See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

March 15 2022

FloorSignage, LLC, launches DriveOn Graphics, the world’s first wide format print media designed to be applied to surfaces that support both vehicle and pedestrian traffic. DriveOn Graphics is the first retro reflective digital print media created with drivers in mind. DriveOn Graphics can be applied directly to streets, parking lots and driveways providing motorists with clear visual communication. This first of its kind material offers ground graphics in full color that will stand up to the rigors of vehicular and pedestrian traffic.

“Placing graphics on outdoor walkways was a radical idea in our industry back in 2013 when we launched AlumiGraphics Grip,” said Scott Wieclaw, President of FloorSignage, LLC. “Thanks to our product, AlumiGraphics Grip, outdoor floor and ground graphics are now commonly used worldwide and known to be the most reliable solution for graphics on concrete, asphalt, and brick, withstanding weather conditions and pedestrian traffic,” says Wieclaw.

“We began R&D efforts for DriveOn Graphics not long after launching AlumiGraphics Grip, in response to customers asking if our material could withstand vehicle traffic,” continued Wieclaw. “The missing piece of the puzzle was to develop a wide format print media product that would combine the ease and utility of a pedestrian use graphic with the strength and durability of a vehicular traffic marking,” said Wieclaw.

Until recently, stenciled, painted graphics and thermoplastic products have been the only options for graphics placed on parking lot and driveway surfaces. “DriveOn Graphics provides a better alternative to these current methods that suffer from design limitations, are difficult and expensive to apply and are not easily removed,” stated Wieclaw.

“Not simply just an outdoor ground graphic, DriveOn Graphics offers vehicle durability,” explains Wieclaw. “When ground graphic materials are used on surfaces supporting vehicle traffic such as parking garages, cross walks, drive thru lanes and transit stations, most graphics cannot withstand the forces they are subjected to by vehicle traffic. Some manufacturers claim their graphic materials can withstand limited vehicle traffic, but the truth is, these materials are thin and soft leaving them susceptible to damage,” according to Wieclaw. “DriveOn Graphics provides dimensional stability, designed to withstand the kinetic friction that takes place between a tire and the graphic material,” said Wieclaw.

“DriveOn Graphics solves the common issue faced by graphic materials used in areas serving both pedestrian and vehicle traffic, providing a retro reflective, slip resistant pedestrian safe product reducing accident risk. DriveOn Graphic’s retro-reflectivity results in a highly visible material both day and night, providing crucial response time for vehicle drivers,” said Wieclaw.

DriveOn Graphics can be cut to shape and used as turn arrows, symbols, and other traffic control and curbside messaging. The material is matte white and direct print compatible with latex & UV flatbed and hybrid printers. USA Made, DriveOn Graphics offers easy, heat free installation, and is sold in 44” x 35’ rolls to suppliers.

“This new material blows the door wide open for endless uses from parking lot traffic markings to creative cross promotion for brands that can now easily access endless amounts of available surface area. Think branded parking spaces or sponsored curbside

pickup areas and electric vehicle charging stations. There are no limits to the uses of DriveOn Graphics,” says Wieclaw.

DriveOn Graphics is a product of FloorSignage, LLC. Headquartered in Sunbury, Ohio, FloorSignage, LLC has built a niche as the industry expert offering premium quality substrates that serve as the most reliable solutions for graphics applied direct to rigid wall and floor surfaces in a wide range of environments both indoors and outdoors.

Inkcups announces the launch of ArtPrep, an automated artwork preparation software for digital printing that will greatly reduce time and labor associated with traditional manual preparation methods.

ArtPrep automatically prepares artwork for digital printing through a flexible user interface that is adaptable to any workflow. The software easily integrates with all Inkcups digital printers and workflows and accepts PNG files directly through any user’s art department or automatically through an API connection. ArtPrep adds desired layers, including customizable trapping, and can manipulate image placement and size as well as perform image adjustments.

By reducing image preparation time, ArtPrep improves overall productivity of Inkcups’ established digital printer workflows. This innovative new software has a unique capability to seamlessly handle variable data, name drops, challenging gradients, and highlights, all while providing maximum control over ink usage and production costs.

“We’re excited to launch our first artwork preparation software, ArtPrep. This new capability will further enhance the Inkcups customer experience by offering significant time savings over manual preparation of artwork for printing. Our main priority is to make sure our customers can easily create high-quality artwork quickly and efficiently, while saving them time and labor,” said Ben Adner, CEO of Inkcups.

ArtPrep is a huge cost and efficiency gain for companies handling any volume of artwork files for printing on Inkcups digital machines. The software is compatible with all Inkcups cylinder and flatbed printers, which include: the Helix®, Helix Hi-Fi®, Double Helix®, Revolution®, X360, X2®, X5®, X5-T, XJET, and XJET800. ArtPrep is especially suited for print-on-demand companies handling one-off printing.

Inkcups will be offering two versions of the software: ArtPrep and ArtPrep Pro. ArtPrep is now available worldwide and will be available in Europe starting Spring 2022.

March 15 2022

Xante is pleased to announce the latest addition to its UV flatbed printer lineup, the Xante X-98. The X-98 takes Xante’s proven UV print technology to the next level with a larger bed size (55″ x 98″), doubling the size of their other flatbed UV products. Utilizing up to four Epson i3200 four-channel printheads, the CMYKW X-98 prints in bold, vibrant color on virtually any rigid media including wood, glass, stone, metal, acrylic, coroplast, and more. This new offering is powered by the award winning iQueue Adobe PostScript/PDF workflow software.

The X-98 UV flatbed printer will quickly produce full-color 4’x 8′ signage, decorative items, personalized awards, or unique promotional items in minutes. With a bed size of 55″ x 98″, customers will be able to simultaneously print up to 12 18″x24″ signs, dramatically increasing speed and efficiency of production. With Xante’s iQueue Adobe PostScript/PDF workflow, customers can now achieve magnificent multi-panel wall art, accurately manage spot colors, control print quality, create multi-up imposed layouts, and much more.

With adjustable print head height up to three inches, and resolutions up to 2880 DPI, the X-98 will allow for printing on a wide array of media with amazing speed and image quality. Printing on dark substrates, or clear material, is also simple using the white option controls embedded within iQueue Workflow. Users have the option where, when, and how white ink is applied. The standard X-98 configuration will contain two Epson i3200 printheads at an economical price of $74,995 and a four-printhead configuration is $79,995 for environments where high speed and production are critical.

“The Xante X-98 demonstrates our commitment to the continued expansion of our outstanding flatbed UV printer lineup. The world of print has changed and Xante is investing in the new reality of print.” stated Robert Ross, CEO and President at Xante. Xante UV High-Density inks for the X-98, and for all Xante UV printers, are sold in economical half-liter bottles. These inks provide incredible outdoor durability and amazing color quality.

The Xante X-98 is currently in full production and ready to ship.

March 15 2022

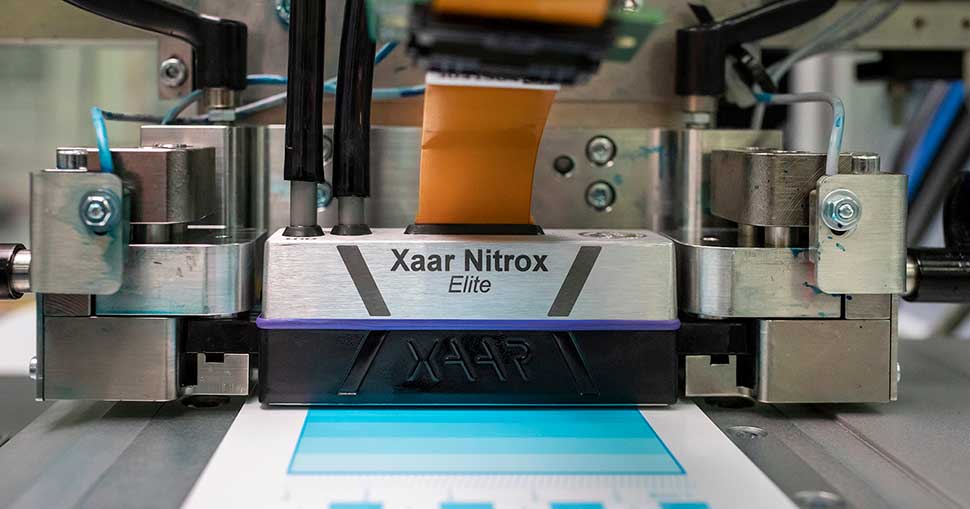

Xaar is launching its new Versatex ‘out-of-the-box’ print engine and the latest Nitrox Elite GS3 printhead at this year’s InPrint exhibition in Munich on 15-17th March.

