A new thick paperboard from Iggesund Paperboard has been certified for HP Indigo for printing high-value applications on commercial digital presses. The 18 pt (457 microns ) Invercote ...

June 01 2020

A new thick paperboard from Iggesund Paperboard has been certified for HP Indigo for printing high-value applications on commercial digital presses.

The 18 pt (457 microns ) Invercote Creato 380 g/m2 is double coated on both sides, offering identical print surfaces on both sides, making it especially suitable for premium packaging applications The paperboard was tested and certified for the HP Indigo 10000 series and HP Indigo 7000 series presses.

“When developing this product’s grammage and thickness, our development team wanted to ensure we meet not only the demanding requirements of conventional printing methods, but also the needs of digital printers who are looking for the thickest possible substrate that today’s digital presses can handle. This grammage is especially interesting to the US market where 18 pt is an attractive thickness for a lot of applications”, says Petra Kreij, Product Manager for Invercote at Iggesund Paperboard.

Tests were conducted at HP Indigo testing center in Singapore in multi-shot mode on an HP Indigo 7600 press and an HP Indigo 10000 press. At Iggesund, the certification process has been coordinated by Wout van Hoof, Senior Technical Manager with a special responsibility for digital printing processes.

“We are very pleased that Iggesund has certified this new thick substrate. It is one of the thickest products that has been certified for our HP Indigo presses, opening new high-value packaging opportunities for HP Indigo commercial press owners,” said Heidemarie Hinger, HP Indigo Commercial Media Manager.

Invercote Creato 380 g/m2 joins the other grammages within the portfolio of which all the lower grammages already have HP certification. All certified products and grammages are available in the HP MediaLocator, and through regular Iggesund distribution.

The Invercote Creato product family, is designed to offer equal printing properties on both sides, with an exceptionally smooth surface that is tailored to faithfully reproduce the most sophisticated printed images. This surface, combined with Invercote Creato's excellent structural, design and embossing characteristics, make it ideal for demanding graphical applications. The whiteness level is tailored to ensure the best print contrast and colour reproduction properties required for high-end print productions.

Screen GP Australia has announced the global parent company’s plans to target the package printing field as a strategic business area and progressively strengthen its product line-up and solu...

June 01 2020

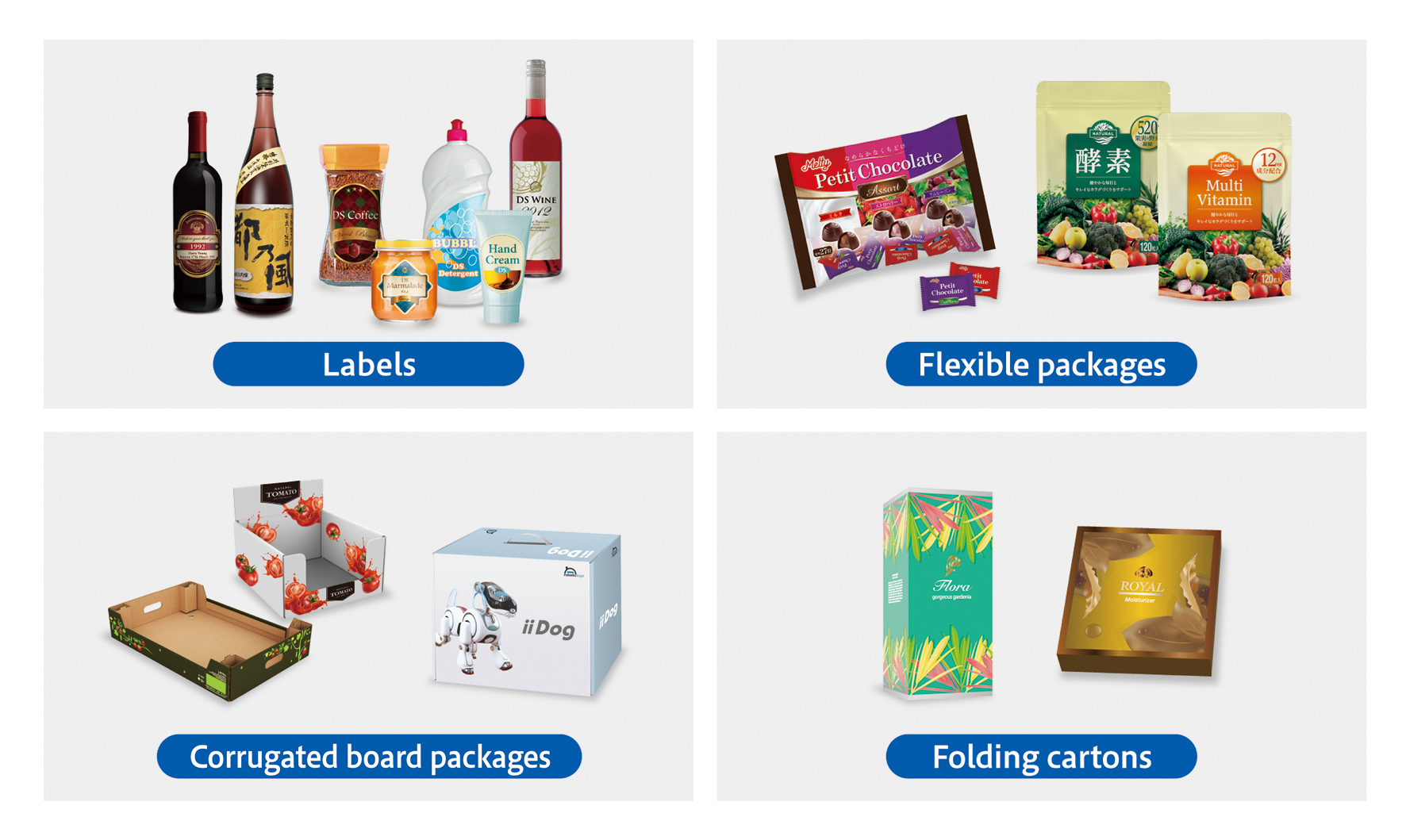

Screen GP Australia has announced the global parent company’s plans to target the package printing field as a strategic business area and progressively strengthen its product line-up and solution development for this market.

Screen GP Australia Managing Director Peter Scott says: “Screen has several exciting new products coming into our portfolio of packaging print, which already includes the highly successful Truepress Jet L350UV digital label press series, with over 170 units shipped; the recently announced L350SAI higher productivity seven-colour label presses and the newly improved ‘N’ series of the PlateRite FX Flexographic digital platemakers.”

