See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

At the beginning of the digital age, the RIP was the premier tool of printers and repro houses. Today, output devices take centre-stage along with file-sharing, remote access and cloud storage a...

December 21 2017

At the beginning of the digital age, the RIP was the premier tool of printers and repro houses. Today, output devices take centre-stage along with file-sharing, remote access and cloud storage applications. However, RIPs still matter – a lot – indeed, print quality depends upon it. In this feature, Radisa Peric, Flexi Product Manager at SAi, looks at what wide-format print providers and signmakers should consider when choosing a RIP. Clearly, one size doesn’t fit all … to read the full article, click here.

SCREEN GP Australia has announced that it will introduce two more ’mini’ digital label presses into Australia in 2018, under the Trojan brand name. As with the existing Trojan-made p...

December 20 2017

SCREEN GP Australia has announced that it will introduce two more ’mini’ digital label presses into Australia in 2018, under the Trojan brand name. As with the existing Trojan-made press sold under the Screen name – the Truepress Jet L250AQ, the new presses will also be available through Jet Technologies, Screen GP’s channel partner for narrow web digital presses.

The Trojan T2-C is a desktop label printer that performs like a bigger machine. Using Memjet printhead technology, it runs at up to 18 metres per minute with a maximum print width of up to 223mm across a 250mm web. It can print on pre-diecut or continuous label reels, for offline finishing.

Peter Scott, managing director of Screen GP Australia says: “The Trojan T2-C has proper web feed and take up with tensioning and yet fits any size print department due to its compact desktop footprint. Ink supply can be either by internal 250ml cartridges or, for higher productivity, external 2 litre tanks. At either 1600 x 1600dpi or 1600 x 800 dpi, the image quality is superb.”

The other new label press from Screen and Jet is the Trojan T4, an all-in-one label press line with top class inline finishing. Print speed, resolution and width is the same as for the T2-C but the T4 is a 1200Kg floor-standing unit with very robust printing, laminating, die-cutting, slitting and rewind for an end-to-end solution.

Scott says: “It’s a mini-marvel unlike any other solution for short-run and variable versioned labels. The engineering standard is first class and the die-cutter can be fully or semi-rotary and used alone to create die-cut blanks or to finish labels from another press. Best of all both the T2-C and T4 are fully supported by Screen GP’s local engineers and Jet Technologies’ expertise.”

He concludes: “We now have a complete range of digital label presses from desktop 18 metres per minute to high-end UV at 60 metres per minute, which I believe is the most complete line-up of such presses available and fully supported in Australia.”

Two companies – the Felix Schoeller Group and DATAPLOT GmbH – have agreed a strategic partnership that combines the strengths of the two partners. With im...

December 19 2017

Two companies – the Felix Schoeller Group and DATAPLOT GmbH – have agreed a strategic partnership that combines the strengths of the two partners. With immediate effect, Felix Schoeller Digital Media’s STYLine® brand – digitally printable non-woven wallpaper – will be marketed in 40 countries throughout Europe by DATAPLOT and its sales network. Conversely, the Felix Schoeller Group will take care of the development and production side of things, and manufacture both partners’ non-woven wallpapers that have been specially developed for digital printing. Customers can now choose between two strong brands: DATAPLOT’s EMBLEM based on Felix Schoeller brand and Felix Schoeller Digital Media’s STYLine®. Both brands have been certified by HP Latex and Xeikon, which guarantees their outstanding quality of conversion on those systems.

Fast service in 40 countries guaranteed

“We are very pleased about the collaboration with DATAPLOT. It will enable us to offer our customers even better service around all aspects of our STYLine®-wallpaper. DATAPLOT has a high degree of expertise in slitting and marketing digitally printable non-woven wallpapers. And their direct contact to specialist retailers and the advertising and printing industry in over 40 countries is another advantage we will benefit from,” says Florian vom Bruch, General Manager at Felix Schoeller Digital Media. As well selling the products, DATAPLOT will also be responsible for slitting and logistics. DATAPLOT will also ensure that customers receive competent support in all aspects of converting the products. Schoeller will provide the necessary product quality and expertise. “Felix Schoeller Digital Media offers the very highest quality products, from development through to production. This expertise is an excellent fit for EMBLEM. That is why we see this partnership as the ideal way of complementing our competencies and ensuring that we continue to offer our distributors and partners nothing less than the very best quality,” says Karsten Werther, CEO of DATAPLOT GmbH. Standard rolls are available in widths of 75 cm and 155 cm and, with run lengths of 55 to 75 m, they are optimally suited to the needs of the market. Special widths and lengths are also available on request. Customers who would like to see the quality of these non-woven products for themselves are welcome to request sample rolls at info@dataplot.de or get in touch with their key contact partners at Felix Schoeller Digital Media.

You will not have to wait long to find out more: Felix Schoeller and DATAPLOT experts will be at Heimtextil 2018 (09.-12.01.2018 in Frankfurt), working together to answer any questions you may have about digital printable non-woven wallpaper. The Felix Schoeller Group will be showcasing its STYLine® wallpaper in all its different facets at Stand F51, Hall 3.1.

Karsten Werther (l.) and Florian vom Bruch (r.) seal the partnership deal in Osnabrück.

Kmart Australia is marketing an in-store personalised labelling experience for Christmas shoppers in more than 200 stores around the country, using desktop printers p...