The Xaar Versatex provides users who have limited inkjet experience with the ability to fast track the digital inkjet development and integration process, allowing a speedy, cost effective and agile way for manufacturers to explore new potential applications.

Comprising a fully integrated datapath, ink supply system and supporting a large array of printheads from the ImagineX platform, the Xaar Versatex is a versatile, user-friendly and ready-to-go solution. It is available as both an evaluation kit, and a larger print engine and can be configured with multiple printheads up to 420mm in width.

Alongside the Xaar Versatex, the Nitrox Elite GS3 printhead will be shown for the first time. The small drop variant printhead is the newest member of the Xaar Nitrox family and delivers improved print uniformity and drop placement, creating high-definition image resolutions for smoother skin tones, gradients and colours. This makes the Nitrox Elite GS3 ideal for label and graphic applications as well as enabling fine details and features for functional fluid applications, such as PCB printing.

Graham Tweedale, Chief Operating Officer at Xaar said, “We are delighted to be demonstrating our latest developments at InPrint, the leading show for emerging printing and industrial manufacturing.

“By providing our customers with the latest inkjet printheads, technologies and infrastructure – available all under one roof – Xaar is helping customers address their latest application requirements and seize their inkjet opportunity.”

Avery Dennison Graphic Solutions has ...

March 08 2022

Avery Dennison Graphic Solutions has today launched a new generation of digital print films to empower businesses in Australia, New Zealand, and Southeast Asia to create durable inspirations on walls and vehicles, quickly and easily.

The new Avery Dennison MPI 2904 Easy ApplyTM is a smooth glossy, flexible vinyl film designed for vivid and high-quality digital print performance. It delivers great value for vibrant and creative applications with intermediate durability requirements, including; outdoor signage, wall murals, indoor and outdoor advertising, floor graphics, and even fleet vehicles with flat surfaces or simple curves. Complementing the MPI 2904 Easy Apply are the new Avery Dennison DOL 2960 Gloss and DOL 2980 Matte overlaminates that give users both improved handling efficiency and superior finished graphics.

“With life returning to pre-pandemic norms, owners and managers of corporate offices and public spaces are eager to offer employees, customers and visitors refreshing new looks and experiences,” said David Newman, Senior Marketing Manager for Graphics Solutions in Asia Pacific, Avery Dennison. “This launch is the result of our focus on customers’ needs to reduce inventory and maximise application options. The MPI 2904 Easy Apply is a dependable solution for converters, designers and building owners to use for multiple applications quickly and easily.”

“Our production teams were able to achieve sharp and smooth printing results with minimal fuss using the Avery Dennison MPI 2904 Easy Apply. It was a seamless process, and we have in fact used the MPI 2904 for a large client with confidence,” said Luke Parisella, Operations Manager, Image Box Group who was one of the early adopters of the new product.

Using the new MPI 2904 Easy Apply film along with either the DOL 2960 Gloss or DOL 2980 Matte overlaminate, business owners and managers can create exciting new possibilities such as remodelling workspaces for staff, reimagining spaces for shoppers and diners in hospitality, leisure and retail industries, or revitalised branding on fleet vehicles, all within a short timeframe. With Easy ApplyTM adhesive technology, the new MPI 2904 has air egress channels to easily eliminate bubbles and wrinkles during application.

The films have undergone extensive and comprehensive testing and are backed by the company’s long-established Integrated Component System (ICS) Warranty Program. All of the films announced today are available through the authorised Avery Dennison Graphic Solutions distributors.

p.p1 {margin: 0.0px 0.0px 0.0px 0.0px; font: 11.0px Arial; color: #000000} p.p2 {margin: 0.0px 0.0px 0.0px 0.0px; font: 11.0px Arial; color: #000000; min-height: 12.0px} p.p...

March 08 2022

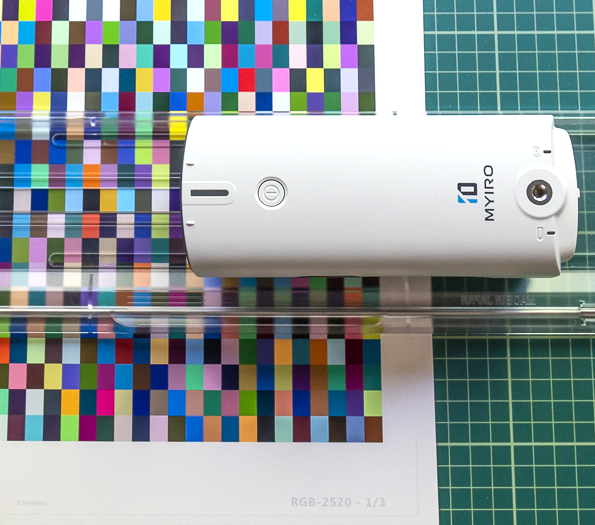

Colour Graphic Services, the Australian colour management, ISO and G7 specialist, also dealer for the highly-rated Myiro spectrophotometers in Australia and New Zealand, has announced a trade-in offer on any older spectrophotometer or colorimiter, to a Myiro-1 complete with Myiro Tools software, scanning/spot colour ruler USB cable, calibration cap, mini tripod for monitor calibration, downloadable spectrophotometer configuration software and storage case.

David Crowther, Managing Director of Colour Graphic Services says: “As someone who is passionate about correct colour in the print and packaging sectors, I like to see people using the right tools to measure, profile and calibrate. I have not found a better instrument for this than the Myiro-1 together with Myiro Tools software. Many printers are using outdated, inadequate or out-of calibration spectrophotometers and colorimiters and wondering why colour is still not right.”

Crowther continues: “To change this paradigm, for the month of March, we are offering 15% off the price of the Myiro-1 with MyiroTools software as a trade-in allowance for any older measuring device. This equates to between $550 and $700 saving, to upgrade to the best hand-held spectrophotometer/software combination available in the world today!”

The Myiro-1 bundle can come with either Basic or Advanced MyiroTools software, which is then owned outright. Colour Graphic Services (CGS) requires the serial number of the traded-in device, which is then sent to CGS, for responsible disposal. The discount is applied at time of purchase.

Trade-In pricing is: Myiro-1 with Basic Tools: $3,209 ex-gst (normally $3,775)

Myiro-1 with Advanced Tools $3,927 ex-gst (normally $4,620)

Crowther adds: “We can be a bit flexible with the March 31st cut-off due to the current shipping and flood situation. I am confident that anyone upgrading to the Myiro-1 bundle will experience colour accuracy they have never seen before.”

