See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

Doggett Labels has invested in new label equipment and expanded their service offering to better service the changing market.With a high percentage of Doggett Labels orders ...

August 08 2023

Doggett Labels has invested in new label equipment and expanded their service offering to better service the changing market.

With a high percentage of Doggett Labels orders being for short runs and with quick turnaround requirements, we’ve improved some of our processes and invested in new machinery which allow us to more closely align with the changing markets we service.

We’ve expanded our “off the shelf” label range to now include over 150 products, all available for same-day despatch.

Our new manufacturing equipment offers increased flexibility, with small run custom-shape orders not requiring the investment and manufacturing of a new die.

So how will these improvements benefit your business?

Roger Gee explains in the video below.

Expand color gamut and improved color saturation for vivid color developmentMUTOH INDUSTRIES LTD., a leading manufacturer of wide-format inkjet printers, af...

August 08 2023

Expand color gamut and improved color saturation for vivid color development

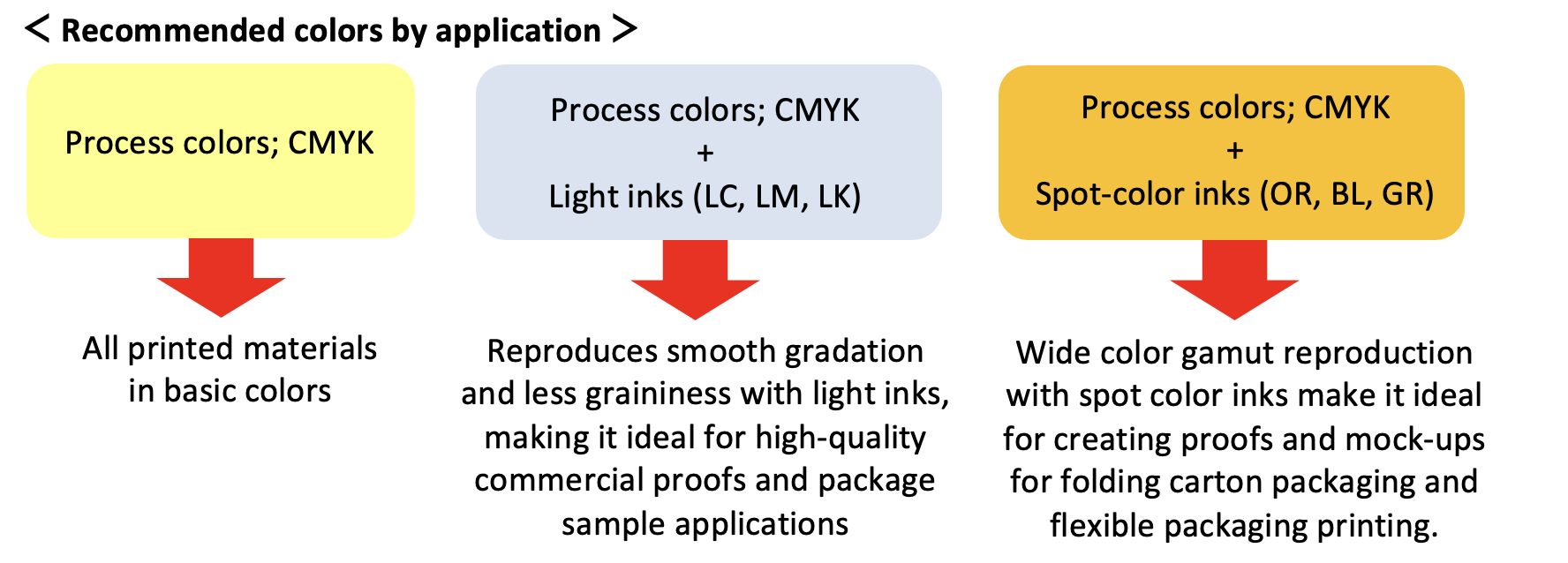

MUTOH INDUSTRIES LTD., a leading manufacturer of wide-format inkjet printers, affiliated with MUTOH HOLDINGS CO., LTD. today announces that it has added spot colours; orange, blue and green inks to its proprietary MP31 ink lineup for the VJ-628MP and VJ-1628MH printers.

The “MP” in MUTOH MP31 ink stands for Multi-Purpose, and MP 31 ink can print directly on a wide variety of materials, including acrylic, PET, metal and synthetic leather, as well as paper. Compared to UV ink, it is less uneven and smoother, and produces a natural finish that brings out the texture of the material.