He continues: “In identifying packaging print as a major growth area of the graphic arts, Screen has conducted extensive R&D to bring sustainable, digital, variable and versatile on-demand production targeting folding cartons, corrugated and flexible packaging in addition to labels. The first new product announced is a new high-speed, water-based inkjet system specifically designed for the flexible packaging market. The PacJet FL830 is currently scheduled for release around Autumn 2021, just in time for drupa.”

Announcing the PacJet FL830

While certain flexible packaging products can be produced on the 350mm web Screen L350UV digital presses, conventional flexible packaging production lines require wider-width roll materials.

Scott says: “This is not an intermediate step-up; it is a whole new approach to flexible packaging based, not only on short-run dynamics but also addressing real FMCG market demands of rapid time-to-market with high quality vibrant packaging, clean, sustainable production by-passing the platemaking stage and the ability to vary the printed content to suit variations in the product packaging such as flavours, versions and marketing needs.”

This new high-speed, water-based inkjet printing system is specially designed for flexible packaging and can handle media up to 830mm wide at speeds of up to 75 meters per minute. It is also capable of printing at a resolution of 1,200 dpi using CMYK and White water-based inks that conform to relevant food safety regulations. These features allow it to deliver both the excellent safety and rich colour expression that is essential for the food products industry.

Thanks to its outstanding quality and productivity, the PacJet FL830 is able to meet a wide variety of print needs, ranging from promotional to production applications. It also demonstrates exceptional responsiveness for small lot jobs of less than 4,000 linear meters, an area that can be problematic for conventional production. At present, the system handles both PET and OPP media, with Screen working to further expand compatibility based on industry requirements.

Corrugated and Folding Cartons using high-speed inkjet

As announced at drupa 2016, Screen has been working with German company BHS Corrugated since 2016 to develop a water-based inkjet printing solution capable of delivering high-speed throughput of 300 meters per minute at widths of up to 2.8 meters. The partners are creating the system in response to growing demand in the shelf-ready packaging and full colour corrugated board markets. The speed of 300 metres per minute is common in high-volume corrugated production and converting, so the addition of variable water-based inkjet in full colour, will open up new markets that currently depend on pre-printed liner and lamination onto corrugated.

In the folding carton segment, Screen is currently cooperating with Cambridge, UK company Inca Digital Printers - a member of its own corporate group - on the development of a single pass, water-based inkjet press. This system is being specially designed to support the transition to digital printing currently occurring in folding cartons. With Inca Digital’s existing ability to print digitally, at high speeds on large cartonboard sheets used in POS and Signage applications, this move into folding cartons is both a logical and eminently achievable advancement.

As Peter Scott says: “Since its founding, Screen has consistently worked to develop proprietary products that combine its core image processing technologies with the latest technologies. During this time, it has maintained a focus on building systems that offer superior stability and reliability, which is so necessary in production facilities for professional applications. We are taking a long-term view, in particular where environmental aspects are considered, which is why the new systems use mostly water-based inks and produce low-waste.

“There will be further announcements over the comping months – it’s an exciting time to be involved with Screen!”

Domino Printing Sciences is gearing up for the spring launch of the Gx-Series, a new range of thermal inkjet (TIJ) printers optimised for fast, efficient, and accurate coding, on product labels, fl...

May 25 2020

Domino Printing Sciences is gearing up for the spring launch of the Gx-Series, a new range of thermal inkjet (TIJ) printers optimised for fast, efficient, and accurate coding, on product labels, flexible films, and cartons.

The Gx-Series is optimised for smart factory applications, providing manufacturers with a future-proof solution for evolving production processes. The printers are easy to use and to integrate into existing manufacturing procedures, with enhanced connectivity, a simple user interface and a smaller overall footprint. The domino Cloud capability provides remote monitoring, while options for EtherCAT and PLC communications allow for fast data transfer and synchronisation.

‘The Gx-Series utilises industry standards, which allows for integration into existing automation systems to provide an industry 4.0 ready coding and marking solution,’ said Alexandros Mountis, TIJ product manager at Domino. ‘The option of the EtherCAT communication allows our TIJ printers to communicate directly with programmable logic controllers to provide greater control of manufacturing processes, translating into increased productivity, and reduced coding errors.

‘In a modern marketplace, consumers, retailers, and governments are demanding more information from manufacturers. We have developed the Gx-Series in response to these changes, to give our customers greater control over their product labelling, with the ability to produce high-quality, machine-readable codes for marketing information, traceability data, and serialisation.’

Domino’s Gx-Series printers are able to print high-density machine-readable codes, including Data Matrix codes, providing opportunities for enhanced product labelling and late stage customisation within manufacturing operations. Advanced track and trace and item-level serialisation are available via Dynamark protocol, with coding in compliance with pharmaceutical regulations, including EU FMD and US DQSA, according to GS1 standards.

Gx-Series are controlled by an intuitive user interface and touch screen or remotely via web browser. Customers can select from one to four print heads, which can be stitched together to allow for print heights of up to 50.8mm (2in), or used separately to print on multiple lines at speeds of up to 300m/min (984ft/m). The maintenance-free print heads are equipped with LED status signals to show which cartridges need changing, while Domino AutoSwap enables cartridges to be changed while printing, without interrupting production.

The print heads are available with a range of advanced coloured inks suitable for use on both porous and non-porous substrates with rapid dry times and good. For food and beverage applications, EuPia and Swiss List compliant ink options are available for coding on direct contact food packaging. This includes flexible films, porous shelf-ready packaging, and shipping boxes.

The next-generation printers are compatible with all languages, and suitable for use across industries including pharmaceuticals, electronics, and food and beverage, with customisable options available to suit individual production needs.

Xeikon has launched CX300, a new digital label press based on next-generation Cheetah 2.0 technology offering shorter lead times and more product diversification to address current market needs for...

April 14 2020

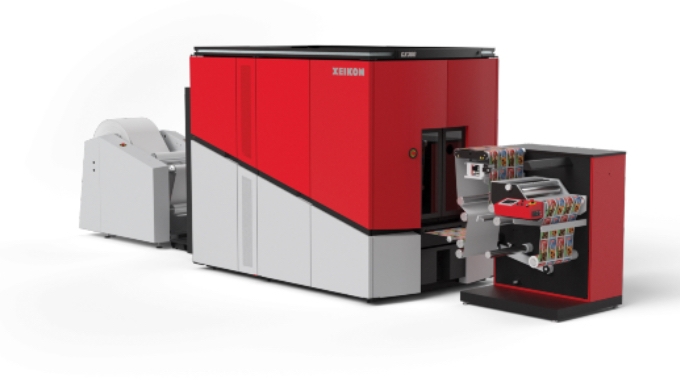

Xeikon has launched CX300, a new digital label press based on next-generation Cheetah 2.0 technology offering shorter lead times and more product diversification to address current market needs for increased versatility, productivity and quality of production.

