Summa nv, a leading supplier of high-end cutting plotters and finishing systems, introduces the L1810 laser cutter, bringing advanced laser cutting technology to benefit the sportswear, apparel, sw...

March 19 2019

Summa nv, a leading supplier of high-end cutting plotters and finishing systems, introduces the L1810 laser cutter, bringing advanced laser cutting technology to benefit the sportswear, apparel, swimwear, dye sublimation garments and technical textile markets.

The new L1810, with its 1.8 m wide flatbed, is the first laser cutter introduced by Summa since the acquisition of CadCam Technology (CCT). This machine is part of the Summa L Series and equipped with proven laser technology, yet with enhanced features.

Wim Maes, Executive Director at Summa explains: “With our eyes focused on the textile market, this launch is an important step for Summa. A number of reasons convinced us that laser cutting is the best way to cut sportswear & apparel and we are ready to show the advantages, such as increased productivity, ease of use, cut accuracy and automated features, to the market. The development of this first Summa branded L1810 laser cutter is a powerful product to start with.”

The L1810 laser system is built to seamlessly meet the requirements for cutting textiles for sportswear.

- Processing sportswear involves sensitive and easily distorted textiles, the laser system uses contactless cutting, enabling users to process materials with high precision.

- Cutting quality that exceeds your expectations, thanks to the perfectly sealed edges.

- Enhanced productivity with the 1.8 m conveyor system for continuous production of roll materials.

- Any deformations are automatically recognised by the intelligent camera system and immediately compensated in the cutting vector.

- Ease of use & Automation thanks to the advanced optional Vision system, which quickly scans the material and automatically creates vectors for cutting, without the need of a cutting file.

- Material optimisation reduces waste with the Vision technology because the laser system does not need markers, the cutting designs can be placed much closer to each other, ensuring maximum use of the material.

- Environment & Safety is a priority. Fumes are removed by the internal extraction system and cutting by laser produces no dust fibres ensuring a clean work environment. The L1810 cutting area is enclosed to meet the Class 1 standard, ensuring the laser cutting source is covered during operation and machine pauses if the cover is open.

The L1810 laser cutter is especially suitable to cut textiles, such as sportswear, dye sublimation garments but also all sorts of raw materials used in the composite industry. All of these substrates are part of the wide variety of materials, which can be cut on Summa’s advanced L1810 laser cutting system.

Moreover, by using the optional Vision system, the L1810 Vision is utmost suitable to be used in high-production environments, demanding fast processing of printed textiles in order to achieve more throughput in less time. Always with the same high-end finishing quality, Summa stands for.

Wim Maes points out, “With the dedication and expertise on board, Summa continues to excel as a supplier of high-performance cutting and finishing solutions, broadening its portfolio in a growing number of markets. The introduction of the L1810 laser cutter is an ideal stepping stone to also build a reputation of a trusted partner in the textile industry. The broad spectrum of Summa’s cutting solutions, offering exceptional cut quality, versatility and productivity will perfectly serve the textile industry, similar as it has been serving the sign & digital market to date.”

DGSHAPE Corporation, a wholly-owned subsidiary of Roland DG Corporation and a leading provider of digital fabrication tools, including 3D milling machines, 3D printers, and engraving machines, anno...