December 19 2017

Kmart Australia is marketing an in-store personalised labelling experience for Christmas shoppers in more than 200 stores around the country, using desktop printers powered by HP technology to personalise jars of popular spread brands for holiday gift-giving.

Vegemite “Name your jar” and personalised Nutella products are now offered by Kmart exclusively for in-store purchases, in a move to attract shoppers to stores amid a rise in online shopping.

Kmart purchased more than 200 Afinia Label desktop label printers from Rawson Print Co. to launch in-store label printing campaigns. The chain is planning to expand personalised promotions to additional brands and holidays. The fast and high-quality HP Thermal Inkjet technology delivered by HP Specialty Printing Systems solutions offers brands the flexibility and freedom to deliver personalised labels on-demand, anywhere they need them.

“As brands continue to look for ways to connect with their audiences, we are seeing a growing trend of mass personalised packaging, including desktop label printing campaigns in stores,” said Jason Beckley, Business Development Manager, Indigo, HP South Pacific. “HP is powering the trend with flexible and affordable in-store printing solutions that make it possible to offer an individual, memorable experience for its customers.”

The Kmart campaign is another example of the growing trend of personalised print on packaging. The ground breaking Share a Coke campaign printed on HP Indigo digital presses was also launched in Australia.

The Afinia Label L301 Industrial Colour Label Printer opens the door to seasonal product labelling, and private labelling products for customers, delivering vivid colour in 4800 x 1200 optimised dpi.

The printer is based on the HP OEM Scanning Imager 850, an affordable print mechanism offering a small footprint, excellent print speed, and ease of use with snap-in, snap-out insertion and removal of ink cartridges.

Electronics For Imaging, Inc. has announced commercial availability of its newest launched printer, the EFI Pro 24f. First ...

December 13 2017

Electronics For Imaging, Inc. has announced commercial availability of its newest launched printer, the EFI Pro 24f.

First exhibited at the recent SGIA Expo, it is the only dedicated flatbed wide-format printer featuring EFI’s proven LED and variable drop greyscale head technologies. It provides precision imaging, fine detail and outstanding image quality for a broad range of applications.

U.S. customer Superior Signs & Engraving in Wichita, Kansas, is the very first user for the printer. The printer’s premium quality imaging capabilities, with white ink included, and the high versatility and productivity of EFI’s “cool cure” LED technology, have vastly improved throughput and quality at the company.

Twice the output, higher quality and exceptional versatility

“We were completely blown away once the printer was up and running,” said Superior Signs & Engraving Co-owner Adam Stiles. “The 24f produces vibrant colours and has great print speed. In fact, we have doubled our output on flatbed work with this new printer. Plus, the printer’s white ink produces a very opaque, bright white colour, which has increased our quality of print. Overall we would recommend this printer 100%.”

While quality and speed were key considerations for Superior Signs & Engraving, Stiles and his team also benefit from the printer’s ability to accurately and consistently handle a broad range of substrates. “The features that are a nice upgrade for us besides the colour quality and speed are the button activated media guides and the media float button,” Stiles explained. “When positioning heavier medias such as 6-mm Dibond and ¼-inch acrylic, the float allows us to easily position the material without having to worry about sliding it, especially on double-sided prints.

“The built-in EFI Fiery proServer with FASTRIP,” he added, “makes RIPing files extremely easy and fast, which helps with our overall output.”

A high-value addition to EFI’s extensive inkjet portfolio

The printer is the newest addition to EFI’s growing wide-format portfolio, a dedicated flatbed device perfect for applications requiring discerning image quality and absolute dot placement accuracy. A highly strategic choice for signage, photographic backlit displays, art reproductions, membrane switches, graphic overlays, lenticular prints and other specialty applications, this printer’s 1.2 x 2.4 metre flatbed architecture features a multi-zoned vacuum system that eliminates masking while ensuring accurate registration for multiple over-prints or panels. EFI’s “cool cure” LED technology ensures low power consumption, minimal waste and compatibility with thinner and heat-sensitive substrates.

The printer’s built-in EFI Fiery proServer Core digital front end gives users the power of faster job processing, along with a host of colour management and production options for a complete, turnkey solution.

Demos and print samples from the new printer are available at EFI’s European and U.S. inkjet demo centres in Brussels and Meredith, New Hampshire. For more information on the EFI Pro 24f, visit www.efi.com.

Heidelberger Druckmaschinen AG (Heidelberg) announced that international packaging manufacturer Multi Packaging Solutions (MPS) becomes the first pilot user...

December 13 2017

Heidelberger Druckmaschinen AG (Heidelberg) announced that international packaging manufacturer Multi Packaging Solutions (MPS) becomes the first pilot user of a Primefire 106.

The Primefire 106 was first introduced at drupa 2016, and is the first industrial digital printing system in B1 format, from Heidelberg powered by Fujifilm Inkjet Technology.

The first pilot phase started back in January in cooperation with the MPS’s German manufacturing facility in Obersulm. US-based MPS specialises in packaging solutions for beauty and personal care, consumer and pharmaceutical brands and employs over 9,000 people in 14 countries. The company is planning a major expansion of its digital packaging printing arm in order to offer customers significant added value at the point of sale.

“Our customers include many well-known brand companies from industries like consumer and cosmetics. Fast, creative changes to the brand and product appearance are crucial here today to sales success. That’s why we offer these customers high-quality, flexible, and variable or personalized packaging solutions that will enable them to tap into additional business potential and set themselves apart from their competition. For this we need a reliable, industrial digital printing press like the Heidelberg Primefire 106 that can be integrated into our existing workflow,” explained Steffen Schnizer, managing director and global head of beauty and personal care sales at MPS in Obersulm.