ENDS

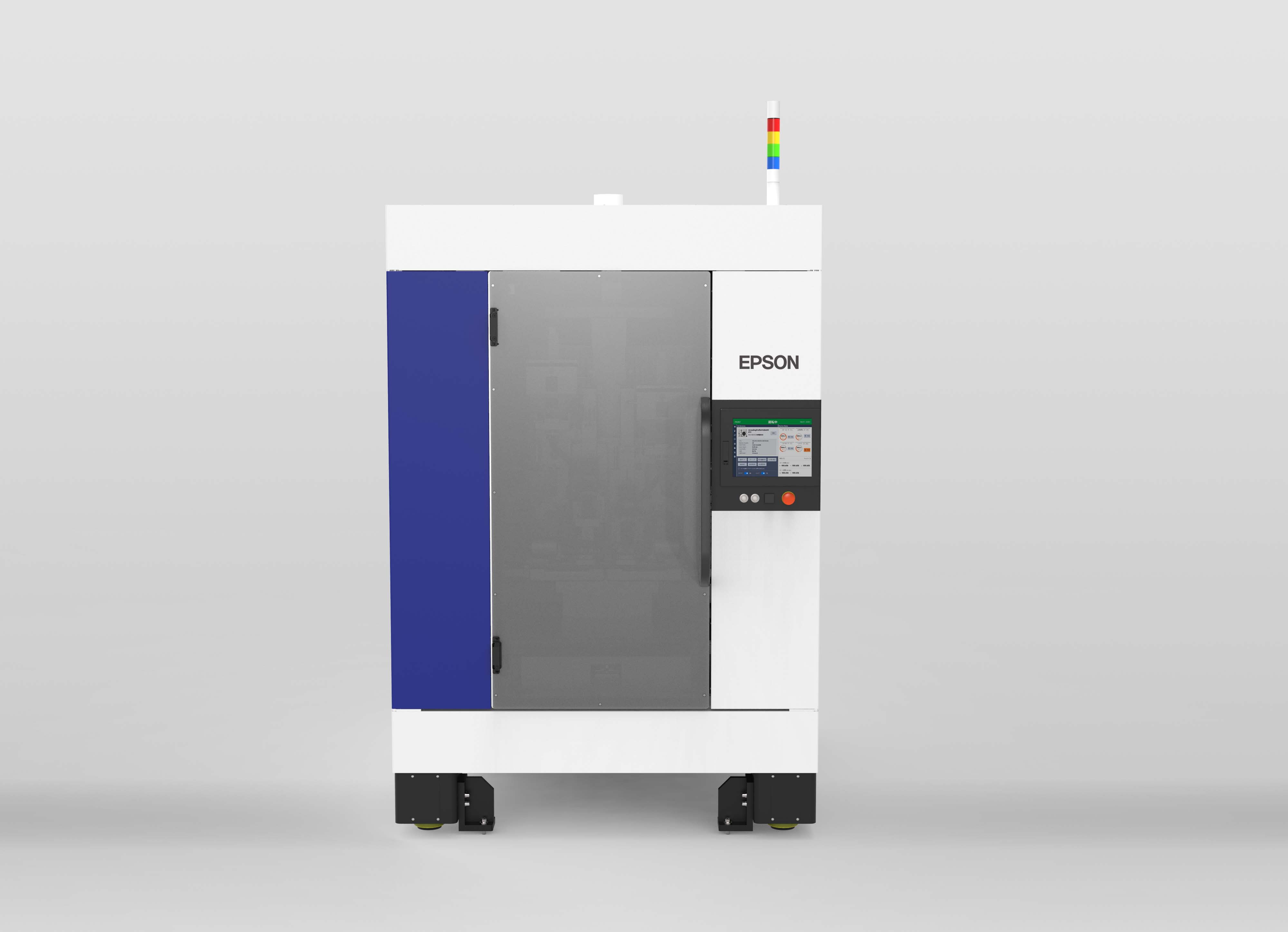

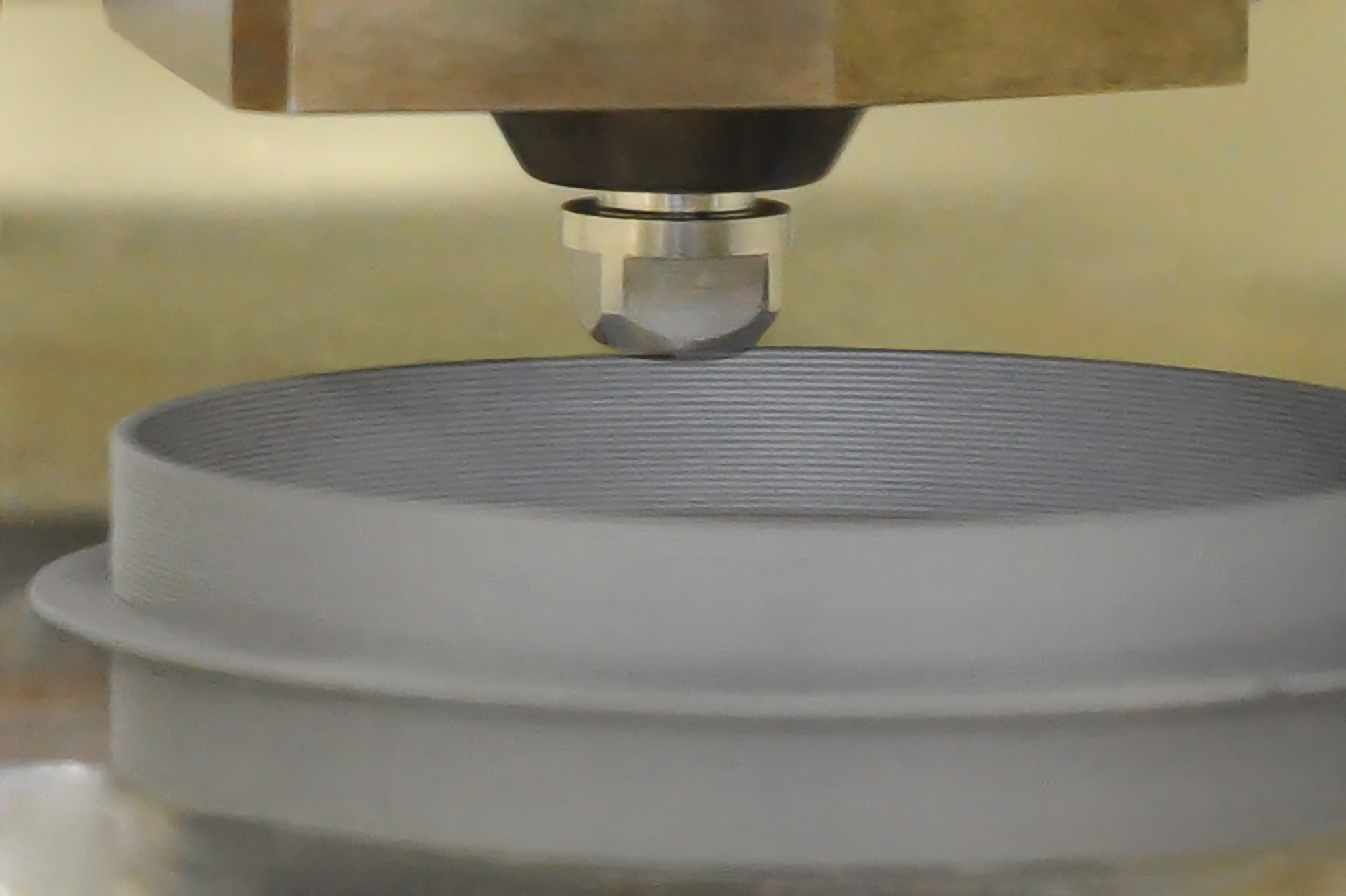

Printer can fabricate parts with the accuracy and strength required for industrial use

SYDNEY, 8 March 2022 – Epson has developed an industrial 3D printer that can use commonly available third-party materials to produce strong, accurate industrial parts of various sizes and functions. 3D printers with these features will have uses in a far wider range of applications, including in the production of parts for final products, and will enable users to mass-customise their goods in support of small-batch production.

3D printers can be used to fabricate a wide variety of goods in small quantities in a short period of time. Manufacturers have responded to this promise by accelerating the development and launch of 3D printers for the industrial market, which is expected to expand rapidly in the future. However, conventional industrial 3D printers require the use of special modelling materials. Moreover, they are not well-suited to the production of objects that offer both strength and accuracy, so their use in industrial parts for final products has been limited.

Epson’s newly developed 3D printer employs a unique material extrusion method that is achieved using a flat screw (an inline screw with a flattened configuration) like that found in Epson’s precision injection molding machines. This extrusion method enables the printer to be used with a variety of common third-party materials, such as resin or metal pellets, which are generally available at lower cost than other materials, environmentally considerate biomass pellets, and PEEK materials, which can provide high heat resistance.

In addition, the amount of material injected is precisely controlled by regulating the pressure within the head and by regulating the action of a valve in concert with the modelling speed. The temperature at the surface of a piece being printed must also be controlled in order to obtain the required strength.

Epson employs a unique mechanism to precisely control this temperature and achieve both strength and accuracy. This 3D printer is thus engineered to manufacture strong, accurate objects with commonly available materials, facilitating printer use in the production of industrial parts for final products. It is ideally suited to mass customisation, as it can produce small batches of parts tailored to customers’ needs with higher quality, shorter lead times, and at a fraction of the cost of traditional manufacturing processes.

Epson is aiming to commercialise the printer after first making needed refinements while utilising it internally to volume-produce certain parts for commercial and industrial equipment.

This 3D printer will be shown in the Epson booth at International Robot Exhibition 2022, which opens on March 9th at Tokyo Big Sight.

In addition to industrial 3D printers, Epson seeks to innovate manufacturing by co-creating flexible, high-throughput production systems that reduce environmental impacts.

Innovation in adversity as customers see continued growth despite pandemic.

• HP reaches a milestone of 100 installations of the breakthrough HP Indigo 100K Digital Press, as Solopress completes latest install

• HP looks back at 10 years of B2 Solutions – over 800 units of the world’s most productive B2 printing solution¹ installed worldwide

• Announcing today the worldwide availability of the HP Indigo 15K Digital Press

• Announcing today new capabilities for the HP Indigo 100K Digital Press - Auto Pallet Replacement and 5TH Colour Station

HP Inc. today announced the delivery of the 100th HP Indigo 100K Digital Press marking a milestone as customers continue to thrive on the breakthrough press. Adding to their existing fleet of 5 HP Page Wide and Indigo products, award winning print service provider Solopress, continues in their digital transformation this month, with the installation of the HP Indigo 100K Digital press.