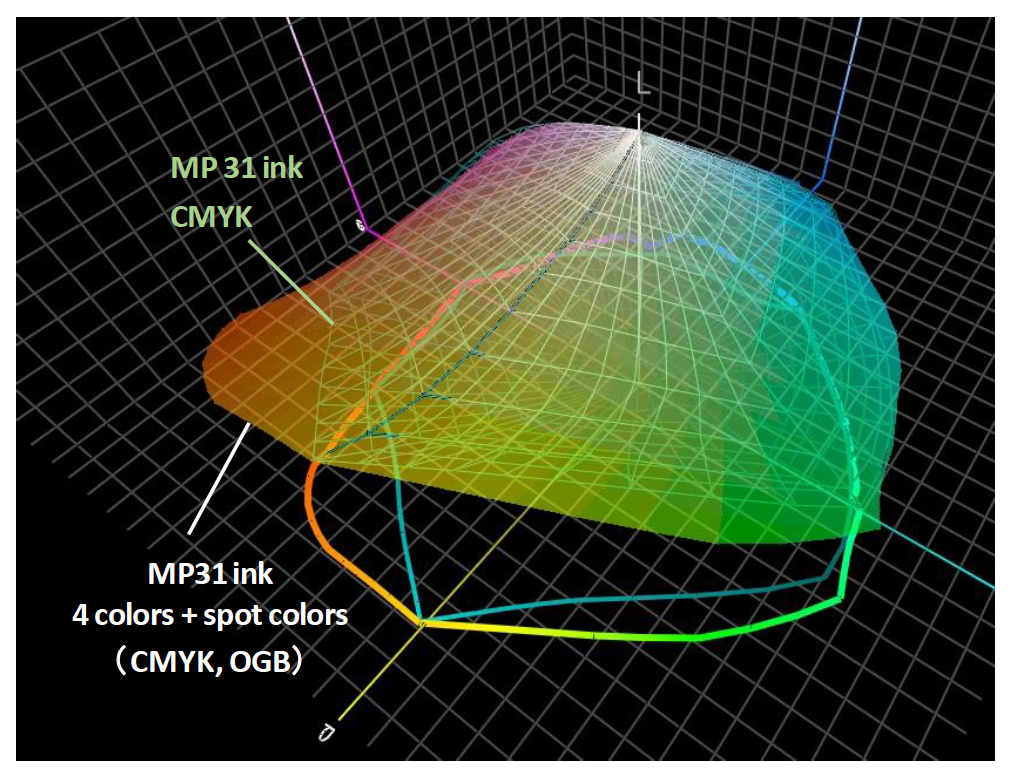

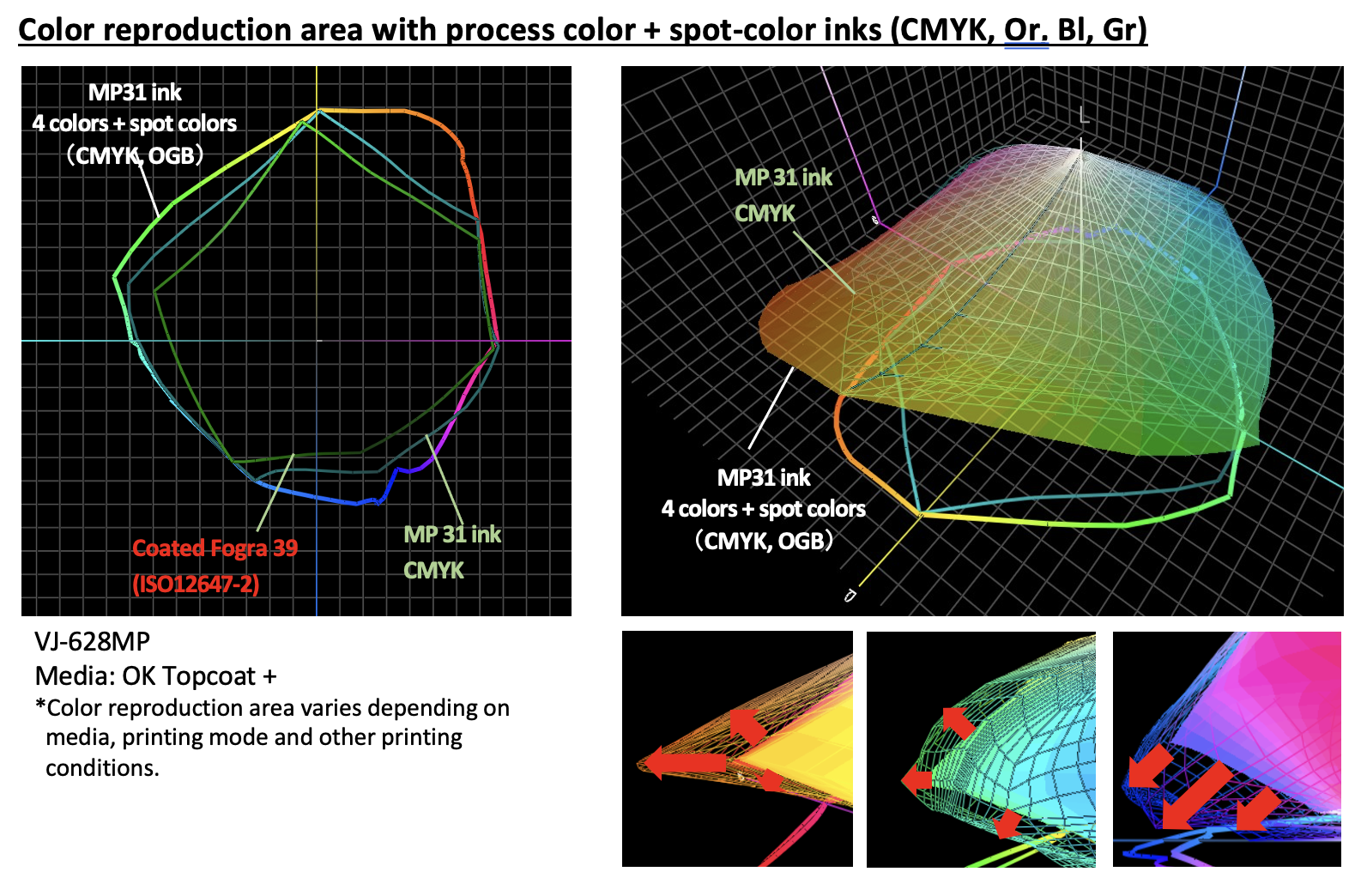

The use of spot colour-inks; orange, blue and green added to the basic CMYK inks expands the colour gamut and broadens the range of colour expression. These inks produce more vibrant and beautiful colour expression including vivid orange and green, and deep blue.

Compared to the colour gamut of CMYK inks alone, the colour reproduction area using spot-colour inks have been extended and the saturation has been increased.

Features of MP31 ink

- Weather resistance*, abrasion resistance, and colour development equivalent to eco-solvent ink

- High-opacity white ink brings out the original brightness of color inks regardless of the underlying

substrate color.

- Natural finish with no unevenness and smoothness compared to UV curable inks, making the most of

the original texture of the material.

- Resistant to heat, stretching and bending, and the printing surface does not crack easily when bent.

Printing and processing on polycarbonate and shrink film used for vacuum forming are possible.

- Selectable from 4, 5, 7 or 8-colour ink configurations depending on application

*Except for orange ink

The VJ-628MP and VJ-1628MH provide highly accurate inkjet colour proofing using the original printing paper. The ability to check the design and colour proof on the same sheet of paper provides a consistent image of the finished product, prevents reversals due to image inconsistencies, and can also be used for colour proofing with high reproducibility.

In addition, effective use of original paper also eliminates the need for dedicated inkjet paper and reduces running costs.

MUTOH makes continuous efforts to provide new products to the market to meet the diverse needs of our customers.

Roland DG Corporation (Headquarters: Hamamatsu City, Shizuoka Prefecture, Japan; President, Representative Director: Kohei Tanabe), a global manufacturer and distributor of wide-format inkjet pr...

August 08 2023

Roland DG Corporation (Headquarters: Hamamatsu City, Shizuoka Prefecture, Japan; President, Representative Director: Kohei Tanabe), a global manufacturer and distributor of wide-format inkjet printers for advertising and signage and 3D tools for manufacturing, today announced the acquisition of shares for UAB Dimense print, a subsidiary of UAB VEIKA, a manufacturer and vendor for wallpaper-related products headquartered in Vilnius, Lithuania.

Roland DG has set the goal of pioneering the future through “Digital and Co-creation” in the midterm business plan (FY2021-23) which focuses on transitioning the business portfolio and examining growth opportunities through M&A to establish new core businesses. Roland DG has decided to acquire a 50.1% stake in UAB Dimense print, a subsidiary of UAB VEIKA, which excels in chemical technology and offers a unique digital printing embossing solution for wallpaper industries. The digitalization of wallpaper printing has not yet fully penetrated the market, but growing demand for personalisation and upcoming market expansion present the perfect opportunity for Roland DG to make its official entry into the market. Furthermore, this embossing technology has great potential as it can bring texture and dimension to various printed applications, such as gypsum moulds.

Roland DG aims to strengthen its presence in the wallpaper market through the continued development, sales, and support of DIMENSE™ and Ecodeco™, both proprietary technologies of UAB Dimense print. Leveraging UAB VEIKA’s excellent technical capabilities and combining them with Roland DG’s manufacturing expertise and global-scale sales network, Roland DG will drive the development and sales of unique and high-value-added new digital printing solutions, with the goal to further expand the market by capitalizing on these strengths.

SISER RANGE OF HEAT TRANSFER VINYLS & EQUIPMENT NOW AVAILABLE AT GRAPHIC ART MART Graphic Art Mart, the leading national supplier of sign, digital, and display solution...

August 08 2023

SISER RANGE OF HEAT TRANSFER VINYLS & EQUIPMENT NOW AVAILABLE AT GRAPHIC ART MART

Graphic Art Mart, the leading national supplier of sign, digital, and display solutions, is excited to announce its new partnership with Siser, one of the most respected names in the global heat transfer materials industry. As of August 7th 2023, Graphic Art Mart will officially become the master trade distributor of Siser products in Australia, further enhancing its commitment to delivering exceptional brands to the industry.

The collaboration with Siser marks another exciting milestone for Graphic Art Mart who are celebrating their 50th year of business. Siser is internationally recognised for its innovation and superior heat transfer materials, catering to various creative industries, including textiles, fashion, promotional items, and more. This partnership will enable Graphic Art Mart to expand its portfolio and provide customers with an even broader selection of cutting-edge materials.

Xaar has launched its Versatex Printbar, enabling specialist label and flexible packaging producers to digitally print the highest opacity whites and colours and add a wide range o...

August 08 2023

Xaar has launched its Versatex Printbar, enabling specialist label and flexible packaging producers to digitally print the highest opacity whites and colours and add a wide range of features to their existing presses.

Building on the Versatex Print Engine and Evaluation Kit launched last year, the new Versatex Printbar provides an opacity of 82 percent at 50 meters per minute, achieving the most brilliant whites and vibrant colours for labels and packaging.Textured and high-build print effects, varnishes, foils, and mass personalisation all become available with the Versatex Printbar which can both be integrated with new machine configurations or retrofitted onto existing presses.

Powered by Nitrox printheads with Xaar’s TF Technology, High Laydown and Ultra High Viscosity Technologies, the Versatex Printbar can handle a wide range of inks and fluids, printing at widths of 410mm and at up to 720dpi with eight grey levels at speeds of up to 75 meters per minute.