System reliability and Heidelberg service pledge key factors in the investment decision

The image quality, reliability and rapid development of the technology following the product premiere at drupa 2016, and the company’s long years of positive experience of working with Heidelberg in the area of offset printing were key factors in MPS’s investment decision.

“Our business model is based on zero tolerance of error, quality, availability, and on-time delivery. We have many years of experience with Heidelberg as a reliable partner in the area of offset technology. Their quality and service pledge are outstanding. As such we’re confident that Heidelberg digital technologies are also the right choice for us, and we look forward to being involved in the market launch of the Primefire 106 as an early adopter,” said Götz Schümann, managing director of MPS in Obersulm.

Based on the leading Fujifilm Inkjet Technology from the co-development partner Fujifilm and the proven Heidelberg Peak Performance platform, the newly designed system is providing dependable offset-like quality production with the benefits of digital printing.

Rainer Hundsdörfer, CEO, Heidelberg, says, “Heidelberg will be setting new standards when it comes to technologies of the future, digitisation, and efficiency. The necessary cultural shift has only just begun.”

Multi Packaging Solutions produces high-end packaging for consumer branded products in the premium and luxury market space, and the technical requirements for the machines they use are correspondingly high. These prerequisites offer Heidelberg the perfect platform to be able to extensively test and enhance the new machine in real-life operation.

Following a massively successful PacPrint 2017, Neopost was delighted to sell its first Duplo DDC-810 to the team at SpotOn Finishing. This is the first placement of its kind in Australia. ...

December 13 2017

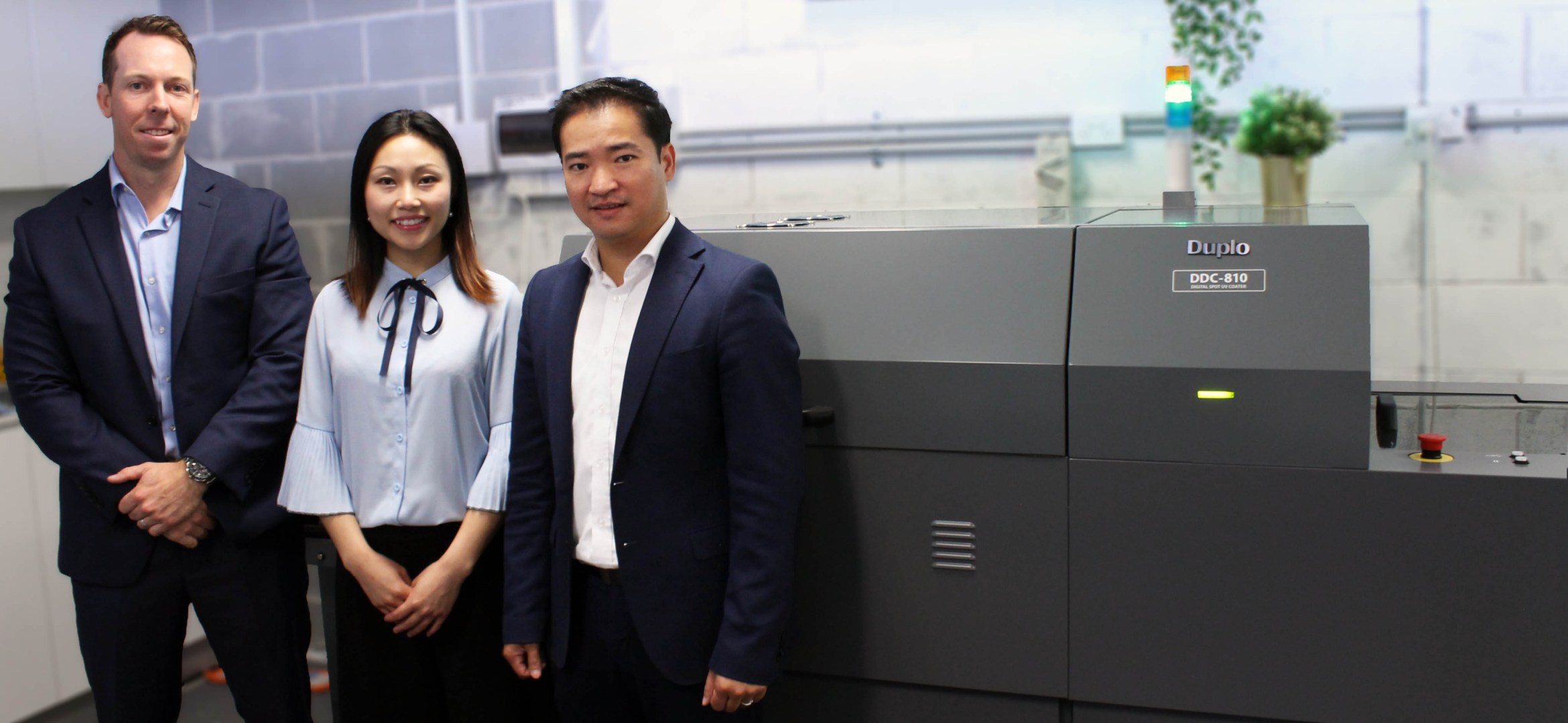

Following a massively successful PacPrint 2017, Neopost was delighted to sell its first Duplo DDC-810 to the team at SpotOn Finishing. This is the first placement of its kind in Australia.