‘The Xeikon CX300 delivers exceptional application versatility, designed to achieve the highest possible OEE (Overall Equipment Effectiveness) and is even more productive than the very successful Xeikon CX3 first generation of Cheetah presses,’ said Filip Weymans, vice president of marketing at Xeikon. ‘Today’s investments need to deliver results. Printing speed is an important factor but combining that with a low OEE would not deliver the value printers and label converters are looking for. With Cheetah 2.0 technology, we have focused on combining high production speeds with a high OEE, ultimately resulting in maximum sellable output.’

The CX300 is a 330mm (13”) label press that can offer production capacity of over 50.000 square meters per month in a single shift operation. It can reach printing speeds of up to 30m/min (98ft/min) and web width between 220mm (8.6”) and 512mm (20.3”) wide using a LED imaging head operating at 1200x3600 dpi delivering offset/gravure image quality. The full-colour press is equipped with five print stations, including CMYK and single-pass opaque white but can also support colour gamut expansion, custom or security colours.

Based on next-generation Cheetah technology, it can operate in a three-shift operation and still deliver high value work. According to Xeikon it will fit specifically into strong growing end-use markets such as food and pharmaceuticals as its dry toner technology offers required food safety. The Cheetah toner also incorporates the recently announced QB technology, making it future-proofed against upcoming legislation and regulatory requirements.

The new machine also targets converters using challenging substrates such as natural structured papers in wine and spirits, craft beer, luxury food, health and beauty who will benefit from high-quality full-colour printing and single-pass opaque white toner. The Xeikon CX300 can also be used to produce heat transfer labels, in-mold labelling, wet glue, wraparound labels, and cartons.

Xeikon’s fleXflow process enables the new press to produce flexible pouches, combining dry toner printing with thermal lamination to deliver a laminated construction with quick turnaround times and increased sustainability driven by the fact that there is no solvent used during either printing or laminating. Xeikon fleXflow is driven by the X-800 digital front end and includes an innovative inline thermal lamination process.

‘The Xeikon CX300 can be the cornerstone of digitising label manufacturing,’ added Weymans. ‘Its built-in technologies enable label converters to address current and future industry demands: connectivity, responsiveness, flexibility and scalability. We believe the Xeikon CX300 can be a valuable addition to any label shop floor and the spark that ignites a digitisation process that is unmatched in the industry.’

The new press is going to be commercially available from the beginning of April 2020.

Durst, manufacturer of advanced digital printing and production technologies, has solved waste and digital capacity issues for family business Wagner Prestige Labels with the installation of a Tau ...

March 31 2020

Durst, manufacturer of advanced digital printing and production technologies, has solved waste and digital capacity issues for family business Wagner Prestige Labels with the installation of a Tau 330 RSC E inkjet label production press.

Wagner’s choice of Durst’s RSC technology was driven by speed, quality and environmental considerations. “We decided to ramp up digital color capacity to the highest we could, and the Durst Tau 330 RSC E came up trumps,” said John Galea, Managing Director of Wagner Prestige Labels, of Wetherill Park, Sydney, Australia. “In only six months it has really proved itself, to the point that digital is now between 30 and 35% of our business. The quality of the labels is right up there with flexo and letterpress.

“Another important benefit is that waste is greatly reduced, with the threaded meterage on the Durst Tau 330 RSC E even being able to be drawn back and printed. Waste is a big issue for label printers, especially with multiple versions, so anything we can do to reduce it is good for the environment.”

The Durst Tau 330 RSC E is the beating heart of Wagner Prestige Labels’ one-stop solutions business, which has diversified into new areas and is also part of the JV Group that brings together label, printing and embroidery companies to provide customers with a complete promotional service. Web inspection devices and processes including flexo, letterpress, screen, thermal paper, hot and cold foiling, die-cutting, laminating and, elsewhere within JV Group, dye-sublimation and embroidery for textiles plus general commercial printing.

“We do everything in-house, and, if a customer wants a fully-embellished label with embossing, foiling, spot varnishing, fancy die-cutting, we have the equipment to do it,” said Mr. Galea. “You have to keep up with changes – change enables growth and diversity, but you also have to make sure the right job goes on the right machine. Before the investment in Durst’s RSC technology we were falling short on digital capacity. Our customers – trade, print brokers and end-user – are tending to order shorter runs, more frequently, so we carefully researched all the available options. The Durst has proved to be the ideal choice.”

Helmuth Munter, Durst’s Segment Manager, Labels and Package Printing, said: “The Durst Tau 330 RSC E was originally launched to bring affordable digital production to increasing numbers of small converters and sets the base for the future of industrial digital inkjet printing in the label industry. In line with our ‘We Keep You Printing’ strategy, it’s also proving to be a real attractive prospect for forward-thinking companies like Wagner Prestige Labels that need variable, versatile, adjustable and configurable digital printing systems to expand their business reach while enjoying other benefits such as waste reduction and a significant jump in production capacity.”

Developed with UPM Raflatac and Magic Add, this cloud-based application enables track-and-trace capability for labels. Xeikon presented its latest advancements at Labelexpo Europe, and...

March 03 2020

Developed with UPM Raflatac and Magic Add, this cloud-based application enables track-and-trace capability for labels.

Xeikon presented its latest advancements at Labelexpo Europe, and among them was a new "smart label" solution developed and created in partnership with UPM Raflatac and Magic Add. Demonstrations are being held at Xeikon and UPM Raflatac’s stands at the show.

The cloud-based application enables track-and-trace capability for labels. It is designed to help brand owners wanting to bring labels and packaging online, they are now better able to measure the success of their campaigns or to control the supply chain. This product is designed to achieve consumer trust and confidence in the brands, and bring added value to the end user.

Jeroen Van Bauwel, director of product management at Xeikon, explains, “More and more brands want to say ‘we are providing the authentic product.’ In creating this smart label solution for brand owners, we have worked with UPM Raflatac and Magic Add to put the ‘smart’ part into label design. Many industries are integrating technology into their product lines and producing ‘smart’ products to meet current trends. Xeikon continues to utilise the constant advancements in technology for the benefit of the label community. This smart label solution incorporates technology that extends the functionality of labels and packaging beyond traditional print methods. What’s exciting is the technology behind the action.”

Every package is made with an image, text, a number or a code, and it is ready to be scanned with standard applications. There are a number of options, such as QR codes, that give consumers the ability to track their product throughout its complete life cycle. End users can trace the place of origin of their product and every step from there through to the consumer. They can check storage conditions during transport and track the journey of the product from supplier to retailer. Knowing that their product is authentic gives the consumer confidence to trust the brand.