Adding a Versatex Printbar to existing machines facilitates printers in meeting the growing demand for embellishments on packaging and labels. Xaar’s High Laydown Technology delivers very high volumes of fluid in a single pass with exact temperature control, enabling the creation of high-build inks and varnishes to deliver an extensive array of tactile effects more efficiently. By complying with European standards for tactile warning triangles on labels, their application onto packaging is now much easier without the added complexity of screen printing.

Ease of use and flexibility are key. The Versatex Printbar’s ‘TIFF catching’ workflow enables operators to simply drop a printable job into the software and make amendments ‘on the fly’. It can also be fully integrated with industry standard workflows, such as Esko, to send the output directly to print for maximum efficiency.Dynamic synchronization technology also ensures maximum uptime and quick registration with pre-printed substrates. The integrated sync to mark reader can be moved into any position across the web, and once running, can be in full registration within three or four image repeats.

The Versatex Printbar includes a fully integrated and flexible control cabinet that houses all the necessary electronics and controls, and can be easily located up to five metres away for ease of operation and access.With sustainability in mind, the innovative Versatex Printbar, when compared to screen printing, offers shorter setup times and a higher utilisation rate, resulting in small run jobs being completed faster. In addition, the ability to jet higher volumes and viscosities of fluids improves the efficiency of print processes, reducing the need for multiple passes, delivering faster print speeds and cutting energy use and costs.

Graham Tweedale, Chief Operating Officer at Xaar said, “We are delighted to add the Printbar to the Xaar Versatex range as it enables OEMs and integrators to take advantage of our proven ready-to-market inkjet technology without further development overheads.

“The highest opacity digital whites and colors, alongside the latest high-build print and visual embellishments, can now be easily added to existing presses, saving time, energy and money across a range of self-adhesive label and flexible packaging applications.”

Canon has announced that 3M has recognised the exceptional quality of the Colorado M-series and approved its UVgel 460 white ink as part of the 3M MCS Warranty program, following i...

August 01 2023

Canon has announced that 3M has recognised the exceptional quality of the Colorado M-series and approved its UVgel 460 white ink as part of the 3M MCS Warranty program, following its successful introduction earlier this year.

The 3M MCS Warranty program provides assurance that applications printed on the Colorado M-series in combination with UVgel 460 inks and 3M’s approved media will achieve the highest quality standards. The applications it covers include vehicle graphics, signs and displays, floor graphics, as well as transparent film and multilayer applications, such as window graphics and many more.

In combination with a variety of 3M media, the Colorado M-series and its UVgel 460 inks, including the new white ink, had to pass a series of rigorous tests carried out under 3M’s stringent assessment conditions to qualify for the approval. Recognised as a trusted industry standard and representing the most comprehensive, all-inclusive warranty for finished graphics, the 3M MCS Warranty provides non-prorated protection for the graphic’s intended lifespan, including protection against fading, cracking, peeling, blistering, discoloration and many other aspects of graphic performance. In doing so, the warranty gives both print service providers and their customers the confidence that their images will perform as expected for the intended lifetime of the printed graphic.

The Canon Colorado M-series was launched earlier this year and is designed as a single, fully modular platform that can be configured to graphics providers’ needs and grow with their business, with easy in-field upgrades. The scalable series includes two base models (M3 and M5) that offer a choice of output speeds and the option to upgrade from one model to the other. Both printers can also be upgraded to include white ink (M3W and M5W).

The Colorado series is Canon's most productive 64-inch printer family and uses the unique UVgel ink technology. It incorporates all the best aspects of alternative ink technologies, such as the colour gamut and light fastness of eco-solvent, the fit for indoor and outdoor use, due to there being no odour and quick drying time associated with latex and the productivity and low-temperature printing process of UV.

The inclusion of the white UVgel ink for the 3M MCS Warranty program maximises the scope for customers to benefit from UVgel’s renowned performance advantages across a full spectrum of premium graphics, including window graphics, labels, interior décor and many multi-layer applications.

UVgel inks produce odourless, ultra-robust output, fully certified for indoor use as well as being very durable for outdoor use. Customers benefit from zero VOC emissions, zero hazardous air pollutants and a low average ink usage of 5.9ml /m2. And with more than 3,000 UVgel engines installed worldwide, UVgel has already proven itself to be a sustainable, cost-efficient and highly productive alternative for latex and eco-solvent technology.

Woonsik Shim, Vice President, Graphics and Personal Auto Business, 3M Commercial Branding and Transportation Division, says: “At 3M we take pride in the ability to provide graphics manufacturers the widest selection of premier printing solutions. Extending the warranty through our partnership with Canon and their growing UVgel portfolio reinforces our commitment to quality and to our customers' success, which in turn inspires confidence in the printed graphics.”

Mathew Faulkner, EMEA Director, Marketing and Innovation, Wide Format Printing Group at Canon Europe, comments: “We’re committed to working with large format graphics producers to evolve their production and enable them to exploit new growth opportunities. With the new Colorado M-series, which has Canon’s UVgel technology at its core, we’re helping our customers to do just that by providing a fully modular printer platform capable of effortlessly handling high-value, white ink applications. Through collaborative efforts with key partners such as 3M and by acquiring the highly regarded 3M MCS Warranty for the M-series including white ink, we’re better equipped than ever to empower print service providers to meet the highest quality standards, achieve boundless creativity, improved efficiency and grow their profitability.”

The Colorado 1630, Colorado 1650 and also the new Colorado M-series with the UVgel 460 ink set, which includes white ink, are now all approved for the 3M MCS Warranty program.

Canon is seeing a rapid growth in the take-up of its Colorado platform and patented UVgel technology and, in 2020, invested in a new, state-of-the-art ink factory at its HQ in Venlo, Netherlands, which is now fully operational and increasing its production capacity continuously to keep up with demand.

Tech in Gov is Australia’s most important event for ICT in Government. The event brings together thousands of government technology leaders, plus public and private sector IT experts to learn, n...

August 01 2023

Tech in Gov is Australia’s most important event for ICT in Government. The event brings together thousands of government technology leaders, plus public and private sector IT experts to learn, network and source ICT solutions for the ongoing digital transformation within government. Epson Australia will showcase a variety of printing and scanning solutions at this year's event, located at stand 124 and the focus will revolve around the theme of "Taking Sustainability Seriously."

Epson WorkForce Enterprise AM-C4000

Taking centre stage on the Epson stand will be the WorkForce Enterprise AM-C4000. This recently released A3 Colour MFD truly demonstrates how its users can take department productivity to a whole new level with 40 ISO ppm (mono/colour).

Then, by utilising Epson’s patented and award-winning Heat-Free PrecisionCore® technology and operating at ¼ of the energy of a laser printer1, the AM-C4000 presents itself with one of the lowest carbon footprint in its market segment and as the ultimate energy-efficient solution for all department sizes. In short, the AM-C4000 is the embodiment of Epson’s Taking Sustainability Seriously message.

Next to the AM-C4000 is the Epson WorkForce DS-360W, an A4 scanner that delivers high quality document scanning and provides a cable-free solution with a built-in battery and wireless connectivity for scanning to mobiles, tablets and computers.

The ultra-portable DS-360W enables you to wirelessly scan to your smartphone, tablet or computer and boasts the fastest scan speeds in its class2 with up to 25 ppm/50 ipm3 and single-step technology which captures both sides in one pass.

Epson WorkForce DS-360W

Another scanner on Epson’s stand comes in the form of the Epson WorkForce DS-790WN, the most intelligent introduction into Epson's scanner portfolio yet. This high-speed sheet-fed scanner is bundled with features that will increase efficiency and productivity in the workplace.

Key among many features of the Epson WorkForce DS-790WN that make it an ideal fit for document scanning is its ability to scan both sides of a double-sided document simultaneously and at great speed. The scanner can also process documents at 45 ppm / 90 ipm with a setting of 300dpi.

Epson WorkForce DS-790WN

The Epson WorkForce DS-790WN also has the ability to connect to a network easily and seamlessly integrate into a department’s operation. Files can be shared amongst multiple users from one single device. Alternatively, its USB 3.0 port allows direct to PC connection.