The new machine meets the latest demands from the market, to provide spot UV finishing for the creation of beautiful prints. The project to implement and set up the new equipment was led on the Neopost side by Jimmy Nguyen, Product Manager for Print Finishing and Simon Birch, Account Manager, Print Finishing.

This investment by SpotOn Finishing shows their commitment to expanding the range of applications they can offer their customers, further cementing their position as a major player in the Australian print market.

‘We are delighted with our investment, states Joanna Lok, Director at SpotOn Finishing. The Duplo DDC-810 allows us to offer further services to our clients, to help them to produce beautiful prints. We are committed to investing in the very latest technology to ensure we are fully abreast of the latest innovation in the print industry and the Duplo DDC-810 keeps us ahead of the game. The machine installation went brilliantly, the team at Neopost have been superb in helping us get set up and we are overall really delighted with our investment”

“I am incredibly excited to add this powerhouse piece of kit to my portfolio, states Birch. We have had an overwhelming response to the exclusive reveal of the Duplo solution at Pacprint this year and the machine has attracted a lot of interest from printers who are looking to expand into new areas of print, or who want to upgrade their existing embellishment technology. We are really happy with the impact the launch has had on the market and delighted to have been chosen for a Print21 ‘Hot Pick’ award for the solution at Pacprint 2017”

For more information on the Duplo DDC-810 click here or email Neopost now on ebusiness@neopost.com or call 1800 422 349

(left to right): Simon Birch (Account Manager, PFS, for Neopost Australia) Joanna Lok (Director of SpotOn Finishing) Jimmy Nguyen (Product Manager for Print Finishing at Neopost Australia).

A company with a long tradition that combines screen printing and digital printing. The firm’s offering includes comprehensive POS campaigns for major brand manufacturers, antibacterial wall ...

December 12 2017

A company with a long tradition that combines screen printing and digital printing. The firm’s offering includes comprehensive POS campaigns for major brand manufacturers, antibacterial wall coverings for healthcare providers as well as signage and printed products (both decorative and functional) for corporate customers and private individuals. The business has gained traction thanks to the Nyala 2 large format printer …

Click here for further details.

Click on this link below, for a good article from Label & Narrow Web about using digital print technology to diversify into non-label markets.

December 12 2017

Click on this link below, for a good article from Label & Narrow Web about using digital print technology to diversify into non-label markets.

Jet Technologies (Jet) is launching a new range of speciality films, Soft Touch, which are available in black, gold, and white from early next year.

December 12 2017

Jet Technologies (Jet) is launching a new range of speciality films, Soft Touch, which are available in black, gold, and white from early next year.

Damon Norton, Sales Manager Films at Jet says, “For a long time we have been offering a high-quality anti-scuff matte film, Durophan Plus. It has been very well received.

“Alongside that in our specialty line up is Soft Touch, which has been around for a while. We have now partnered with Derprosa, the coating technology patent holder in Europe. With Derprosa we have the right products, with the right supply lines.

“Knowing that we are working with the inventors of soft touch gives us a lot of pride in offering these films.

“It is a wonderful standalone in clear, and now we have added black, gold, silver and white. So for us it is about value-add. We want our clients to recover as much as they can when laminating.

“On the Soft Touch films, embellishing can be achieved via spot UV, hot foil stamping and embossing.

“We want our clients to offer a point of difference to creatives and brand managers. Once they get a sense of what is possible with these products, we feel strongly that they will create new levels of emotional response to their print work. Through Jet the general trade will have a supply line that they can work with alongside creatives to make the most of the tactile and visual possibilities that our films offer.

“It is all about options and being able to offer our expertise to clients so they can lift their return on finishing processes.”

They will be formally released early next year, with the company noting limited amounts will be available prior to that.

Norton says, “I believe we have the product right, and the supply lines right. It is about making sure people know about it.

“Keep a look out for digital versions of the Durophan Plus and Soft Touch films. It is something we are working on.”

Epson have brought their new printer to Australia. The SC-F9360 combines the latest Epson Precision Dot Technology, with advanced media management, and UltraChrome DS HDk ink, to enable except...

December 12 2017

Epson have brought their new printer to Australia. The SC-F9360 combines the latest Epson Precision Dot Technology, with advanced media management, and UltraChrome DS HDk ink, to enable exceptionally high speed production with outstanding print quality. It achieves an exceptional gamut using just 4 colours and will print at speeds up to 109m2/hr. The 64″ wide print engine is supported by a large Continuous Ink Supply System (CISS) and a high precision Auto Take-Up. It is simple to operate, ships complete with software, and its self-cleaning system ensures reliable operation with minimal maintenance. The printer is designed for soft signage and fabric production and can also be used for hard surface work. Click here for more information.

Salt Lake City, Utah, USA – SA International (SAi), the leading provider of software solutions for the professional signmaking, wide-format digital printing and...