Engaging with the consumer through smart labels offers creative possibilities. Information can include recipes, wine recommendations, details and advice on food calories, health and dietary information. Importantly for the pharmaceutical sector, an extra layer of information can be added to communicate on vital guidelines and safety warnings. In the food sector, brands can use the smart label to show the origin and composition of their product. This is a good example of one of the key benefits of Xeikon’s smart label solution. Because the smart label makes the product uniquely traceable, each end user can be sure that every single unit they buy has been tracked through its whole production cycle and meets legislation requirements for purity and health and safety compliance.

Xeikon’s smart label solution works in a number of ways. The end user benefits from the engagement and the experience of access to added value information and advice, while the brand owner and the product supplier can gather data, which helps them research into consumer preferences and the most popular products. Converters can widen their application range and offer new functionality to their customers, and marketers can plan more meaningful and targeted campaigns.

Through Xeikon’s smart label solution, brand owners searching for new ways to maximise their brands can see who is buying their product and build a buyer’s profile that adds to the market intelligence, which helps them meet consumer demand.

Xeikon has been demonstrating examples of its smart label solution at Labelexpo. Using three bags of coffee with three different label designs, the experiment has shown the brand owners which out of the three is the "best seller" in the market. The example reveals live data showing the tracing of the coffee to a specific farmer, and the tracking of the product through its journey to the store and to the end user.

Van Bauwel concludes, “Every new development comes under our commitment to ‘Transform’ the world of labels. Xeikon has the experience, the expertise, the tools and the technology available to make smart label solutions a reality. We are recognised as a technology agnostic supplier and a trusted advisor to the label community. Every product we bring to market is designed and created for tomorrow’s challenges. Our mission is to provide added-value solutions and automate label production. We are excited about these new 'smart' developments and can see many opportunities for brand owners and converters to benefit. We are delighted to have presented our smart label solution at Labelexpo 2019 in its 40th Anniversary Year."

Nestlé today announced that it will invest up to €1.68 billion to lead the shift from virgin plastics to food-grade recycled plastics and to accelerate the development of innovative sus...

January 28 2020

Nestlé today announced that it will invest up to €1.68 billion to lead the shift from virgin plastics to food-grade recycled plastics and to accelerate the development of innovative sustainable packaging solutions.

Building on its 2018 commitment to make 100% of its packaging recyclable or reusable by 2025, Nestlé is aiming to reduce its use of virgin plastics by one third in the same period whilst working with others to advance the circular economy and endeavour to clean up plastic waste from oceans, lakes, and rivers.

In the company’s view, food quality and safety are paramount, and packaging plays a major role in assuring this. Nestlé argues that most plastics are difficult to recycle for food packaging, leading to a limited supply of food-grade recycled plastics. To create a market, Nestlé is therefore committed to sourcing up to 2 million metric tons of food-grade recycled plastics and allocating more than €1.39 billion to pay a premium for these materials between now and 2025. Nestlé will reportedly seek operational efficiencies to keep this initiative earnings neutral.

Packaging innovation, including new materials, refill systems, and recycling solutions, is another key challenge on the path towards a waste-free future. In addition to its in-house research through the Nestlé Institute of Packaging Sciences, the company will launch a €232 million sustainable packaging venture fund to invest in start-up companies that focus on these areas.

These two initiatives come in addition to Nestlé’s ongoing efforts in research, sourcing, and manufacturing to make its packaging recyclable or reusable and contribute to its goal to achieve zero net greenhouse gas emissions by 2050. As part of the company’s packaging commitment and in an effort to increase transparency, Nestlé will continue to outline further initiatives and provide regular progress updates.

“No plastic should end up in landfill or as litter,” said Mark Schneider, CEO of Nestlé. “Making recycled plastics safe for food is an enormous challenge for our industry. That is why in addition to minimising plastics use and collecting waste, we want to close the loop and make more plastics infinitely recyclable. We are taking bold steps to create a wider market for food-grade recycled plastics and boost innovation in the packaging industry. We welcome others to join us on this journey.”

"We are pleased to see Nestlé commit a €1.68 billion investment toward creating a circular economy for plastics, alongside a reduction of its use of virgin plastic in packaging by one third by 2025. By eliminating the plastics we don’t need, innovating in areas like reuse models and new materials, and circulating the plastics we do need – also in more challenging food-grade applications – we can create an economy where plastic never becomes waste. Achieving the commitments announced today will significantly contribute towards realising this vision,” said Andrew Morlet, CEO, Ellen MacArthur Foundation.

UK manufacturer Liquid Lens, has announced the availability of a broad range of end-to-end domed label production solutions. The solutions include complete full colour label production...

January 14 2020

UK manufacturer Liquid Lens, has announced the availability of a broad range of end-to-end domed label production solutions.

The solutions include complete full colour label production systems for either indoor or outdoor use with integrated cutting capabilities or separate cutter and the Liquid Lens Label System best suited to the required volumes.

Liquid Lens Managing Director, Steve Hastie, comments, “The key to our production systems is the sheer quality of the mercury free resin we use for the domed labels. It is far superior to any other resin in the market and this means our customers are demanding more and more labels. We produce hundreds of thousands of labels each week from our own production centre and this continues to be a major part of our business. However, increasingly we are finding more and more customers are identifying the financial and operational benefits of taking their domed label production in-house and we are delighted to provide them a fantastic solution that is optimised to their specific requirements.”

The Liquid Lens Label Systems range from an entry level solution designed for the daily production of 1 to 500 labels, through to the Label System 750 capable of producing many thousands of outdoor durable domed labels every day. Each solution includes a digital inkjet printer, a cutter (or integrated print and cut machine), from premium manufacturers such as Canon, Graphtec, Mimaki or Roland, together with a specialist doming machine. Liquid lens will work with customers to determine the correct configuration to suit each company’s current and future requirements.

Resin Quality

Liquid Lens is the only global supplier of its automotive production grade polyurethane resin in easy to use cartridge format. This resin is demonstrably superior to other products in the market. Hastie explains, “Our resin is very easy to use and apply, cures quickly and provides a consistent and reliable finish. Our resin always delivers a smooth, resilient surface, compared to many other resins, which are often rough or sticky to touch. This is because our resin, which always fully closes, comes from one of the world’s largest and best manufacturers of polyurethane resin.”

He concludes, “Don’t take our word for it! We invite anyone to compare the quality of our resin in a huge range of applications, including domed labels, number plate gel characters and advertising, digital mosaics and more. Ours is the only cartridge resin with a 12-month shelf-life guarantee, which makes us the industry’s largest supplier of cartridge resin and the best source for reliable, high-quality doming resin.”

Sato has revealed the CT4-LX smart mini label printer equipped with a colour touch panel LCD for intuitive operation, space-saving and suitability across many sectors and geographic regions. ...