The final Epson product on display at Tech in Gov is the WorkForce Pro WF-C579R high-productivity colour printer. Powered by Epson’s Heat-Free PrecisionCore inkjet technology, this compact MFP features a replaceable ink pack system with extra high-capacity packs that can deliver enough ink to print up to 50,000 ISO pages black/20,000 ISO colour before changing the packs4

WorkForce Pro WF-C579R high-productivity colour printer

With energy efficiency at the forefront of the company, Epson will also be demonstrating a live comparison between their Heat-Free business inkjet printer and a laser printer to measure the amount of energy consumed when printing the same document at the same time.

The demo will also compare and highlight the productivity benefits between an Epson inkjet device that prints immediately and on demand, as opposed to a laser device that needs time to warm up before printing can commence.

Epson representatives at Tech in Gov 2023 include senior business development manager Eddy Moussa and pre-sales engineer Craig Skilton, both of whom will be available on Epson stand 124 to assist with technical queries and steps towards improving sustainability for any business.

1Epson's AM-C4000 model is 75% more energy-efficient than 27 competitive models in the 35 to 45ppm A3 Colour MFD segment as at 1 May 2023 according to data from Keypoint Intelligence (comparing maximum power consumption figures).

2In its class, as compared to other portable consumer document scanners with an ADF, using the AC adapter and power cable, priced under $500 RRP AUD (sold into Australia and New Zealand at June 2016).

3Based on letter-sized scans at 300 dpi in Black-and-White, Grayscale or Colour Mode, using the AC adapter.

4Replacement ink pack yields are estimated based on ISO/IEC 24711 test in Default Mode printing continuously. Ink pack yields vary considerably for reasons including images printed, print settings, temperature and humidity. Yields may be lower when printing infrequently. Ink is used for printing and printer maintenance, and ink has to be installed for printing. For print quality, part of the ink from the included ink packs is used for printer startup and a variable amount of ink remains in the ink pack after the "replace ink pack" signal. For details, see www.epson.com/inkinfo

Are you ready to unlock limitless possibilities in the world of printing and packaging? Look no further! Currie Group, Australia and New Zealand’s leading provider of innovative pr...

August 01 2023

Are you ready to unlock limitless possibilities in the world of printing and packaging? Look no further! Currie Group, Australia and New Zealand’s leading provider of innovative print and finishing solutions, is thrilled to announce our exciting partnership with B&R Moll, Inc., a renowned pioneer in the post press finishing industry headquarter in Pennsylvania, USA with a European full service /sales facility in the UK.

With great pride and enthusiasm, Currie Group is now the exclusive representative of B&R Moll, Inc. in Australia and New Zealand. This collaboration brings together two powerhouses in the industry, combining our expertise, passion, and commitment to delivering cutting-edge solutions to our valued customers.

Global Excellence, Local Expertise ……. at Currie Group, we understand the unique needs and challenges faced by the printing and packaging industry in Australia and New Zealand. With over 74 years of experience, we have established ourselves as the go-to partner for businesses seeking unparalleled support and solutions.

The Moll family in the same respect, has had a rich legacy of innovation and a global reputation for its high-quality post press finishing equipment for over 40 years. By joining forces, we are bringing B&R Moll's world-class technology and solutions closer to your doorstep, providing you with access to the latest advancements and a comprehensive range of options for all your finishing requirements.

Unmatched Solutions …… the partnership between Currie Group and B&R Moll opens a world of possibilities for businesses in Australia and New Zealand. Whether you're looking to enhance your finishing capabilities, improve efficiency, or explore new creative solutions, our joint expertise will empower you to achieve remarkable results.

From our digital registering, nick-less cutting FlexCut rotary die cutters, versatile folder-gluers to our advanced bindery systems, our extensive portfolio of B&R Moll, Inc. equipment is designed to streamline your operations and maximise productivity. With their state-of-the-art technology, you can achieve precision and excellence in folding, gluing, die-cutting, and more, all while staying ahead of the competition.

Your Success is Our Priority…. at Currie Group and B&R Moll, Inc., we are more than just solution providers. We are dedicated partners invested in your success. Our team of highly skilled professionals will work closely with you, offering expert advice, tailored solutions, and comprehensive support at every step of your journey.

Together, we will help you revolutionise your printing and packaging processes, reduce costs, improve turnaround times, and elevate the quality of your finished products. Your success is our driving force, and we are committed to going the extra mile to ensure your complete satisfaction.

Contact us today ….... don't miss out on this extraordinary opportunity to transform your printing and finishing capabilities. Contact Currie Group, the exclusive representative of B&R Moll, Inc., in Australia and New Zealand, and let's embark on a journey of innovation and growth together.

Click HERE to contact Currie Group and learn more about how our partnership can benefit your business.

Currie Group and B&R Moll, Inc. — where cutting-edge technology meets unparalleled service, delivering exceptional results for your printing and packaging needs. Get ready to thrive!

High productivity, high image quality, and ability to print on various media MUTOH INDUSTRIES LTD., a leading manufacturer of wide-format inkjet printers, affil...