December 12 2017

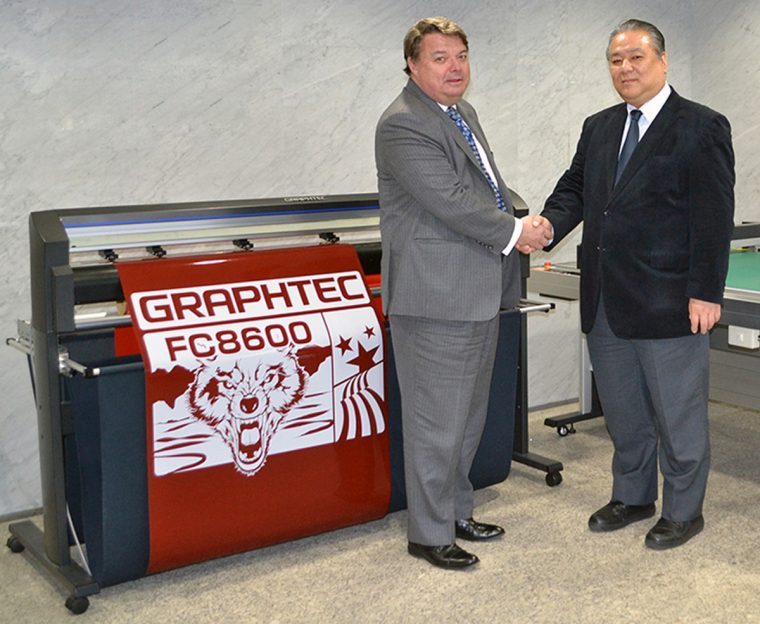

Salt Lake City, Utah, USA – SA International (SAi), the leading provider of software solutions for the professional signmaking, wide-format digital printing and CAD/CAM for CNC machining industries, has announced a worldwide agreement with cutting technology giant, Graphtec, to supply three newly-created cutting software packages with the company’s entire range of large format vinyl cutters.

Driven by SAi’s market-leading Flexi software, the feature-rich cutting solutions – Cutting Master 4, Graphtec Pro Studio and Graphtec Pro Studio Plus – have been designed to meet the varied requirements of print service providers and sign & display companies.

The new three-tier offering replaces Graphtec’s previous software solution, also named Graphtec Pro Studio, and provides users with access to the specific design and cutting tools to suit their respective needs.

Commenting on the agreement Hiroyuki Takahata, Senior Managing Director at Graphtec, said: “Our goal is to provide our customers with full access to a complete workflow to ensure that they can maximum the potential of our cutters. With the enhanced design and editing functions, the new SAi software solutions work in conjunction with our cutters to deliver greater productivity and incredible output. This partnership brings with it fantastic opportunities to expand application offerings and improve business operations for users.”

As a world leader in cutting technology, Graphtec’s portfolio includes flatbed, roll- and sheet-fed cutters, which deliver cutting widths of up to 162 cm / 64 in. The new software packages comprise:

Graphtec Pro Studio Plus

Driven by FlexiSIGN, Graphtec Pro Studio Plus offers users the most comprehensive offering with a haul of new tools including smart nesting for designs that are larger than the substrate. Graphtec Pro Studio Plus will automatically nest the sections of the design that exceed the material into available vacant space. This ability to maximise material usage ensures that print service providers and sign & display companies can enjoy greater capital saving. The Animated Cut Viewer tool allows users to view and analyse the cutting order and amend this ahead of the cutting process for optimum productivity. This solution is available as a payable upgrade from Graphtec.

Graphtec Pro Studio

Graphtec Pro Studio offers a vast catalogue of options when creating original designs. It includes enhanced functions such as auto-shapes. This enables faster and easier output of sign and display applications and crucially, reduces the time-consuming barriers of designing from scratch. Using the new Advanced Registration Mark Sensing System (ARMS), users can easily achieve highly accurate results. Graphtec Pro Studio is included with all Graphtec cutters.

Cutting Master 4

Designed as a Graphtec plug-in software for Adobe Illustrator and CorelDRAW Graphics Suite, Cutting Master 4 enables users to drive the cutter with minimum input. New capabilities enable simple creation of registration marks to locate the design, which improves accuracy and allows users to enjoy greater production efficiency. This tool is included with all Graphtec cutters.

Mark Blundell, CEO at SAi concludes, “We are proud to join forces with Graphtec and add it to a roster of leading strategic partnerships. With almost 70 years’ experience, Graphtec has built a reputation as the number one for pioneering cutters which is complemented by our industry-acclaimed Flexi-driven bundles. This collaboration provides Graphtec customers the opportunity to enhance their business performance by increasing throughput and achieving premium quality applications.”

Available now, Graphtec Pro Studio and Graphtec Pro Studio Plus are compatible with Windows, and Cutting Master 4 is accessible on both Windows and Mac platforms.

Mark Blundell, CEO of SAi (left) and Hiroyuki Takahata, Senior Managing Director at Graphtec (right)

Invoicing is a critical activity for all businesses but it can be a frustrating drain on time and resources. Many businesses still create and issue invoices by hand; even when they’re sent by...

December 12 2017

Invoicing is a critical activity for all businesses but it can be a frustrating drain on time and resources. Many businesses still create and issue invoices by hand; even when they’re sent by email, a number of time-consuming manual processes are involved. If time spent on the invoicing function can be slashed, small businesses will instead be able to devote it to revenue generating activities. That said, NEOPOST have released a fantastic eBook that will help you and your business improve your invoicing options. Click here for the eBook.

Sun Chemical has launched two new UV/EB inks for primary and secondary food packaging that are compliant with the strictest global standards i...

November 20 2017

Sun Chemical has launched two new UV/EB inks for primary and secondary food packaging that are compliant with the strictest global standards in the marketplace, including Nestlé food packaging requirements and Swiss Ordinance chemical composition requirements.