Simon Cooper, MD of Solopress, comments, “We’re really pleased to see the market turn a corner and orders start to increase after a very tough period. During the last few years we’ve spent time as a business making changes which deliver more value to our customers. And in of support of that goal, we recently added the HP Indigo 100K to our fleet, which alongside the introduction of HP Siteflow, compliments our existing automation capabilities.”

Founded in 1999, Solopress has over 20 years of experience in digital printing, supporting tens-of-thousands of businesses and resellers. Following the lifting of Covid restrictions, a surge in demand has driven the need for additional capacity. Citing productivity and reliability in the HP Indigo 100K, Cooper continued, “as a business we strive to maximise productivity at all times, and the 100K gives us the additional capacity, reliability and quality we seek for our customers.”

Haim Levit, Vice President and General Manager HP Indigo comments, “I’m incredibly proud we have achieved such a significant milestone for the business. This is a credit to the team and also to our customers in joining us on a journey to launch, refine and build a portfolio which supports true digital transformation. The drupa portfolio which we presented in 2020 was successfully adopted across all segments. The HP Indigo 100K not only delivers agility for our customers, but also performs above and beyond, something we have seen in particular from offset PSP’s that have found the 100K is a good solution to fit their needs. There are no doubts that this unique combination between quality and productivity enabling many of our customers to stand out during pandemic. I’m pleased to see our long standing collaboration with Solopress continue and develop in these exciting years to come.”

Also being celebrated today, is the 10 year anniversary of the introduction of the HP Indigo B2 portfolio. Since we first introduced the HP Indigo 10000 at drupa 2012 we saw a real revolution in this market. During the last decade, some customers choosing to make long term investments in new fleets, in order to continue to keep up with a surge in orders and customer needs, as the expansion in digital transformation continues globally.

The HP Indigo 100K Digital Press – the most productive digital B2 press in the market, printing up to 6000 sheets per hour, allowing commercial printers to shift greater volumes from offset to digital to meet today’s needs producing a range of commercial applications with superb print quality, high productivity, the range responsible for delivering 60 million B2 sheets per month and shows no sign of slowing.

Also announced today, is the global availability of the B2 HP Indigo 15K Digital Press. Continuing to offer the widest range of B2 application printing in the market, the world’s best selling B2 digital platform, currently has 1200 operating presses in 70 countries globally. The B2 HP Indigo 15K is engineered to address the broadest variety of customer demands in a highly productive way, it features greater media support, including 15 electroinks and unlimited spot colours.

Continually evolving the platform, HP also announces today the availability of the Auto Pallet Replacement and 5th color station for the HP Indigo 100K Digital Press. Ensuring the printing process doesn’t pause, users are able to utilise a new standby pallet which engages every batch and job as the user requires, pushing the printed stack outside the delivery unit allowing the operator to print, stack and unload as much or little as they need. This system will be available in 2022.

Ending 2021 with increased momentum, following strong quarterly results and the introduction of technologies including HP xRServices powered by Microsoft Hololens 2 and Print OS Site Flow, HP Indigo continues to match customer demand with services and solutions that support growth, drive digital adoption and integration and support an ever changing industry in 2022. Haim Levit comments further, “what we’ve seen in the last two years is not just the determination of the industry to maintain their businesses during the pandemic, but also broaden their applications and future proof their work by continuing to drive to a fully digital set up. We’ve seen a huge surge in those utilising our workflow and automation tools with an increase of 162% since the start of 20213 and had huge interest in our HP xRServices Microsoft Hololens news, as the world pivots to a new normal and looks toward a more automated future. All in all a fascinating time to be working in print!”

More information about HP Inc. is available at www.hp.com.

March 08 2022

A high-tech product is never finite and if you want to play in the highest echelons, you have to be up to speed, follow the markets closely and, above all, be innovative and flexible.

Since Summa embraced laser technology, the company continued to develop the laser portfolio to meet the highest industry standards for the (technical) textile, sportswear and apparel industries. Summa is, therefore, proud to present the L1810 2nd generation laser cutter and its new software GoProduce Laser Edition.

The new L1810 2nd generation is the first laser cutter fully developed by Summa. It combines the know-how and years of experience by Summa’s laser division in the UK with the experience Summa has in producing on a larger scale. The new GoProduce software perfectly complements the L1810 2nd generation and results into a powerful laser cutting solution. The software includes several smart, easy-to-use options and features to establish a fully automated workflow where operator comfort is key.

The L1810 2nd generation laser cutter combines industrial design with an excellent laser source, optimal power control, an efficient feeding system and an improved scanning system. All of which results in a top-notch high performing laser cutter.

Benefits of the new L1810 laser cutter are:

• Optimal power control through Summa OptiPower Technology (OPT), which keeps the laser-focused and precise, even in larger working areas for a longer time.

• Consistent precision and quality thanks to the small, extremely focused laser beam leaving edges sealed and soft without fraying.

• High productivity thanks to quick acceleration and working methods such as cut-on-the-fly. The increased production capacity even enables businesses to process rush jobs, as well as bulk orders and peak production assignments.

• Optimal safety thanks to Class 1 safety system and top-notch extraction system.

• Far-stretched stability thanks to the industrialized welded steel base, enhancing accuracy, easier placement and maintenance.

• Future-proof with multiple field upgradeable (retrofit) options enabling the cutting equipment to grow with the business.

• Enhanced Vision system with scanner bridge, enabling the machine to cut while the material is being scanned and fed (cut on the fly).

• Powerful and intuitive software with GoProduce laser edition from Summa. It includes many smart functionalities and has been developed to handle jobs easy, efficiently and robust whilst optimally using material.

The robust construction, field upgradable options and software makes the L1810 2nd generation laser cutter a true future-proof working horse that thrives even in the most demanding, high-volume production environments. The L1810 2nd generation is built according to strict safety requirements, specific to Summa laser equipment. Designed with premium components for long durability and in such a way that the installation of these parts remains straightforward.

Christof Van Driessche, Chief Commercial Officer at Summa, adds: “With the experience and dedication on board, Summa continues to show true leadership as a supplier of high-end cutting solutions. The introduction of the 2nd generation L1810 laser cutter is once more a milestone in Summa’s large history of legendary performance. This 2nd generation sturdy workhorse will undoubtedly bring great performance and pleasure to many businesses, active in the textile, apparel and sportswear industries.”

The L1810 2nd generation is available for orders in Europe and the GoProduce Laser Edition software will be available on www.summa.com in March. In the US and Asia-Pacific regions, the launches follow in May.

March 08 2022

Flatbed die-cutter can handle corrugated, carton and litho-laminated board without compromising productivity and quality.

BOBST has announced that its flagship flatbed die-cutter, MASTERCUT 1.65, is now commercially available to folding carton and corrugated box manufacturers around the world.

Bringing together the very best in BOBST technology and innovation, MASTERCUT 1.65 is completely unique as it is the only machine on the market that has been specially designed for litho-laminated converting and can handle strong corrugated board and carton equally well – making it one machine for all jobs. Importantly, tooling compatibility and an exceptional level of automation guarantee minimal downtime when switching from one material to another.

Marco Lideo, Product Line Director for Die-cutters, Hot foil stampers, Flexo post printers and Litho-laminating at BOBST said: “The development of this machine is the result of great engagement with some of the most experienced professionals in the packaging world. When we asked what they were looking for in a flatbed die-cutter, the feedback we received was for a unique machine that had the capability to handle multiple substrates, while still offering a high level of productivity and unrivalled production quality.

“The MASTERCUT 1.65 delivers on all these fronts. It can process both robust and delicate materials, ranging from 300g solid board to 7mm BC double wall litho-laminated at speeds of up to 7,000 sheets per hour, and its high-cutting force enables extremely precise and exceptional die-cutting quality, even for complex box designs.”

Marco Lideo added: “With the BOBST MASTERCUT 1.65, we have brought together a combination of tools and technologies that reflect and support our vision for the future of the packaging industry, in terms of automation, connectivity and sustainability. It has been built to serve as a long-term asset for converters.”

The BOBST MASTERCUT 1.65 combines the best of corrugated board and folding carton machines. It has been designed to be versatile, robust and equipped for Industry 4.0 and can be combined with a range of downstream peripherals to create a full production line. Outstanding precision and ergonomic quality control features guarantee minimal waste, saving resources and reducing cost.

With a re-designed top feeding system, SMART FEEDER 3, ensures a smooth start to operations. Built-in suction units ensure friction-free feeding for all substrates. Meanwhile, a feeding table with dedicated pressing device has been tailored for careful processing of warped materials. With delicate and precise feeding, production stoppages are reduced to a minimum and blank quality is assured.