January 14 2020

Sato has revealed the CT4-LX smart mini label printer equipped with a colour touch panel LCD for intuitive operation, space-saving and suitability across many sectors and geographic regions.

‘I am excited to unveil this irresistible smart mini, which is a totally new category for barcode label printers,’ said Hayato Shindo, president of Sato International. President Hayato Shindo. ‘The great potential of the CT4-LX is its value-added features that users in different sectors can pick and choose from to optimise their on-site operations. Together with our customers and partners, we want to turn ideas into reality.’

According to the company, the new printer can enhance business by supporting existing applications and operations as it allows users to print labels without a PC by connecting to peripherals.

The CT4-LX is equipped with a large 4.3in colour TFT LCD touch panel for a user-friendly interface, has a small footprint and supports menu display in 31 languages and printing in 47 languages.

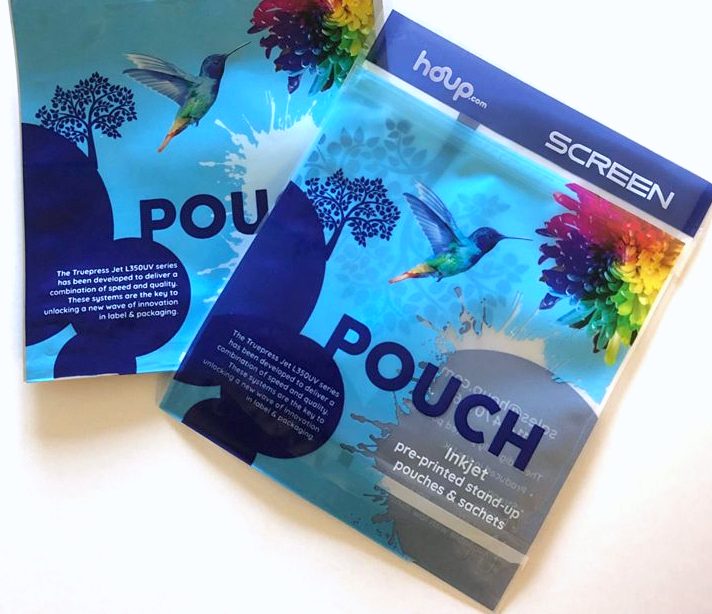

Screen has extended its reach into flexible pouch production with its Truepress Jet L350UV+LM (low-migration ink) used for food safe short-run stand-up pouches. The first installation is to a UK la...

January 07 2020

Screen has extended its reach into flexible pouch production with its Truepress Jet L350UV+LM (low-migration ink) used for food safe short-run stand-up pouches. The first installation is to a UK label printer, Hine Labels, who was already using the Screen press for labels. The move into pouches, under a new division named www.houp.com, will expand its application offering into a fast growing market where standable pouches and sachets are being printed and filled with a wide variety of foods, liquids and FMCG products.

Hine Labels purchased the Screen L350UV+LM in 2018 due to its low migration inks, which are compliant with the strict safety standards of food labeling and packaging. Hine then found the press’s high uptime, reliability and quality in combination with the industry leading productivity of up to 60 metres per minute, made it a good investment, which is now set to return even higher dividends.

Bill Hine, The Managing Director of Hine Labels says: “It was a logical decision to apply our existing Truepress Jet L350UV+LM to digitally print pouches. With its low migration inks, the press is perfect to produce premium pouches that are compliant with the strict food safety standards. This allows houp.com to differentiate its offering and enjoy a new and exciting revenue stream.”

Hine continues: “We have identified a gap in the market for digitally printed short-run pouches. Our clients are looking to achieve professional packaging without the commitment of ordering larger volumes, and they are looking for multiple applications from the same provider. The Screen Truepress Jet L350UV+LM allows us to move into various different markets in order to satisfy our customer-base and the ever-demanding needs of a competitive market.”

Peter Scott, Screen GP Managing Director for Australia and New Zealand, notes: “We have been working on pouching solutions for a while now and the level of interest is escalating. The key is combining the short-run benefit of digital printing with a converting line to laminate and make the pouches. These lines are readily available from manufacturers such as Karlville, Uflex and others. A variety of closures such as zip-locks, vent valves (for coffee) and spouts can be built in, when the pouches are ready for aseptic filling and sealing. The L350UV+LM is ideal for pouches because of the food-safe inks and ability to print a 700mm wide PET or other roll, already seamed on one side by folding it to 350mm and printing both sides.”

Pouch packaging of food and drink was originally developed by the US military and NASA for servicemen and astronauts and is now finding wide consumer acceptance and shelf appeal as a way of packaging foodstuffs cleanly and securely.

Scott sees it as a powerful new direction for label producers, with the short-run benefit of digital bringing ‘big brand’ marketing to SME producers: “There is one case of a small manufacturer of 16 kinds of fragrant bath salts moving to digitally-printed pouches and selling them through Amazon online, with excellent sales worldwide. This is just one of the opportunities offered by Screen Truepress short-run pouch printing and converting – as well as labels of course!”

www.screenaust.com.au

Kodak is introducing its superior ULTRASTREAM technology in the NEW UTECO Sapphire EVO W, the first flexible packaging press to enter the market using Kodak’s latest continuous inkjet technol...

December 10 2019

Kodak is introducing its superior ULTRASTREAM technology in the NEW UTECO Sapphire EVO W, the first flexible packaging press to enter the market using Kodak’s latest continuous inkjet technology. The first ULTRASTREAM system with a print width of 1.25 meters has been sold into the market in advance of its expected debut at drupa 2020 in Dusseldorf, Germany with a healthy pipeline of active prospects. The wide format of the new Sapphire EVO W allows brands to leverage digital printing in their traditional flexographic print formats.

As packaging converters and brands look for more cost-effective solutions for shorter production runs, Kodak and Uteco have created an industry-changing press. Enabled by water-based inks and production speeds equivalent to analogue presses, the Sapphire EVO W can print short- to medium-run length jobs, achieving price points favorable to flexography. Sapphire digital solutions execute variable data campaigns and reduce waste and excess inventory delivering increased sales at lower costs. Included in the delivery of the Sapphire EVO W is Kodak’s environmentally friendly and industry compliant inks and fluids which open the door for applications in food, beverage, and personal care.

“ULTRASTREAM is revolutionizing flexible packaging for brands,” said Randy Vandagriff, President, Enterprise Inkjet Systems Division and Vice President, Eastman Kodak Company. “Uteco’s application of our technology in their new press is a game changer and a great example of how Kodak is helping printers to lower their costs and drive efficiency. We are proud to be delivering on the promise we made in February to have units in the market by the second half of 2020.”