The two new inks—SunBeam Advance EB offset inks and SunCure Advance UV inks—meet the latest photoinitiator-safe packaging guidelines and are made with no BPA-based chemical to meet the most stringent global standards. They provide low odor, as well as very low residual extractables characteristics while maintaining the highest standards of pressroom performance at the highest press speeds.

Specifically formulated to help increase productivity by significantly reducing the number of blanket washes, these ink systems work on a variety of substrates and specifically address concerns that brand owners face due to strict labeling laws like California’s Proposition 65.

Designed for high-speed web folding carton and flexible packaging applications, SunBeam Advance electron beam (EB) curable offset inks offer high transfer and excellent lithographic water window properties, adhesion and abrasion resistance, outstanding cure response, excellent color recovery after a stop, and hold density well to help improve overall quality. SunBeam Advance inks are considered high strength to help improve mileage and can also reduce startup and running waste.

SunCure Advance UV inks are designed for food packaging applications and offer excellent runnability on both super high speed sheetfed and web presses. In addition to extremely high transfer properties and very good lithographic water window, these inks hold density well and provide very good UV cure response under either inter-station curing or delivery positioned lamp conditions. SunCure Advance inks also offer adhesion to some non-porous type stocks. This ink system can be used for the most sensitive packaging applications where low odour and extractables are essential.

Sun Chemicals has released a guide called ‘Brighter Ideas for Labels’.

November 20 2017

The 2017 F1 US Grand Prix saw Mercedes-AMG Petronas Motorsport secure their 75th victory and, as a result, seal their fourth consecutive FIA Formula One™&n...

November 14 2017

The 2017 F1 US Grand Prix saw Mercedes-AMG Petronas Motorsport secure their 75th victory and, as a result, seal their fourth consecutive FIA Formula One™ World Constructors’ Championship. Completed in remarkable style with three races to go in the 2017 Championship, this marked their third championship title in partnership with Epson.

One week later in Mexico, Lewis Hamilton was able to hold off the competition and secure his fourth world title, his third with the Mercedes-AMG Petronas Motorsport team.

The challenge of the 2017 season was magnified by the FIA rule changes coming into the new season. They had the objective of speeding up the cars but also of shaking up the competitive order. The win of this fourth World Championship is testament to the team’s hard work and dedication to repeatedly deliver top-class performance. During the season, this unrivalled performance on track has seen Lewis Hamilton take the record for the most number of pole positions, beating Michael Schumacher’s previous record of 68.

This constant pursuit for the highest level of performance represents a shared value with Epson, which is committed to creating value that exceeds its customers’ expectations through continual innovation.

Since the partnership began in 2015, over 130 Epson products have been integrated into team operations at the HQ in Brackley, United Kingdom, and at the 20 Formula OneTM tracks worldwide, showcasing Mercedes-AMG Petronas Motorsports’ belief in Epson products to deliver when speed and reliability are crucial.

Epson’s extensive range of products enables it to equip Mercedes-AMG Petronas Motorsport with products specific to their requirements. For example, its SureColor T-Series printers allow high-precision CAD drawings at Brackley, whereas its WorkForce Pro printers allow high-speed and reliable printing in potentially challenging conditions trackside.

The 2017 season has also seen the team reach new boundaries off-track with the Mercedes-AMG F1 M08 EQ Power+ Power Unit achieving a conversion efficiency of more than 50% during dyno testing in Brixworth. This milestone again reflects the shared vision of these two world-renowned brands to develop a more sustainable society. Trackside, Epson support the team with multiple WorkForce Pro RIPS printers which are 95% more energy efficient than laser printers* and free up valuable power for other vital equipment from a sometimes limited power supply.

Toto Wolff, Head of Mercedes-Benz Motorsport said: “I am so proud of what has been achieved: winning across a rule change, something has never been done before in the sport, and doing it because every team member has dug deeper to find performance, been even more diligent on reliability and this has come together in the most special way. ”

Ian Cameron, General Manager of Brand and Communications at Epson said: ‘We are delighted to be celebrating our third consecutive World Championship with the team. It’s testimony to both Mercedes-AMG Petronas Motorsport’s and Epson’s constant desire to continually achieve ground-breaking innovation and performance on and off the track.’

Full details of the Epson and Mercedes-AMG Petronas Motorsport team can be found on the image below.

Fuji Xerox is launching a new toner-based digital press, the six-colour Iridesse Production Press (Iridesse), offering speeds of 120ppm with substrates up to 400gsm, ...

November 14 2017

Fuji Xerox is launching a new toner-based digital press, the six-colour Iridesse Production Press (Iridesse), offering speeds of 120ppm with substrates up to 400gsm, with print resolution of 2,400dpi.

The company says the new high speed Iridesse offers printers new levels of flexibility and versatility, and will enable them to increase their product range to the market.

Iridesse is able to print specialty colours including metallic with a single pass, by housing up to two additional specialty dry inks of gold, silver, clear and white.

Quentin Sandery, national manager, Production Solutions Business Group, Fuji Xerox Australia, says, “It is about personalisation for end users. Businesses should be able to align their collateral in accordance with their brand. With the Iridesse Production Press, collateral colours can be matched to brands or personalised, with colours patterned, mixed, enhanced to provide more than printed communications. It all ties into the notion of creating that bespoke feeling amongst end users.

“To the commercial printer who wants to focus on producing jobs more efficiently and effectively, this is the ultimate press to do it.