A bespoke POWER REGISTER offers contactless sheet registration and preserves perfect sheet integrity. The optical register can read printing marks from top/bottom and lateral/lead edge, allowing flexibility in lay-outs and substrate choice. Perfectly registered sheets pass into locked gripper bars for exact die-cutting – MASTERCUT 1.65 provides folding-carton print-to-cut precision for corrugated and litho-laminated board.

The die-cutter is also the only solution in the market for corrugated and litho-laminated board blanking in size VII and offers a cutting force of up to 5.5 MN for perfect cutting of solid substrates, while low pressure on the sheet ensures delicate materials remain undamaged. The unique blanking system incorporates a dynamic waste ejection feature and automatic cutting force adjustment increases tool longevity. Single cut, double cut or full sheet delivery: all options are available on this machine.

To enable short job changeovers, the intuitive BOBST HMI SPHERE allows for quick navigation and the storing of up to 5,000 job tickets. This is supported by the BOBST MATIC system which supports a vast number of automatic settings. These two features combine exceptional ergonomics, accessibility and a maximum level of automation for fast and easy handling, guaranteeing optimum productivity. With HMI SPHERE, the machine is also ready to join the BOBST Connect platform, opening up the possibility to interlink and optimize the whole converting process in the future.

“To further support our vision for a connected packaging supply chain, MASTERCUT 1.65 is available with TooLink,” said Marco Lideo. “TooLink is a platform that connects the die-cutter with tooling to bring together the entire converting process and retrieve job data in a matter of seconds. Ultimately, it simplifies job changeover by automating the recipe management, saving time and eliminating the risk of human error. Operators have access to a higher level of production data and insight, and benefit from increased control, automation and efficiency!

“We are delighted to be able to bring this machine to market and enable converters to see for themselves the value it can bring to their operations, not only today but well into the future too.”

The ASGA Board of Directors is pleased to announce that it has appointed Mick Harrold as the new ASGA President, effective immediately. Harrold succeeds Julie Roc...

March 01 2022

The ASGA Board of Directors is pleased to announce that it has appointed Mick Harrold as the new ASGA President, effective immediately. Harrold succeeds Julie Rochester who stepped down from the President role following the ASGA Annual General Meeting on 25 February.

Harrold previously held the position of Vice President for one year and held the position of Victorian Chair and Treasurer for two years.

As a qualified engineer and more than 18 years as Managing Director of one of Melbourne’s prominent sign companies, Visual Exposure, the Board is confident that ASGA will continue to deliver value to its members and to drive and promote excellence within the industry.

“I’m proud to say the ASGA has achieved a lot over the past couple of years while I’ve been at the helm, but this could not have been achieved without the time commitments and contributions of the rest of the Board. I was especially fortunate to have the support of Mick during my time”, said Julie Rochester.

“Mick contributed a significant amount of his own time in making improvements across a number of areas and getting new initiatives off the ground, such as the Sign Industry Directory and program of webinars. His industry expertise across a number of areas, strong leadership and vision for ASGA make him an ideal choice for the role.”

“I’m delighted to accept the position of President knowing that I am supported by a dedicated Board and skilled staff”, said Harrold.

“I want to thank Julie for spear-heading one of the most transformative years in ASGA’s history. My goal in leading the ASGA is to build on the achievements of the past fifty years and to continue to provide even greater value and benefits to our members.”

Other ASGA executive appointments changes took place at the meeting: Damien Nielsen was appointed Vice President, Marc Martello was appointed Public Officer and Treasurer and Wade French was appointed WA State Chair. Regional committees are represented by the following Chairs: Marc Martello (NSW), Mick Harrold (VIC), Julie Rochester (SA) and Wade French (WA).

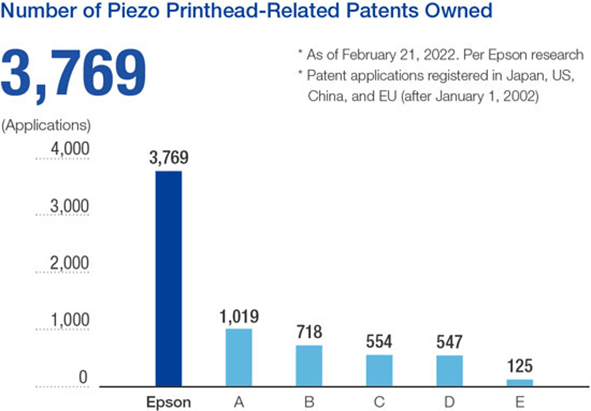

Epson has been listed as one of the Clarivate Top 100 Global Innovators 2022, announced by global information services firm Clarivate Analytics. This represents the ninth time Epson has been named to the list since its inception in 2012.

The Top 100 Global Innovators model of excellence calculation uses a mathematical foundation focused on comparison and is based on a twin track approach to evaluation.

The first track identifies innovating organisations that pass qualification criteria based on volume of inventive activity. The second track evaluates all inventions in the Derwent World Patents Index™ (DWPI™) and score them on four factors: Influence, Success, Globalisation and Technical Distinctiveness. Each invention returns a Derwent Strength Index based on these four factors, creating a holistic baseline that compares each idea with all other patented ideas.

Epson considers its unique, advanced core technologies to be its most important asset and intellectual property activities to protect these core technologies are a vital and integral part of Epson’s business strategy.

Piezo printheads are a core device in the printing sector and Epson owns more patents related to these printheads than anyone else in the industry*. This IP has given Epson a formidable competitive advantage.

Toshihiko Kobayashi, General Administrative Manager of Epson’s Intellectual Property Division, said, "It is an honour to be selected as one of the Top 100 Global Innovators. We at Epson are seeking to address societal issues through our aspirational goal of achieving sustainability and enriching communities. We are thus working to convert intellectual property into value and to sustainably increase corporate value so that we can promote innovation, shape the future, and further enhance our brand image. We will continue to conduct our business and intellectual property activities in line with Epson 25 Renewed, a corporate vision that makes finding ways to use Epson's strengths to help solve societal issues a top priority."

For more details about Epson's intellectual property, click on the link below.

https://global.epson.com/technology/intellectual_property/?fwlink=meganav

March 01 2022

Automated Marking Inc. (AMI), a marking and coding solutions provider, continues to expand its product portfolio with the addition of the CAMI Pro Cure HR (high resolution) inkjet printer for a wide variety of commercial print, graphics and packaging applications.

The high resolution CAMI Pro Cure HR printer provides a versatile, cost-effective solution to meet the need for variable data printing on a range of coated and uncoated substrates and is capable of printing addresses, barcodes, 2D codes, QR codes, numbering, logos and graphics.

“I’ve seen a lot of equipment over the two decades I’ve been in this industry and this printer is by far the most impressive,” said Wilfred (Bill) Allen, VP of Sales and Service for AMI. Allen continued, “When you combine the small footprint with the higher throughput and minimal maintenance, I just don’t think you can find a better printer for commercial print, graphics, card and label printing and addressing applications.”

Simplicity is the key to the Cure HR Design. From the patented ink delivery system (Patent No: US 970773B1) to the electronics, housing and interface connectors, the Cure HR has been designed with ease of use in mind.

The standard software will have users up and running in minutes, from the design of the job template to hitting the start button for production. The Cure HR also allows the integration of databases and easy-build templates that fully utilise the power of dynamic text, bitmaps, counters and inserting lot codes, expiry dates and any of over 100 different barcodes. For more information about the Cure HR, go to: https://automatedmarking.com/products/mailing-hi-res/cure-hr

Mimaki announced the simultaneous worldwide release of large format inkjet printers,

March 01 2022

Mimaki announced the simultaneous worldwide release of large format inkjet printers, "330 Series".

Since the world's first eco-solvent inkjet printer, "JV3-130S/160" was introduced to the market in 2002, we have been leading the industry by introducing printers with new values, always focusing on "something New, something Different" to meet customers' needs for high image quality and quick delivery.

With the catch copy, "Give your creativity a Glow up", in pursuit of new value, we designed and developed the casing of these products from the ground up, with bringing together the technological expertise we have accumulated over the past 20 years for the newly announcing " JV330-130/160" and "CJV330-130/160" of large format inkjet printer. And the "330 Series" will make an appearance in the market as new models bearing the "3", which has been really loved from the customers engaged in sign graphic industry.

JV330-130/-160 and CJV330-130/-160 are added to the line-up of the entry model "100 Series" and the standard model "300 Series" as middle and high-end models to meet the needs of customers. In addition to its impressive image quality and high productivity, the high value-added functions are mounted to assist customers in saving work and labor.

