The new exhibition area offers customers and visitors close-up view of SCREEN’s innovative inkjet printing technology for label, commercial and packaging markets. Local MD Peter Scott visited the centre during Labelexpo, describing it as 'amazing.'

SCREEN Europe unveiled its new Inkjet Innovation Center (IIC) in Aalsmeer, the Netherlands, with a ‘Grand Opening’ exhibit late last month. For the first time, the leading manufacturer of inkjet digital printing equipment showcases all its series of innovative presses for label, packaging, commercial and CtP printing in one room. More than 100 customers, sales agents, partners and local community representatives attended the celebratory event at Screen Europe’s new headquarters.

SCREEN Grand opening of the IIC/HQ Sept 2023

“Establishing the IIC reflects our confidence in the status of the printing industry and Screen’s position as a leading player in the market for inkjet digital printing equipment,” said Mr. Eiji Kakiuchi, chairman Screen Holdings. He adds: “We overgrew our previous building due to our solid and steady growth in existing inkjet and CTP markets and also needed more space for the next wave of industrial inkjet digital innovations for both existing markets, such as label and commercial, as well as new markets such as flexible packaging.”

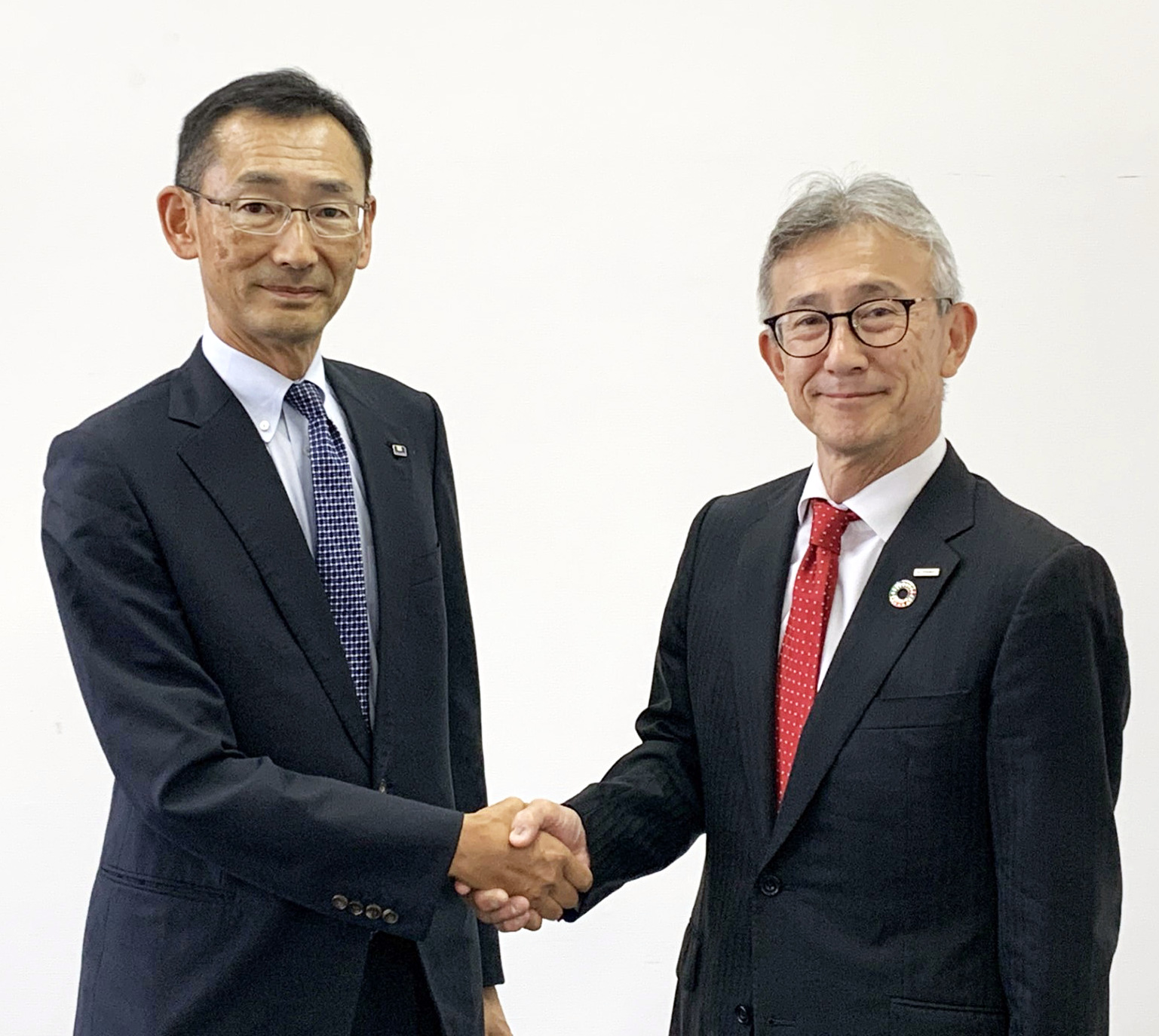

Chiyoda President Hiroyoshi Sato (L) and SCREEN GA President Yukiyoshi Tanaka confirm the PAC 830F deal.

In the 2,000m² showroom and demonstration center, visitors can explore Screen's inkjet digital printing solutions across three distinct product lines: Truepress JET for Commercial Printing and Direct Mail, Truepress LABEL for label printing, and the new Truepress PAC range for Flexible Packaging. The new IIC also showcases Screen's well-established CtP product range.

“In addition to showcasing our expanding range of digital printers, the Inkjet Innovation Center will serve as a hub for innovations in digital printing. Collaborating closely with our software and finishing partners, our aim is to provide customers with end-to-end printing solutions, offering a glimpse into the future of the printing industry,” said Osamu Yamagata, President Screen Europe.

Screen Europe was honoured to host distinguished guests, including Mr. AJ Kakiuchi, Chairman of Screen Holdings, Mr. Yukiyoshi Tanaka, President Screen Graphic Solutions, and Mr. Takanori Kakita, Advisor of Screen Graphic Solutions.

Also present was the esteemed Mayor of Aalsmeer, Mr. Gido Oude Kotte, for a momentous ribbon-cutting ceremony at the official Grand Opening event. Japanese drummers marked the occasion with a thrilling performance of traditional Taiko drums.

First PAC 830F flexible packaging press installed

The Screen Truepress PAC 830F, now entering the market