“Production teams can now get colours that would previously take hours to achieve and they do not need to worry about finishes or sheet sizes. This machine will do it all. It has the potential to change the core of the print provider’s operations and how they look at their business.

“With current market pressures to be in a constant state of innovation, we have released a solution that will ensure print providers are able to either accelerate their operations or advance their service offering.”

The newly launched print engine enables CMYK dry ink layers to be processed on top of the special dry ink layer. An overlay of another specialty dry ink can be processed on top of CMYK dry ink layers, a feature made available with another Fuji Xerox digital printer, the Color 1000i Press.

Fuji Xerox says, “While conventional offset printing requires mixing silver ink to make metallic ink, this new product allows for simultaneous printing of several metallic colours during a single printing process.”

The standard colour library contains Pantone+Metallic and Pantone+Premium Metallic, which are swatches of metallic colours commonly used in the printing industry. With these colour swatches, the operator can reproduce colours similar to Pantone metallic colours on printing materials by designating the colour codes.

Fuji Xerox says, “Going forward, white dry ink will also be added to the specialty dry ink lineup to accommodate printing on dark coloured or other specialty papers. Compared to printers using only conventional CMYK dry inks, adopting special dry inks expands the range of expression, which adds value for effective marketing activities.”

Finishing options include Fuji Xerox’s Finisher D6 with Booklet Maker, Crease/Two-sided Trimmer D2, and SquareFold Trimmer D1, which can be connected to the Iridesse press, allowing for automatic production of professional booklets and folded leaflets.

The company says the finishing options expand the possible printing applications by enabling to produce complex folded leaflets including accordion-fold and gatefold.

“CMYK dry inks are made of High Definition EA Dry Ink (HD EA Dry Ink)—one of the world’s smallest particle size toners. The HD EA Dry Ink fuses quickly at low temperature and is evenly fused onto the paper by through our marking technology that achieves even transferring of six layer of dry inks.

“Against the backdrop of rapidly diversifying consumers’ needs, the printing industry is adjusting its use of printing techniques. Instead of just relying on conventional offset printing, which performs well for high-volume jobs, more businesses are choosing on-demand printing, which is shorter in turnaround time and prints the necessary number of copies for catalogs, manuals, and advertising materials.

“While offset printing involves significant time and cost for making plates, adjusting colours and proofreading, digital printing can process jobs with less time and cost and add value to printed materials. Enhancing the value of print products with the use of their capital equipment, such as digital printers, is critical for printing companies to grow their businesses.”

Roland DG Australia, a leading manufacturer of wide format inkjet printers and 3D devices, has today announced the appointment of Andrew Poperechny to the role of Southern Region Account Manager...

November 08 2017

Roland DG Australia, a leading manufacturer of wide format inkjet printers and 3D devices, has today announced the appointment of Andrew Poperechny to the role of Southern Region Account Manager.

Based in Melbourne, Andrew’s role will focus on delivering sales growth for Roland DG in the region. In Andrew’s most recent roles as a Key Account Manager, Graphics (Victoria and Tasmania) at Fujifilm and as Business Development Manager at Point Trading Group, he grew sales channels and exceeded budgeted sales targets in both roles whilst managing and growing relationships with suppliers, customers and the industries as a whole.

“The addition of Andrew to the sales team strengthens Roland DG’s sales efforts and dealer channel support,” said John Wall, President and Director at Roland DG Australia. “As we head in to 2018, he will become integral to supporting the company’s existing dealer and customer base, while helping us move toward new market segments.”

This addition is possible as Roland DG undertakes efforts to provide even greater support to our customers with the restructure of Darren Sunderland from his Account Manager role in Melbourne, into a technical support role. This local support role, with Darren’s extensive experience with software and production workflows, will be of great benefit to our customer base as part of the industry leading Roland DG Care offerings.

Epson’s WorkForce ET-4750 inkjet printer and PaperLab A-8000 dry-process*1 office papermaking system have been selected to join the list of the Good D...

November 02 2017

Epson’s WorkForce ET-4750 inkjet printer and PaperLab A-8000 dry-process*1 office papermaking system have been selected to join the list of the Good Design Best 100 with PaperLab also taking out the Good Design Gold Award (METI Minister Award).

The Gold award is presented to the design judged by the Good Design Award Judging Committee to be particularly outstanding among the Good Design Best 100, which are selected from all 2017 Good Design Award recipients (4,495 entries). The winner is selected based on a comprehensive evaluation of criteria including the design’s potential as a solution for social issues, future applicability, and level of completion.

Kazuhirosearch & Development Division, involved in the development of the PaperLab A-8000 says, “It i 2 office papermaking system that enables the processing and creation of paper locally, in the amount you need and when you need it. Epson is committed to promoting a zero-waste society.”

Good Design Awards celebrate designs that benefit and enrich our lives and society. In 2017 Epson won Good Design Awards for a total of seven products, including two projectors, four printers, and the office papermaking system, but only the most notable or significant designs make it to the Best 100 list.

Designs that made it into the Best 100 will be displayed at Good Design Exhibition 2017 (“G Exhibition”), held from 1-5 November at various sites in Tokyo. The Best 100 are also eligible for the Good Design Grand Award, Good Design Gold Award, and Good Design Special Awards. Winners of these awards were announced on 1 November 2017.