August 01 2023

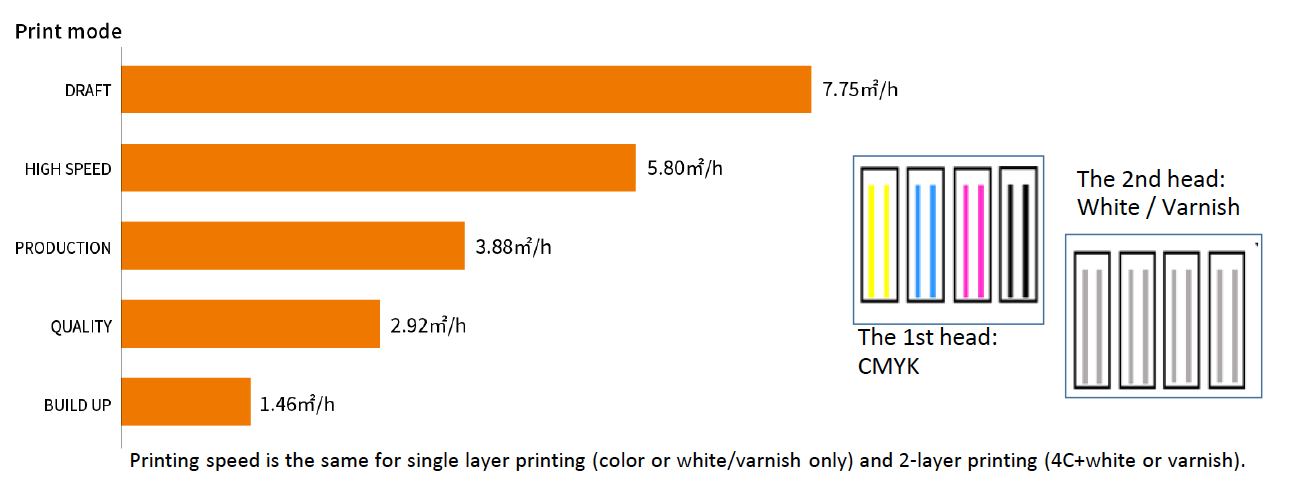

High productivity, high image quality, and ability to print on various media

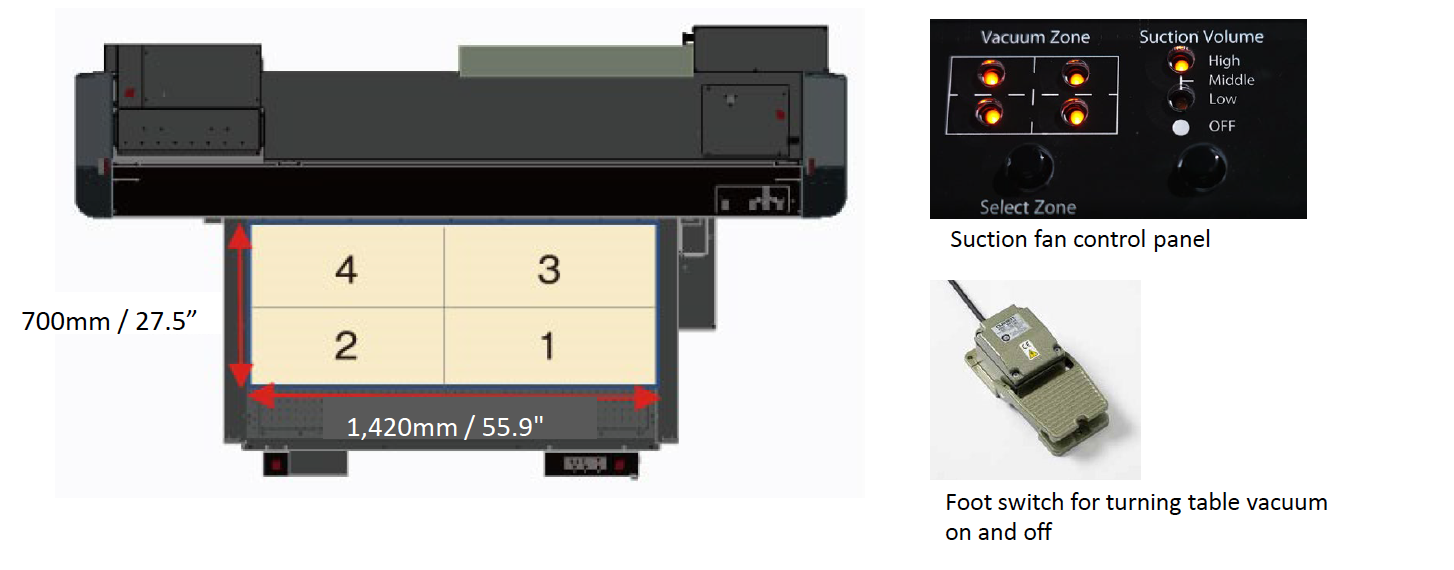

MUTOH INDUSTRIES LTD., a leading manufacturer of wide-format inkjet printers, affiliated with MUTOH HOLDINGS CO., LTD. today announces the release of the XpertJet 1462UF, a flatbed UV-LED printer with a table size of 1,420 mm (55.9”) x 700 mm (27.5”), which combines high productivity and high image quality to meet diverse user needs.

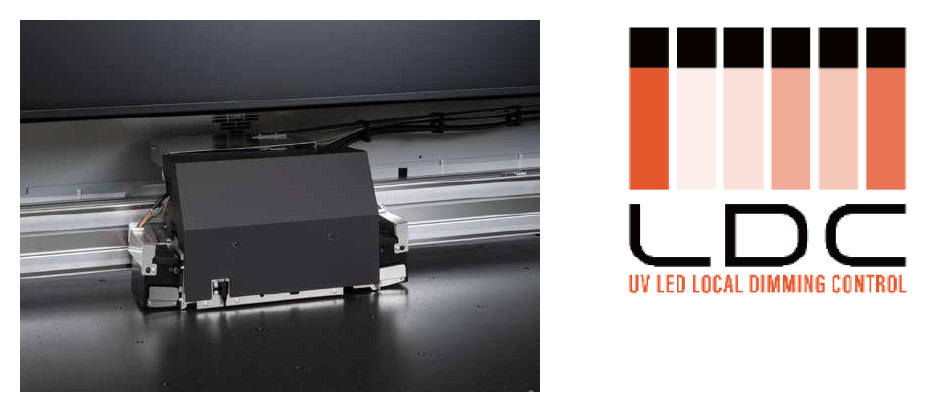

The XpertJet 1462UF is equipped with two newly developed 4-inch UV-LED lamps and staggered dual print heads with independent CMYK and white/varnish for faster two-layer printing.

The highly rigid and precise chassis and MUTOH's unique alluminum rail mechanism deliver high ink dot placement accuracy.

The printer supports media up to 1,420 mm (55.9”) x 700 mm (27.5”), 150mm (5.9”) thick, and 50 kg/m2 in weight. The table unit is equipped with a 4 zone vacuum table with 4-stage suction force control, and service holes for fixing jigs, allowing greater flexibility in media selection.

The XpertJet 1462UF brings the best "Made in Japan Quality" to various markets such as personalised items, store decoration, sign, industrial products and more.

Key Features of the XpertJet 1462UF

Both high productivity and high image quality in bi-directional printing enable faster 2-layer printing

- Two new 4” wide UV LED lamps

Newly developed 4-inch wide UV-LED lamps are placed on both sides of the print head. Combined with "UV-LED local dimming control technology," which individually controls the UV-LED lamp irradiation for each segment according to the printing conditions, it achieves optimal ink curing even in bi-directional printing.

Dual print heads in a staggered setup

Staggered dual printheads ensure high-productivity. The first head prints CMYK, the second head prints white/ varnish, which enable 2-layer printing without speed loss. It is ideal for braille and 2.5D structure prints.*ADA-compliant Braille printing will be supported in NorthAmerica.

Highly rigid & high-precision chassis

Highly rigid and precise chassis and adjustment of MUTOH’s high precision alluminum rail mechanism deliver high ink dot placement accuracy.It enables stable and high-quality printing.

4 zone vacuum table

The XpertJet 1462UF has both sufficient table area and strength, it is capable of printing on heavy or thick media. The media size of 1,420mmx700mm (55.9”x27.5”) supports a wide range of applications from large signage to small print runs . It improves productivity and shortening delivery time. The 4-zone vacuum table can be configured for single or multi area vacuum suction securing virtually any media in place. Select from four levels of suction force (strong, medium, low, and off).

Designed for ease of use to improve operability

Table function for easy media fixation

Suction holes and pre-drilled holes outside the print able area can be used to secure custom jigs. In addition, unique ferro magnetic table easily secures a variety of products with magnets.

The simple nozzle check function

Even after the jig and media to be printed are set on the table, nozzle check can be performed at anytime in a dedicated area next to the print table.

Other key features of the XpertJet 1462UF are as follows.

Ease of use Signal tower light - The status of the printer can be checked at a glance from a distance.

Automatic nozzle checking unit - Automatically detects missing nozzles and performs nozzle cleaning.

Nozzle area select - Nozzle area select temporarily prints using selected areas of active nozzles when clogged nozzles fail to recover.

Automatic media detection - The onboard laser sensor automatically detects media thickness.

Ink circulation system - Three circulating pumps for white, black and yellow inks are installed to ensure stable colour reproduction.

Ionizer (optional) - Optional ionizer neutralises static charges on the media surface to support stable printing.

MUTOH genuine RIP software VerteLith - Genuine RIP software that achieves unmatched image quality and workflow efficiency.

Sarah Moore has been promoted to General Manager for Visual Connections, stepping into the role at an exciting time for the supplier association.Sarah has been with Visual C...

August 01 2023

Sarah Moore has been promoted to General Manager for Visual Connections, stepping into the role at an exciting time for the supplier association.

Sarah has been with Visual Connections for more than 15 years, joining the association in 2008 as Events Manager. In early 2019, she was appointed Business Development Manager, working with the Sydney-based team to develop new business opportunities as well as deliver on its member services.

Peter Harper, CEO, says Sarah has contributed significantly to the organisation’s success, and will now oversee the whole team and lead all Visual Connections initiatives going forward.

“As an organisation, we are excited by the challenges presented by today’s market, and we are very pleased that Sarah has agreed to step into this newly-created role to help lead the organisation as we seek to deliver on our promises to members and to support and contribute to a sustainable future for the print, sign and graphics sector,” he said.

“Sarah has many years of event management experience, both in our industry and in others prior to joining Visual Connections. She has been instrumental in the success of events including PacPrint, PrintEx, Visual Impact and the Label & Packaging Expo, among others, and more recently has excelled in her business development role, working closely with our Board and members to create new opportunities and deliver on our vision and values.

“The success of recent exhibitions and other initiatives puts Visual Connections in a strong position and we are excited by the many potential opportunities we are exploring for the future. Capitalising on those opportunities will require strong leadership, and we are confident Sarah will shine in her new role and continue to brilliantly represent Visual Connections.