In other Screen news, Screen Japan and Chiyoda Gravure Printing have reached an agreement that will see them work together to drive the use of digital printing for flexible packaging materials. The initiative will use Screen's Truepress PAC 830F, a new water-based digital inkjet system that is capable of full-scale production of small to medium lot jobs, first announced in developement in 2020.

Countries worldwide have increasingly moved to create a sustainable society and the packaging industry has also seen a growing need for more environmentally - conscious production methods and greater responsibility in its supply chain. At the same time, maturing consumer preferences have also created a trend toward diversified small lot production using flexible packaging.

Pouches for pooches? Typical flexible packaging work printed inkjet on the PAC 830F - Pet food pouches

Solving the short-run issue

While gravure, and some Flexo printing has been the standard across the industry until recently, this method is best suited to large print runs. When it is used for small to medium lot work, a number of problems arise, including low productivity, significant strain on operators and considerable losses due to the discarding of unused products. Naturally, these issues have led affected companies to search for potential solutions.

Against this backdrop, Chiyoda and Screen GA have recently worked together to install the Truepress PAC 830F at Chiyoda’s facility. Screen has specifically developed this water-based digital inkjet press to enable full-scale mass production of small to medium lot jobs. Both companies have agreed to jointly drive the increased use of digital printing for flexible packaging, with the shared aims of expanding target applications for the Truepress PAC 830F as a production system, constructing an improved digital workflow, and identifying and resolving various issues that occur in small to medium lot production processes.

The two companies intend to pursue this initiative based on Chiyoda’s corporate philosophy of: “Trust, continuous growth and human resource development” as well as the Screen Group’s corporate purpose of “Innovation for a Sustainable World.” In addition to making a social contribution, they hope to upgrade the working environment at production sites for flexible packaging and deliver print quality that will make the world an evermore colorful place. The two companies cooperate closely in order to achieve the necessary technological innovations.

It is expected that a PAC 830F will be installed in the new IIC in The Netherlands, and may be exhibited at drupa 2024, late May-June in Düsseldorf, Germany.

Sales in Australia will be through Screen’s label press partner Jet Technologies

www.jet-ap.com

ENDS