The 330 Series have newly the "Mimaki Weaving Dot Technology (MWDT)", a printing technology that changes the order of ink droplet placement depending on the printing conditions. It suppresses unexpected occurrence of streaks or unevenness of printing caused by slight individual differences in the print head or subtle deviations in adjustment.

We have also released a new input profile "Deep Colour Natural", a standard format for colour management. It makes full use of the wide colour gamut of the market-proven "SS21", our eco-solvent ink and reproduces fully vivid solid colour*1 expression, natural gray tone, and natural skin tone, which were difficult to coexist in the past.

Printing speed is 21.0m2/h in standard mode with 4 colour (C, M, Y, K), and 13.2m2/h with 8 colours (C, M, Y, K, Lc, Lm, Lk, Or), of high productivity. As befits our flagship model, it promotes work efficiency with high image quality and high productivity.

The "XY slitter" and the "Media changer" are two high value-added functions that assist in your saving work and labor. The XY slitter has an in-line function that cuts all sides of the media after printing, enabling automatic slit processing without the need of taking-out media. This will significantly shorten the post-process work and reduce the space required for the cutting work that used to be done manually.

And the Media Changer accommodates up to three rolls of media to be able to change by simply turning the handle with light force. The Media changer reduces the time and effort required to change media, contributing to a more efficient work environment.

In addition, these new models are compatible with "Mimaki Remote Access (MRA)", which allows you to remotely operate the machine and check its operation status from your smart phone*2 or PC, if inside a LAN environment of the same segment. Operation of the printer without worry even from a remote location provides you with a desirable work environment.

As the other new mechanism, there are an ink supply unit that enables agitation of large-capacity 2L ink packs without removing them from the unit, and the drive motor, which was conventionally mounted on only one side, is now mounted on both the left and right sides of the media winder for more stable winding. These new designs ensure uninterrupted long-hour operation.

Furthermore, Mimaki Advanced Pass System 4 (MAPS4)*3, Nozzle Check Unit (NCU)*4, Nozzle Recovery System (NRS)*5, and Dot Adjustment System (DAS)*6 have inherited our printing functions for supporting a stable operation. Focusing large indoor and outdoor signage and graphic market, the new models are equipped with "JV330 Series" only for printing function and "CJV330 Series" having print & cut functions each with the lineup of -130 (maximum media width of 1,361 mm) and -160 (maximum media width of 1,610 mm) to be released in April 2022.

With "something New, something Different" as our management vision, Mimaki Engineering will continue to pursue new technological innovations constantly and to realise the "beauty and speed" that our customers demand.

Mimaki announced the release of large format inkjet printers

March 01 2022

Mimaki announced the release of large format inkjet printers TS330-1600 sublimation transfer inkjet printer

We have been leading the industry by introducing printers with new values, always focusing on "something New, something Different" to meet customers' needs for high image quality and quick delivery.

With the catch copy, "Give your creativity a Glow up", "TS330-1600" is our newly releasing large format inkjet printer of which casing was designed and developed from the ground up, by bringing together the technological expertise of Mimaki’s accumulation over the past 20 years.

TS330-1600 is a sublimation transfer inkjet printer that enables high production with high image quality suitable for a flagship model and is equipped with new functions to improve stable operation and pursues work and labor saving for customers.

The "Mimaki Weaving Dot Technology (MWDT)" a printing technology is newly installed, and it changes the order of ink droplet placement depending on printing conditions. This new technology suppresses unexpected occurrence of streaks or unevenness of printing caused by slight individual differences in the print head or subtle deviations in adjustment to produce both the best solid print*1 quality in our company's history and the beautiful printing quality.

Printing speed of 69m2/h in Draft mode (600x600 dpi, 2Pass) with 4-colour ink set (Bl,M,Y,K) is achieved,

which is increased to about 138% of speed compared to our conventional model*2. In addition, MAPS4 (Mimaki Advanced Pass System 4) *3 reduces banding (horizontal stripes) during low passes.

Two optional units of the "10 kg ink tank unit" and the "Mini jumbo roll unit" that have been popular with our other models*4 are customised to be able to attach to TS330-1600.

The 10kg ink tank*5 of large capacity type can be installed to the "10kg ink tank supply unit"*6 to be able to significantly reduce running costs compared to the standard 2L ink pack apply. The "Mini jumbo roll unit "*6 is a feeding option that can be equipped with Mimaki VisionTM Jet-X Mini-162, our genuine transfer paper of approximately 2,500m length roll that have achieved low running costs.

With the lower running costs, these two optional units contribute to reducing downtime of ink and media replacement, as well as reduced workload for customers.

TS330-1600 adopts a new function to prevent conveyance misalignment in long length media winding. The drive motor for winding, which used to be mounted only on one side, is now mounted on both the left and right sides to distribute the load and strengthen the winding force. The "V-shape cut function" cuts the media into a V-shape, allowing the tape to be fixed at a single point straight against the paper core is added. Moreover the "Media edge guide" for assisting in media winding is downsized to make it easier for customers to attach and remove it by themselves.

Those new additional three functions and item can reduce human error and prevent media feeding misalignment.

Mimaki’s printing functions such as, NCU (Nozzle Check Unit)*7 , NRS (Nozzle Recovery System) *8, DAS (Dot Adjustment System)*9 are taken over to ensure stable operation for long-time printing.

New features to improve usability

As a new cleaning mechanism, a "cloth wiper" has been adopted to increase the removal rate of unwanted ink droplets adhering to the nozzle surface.

Compared to conventional "rubber wipers", the new wiper reduces ink splattering on the head station and improves maintainability and cleanliness. The maintenance space has been expanded, and LED lighting has been installed inside the main unit as standard, making it even easier to view and use.

"Mimaki Remote Access (MRA)", which allows you to operate the machine panel and confirm the operating status like error-check from a smartphone*10 or PC within the same segment LAN environment is applied to the new model. The operability of printer from a remote location without worry provides the work environment that customers require.

"Sb411" and "Sb410"*11 inks proven in the market are applied to TS330-1600

All colours of these environmentally friendly inks have acquired "ECO PASSPORT"*12, as an international certification of safety and security against chemical substances for dyes, pigments, auxiliaries, and finishing agents, that are used in the production of textile products.

Ink sets are available in 4, 6, 7, and 8 colours. Besides the basic colour of blue, magenta, yellow, and black for 4 colour ink set, there are light blue, light magenta, light black, fluorescent pink, and fluorescent yellow that are selectable among 6/7/8 colour ink sets to suit your work.

The print width corresponds to 1,600mm, which is frequently used in textile and apparel applications. TS330-1600 is compatible with two types of RIP software for printing,"RasterLink7", which is both easy to use and highly functional and,"TxLink4 Lite", which is suitable for textile printing, and either can be selected at the time of purchase.

With "something New, something Different" as our management vision, Mimaki Engineering will continue to strive as an innovator company to provide products that are close to our customers.

Mimaki announced the release of new cutting plotters in three sizes with different cuttable areas: "CG-60AR (cut...

March 01 2022

Mimaki announced the release of new cutting plotters in three sizes with different cuttable areas: "CG-60AR (cuttable area: 606 mm width)", "CG-100AR (cuttable area: 1,070 mm width)", and "CG-130AR (cuttable area: 1,370 mm width)".

For more than 30 years since 1988 of the release of the CG Series of high-accuracy cutting plotters for the signage industry we have been highly evaluated by customers around the world. As more jobs require shorter delivery times, we have received various requests such as speedy and accurate cutting of more diversified materials and beginner-friendly operability.

The "CG-AR series" to be released this time are the reasonably-priced latest cutting plotters of entry-model with improved usability, combining more advanced cutting performance and the ability to handle a wide range of cutting materials.

The highest cutting pressure in its class of 550g and a cutting speed 105% compared with our conventional product*1 have been achieved as the basic performance. By the increasing of 50 g of cutting pressure allowing the cutting of a wider range of materials, including PVC, fluorescent and reflective sheets, and rubber sheets. Also, CG-AR series are now capable of full cutting of cardboard. Using the dedicated optional products*2, they can produce high-quality cutouts from plain paper to cardboard, and an additional line-marking gauge enables a fold line making. These features help to create paper crafts and packages that could not be produced with the conventional models and expand not only the range of processable materials but also the range of applications.

We have also added a function that focuses on "usability" so that a variety of customers can use these products. Now that they support Windows plotter drivers, it will be easy to output data to the cutting plotter. You can send data directly from Microsoft Word, for example, without using design software such as Adobe Illustrator*3, to perform cutting. This allows you to cut and plot text and graphics easily, just like outputting them with a general office printer.*4

Moreover, support for "Mimaki Remote Access (MRA)" allows the operator to remotely use the machine and check its operation status. It would be possible through smartphone*5 or PC in the same segment network environment to operate the machine's panel, check errors, and operational status of cutting progress etc. By running a cutting plotter from a distance without worry, the customer is provided with their desired working environment.