“The Board, and the Visual Connections team, congratulate Sarah on her new role and wish her every success in the future.”

Visual Connections is the association representing suppliers to the print, signage, graphic arts and visual communications industries. It was formed in 2005 through the merger of the Graphic Arts Merchants Association of Australia (GAMAA) and the Visual Industries Suppliers Association (VISA). As well as providing a suite of services and resources for its members, the organisation has the industry’s largest portfolio of events, including industry expos, awards and educational initiatives, and represents the supplier voice at an industry level on key issues affecting the industry.

Ball & Doggett last night welcomed a delegation of about 25 visitors to its Moorabbin converting facility, for a plant tour and networking event organised by LIA Victoria.Th...

July 28 2023

Ball & Doggett last night welcomed a delegation of about 25 visitors to its Moorabbin converting facility, for a plant tour and networking event organised by LIA Victoria.

The company, which is a major sponsor of the LIA’s Graduate Awards, opened its doors to the delegation as part of the Victorian chapter’s program of technical events. Attendees included representatives from industry businesses, TAFE and other associations.

After the tour, guided by Ball & Doggett experts, National Business Development Manager Zaidee Jackson gave a presentation about the company, its ethos and its range of products and services, which include papers, boards and other printable media, a wide range of press consumables and printing equipment.

Key take-aways were Ball & Doggett’s impressive and absolute commitment to its clients, staff, the industry and the wider community, and the innovative way the company is achieving its sustainability goals across the entire value chain, from sustainable sourcing of product and innovative converting technologies, through to sophisticated waste management systems and partnerships, which virtually eliminates waste to landfill from the facility

LIA Victoria President Robert Black thanked Zaidee for the opportunity, saying the support of companies like Ball & Doggett was a great illustration of the generous collaboration which can be so valuable to industry professionals and particularly encouraging to graduates and those new to the industry.

“Tonight’s gathering was typical for LIA, with a wide cross-section represented from new graduates to industry stalwarts, and from business owners to machine operators – we even welcomed a young student who is interested in exploring industry careers,” Robert said.

“It was a fantastic learning opportunity for all involved, and we very much appreciate the support of industry partners like Ball & Doggett in making these opportunities available.”

Membership to the LIA is open to ‘all people in print’ with individual memberships at $45 and corporate memberships at $120. The 2023-24 membership year commences in October – to apply, contact Jenny Berry at vic@lia.com.au

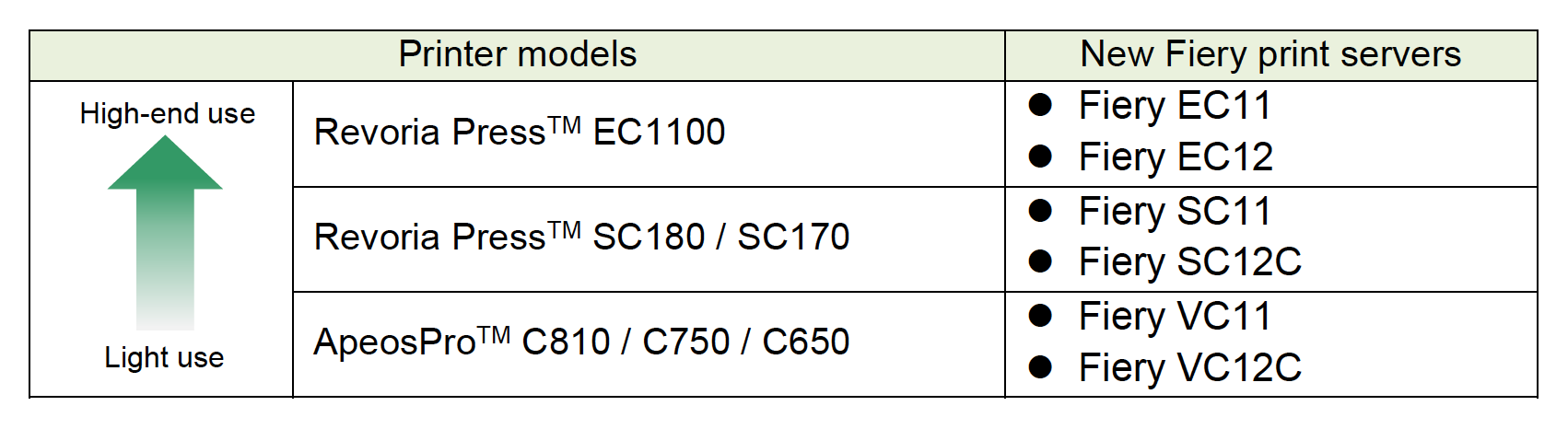

FUJIFILM Business Innovation Asia Pacific announces the launch of new Fiery® print servers and workflow software for Revoria PressTM EC1100, Revoria PressTM SC180 / SC17...

July 28 2023

FUJIFILM Business Innovation Asia Pacific announces the launch of new Fiery® print servers and workflow software for Revoria PressTM EC1100, Revoria PressTM SC180 / SC170 and the ApeosProTM C Series. Sales of the new Fiery print servers for these printer models—Fiery EC11 / EC12, Fiery SC11 / SC12C and Fiery VC11 / VC12C—has begun in the Asia-Pacific*1 region.

Fiery EC11 and EC12 drive high productivity with professional quality prints with the Revoria PressTM EC1100, a production colour printer for the high-end professional printing market of both commercial printing and quick printing.

Fiery SC11 and SC12C create high resolution quality prints in various document types with the Revoria PressTM SC180 / SC170: production printers for quick printing and in-house printing with office functions.

Fiery VC11 and VC12C improve usability and enable seamless integration across Windows and macOS business environments with the ApeosProTM C810 / C750 / C650: production printers for on-demand printing both for professional and office use.

In addition, all Fiery print servers are equipped with Fiery Command WorkStation® allowing a central control to all Fiery print servers, thus gaining operational efficiencies to increase work productivity. Its familiar and easy-to-use unified interface provides clear process visibility to customers regardless of print requirements.

Fiery servers are now available for all Fujifilm-brand toner-based production printers including Fiery PC11 for Revoria PressTM PC 1120 and Fiery E11 for Revoria PressTM E1 series. Therefore, users can choose between FUJIFILM Business Innovation proprietary print server technology – the Revoria FlowTM for Revoria PressTM or GP Controller for ApeosProTM – and the Fiery print servers, allowing more options to meet their various application and workflow needs.

Pozitive Signs and Graphic Supplies are excited to announce a significant milestone in their ongoing dedication to sustainability and philanthropy, welcoming Lynette Hawthorne as their new Chief Su...

July 25 2023

Pozitive Signs and Graphic Supplies are excited to announce a significant milestone in their ongoing dedication to sustainability and philanthropy, welcoming Lynette Hawthorne as their new Chief Sustainability Officer (CSO).

Lynette will be delving deep into every aspect of their operations, from our supply chain to the end-user experience, with a mission to unearth opportunities where the company can boost their sustainability even further.

Additionally, Lynette will guide the team in ramping up their efforts to give back to the community. With Lynette's wealth of experience and passion for sustainability, Pozitive are ready to take their environmental commitment to new heights. Stay tuned for more updates as they journey towards a greener future for all of us.

Read the full story at https://buff.ly/3rFFrPU

Megnajet has launched the JetSource HFR Core, a new fluid management system designed to meet the challenges of high-volume, inkjet printing and additive manufacturing applications....

July 25 2023

Megnajet has launched the JetSource HFR Core, a new fluid management system designed to meet the challenges of high-volume, inkjet printing and additive manufacturing applications.

Developed in response to the increasing industry demand for jetting large volumes of fluid, Megnajet’s latest fluid management system recirculates fluid at up to four litres per minute across up to five independent ports for printheads.

In addition, the JetSource incorporates an impressive system architecture which minimises any restrictions and enables peak flow rates to be achieved, thereby maintaining print system productivity.

This innovation in inkjet fluid management systems helps OEMs and integrators to overcome the common challenges in jetting large volumes of fluids. The system provides accurate, high-quality results across a range of applications including labelling and packaging embellishments, special varnish effects, braille and high-build 3D printing.