“As the world leader in the production of printing and converting machines for flexible packaging applications, we recognize the need for digital solutions in our customers’ operations,” said Aldo Peretti, President and CEO of the Uteco Group. “Converters and brands expect quality solutions that are sustainable and uphold brand integrity. We are proud to work with Kodak to deliver new technologies that meet such demands and enable growth.”

Memjet, a developer of inkjet printing technology, and COASO Incorporated have announced that COASO has used Memjet’s DuraFlex technology to develop a new label press called the iCueLabel Pre...

December 03 2019

Memjet, a developer of inkjet printing technology, and COASO Incorporated have announced that COASO has used Memjet’s DuraFlex technology to develop a new label press called the iCueLabel Press.

Released in September, DuraFlex is a modular single-pass print solution that combines Memjet’s signature features of speed, simplicity and affordability with new attributes that include enhanced durability, A4- and A3-plus widths in a four-colour printhead, a high-speed data path and modules that control all printhead functions. Together, these features give OEMs like COASO the resources to create affordable presses with quality and speed previously not available in these types of solutions.

“Our iCueLabel press is an example of what an OEM can accomplish with DuraFlex technology,” says Frank Xu, general manager of COASO. “In less than three months, we were able to develop a new breed of label press that is a viable performance alternative to more expensive toner or other inkjet-powered printers. Converters can use the iCueLabel Press to produce high-quality labels the market demands — including food-safe and high-security labels — in a fast, affordable way.”

The iCueLabel 420 will create a new market for itself due to its 1600 dpi print quality and competitive pricing. Print speeds are as fast as 46 m/m in production mode and 27 m/m in high-quality mode.

“Our goal with designing DuraFlex was to create a simple yet robust technology that could give OEM partners the resources to create printing solutions that are powerful but also affordable,” says Bent Serritslev, Senior Vice President, business development, APAC at Memjet. “It is gratifying to see how COASO has used DuraFlex’s compact, modular design, category-leading speed, and 1600-dpi quality to develop this new label printer. We look forward to seeing the success of this partnership at SWOP and in months ahead.”

Czech Republic based Soma has launched Optima, its new mid-web flexo press developed especially for short run jobs such as wrap around labels, shrink sleeves, sachets and various pouches.

November 18 2019

Czech Republic based Soma has launched Optima, its new mid-web flexo press developed especially for short run jobs such as wrap around labels, shrink sleeves, sachets and various pouches.

Soma produces flexographic printing presses, slitter rewinders and laminators used K 2019 as the platform for the formal launch of the next-generation Optima press. Its first generation has earned a reputation as an easy to operate flexo press for short runs with many installations around the world.

The next-generation Optima is now available in a 41.3in width and 25.6in length and has been developed for short runs, handling up to 20 jobs a day. It focuses on features that offer easy and fast job changeovers, print consistency and reduction in operating costs.

Additionally, Optima can now be installed with the Arun system for automatic job setting, a unique off-line solution that combines the advantages of a plate mounter with a fully automated device for plate topography and register measurement. The new Zero Meter waste set-up system helps with short runs.

Soma also added new ink cartridge which enables spot colour printing and the operational cleanup as efficient as possible. It uses between one and five liters in the inking loop as well as short ink hoses to significantly reduce residual ink.

The modular design lets printers build several combinations of face-to-face single shaftless, nonstop flying splice, or cantilevered flying splice winders.

‘Soma’s policy includes a permanent re-innovation process, which always starts from market needs– obviously derived from customer needs. The platform of the K exhibition allowed us to globally present what is our answer to customers’ daily challenges. And, I am personally very proud that many clients from all continents trust, appreciate and decide to implement our approach as the solution for their challenges,’ commented Pavla Kusa, commercial director at Soma.

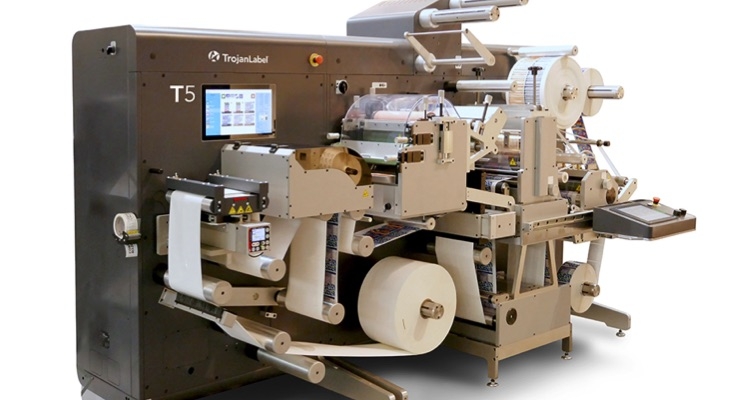

AstroNova, Inc. has announced the global launch of the TrojanLabel T5, a larger version of the company’s TrojanLabel T4 label press and finishing system with the addition of UV flexo varnish ...

November 06 2019

AstroNova, Inc. has announced the global launch of the TrojanLabel T5, a larger version of the company’s TrojanLabel T4 label press and finishing system with the addition of UV flexo varnish capabilities.

The T5 all-in-one digital print and finish in-line labelling solution was demonstrated for the first time in September at Labelexpo Europe 2019 in Brussels, Belgium. The T5 is already up and running at customer sites in Europe and the United States.

The TrojanLabel T5 is built on AstroNova’s industry-leading TrojanLabel T3 Digital Inkjet Label Press platform integrated with a smart, compact converter unit featuring UV flexo varnish, lamination, rotary die-cutting, slitting, and waste removal. Following the introduction of the T4 two years ago, the T5 is the Company’s latest high-production label printing and converting solution for the professional printing market. The T5 adds several additional enhancements such as spot and SUPERgloss varnish, lamination, slit & rewind, and cold foil application for silver, gold, and metallic decorative accents, all in a single compact platform.

“The T5 is a great step up in our offerings, providing professional printers and large brand owners with a high-performance system that delivers great results from start to finish,” said AstroNova President and CEO Greg Woods. “We are excited about the addition of this unique, versatile solution to our TrojanLabel family of professional digital colour label presses and specialty printers.”

With the addition of the T5 to its ever-expanding product line-up, AstroNova continues to offer a broad range of products to suit a variety of labelling and production needs. From QuickLabel tabletop, on-demand printers to TrojanLabel full-print finishing systems, and a wide range of complementary solutions including software, label materials, accessories, and global technical support, AstroNova provides total peace of mind to customers and channel partners alike.

Epson Australia has launched two new ultra-low cost POS printers – the TM-T82III and the TM-T82IIIL – both specifically designed for price- and cost-conscious retail and hospitality bus...