January 30 2019

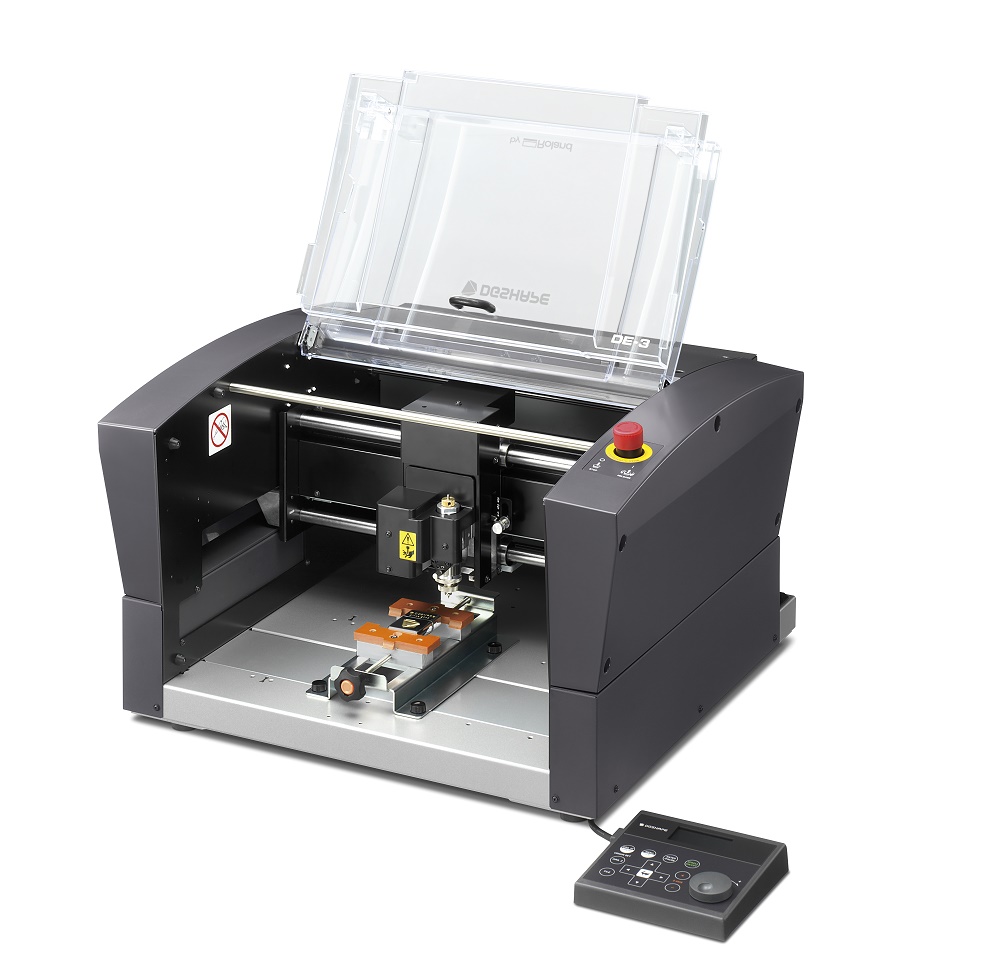

DGSHAPE Corporation, a wholly-owned subsidiary of Roland DG Corporation and a leading provider of digital fabrication tools, including 3D milling machines, 3D printers, and engraving machines, announced today the launch of its latest decorating solution, the DE-3. DGSHAPE continues the legacy of Roland engraving with a new model that features laser-pointing technology, ethernet connectivity, automatic depth regulation, and other intelligent enhancements.

According to Hisashi Bito, President of DGSHAPE Corporation, “The DE-3 builds on the legacy of Roland engraving solutions that is advanced today by DGSHAPE Corporation and affirms DGSHAPE’s commitment to providing reliable desktop solutions for the entrepreneur to build their business.”

The DE-3 can produce a variety of engraving applications including industrial nameplates, signage, awards, and gift personalisation. This next generation engraver incorporates many new improvements including: Ethernet connectivity, updated nosecone technology for higher quality engraving on uneven material, data buffer for offline engraving, laser pointer for precise material alignment, and new bundled software: Dr. Engrave Plus. This new software has advanced features such as AI and EPS file support, leveling and drilling functions, and Variable Data Printing.

A cornerstone of all DGSHAPE machines, Bito said, is their ease of use. Operation is as simple as pressing a button. DGSHAPE prides itself on the concept of the “Open System.” This open architecture offers the flexibility of using design software and tooling that engraving professionals are already familiar with. The DE-3 can be connected via USB or LAN which allows for increased flexibility in any environment. Dr. Engraving Plus is a design software that can create new artwork or take existing files from popular design software packages to output to the DE-3 for a true out-of-the-box solution.

The DE-3 easily produces popular engraving applications in a variety of materials. The DE-3 can be installed via USB or Ethernet. An optional centre vice increases the available materials that can be engraved

COLORTUFF EXT ® : THE NEXT WAVE IN SIGNMAKING SUBSTRATES ColorTuff EXT ® is the industry’s first 5 year exterior sublimatable aluminium sheeting. Available in sizes up to...