Optimised tank volumes ensure continuous availability of conditioned fluids with the advanced dual heating and sensing system providing precise temperature regulation for jetting.

Pressure stabilisation is also guaranteed with the JetSource HFR Core, providing a fast response to changes in print duty and maintaining control when ejecting large volumes of fluid. Thanks to a compressed air venturi system, it can react quickly and accurately to deliver high quality print regardless of the duty cycle.

Easily integrated to customers’ inkjet systems, its compact nature and ease of use make the JetSource HFR Core the ideal fluid management solution in high volume applications. Units can also be customised to suit specific fluid types, including the use of alternate body materials such as FDA approved food grade acetal or a choice of gasket materials and customisations to user software.

The launch of the JetSource HFR Core opens up the opportunity for OEMs to take advantage of the benefits of high productivity printheads and printbar-based architecture, without having to invest in developing their own solution.

Mike Seal, General Manager at Megnajet said, “We’re delighted to launch the JetSource HFR Core as it meets the growing demand to precisely and accurately control large volumes of fluid across high productivity printheads.

“JetSource will help our customers to access the many opportunities of high-volume inkjet applications, delivering print quality that is essential to their success, while saving them time, effort and resources in having to develop their own standalone solution.”

SBS-E Certification allows Scodix embellished products to use recycling symbol where relevantScodix, Israel – Scodix, the leading provider of digital embellishment solu...

July 25 2023

SBS-E Certification allows Scodix embellished products to use recycling symbol where relevant

Scodix, Israel – Scodix, the leading provider of digital embellishment solutions for the graphic arts industry, announces the successful completion of its latest recyclability tests, further reinforcing the company’s commitment to sustainability. The results demonstrate that Scodix embellishments can be repulped during the recycling process, allowing products enhanced with Scodix embellishments to carry the recyclable symbol.

Scodix EVP Global Sales & Marketing, Mark Nixon, comments, “Sustainability is a core pillar of our business operations. As such, we are thrilled to share our latest test results which underscore the positive impact Scodix products can have on building a more sustainable future. With our repulpability and recyclability certification coupled with our Life Cycle Assessment (LCA) findings, Scodix users can confidently embrace data-driven sustainability practices.

FTC guidelines require third party independent testing to allow manufacturers to use a recyclable symbol. Scodix worked with Western Michigan University (WMU) to implement the SBS Equivalency (WMU SBS-E) testing protocol, which models the Fiber Boxboard Associations (FBA) wax coating replacement protocol.

The testing was performed on 16pt SBS Printkote C1S paper with a fifteen percent coverage. Sheets were taken through the process of repulping, screening and cleaning to ensure that the digital embellishment would not inhibit the recycling process.

The tests produced positive results showcasing the recyclability of Scodix digitally embellished sheets. Passing the WMU SBS-E protocol proved that sheets with Scodix embellishment would qualify for recycling and could be repulped during the process. Brands and manufacturers using Scodix embellishment under this control protocol are able to use the FTC recycling symbol as long as the substrate used is also certified as recyclable.

"Today is a momentous day for Scodix, but our journey towards sustainability doesn't end here," affirms Nixon. " Coupled with the commissioned LCA that clearly states that Scodix is over 7 times less harmful to the environment than the traditional foiling process, we believe the time is now to remain steadfast in our commitment to driving continuous improvements in sustainability - equipping manufacturers with the necessary data to accurately measure their processes."

For more information about the testing process or to learn more about Western Michigan University standards, visit their website at http://wmupilotplant.com. The verifying documents for Scodix can be requested for download at www.scodix.com/sustainability.

Partnership combines digital textile inkjet and dry fibre technologies to create new clothes from recycled, re-fibreised fabricsEpson has further progressed its partnership ...

July 18 2023

Partnership combines digital textile inkjet and dry fibre technologies to create new clothes from recycled, re-fibreised fabrics

Epson has further progressed its partnership with renowned Japanese fashion designer Yuima Nakazato and his eponymous YUIMA NAKAZATO brand that aims for better sustainability in fashion and has now resulted the creation of an exciting new couture collection displayed during the recent Paris Haute Couture Fashion Week at the Palais de Tokyo.

Part of the new YUIMA NAKAZATO collection created, in most part, using a combination of Epson's more sustainable digital textile printing technology and a new fabric production process

The new collection has been created, in most part, using a combination of Epson's more sustainable digital textile printing technology and a new fabric production process that has the potential to transform the fashion industry, contributing significantly to the creation of an innovative, colourful, and ground-breaking collection of beautifully designed couture pieces.

Yuima Nakazato

Epson's dry fibre technology, which is already used commercially to recycle paper and requires virtually no water to produce, has been adapted to produce new non-woven re-fibreised fabric from used and discarded garments.

This experimental fabric production process was first revealed in January this year as part of a three-year collaboration between Epson and YUIMA NAKAZATO. For the show in July, Epson made further significant advances to the quality of the fabric, making it thinner, more flexible and much easier to print on using Epson's sustainable Monna Lisa direct-to-fabric digital textile printing technology.

Part of the new YUIMA NAKAZATO collection created, in most part, using a combination of Epson's more sustainable digital textile printing technology and a new fabric production process

As the new collection was revealed, Epson and YUIMA NAKAZATO also raised awareness of the water and material waste associated with traditional and excessive garment production.

The Paris Show illustrated how switching to digital textile printing using more sustainable pigment inks offers the fashion industry a less wasteful and more environmentally responsible means of textile printing.1

The new couture range on display at the Palais de Tokyo was printed using the Epson ML-13000. This is a prototype and highly flexible direct-to-fabric digital textile printer capable of achieving vivid colours with pigment inks on a wide variety of fabrics and surfaces.

The fabric taken to create the new YUIMA NAKAZATO fashion line was derived from material from used garments sourced from Africa, the destination for many discarded garments from elsewhere in the world.

Yuima Nakazato visited Kenya where he purchased around 150 kg of used garments destined for the many "clothes mountains" that comprise discarded Western garments. Epson then applied its dry re-fibreisation process to the waste material which resulted in the production of over 150 metres of non-woven fabric, which was then printed on using pigment inks by Epson's Monna Lisa digital printing technology.2

Hitoshi Igarashi from Epson's Printing Solutions Division explains the importance of the technology: "Although in its early stages, Epson believes its dry fibre technology combined with pigment ink digital printing could offer the fashion industry a much more sustainable future, significantly reducing water use while allowing designers the freedom to fully express their creativity.

"Since January this year Epson has continued to make significant advances in the quality and printability of re-fibreised fabric. It is now less dense, tougher and much more flexible, making it better suited for printing on using Epson's Monna Lisa direct-to-fabric digital textile printer. The fabric used this time was much thinner than before, leading to a 37.5% weight reduction from 160 g/m2 previously to 100 g/m2 now."

The ML-13000 significantly contributes to reducing the environmental footprint. It uses a pigment ink process that leads to a 96% reduction in water3 use compared to dye-based inks. It has also increased productivity by 300% compared to conventional production processes thanks to an inline solution involving built-in pre- and post-printing processes.

"The prototype ML-13000 is capable of printing not just ink, but also three different types of liquid onto fabric at the same time, thereby enhancing brilliance, durability, and flexibility. Epson has utilised this printer to print on fabric with an optimised balance of ink and liquids. This innovation achieves quick production, reducing water usage, and saving use of energy. This initiative shows how discarded garments can be upcycled into new types of clothing thanks to the combination of YUIMA NAKAZATO's creativity and Epson technology. Epson's Environmental Vision commits us to contributing to a circular economy, and this development could be one step towards achieving this. Although still at the experimental stage with textiles, we believe dry fibre technology has tremendous potential for making the fashion industry more sustainable."

Follow Epson on social media:

LinkedIn: @Epson-Australia

Facebook: @EpsonAustralia

Twitter: @EpsonAust

YouTube: @EpsonAustralia

Instagram: @EpsonAust

Spotlight on One Connected Workflow across Label and Packaging Supply Chains“Connected ecosystem increases efficiency, enhances sustainability & maximises resources.”...