Manabu Kawahara, general manager for design in Epson’s Printing Solutions Operations Division, says, “Our customers have praised our high-capacity ink tank printers because they can print as much as they need to without worrying about the cost. We paid meticulous attention to the appearance and usability of the WorkForce ET-4750 inkjet printer. As the next generation of ink tank printer, this printer offers more than just great value. It is compact, stylish, easy to use, and greatly reduces the frustration people feel when they run out of ink. We will continue to use printing to improve the quality of people’s life and work, and will develop printer designs for products that exceed customer expectations.”

This A4 inkjet multifunction printer features large ink tanks, and boasts high productivity and cost efficiency. The ink tanks and ink bottles are designed to make refills clean and quick, and the printer is intuitive and easy to navigate. The tank is in the front, which improves accessibility and makes it easier for you to check the ink level. Simply insert the ink bottle, and the mechanism automatically refills the tank to its full capacity. The tank juts out from the printer, showing its impressive capacity, and the simple, round shape of the casing expresses a robust durability that fits perfectly into any living space.

Judges’ comments

Multifunction A4 inkjet printers with high-capacity ink tanks sharply dispelled users’ dissatisfaction with ink. Epson adopted high-capacity ink tank designs to address the routine out-of-ink issue and the issue of expensive ink cartridges. The ink tanks are positioned in the front of the printers. The shape and colour of the ink tank unit are unobtrusive, and the unit blends well with the rest of the printer. The tanks are easy to fill, and you can tell at a glance how much ink remains. The design is both beautiful and functional. In addition, the design of the ink bottle spout and ink tank inlet are unique for each colour to prevent misfilling. No compromises were made with the design of the ink bottles. An auto-stop mechanism prevents ink from leaking when a bottle is removed from the tank, even when the nozzle is pointing downward, so there are no spills. We also appreciated the exquisitely designed adjustable control panel, the printer’s soft curves, and the smooth, clean appearance.

The PaperLab A-8000 is the first*2 office papermaking system to employ a dry process to securely destroy used documents and produce new sheets of paper. Epson’s dry fibre technology enables paper to be produced without the huge volumes of water that ordinary papermaking requires. Since no plumbing is needed, the PaperLab can be installed in a back office or anywhere else with available space to upcycle used paper. The PaperLab is changing office operations by increasing information security, producing paper of various weights and sizes, and reducing users’ environmental impacts.

Judges’ comments

There is a lot of discussion about the use of paperless processes. The PaperLab is a truly outstanding solution as one answer to the question about future paper use. The fact that you can recycle used paper right in the office and thus increase information security is particularly praiseworthy.

Other Epson products recognised with 2017 Good Design Awards

• EB-1795F projector

• EB-L1000 projector series

• Workforce WF-3720/4720/4740 business inkjet printers

• WorkForce Enterprise WF-C20590/C17590 A3 colour multifunction inkjet printers

Good Design Awards

The Good Design Award is a comprehensive design-promotion system that picks good design out of a variety of unfolding phenomena. It is hosted by the Japan Institute for Design Promotion, a public interest incorporated foundation. It’s precursor, the Good Design Selection System (or G Mark System), was founded in 1957 by the Ministry of International Trade and Industry (the current Ministry of Economy, Trade and Industry), and has been engaged in this work for about 60 years.

For more information on PaperLab A-8000 go to: http://global.epson.com/innovation/paperlab/

Avery Dennison Graphics Solutions announced that Lei’d Low by Exotic Graphix is named the Australia and New Zealand Regional Wrap King in the “Wrap Like a...

November 02 2017

Avery Dennison Graphics Solutions announced that Lei’d Low by Exotic Graphix is named the Australia and New Zealand Regional Wrap King in the “Wrap Like a King” Challenge featuring Avery Dennison® Supreme Wrapping™ Films, Conform Chrome and digital Supercast vinyl wrap films.

“Congratulations to Nick and his team for this win,” said Jordan Leach, business manager, Avery Dennison Graphics Solutions, Australia & New Zealand. “Their planning, creativity and installation techniques are testament of the dedication to their craft, impressing the panel of international judges.”

As Regional Winner for Australia and New Zealand, Exotic Graphix is automatically awarded as the Continent Wrap King, and will be judged alongside other continental winners for the ultimate “King of the Wrap World” title at the 2017 SEMA Show, October 31 – November 3, 2017 in Las Vegas, Nevada.

The 2017 Challenge judges include Justin Pate, co-owner of The Wrap Institute; Molly Waters, senior technical specialist, Avery Dennison; Myles Kovacs, co-founder of DUB Magazine; Peter Wright, technical marketing manager, Avery Dennison; Jun Kinoshita, sales manager, Avery Dennison; Stefan Ude, owner of Ude FolierungsKonzepte; Anders Prates, co-owner of WTP Dekor; and Jurriaan de Vries, technical services and support manager, Avery Dennison.

The eight professional judges evaluated the 159 total submissions based on the following criteria: visual transformation (difference between the before and after pictures submitted), quality and skill level of installation, overall public look and appeal and uniqueness of the design.

Prize pack for Continent Wrap King is valued close to US$3,200 and consists of a Continent Wrap King trophy, personalized Wrap Like A King swag, US$500 in gift vouchers, a 67” Race Ramp, a large banner stand display, passes to the SEMA show, and a variety of promotional and marketing tools for the winner’s wrap shop.

Wrap installers can learn more about Supreme Wrapping Film, digital Supercast films, official rules, judges and prize information via www.wraplikeaking.com