August 29 2018

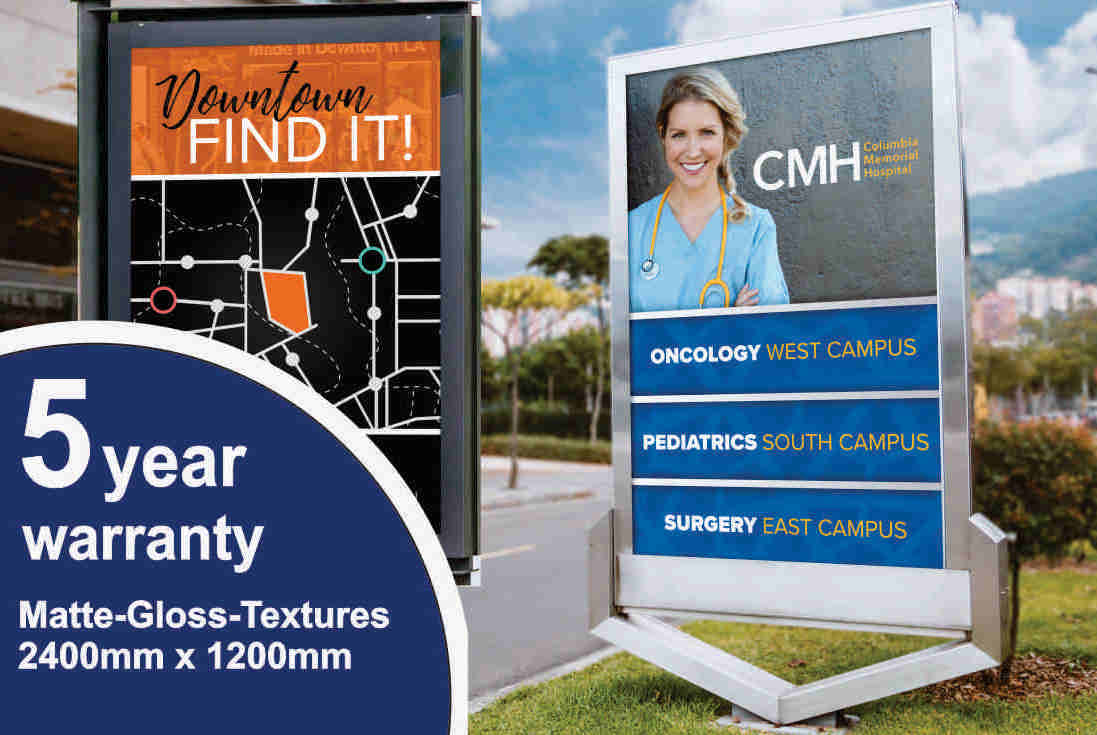

COLORTUFF EXT ® : THE NEXT WAVE IN SIGNMAKING SUBSTRATES

ColorTuff EXT ® is the industry’s first 5 year exterior sublimatable aluminium sheeting. Available in sizes up to 2400mm x 1200mm and in 3 different finishes, it will stand up to the demands of the harshest environment.

Tom Johns from Rowmark Australia stated, “Come and see our ColorTuff EXT ® display at VI Sydney. The look and feel of the Texture finish bring an authenticity to signage that will change your perception of the applications and potential of sublimation.”

With great outdoor weatherability, durability of colour and 5 year performance guarantee, ColorTuff EXT ® will open many opportunities for sign makers from Architectural, Wayfinding, Exterior Signage to Compliance Signage, Garden Art and Outdoor Informational Graphics.

Colortuff EXT ® guillotines cleanly, drills without chipping and crazing and is graffiti resistant for easy removal of spray paint and permanent markers and will provide great new option for sign makers.

For more information about ColorTuff EXT ® contact: sales@rowmark.com.au , phone 1300 023 370, see us at VI Sydney 2018 or click here for more details.

HP Showcases Multi Jet Fusion 3D Printing Applications, Announces Expanded Partnerships HP‘s Multi Jet Fusion technology has been spreading to every corner of the industry...

May 27 2018

HP Showcases Multi Jet Fusion 3D Printing Applications, Announces Expanded Partnerships

HP‘s Multi Jet Fusion technology has been spreading to every corner of the industry as the company cements partnerships all over the world. This week in Barcelona at the HP Innovation Summit, HP announced additional collaborations that will see the technology further utilized by some industry heavyweights, as well as highlighting several of the applications in which Multi Jet Fusion is already being used to change how things are made.