July 18 2023

Spotlight on One Connected Workflow across Label and Packaging Supply Chains

“Connected ecosystem increases efficiency, enhances sustainability & maximises resources.”

Visitors to this year’s Labelexpo will see first-hand how a connected Esko and X-Rite Pantone ecosystem of automated workflow, colour management, flexo platemaking, digital printing, and print inspection tools can deliver consistent performance and accelerate business growth.

The companies will lead a deep dive into all facets of labeling and packaging when the event returns to Brussels in September. “Visitors to our combined booth will discover how Esko and X-Rite Pantone are helping the packaging industry achieve consistent performance from concept to market,” said Jan De Roeck, Esko Director of Marketing, Industry Relations & Strategy. “Using demonstrations of the latest technology, displays, and expert discussions, we will highlight how an end-to-end ecosystem of new colour management software and measurement solutions supports digital workflows to increase efficiency, enhance sustainability, and drive growth opportunities.”

Esko and X-Rite Pantone will showcase their entire range of digital workflow solutions from design through production. Highlights include:

Phoenix, Esko’s AI-based tool that unlocks planning and imposition productivity improvements, with a seamless interface between prepress data and production data in Esko applications.

The award-winning CDI Crystal XPS 4835, utilising UV main and back exposure to produce highly consistent digital flexo plates while minimising waste.

AVT Helios System, which automatically inspects printed labels or packages for defects and imperfections, delivering exceptional quality results and eliminating customer rejections.

The latest Esko Software version, which delivers a combination of prepress editing and cloud-based workflow automation solutions, now more integrated and connected throughout the entire prepress workflow.

X-Rite eXact™ 2, the most connected and easy-to-use handheld spectrophotometer that can measure colour across various substrates - including flexible film and paper - in a single device, while also verifying customer standards.

X-Rite ColorCert® Suite, which works with Esko WebCenter, AVT’s Spectralab, and eXact 2 to provide printers an overall view of print quality and colour performance in a single number score to confirm compliance with brand specifications.

PantoneLIVE™ digital colour libraries for the creation and sharing of accurate brand colour standards that are achievable across printing technology and substrates.

“Error and waste reduction have a direct impact on the environmental footprint of a packaging business,” said Jan. “As we are all looking to protect the environment in which we live and to safeguard it for future generations, we must reduce the impact of our operations on the environment. With sustainability and digitalisation fundamentally altering how the industry operates, it is imperative that today’s label and packaging companies invest in digital workflow technology that enables them to boost efficiency, reduce costs and improve their overall productivity,” he said.

Jon-Michael McCartney, Director Print and Packaging, X-Rite Pantone, added: “The combined X-Rite Pantone and Esko ecosystem helps to streamline the design, prepress, formulation, and production workflow with the sharing of packaging and colour data to reduce errors and improve reporting.”

“With a digital workflow you can eliminate on-site press approvals, clearly define and share print requirements across a global supply chain, reduce waste and rework, save resources, and support sustainability goals,” he said.

Labelexpo returns to Brussel from 11-14 September 2023 – visitors can join Esko and X-Rite Pantone at booth #C60 in Hall 3 of the Brussels Expo.

For more on the full range of integrated Esko solutions, visit www.esko.com.

For more about X-Rite print and packaging solutions, visit https://www.xrite.com.

There's going to be plenty to see and do at this year's Letterheads 2023 Sydney.

July 18 2023

May 09 2023

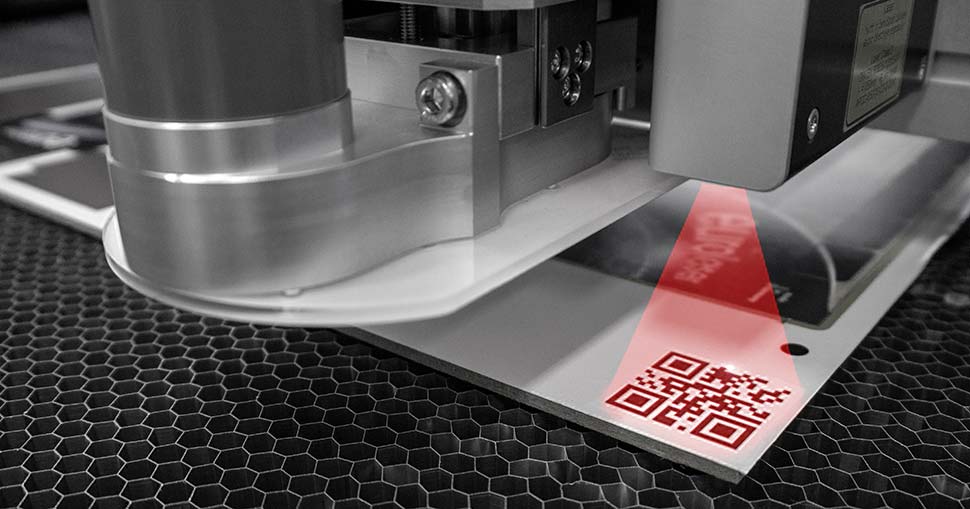

Precise, automated and consistently high cutting quality - by meeting these requirements the laser cutting systems from the German manufacturer eurolaser have been scoring points with users worldwide for many years.

At this year's FESPA in Munich, eurolaser is presenting a new camera system for the efficient and precise processing of printed materials. The new technology increases process speed and expands processing possibilities. The camera system will be presented on the large-format laser system 3XL-3200, on which printed textiles are automatically cut live. In addition, the cutting of plastic sheets on a smaller laser system and the processing of cardboard on a Zünd cutter will be demonstrated.

Since its foundation in 1994, eurolaser has specialised in cutting non-metallic materials. These include plastics such as polyester or acrylic, wood and MDF, textiles and composites as well as many other materials. Today, the universal cutting systems are used, among other things, for cutting large-format textiles in the soft signage sector, for technical control elements made of plastic films or printed acrylic displays for shop fitting. In particular, the demand for large processing areas and automation solutions is increasing across all industries. With the new, optional camera system, called POSITIONplus professional, eurolaser picks up on this trend and offers exciting competitive advantages especially for processors in the printing industry.

Many applications require precise cutting to existing fiducial marks or other material references. For this purpose, eurolaser offers a smart solution consisting of a camera and evaluation software. Using reference points, the optical recognition system allows printed materials to be cut out precisely along the print contour. The new camera technology considerably reduces the time needed to read in the fiducial marks. The entire working area is quickly captured via area scan, thus optimising the process time. In addition, this process expands the range of possible applications. For example, contours on materials can be detected, whereupon suitable cutting data is created under software control. Pattern matching is also possible. Material patterns are detected so that the positioning of the cutting data is done taking the pattern into account. Useful functions that save time and money in further processing.

Working without contact means more than you might imagine at first glance. No influence of force on the material, no material distortion, no clamping of the material, better material utilisation, less waste, no re-sharpening of the tool are only some of these benefits. The thermal cutting process of the laser is very advantageous in many applications. Fringe-free, slightly fused cut edges in synthetic textiles, sealed multi-layer foils or crystal-clear, smooth cut edges in acrylic are just a few examples. The laser processing is carried out with the highest precision, even very filigree details are cut exactly. Since the laser beam itself is wafer-thin (approx. 0.2-0.3 mm), even inner contours are cut radius-free, without taking the tool diameter into account. Unlike other machining processes, the laser does not become blunt over time. The quality of the cuts remains consistently high for years, from the first to the last workpiece.

Of course, there are also machining requests that cannot be optimally implemented with the laser, such as mitre cuts or milling and V-grooves. In this case, eurolaser offers unique flexibility. Additional mechanical tools can be installed on all laser systems. For this purpose, the user has access to well designed eurolaser solutions as well as the entire high-quality tool range of Zünd Systemtechnik AG from Switzerland. For example, milling and marking tools can expand the processing possibilities. Materials that are not suitable for the laser, such as PVC, can also be processed on the same cutting system.

eurolaser will be presenting its cutting solutions at FESPA in Hall B2, Stand D16.