Also, a feature "ID Cut function" newly applied in the entry-level model further improves usability. *6 This function is used to perform Print & Cut efficiently by cooperation with Mimaki printers. By reading the printed register mark with ID, the data contained in the ID is automatically cut. Data transmission from the PC is completed with one-time operation, and once you set the printed sheet on the cutting plotter, cutting is completed automatically. Though being an entry-level model, it has achieved a cost performance that even enables unattended operation.

This selectable "usability" not available in the previous series allows a wide range of customers to build an efficient output system.

This "CG-AR series" cutting plotter delivers overwhelming cost performance to further support your business as an entry-level model that is easy to use by both existing and new users of cutting plotters and goes beyond the normal functional limits. The product suitable for a wide range of applications such as car wrapping, wall decoration, paper crafting, and packaging, in addition to signage applications such as stickers, labels, POP, and signs will be released worldwide in April 2022.

With "Newness & Difference" as our management vision, Mimaki Engineering will continue to push forward as an innovative company creating new value for our customers.

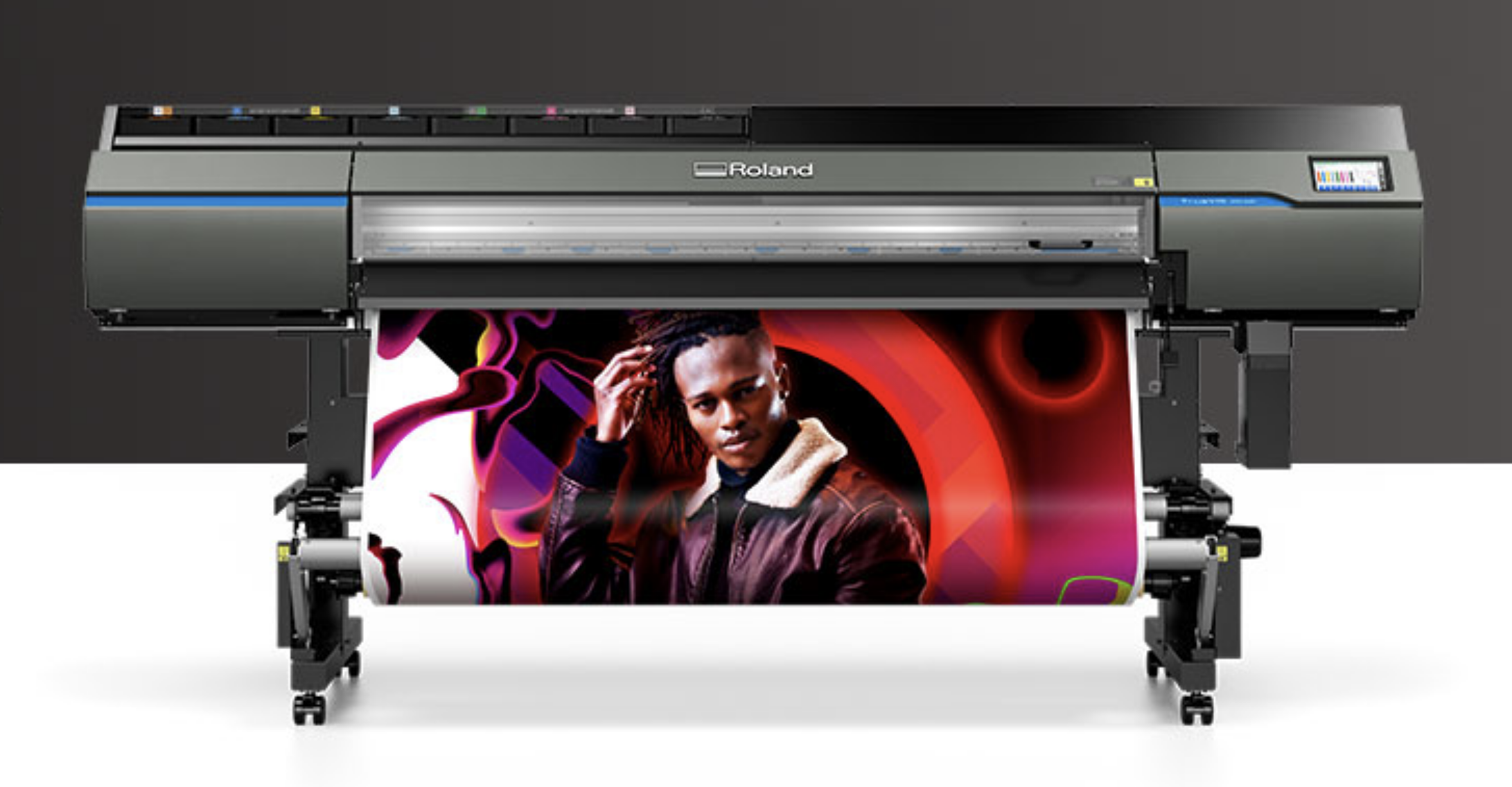

Roland DG Corporation, a leading manufacturer of wide format inkjet printers and printer cutters, announced today the launch of its third generation of TrueVIS wide format inkjet printer cutters, including the professional flagship VG3-640 and VG3-540 models with up to eight ink colours and the value-packed SG3-540 and SG3-300 with four ink colours.

"Since its launch in 2016, we have focused on building upon our award-winning TrueVIS brand, to produce durable graphics with the extraordinary power to excite hearts and minds," said Tony Miller, President of Roland DG’s Global Sales and Marketing Division. "The combination of unparalleled colour, durability and ease of use has appealed to large numbers of digital print business owners, resulting in sales of more than 23,000 units." "Our exciting new products were developed based on user feedback, with the goal of making the performance of the next instalment of the renowned TrueVIS brand even more intelligent and user-friendly than before," Miller said. "After thoroughly reviewing the previous hardware design, we developed a new platform from scratch. The rigidity of the body has been increased by four times, and the dot shape and position of the ink droplets can be controlled more accurately and consistently than ever before. Taking TrueVIS' best image quality to the next level has resulted in the next generation standard of excellence for Roland DG." The flagship VG3 Series adopts a new eight-colour ink set of CMYKLcLmOrGr for unequalled colour matching and visual expression with a wider colour gamut using special Orange and Green inks, and smoother colours with reduced graininess using Light Cyan and Light Magenta. The new True Rich Color 3 preset optimises the potential of both superior colour reproduction of the printer and the wide colour gamut of TR2 inks to achieve a unique combination of vividness and natural appearance in a single graphic. According to Miller, the new TrueVIS was also designed to offer excellent usability without relying on operator proficiency. The new TrueVIS features an easy-to-read colour LCD touch panel for quick and easy access to check settings, get a real-time view of ink levels and media, and perform device commands. Both VG3 and SG3 models include a new media setting support function that reduces media skew for easier and more accurate media loading. TrueVIS also supports automatic media gap and feed compensation for a more stable, unattended workflow. The newly developed centre and side pinch rollers further optimise the pressure to hold the media in place, resulting in improved print and cut quality. For increased productivity and profitability, TrueVIS inkjets are designed to work with Roland DG Connect, a cloud-based app that provides numerous helpful functions by connecting your devices and sharing information. For example, based on the shared product information, you can achieve faster, more proactive support, view the status of various functions and machine up-time, easily calculate profitability, and quickly download media output profiles. This helps customers to reduce downtime, improve work efficiency and realise more efficient business operations. "The world is changing dramatically," Miller added. "We live in an era where special experiences are required to excite people so print producers are challenged to work more efficiently and creatively than ever. The VG3 and SG3 Series has been developed to create exceptional value for the future of the printing business and provide the finest image quality to as many customers as possible. Through the new TrueVIS, we are passionate about working together with our customers to open up new possibilities in the printing business." To find out more about the VG3 Series, go to: https://www.rolanddg.com.au/products/printers/truevis-vg3-series-printer-cutter To find out more about the SG3 Series, go to: https://www.rolanddg.com.au/products/printers/truevis-sg3-series-printer-cutter |

March 01 2022

Xaar has launched Sure Flow, its new ultrasonic self-cleaning mode, designed to help users keep their print at its very best – and without the need to remove the printhead at any stage during the process.

With Xaar’s TF Technology ink recirculation, a regularly maintained printhead is extremely unlikely to block. However, external factors and challenging applications can create exceptionally harsh operational environments for inkjet printing.