October 29 2019

Epson Australia has launched two new ultra-low cost POS printers – the TM-T82III and the TM-T82IIIL – both specifically designed for price- and cost-conscious retail and hospitality businesses that require reliable point of sale transactions.

The new Epson TM-T82III thermal receipt mid-range printer designed for tier two retail and hospitality businesses is built with speed, reliability, usability and functionality in mind. The TM-T82III features a new more durable printhead with improved reliability, capable of printing up to 150 km of thermal paper. Also, with an improved print speed of 250 mm/s, the TM-T82III is not only cost effective for any business, it is an easy-to-use thermal receipt printer.

The TM-T82III supports both English and simplified Chinese characters and WiFi connection can be achieved by attaching the optional Epson OT-WL06 WiFi dongle.

All-in-one convenience is clear and evident with the TM-T82III as accessories required to get the printer up and running are supplied in the box and this includes a power supply adapter, power cables, wall bracket, 58 mm paper guide and waterproof cover so getting started couldn’t be easier.

Epson’s cost effective new entry-level TM-T82IIIL thermal receipt printer is an economical, convenient and easy-to-use thermal receipt printer designed for retail and hospitality businesses with low volume point of sale transactions.

For added reliability, the internal printer’s mechanisms are housed in a rigid sheet metal chassis providing extra protection and enabling easy replacement and maintenance, thus reducing the cost of repair and repair time.

The new printer design also has multiple ease of use features including all the control buttons being located at the front of the printer for quick access, drop-in paper loading, partial-cut and auto-cutter status LED. There’s also a built-in AC adapter, eliminating the need for an external AC power adapter.

If that wasn’t enough both new printers are also able to reduce paper usage by up to 30% by using clever paper saving features and both come with Epson’s renowned two year manufacturer’s warranty.

The new TM-T82III and the TM-T82IIIL thermal receipt POS printers are available now through all Epson Australia business system distributors.

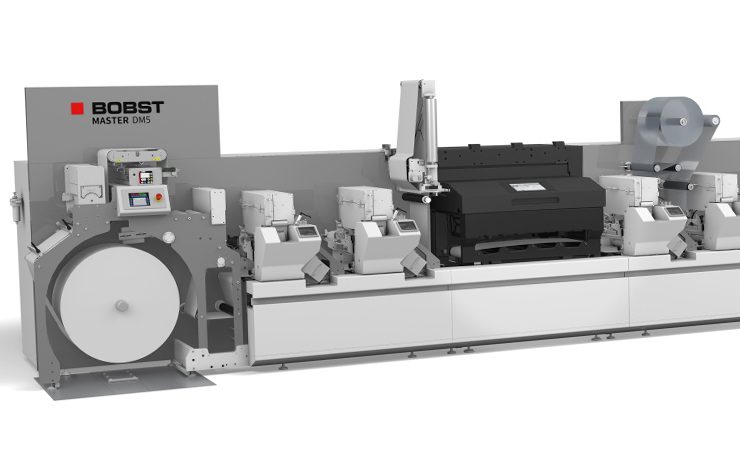

Bobst has formally entered the hybrid printing market with the launch of Master DM5, a platform combining its flexo expertise with Mouvent UV inkjet printing technology. Announced earl...

October 15 2019

Bobst has formally entered the hybrid printing market with the launch of Master DM5, a platform combining its flexo expertise with Mouvent UV inkjet printing technology.

Announced earlier this year, the digital capability of Master DM5 is built on the Mouvent Cluster, a compact printhead design with all-in-one fully integrated inking, conditioning and electronic circuits. Bobst’s DigiFlexo technology has automated key parts of flexo in an effort to ‘digitise’ the process. The new Ink-on-Demand (IoD) system is available as an optional extra for DigiFlexo print units, which replaces conventional inking reservoirs with a single rubber pipe that dispenses 30g of ink to the print unit. The system eliminates ink trays and chambered doctor blades and performs fully automated washing of the print unit in less than one minute.

Bobst CEO Jean-Pascal Bobst confirmed, ‘Master DM5 is our first ever fully digitally integrated hybrid press and represents a new era in the production of self-adhesive labels with totally new standards of productivity and profitability.’

Moreover, by combining Mouvent’s inkjet technology with Bobst’s DigiFlexo analogue process, Master DM5 is said to combine the best of both worlds.

Federico D’Annunzio, hybrid printing programme manager at Bobst, said, ‘Two of the greatest benefits of the Master DM5 are productivity and reliability. It represents a total flexo-digital-converting integration, with non-stop productivity, and the highest press uptime in the industry. It prints at speeds of up to 100m/min at the highest quality, 1200 x 1200dpi. Full digital automation means that only one press operator is needed to print high added value label jobs, in short and medium runs. Job changes on-the-fly, without stopping the press, are possible for flexo, digital, die-cutting and stripping processes. All analogue tools (print cylinders, flexible dies) are changed automatically. Waste stripping is also fully automated. Eliminating traditional analogue bottlenecks, the Master DM5 is the very first digitised ‘non-stop’ label press.’

Mactac has introduced three new oil-tolerant labelstocks that are marketed for a wide range of product labelling applications: LTC0T8060 white matte polypropylene film, LTC0T5040 white gloss polyes...

October 15 2019

Mactac has introduced three new oil-tolerant labelstocks that are marketed for a wide range of product labelling applications: LTC0T8060 white matte polypropylene film, LTC0T5040 white gloss polyester film and LTCOT5050 clear polyester film.

Mactac has introduced three new oil-tolerant labelstocks that are ideal for a wide range of product labelling applications: LTC0T8060 white matte polypropylene film, LTC0T5040 white gloss polyester film and LTCOT5050 clear polyester film.

The new labelstocks feature an oil-absorbing adhesive that allows them to be applied to oily surfaces that would typically need to be cleaned before application—reducing production time and material costs.

'The new oil-tolerant labelstock offerings are a testament to Mactac’s focus on innovation and ongoing commitment to meeting the needs of businesses across industries,' said Kim Hensley, senior marketing manager, Mactac Performance Adhesives. 'Historically, it has been a challenge for brands to keep labels in place on oily products. By developing our new oil-absorbing labelstocks, we can offer brands a simple, yet effective labelling solution for even the greasiest surfaces.'

Mactac’s oil-absorbing labelstocks include:

- LTCOT5040, a 2-mil top-coated white gloss polyester film coated on one side with an oil-tolerant acrylic adhesive and protected by a 45# blue glassine liner.

- LTCOT5050, a 2-mil top-coated clear polyester film coated on one side with an oil-tolerant acrylic adhesive and protected by a 60# blue glassine liner. • LTCOT8060, a 3.1-mil top coated white matte polypropylene film coated on one side with an oil tolerant acrylic adhesive and protected by a 45# blue glassine liner.

