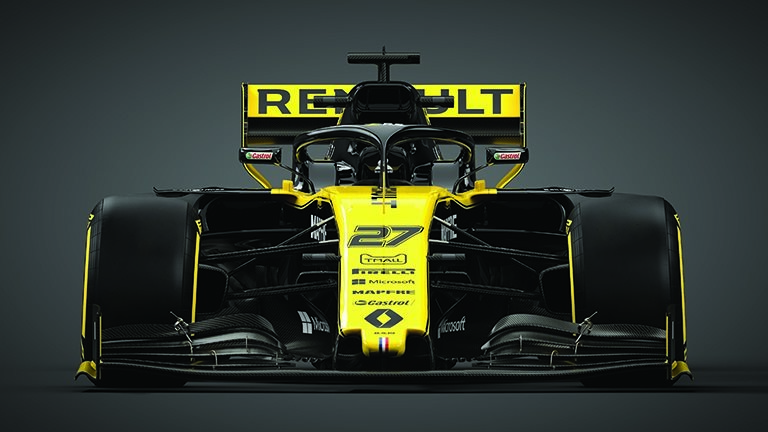

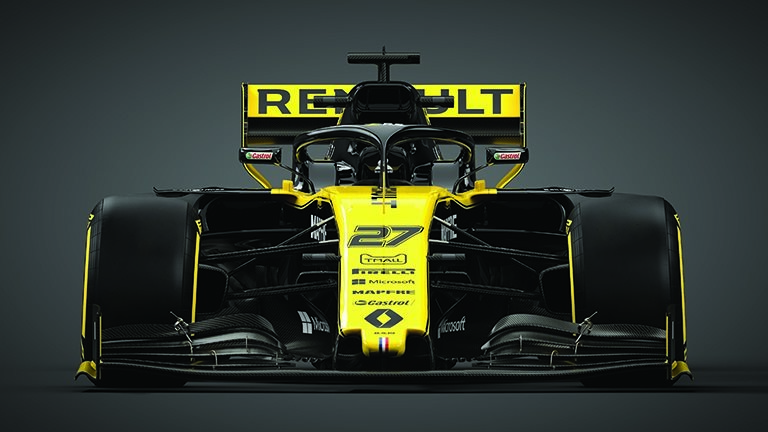

When you're one of the best car racing teams in the world, you need the very best graphics. That's why Renault F1® Team has chosen Roland DG’s new TrueVIS VG2, the second-generation eco-s...

June 04 2019

When you're one of the best car racing teams in the world, you need the very best graphics. That's why Renault F1® Team has chosen Roland DG’s new TrueVIS VG2, the second-generation eco-solvent print and cut device, to produce its race-leading Grand Prix prints.

Renault F1 Team has relied on Roland TrueVIS printer cutters for many years, using the reliable and high-quality systems at its Technical Centre in Enstone, Oxfordshire, to produce stickers for its racing cars, livery for its support vehicles, displays for its hospitality areas, and much more. Grand Prix events can attract worldwide audiences of more than 400 million viewers, and sponsorship is as competitive as the races themselves. High-end sponsors demand the highest precision in their brand colours and immediate replacement of any damaged advertising graphics; Renault F1 Team always travels with 30 identical versions of every sticker, totalling around 1,400 stickers for every race.

The award-winning TrueVIS VG2 Series has over 40 incredible enhancements, allowing Renault F1 Team to push its boundaries for accuracy, reliability and turnaround speeds even further. Those who have seen the VG2 in action describe it as both ‘best printer/cutter’ and ‘best print device in the industry today’. Designed to meet and exceed the needs of today's most demanding print professionals, the Roland DG TrueVIS VG2 is already proving incredibly popular, and attracting widespread attention at trade shows around the world.

Joe McNamara, Head of Paint and Graphics at Renault F1 Team, has praised the extended colour gamut, now with bold Orange for vibrant colours, natural skin tones and exceptional colour replication. "One of the first things we noticed was the improvement in the colour matching, because a lot of what we do covers an entire season," he comments. "It gives us a good opportunity to have a consistent colour." He adds: "It also comes with the new orange swatch which has about a hundred colours in there – yellows and oranges. It really makes our life easy when it comes to matching colours exactly for our corporate sponsors, and also for our own branding on cars, on garages, and on everything we take to races with us."

A video featuring Joe and his review of the new TrueVIS VG2 is available to watch at the link below. In the video, Joe notes that the new TR2 inks deliver brilliant bonding and stretching abilities for vehicle wrapping applications, and their fast-drying time allows his team to print, laminate and ship graphics to Renault F1 Team colleagues across the world on the same day. He adds that the VG2's perf-cut feature is making work "much easier" when producing multiples of the same sticker, while the new media clamp system is "a really clever piece of engineering".

"What's really impressive about this machine is what it can do for the price it's pitched at," he says. "To have that colour gamut for that price point is really amazing. I just don't know how Roland does it."

To learn more about Roland DG's award-winning TrueVIS VG2 series wide format printer cutters, visit: https://www.rolanddg.com.au/products/printers/truevis-vg2-series-printer-cutters

Find out more about Renault F1® Team at www.renaultsport.com.