Sure Flow enables users to clear and prevent nozzle blockages without the need to remove the printhead, maximising operational print time for optimum productivity. Enabled by software, users simply activate the mode as required by adjusting the settings and loading a command file. This drives each channel to work at maximum power and frequency to create ultrasonic waves that produce controlled vibrations of the channel walls without pausing production or the need to remove the printhead.

Graham Tweedale, General Manager of Xaar’s printhead business, said: “By minimising downtime and maintenance, Sure Flow can provide users with unrivalled reliability and enhanced productivity across the Xaar recirculating printhead range.”

Xaar worked in collaboration with a number of customers and Sure Flow has already been tested in real-world operations worldwide. To date, feedback has been extremely positive, and all Xaar recirculating printhead users are invited to contact their representative or use the Xaar Community to gain access to the new Sure Flow mode.

Graham concluded; “Sure Flow is the latest development from Xaar that continues our focus on delivering practical innovation for our customers, helping them keep their print at its very best in even the harshest environments.”

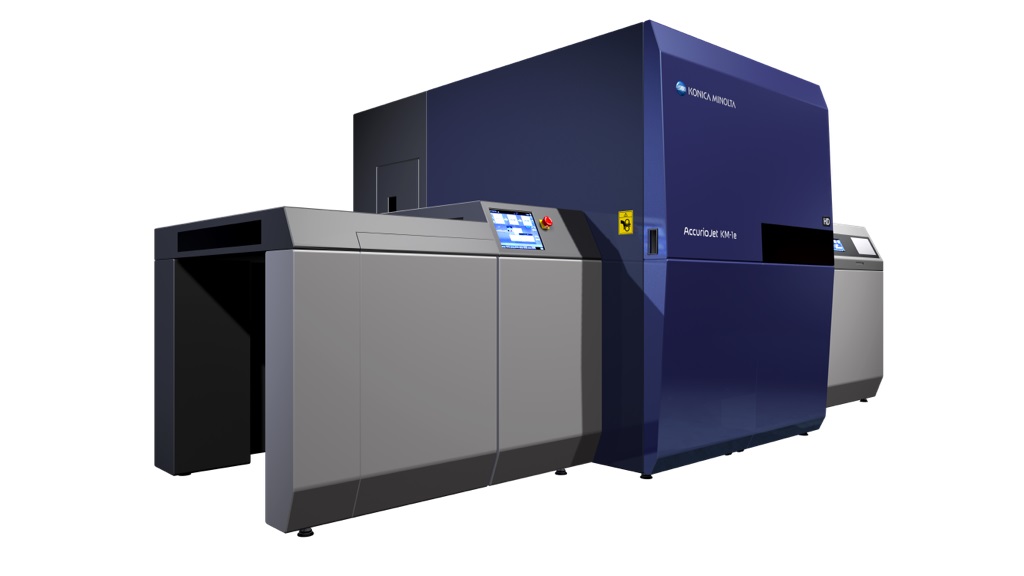

Konica Minolta Australia has introduced the AccurioJet KM-1e HD (high definition) option to provide even higher quality printing for customers, as it continues to grow its presence in packaging, commercial print, and industrial sectors. This further evolution of the AccurioJet KM-1e will contribute to increased expansion of Konica Minolta customers’ businesses.

With the new HD technology upgrade, improvements have been made to the quality of production for the AccurioJet KM-1e. These include the skin tones, the uniformity of solid backgrounds, and the reproduction of textures, with a ‘best in the industry’ image quality. Photobooks, ID applications, and digital package printing are among niche markets suitable for the new model.

Since unveiling the AccurioJet KM-1 B2+ perfecting sheetfed, full colour UV inkjet digital press in 2016, the global technology leader has been supporting its customers’ business transformations and expansions with a primary objective of staying close to its customers while building on Konica Minolta’s proprietary technologies. The AccurioJet KM-1 has become known as the ‘Swiss army knife of printing’ because it has so many uses.

In 2020, the KM-1e was launched, enabling high value-added printing with improved connectivity to third-party vendor post-processing and a wider range of substrates. Substrates that can be used include: uncoated; coated; art coated paper; coloured and metallic papers; transparency media; plastic media; canvas; and stone paper.

Using these strengths, Konica Minolta’s HD upgrade has further enhanced its appeal for applications such as booklets, postcards, and clear files. Working closely with customers’ existing post-processing machines, Konica Minolta worked in a partnership approach to customise the connection systems. In addition to the technical side, areas such as analysing machine operation status and productivity improvements have been developed in close cooperation with customers.

Tatjana Ferguson, product marketing manager – production and industrial print, Konica Minolta, said, “The new, optional high-quality HD mode will further expand the applications available to customers, bringing them new opportunities and revenue streams. Using HD, it is possible to improve the smoothness of skin, the uniformity of solid backgrounds, and the reproduction of textures. Image quality is the highest level in the industry, with any change in ink consumption negligible.

“The AccurioJet KM-1e and KM-1e HD models are key pillars in Konica Minolta’s strategy to help its customers rethink creativity. We continue to work closely with our customers locally to leverage the opportunities digitalisation in print brings and supporting them in making the switch from offset to inkjet printing so they can benefit from this growth market.”

About Konica Minolta Australia

Konica Minolta Business Solutions Australia Pty Ltd is a market-leading provider of trusted technology solutions for enterprise, government, small business, education, and manufacturing.

Konica Minolta Australia helps Australian organisations keep pace with the needs of the changing workplace to start leveraging the technology of tomorrow today.

Through innovation and investment in building a portfolio of technology solutions that will help organisations shape their future workplace, Konica Minolta Australia has key partnerships that extend its offering into future products such as data capture; business process automation; content management; business security; artificial intelligence (AI), machine learning (ML); robotics; robotic process automation (RPA); data analytics; and 3D, now.

Part of the future workplace includes creating businesses, and working with businesses, that are responsible for their impact on and contribution to employees, key stakeholders, and the wider community. Konica Minolta Australia actively promotes and innovates in these areas through diversity and inclusion, ethical supply chain, and climate change action strategies. Konica Minolta Australia recently released its first Reconciliation Action Plan to demonstrate its public commitment to reconciliation between Aboriginal and Torres Strait Islander peoples and all other people in the community to help improve life outcomes and opportunities and to create a better future for society at large.

For more information visit: konicaminolta.com.au/home

CMYKhub has announced it will showcase its Design Desk and online Subscription, Graphic Design & Prepress Platform at PacPrint in June, with attendees enc...

February 22 2022

CMYKhub has announced it will showcase its Design Desk and online Subscription, Graphic Design & Prepress Platform at PacPrint in June, with attendees encouraged to pre-book a demo or visit Stand D26 to learn how some printers are saving up to $50,000 a year on graphic design and prepress expenses.

Australia’s largest trade printer, CMYKhub has heard the calls from their 4000 strong trade partners for greater support in filling the gap between client brief and putting ink on paper.

Design Desk was launched 18 months ago to provide the print industry with access to a whole team of graphic designers and prepress operators at the click of a button. This service fills the void left post pandemic of many creative staff that were forced to move on or reduce their hours in the wake of business downturn. Design Desk has also provided many businesses including designers and creative agencies the ability to scale quickly at a very low cost.

The multi-level monthly subscription web platform connects the Australian Visual Media industry to CMYKhub’s team of qualified designers. Users simply select from the list of services, whether it be adding bleed to existing artwork or creating a printed product from scratch. Collaboration with the design team is easy via the Design Desk workflow. Anyone can instantly become a Creative Director to manage their artwork without any formal training.

CMYKhub’s National Communications Manager, Glen Francis explains that Design Desk was particularly useful to businesses earlier this year when the pandemic struck down much of Australia’s workforce.

“Design Desk never calls in sick and never goes on holidays, it is a dependable resource”, he points out.

“Many of our early subscribers have also utilised the service to be that extra half a staff member they need when they get busy or their designer needs to concentrate on a complex job”.

Design Desk in numbers looks like this:

As a trade printer, CMYKhub manufactures for other printers, graphic designers, signwriters, marketing and advertising agencies. They operate out of five production hubs based in Melbourne, Sydney, Brisbane, Cairns and Perth. Every factory is equipped with Indigo digital presses, roll to roll and flatbed wide format machines along with A1 offset presses in capital cities. The large national manufacturing footprint provides speed to market for their trade partners.

PacPrint 2021 is co-hosted by Visual Connections and the Print & Visual Communications Association (PVCA). The show will co-locate with Visual Impact Melbourne and the Label & Packaging Expo at the Melbourne Convention & Exhibition Centre from Tuesday 28 June to Friday 1 July, 2022.

To register, or for more information, go to www.pacprint.com.au