- Mactac’s oil-tolerant labelstocks can be applied to smooth or textured surfaces.

They can be applied in temperatures ranging from -40 degrees to 212 degrees Fahrenheit. The labelstocks can be printed with conventional ink or thermal transfer ribbon and will remain legible and firmly affixed under all conditions.

Durst, manufacturer of advanced digital printing and production technologies, has announced major expansions with its leading-edge RSC platform of UV inkjet label presses. New dedicate...

October 07 2019

Durst, manufacturer of advanced digital printing and production technologies, has announced major expansions with its leading-edge RSC platform of UV inkjet label presses.

New dedicated label workflow and prepress software together with an advanced modular Tau RSCi UV inkjet digital label press and low-migration inks were shown for the first time on its stand C50 in Hall 9 at Labelexpo.

Under an official slogan of “We Keep You Printing”, Durst announced a raft of groundbreaking innovations and world firsts as it continues to accelerate its presence in digital label inkjet printing, an industry it first established a presence only a decade ago.

Dedicated workflow software for Web2Production and Durst’s own prepress software “Workflow Label” offered by Durst Professional Services to customise MIS integration software packages were being showcased. New features of the Durst Workflow Label combined with the adapted Durst Smart Shop and integration packages help to fulfil Industry 4.0 standards and drive forward the expanded Tau RSC portfolio.

The new Tau RSCi - on show together with current Tau 330 RSC and RSC-E presses - has print widths of 330, 420 or 508mm (13, 16.5 or 20 ins) and a higher printing speed of up to 100 linear m/min. New features for the RSC portfolio include a high opacity White Print Mode for an increased screen-like opacity and a High Speed White mode that allows high speed printing at 80 lin. m/min of all colours, including white. Another spotlight at Labelexpo was the new low-migration UV ink developed for the RSC platform, which is compliant with EUPIA and Swiss Ordinance regulations for food and pharmaceutical packaging.

Visitors to the Durst stand will have the chance to have a close look at the software and printing technology and how it is used by customers who benefit from an automated production unit. The offering is completed by consulting, training and integration provided through Durst Professional Services.

Helmuth Munter, Durst’s Segment Manager, Labels and Package Printing, said: “Labelexpo marks 10 years of Durst in the label industry with a raft of new innovations: first with 7 colours, first with chill roller, first with low-migration ink and first with an inert curing system. Introduced two years ago, the Tau 330 RSC and Tau 330 RSC E set a new benchmark in label printing and we now have more than 50 installations around the world. We are confident that our updated Tau RSC platform will once again set the base for the future of industrial digital inkjet printing in the label industry.”

AstroNova has launched the TrojanLabel T2-L, which, according to the company, is the world’s first narrow web digital flexible packaging press. Customers will have the opportunity to see and ...

September 30 2019

AstroNova has launched the TrojanLabel T2-L, which, according to the company, is the world’s first narrow web digital flexible packaging press. Customers will have the opportunity to see and test the new T2-L for the first time at Pack Expo Las Vegas and Labelexpo Europe 2019.

Designed to accommodate both short-run and high-volume digital printing, the T2-L can provide flexible packaging products for brand owners, manufacturers, and commercial printers to efficiently scale and grow their businesses. Using Natura inks, which are formulated with nearly 70% water, the T2-L delivers excellent print quality onto flexible packaging using inks that are safe for food labels. The product is designed to create savings for customers over the lifetime of the printer.

To support the growing digital print for packaging business, AstroNova has partnered with Sihl for digital print substrates. In addition to offering Sihl’s environmentally friendly ARTYSIO brand packaging product portfolio for the T2-L, AstroNova is partnering with Sihl to develop a range of new flexible packaging materials. Independent auditing firm Intersoh recently awarded the highest rating for recyclability to Sihl’s ARTYSIO materials, which include metalised ultra-high barrier and pure polypropylene versions.

“Its high-quality, recyclable, flexible packaging materials make Sihl a perfect partner for AstroNova in providing a total solution that is environmentally friendly, food-friendly and sustainable,” says AstroNova president and CEO Greg Woods. “We are proud to partner with Sihl on this initiative, offering our customers what we believe will be the flexible packaging solution with the highest return on investment in the industry.”

According to research firm Smithers Pira, total worldwide sales for flexible packaging are expected to grow to $269 billion in 2024 from $228 billion this year. “Our T2-L plays directly into strong secular trends driving the growth of the flexible packaging industry, including increased urbanisation, a greater consumer focus on sustainability and the growth of e-commerce,” Woods adds. “Our technology helps to create lightweight, durable packaging that reduces waste, lowers transportation costs, and is safer for the environment.”

DTM Print, an international OEM and solution provider for specialty printing systems, has added the new FX510e Foil Imprinter for finishing and highlighting product labels. With the FX510e, printer...

September 30 2019

DTM Print, an international OEM and solution provider for specialty printing systems, has added the new FX510e Foil Imprinter for finishing and highlighting product labels. With the FX510e, printers can add brilliant, shiny metallic or laminated highlights to blank or already pre-printed labels, whether they have been produced by inkjet, laser, offset or flexo printing.

As the imprinting process is completely digital, virtually any design elements like borders, graphics, fonts and backgrounds can be printed. A fast and efficient, one-colour personalisation for POS or POI applications is possible, as well.

The FX510e differs far more than in mere appearance from the previous model, the FX500e. Besides a new chassis, the printer contains an internal multifunctional roll holder, allowing the use of rolls with a core of up to 3”. An external passive label unwinder mounted on roller bearings is included as well. It supports label rolls with a maximum size of 4.5" (114 mm), a core of up to 3" (76 mm) and an outer diameter of up to 10" (254 mm).

Metallic foils in gold, silver, blue and red are available for the FX510e, as well as various spot colours and clear foil. With the clear laminating foil partial glossy add-ons, comparable with a UV coating, can be applied to the product labels for logo design or graphical areas, for example.

As a special highlight, DTM Print offers a new thermal transfer label substrate for the FX510e: DTM Poly Clear Gloss TT. This substrate enables the production of crystal-clear product labels with imprinted elements.The new foil imprinter is available in two versions. Next to the standard model, the FX510e, there is the FX510ec, featuring a built-on guillotine cutter, which allows horizontally cut die-cutting, reflective and continuous label stock. Fast print speeds and a low purchasing price allow users to quickly and cost-efficiently produce labels on-demand in the amount that is actually needed.

The FX510e is easy to set up and operate. Besides the passive label unwinder, the printer driver for Windows 7/10 is included along with the design software NiceLabel Free 2019 DTM Edition (for Windows) and four colour ribbon starter rolls (gold, silver, red and blue metallic).