“The digital transformation of the $12 trillion manufacturing industry is changing the game for the world’s designers, product developers, manufacturing and supply chain professionals, creating massive opportunity for the 3D printing ecosystem,” said Ramon Pastor, General Manager of Multi Jet Fusion, HP Inc. “In collaboration with our customers, we are proud to reinvent the way the world designs and manufacturers and to drive innovative new applications made possible with HP Multi Jet Fusion. Whether it’s helping the Swiss Guard protect the Vatican or reinventing what can be done for an entire industry like orthopedics, the possibilities are endless.”

Protolabs was one of HP’s original partners when Multi Jet Fusion technology was initially launched, and now the service bureau is upgrading its seven HP Jet Fusion systems to industrial HP Jet Fusion 4210 systems in order to meet growing demand for production-grade 3D printing. Applications in which Protolabs has already been using the technology to help customers include specialized packaging, such as a promotional series of Black Panther masks put out by Pepsi. In addition, Protolabs used MJF to help customer Stream Lion Design to solve a combustion turbine issue, 3D printing a modal hammer to survey engines in the field and double the speed of data collection.

“The demand for 3D-printed production applications continues to grow and HP’s Multi Jet Fusion technology is furthering our ability to deliver our customers industrial-grade parts quickly and cost-effectively,” said Vicki Holt, president and CEO, Protolabs. “By expanding the capacity of our HP Multi Jet Fusion services and installing printers in the United States and Europe, we are meeting the needs of our global customer base and demonstrating that geographically distributed, on-demand production is a reality today.”

Materialise was another early MJF partner, and has been using eight HP Jet Fusion 4200 3D printers. Now Materialise and HP have joined with RSPrint to scale an end-to-end solution for the production of personalized 3D printed insoles. Through RSPrint, FitStation powered by HP uses customer data to design custom insoles, which are then 3D printed on Materialise’s Jet Fusion 3D printers.

Belgian service bureau ZiggZagg has also jumped on the MJF train, investing in six HP Jet Fusion 4210 3D printers. ZiggZagg serves a variety of customers across industries including medical, consumer goods, industrial and automotive. According to CEO Stijn Paridaens, the company also plans to purchase an additional five Jet Fusion 3D printers by the end of the year.

IAM 3D Hub, an organization that brings together private companies, public entities, and R&D organizations to integrate and coordinate 3D printing activities around the world, has installed eight HP Jet Fusion 4200 systems and is also working with HP to expand educational and training opportunities and offer business mentoring.

“IAM 3D Hub shares HP’s vision to accelerate the adoption and development of 3D printing technologies for industrial production, and provide expansive education and training opportunities to grow the market,” said Aintzane Arbide, General Secretary, IAM 3D Hub. “HP’s leadership has already helped us move the needle across our various programs specific to technology innovation. The advanced capabilities of Multi Jet Fusion allow organizations to completely rethink their approach to product engineering and design, complex workflows, and advance the future of their manufacturing processes.”

At the summit, HP also showcased several of the applications in which customers have been using Multi Jet Fusion technology, such as 3D printed helmets worn by the Vatican’s Swiss Guard, lightweight bicycle helmets produced by Sculpteo for customer Syncro Innovation, and an ankle foot orthosis 3D printed by Crispin Orthotics.

The New Roland DGSHAPE LD-80 Laser Decorator Create dazzling customised products with digital laser foil decoration An industry-first in personalisation, the...

May 27 2018

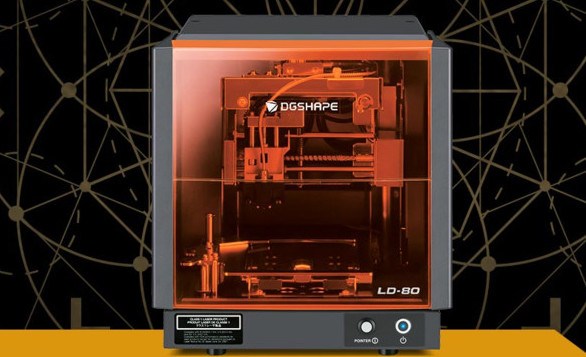

The New Roland DGSHAPE LD-80 Laser Decorator

Create dazzling customised products with digital laser foil decoration

An industry-first in personalisation, the DGSHAPE LD-80 laser foil decorator offers a unique opportunity for your print shop, kiosk, online store or personalisation business to create exciting new custom products with stunning text and reflective graphics.

Using a Class 1 laser the LD-80 heat transfers a wide variety of metallized foils onto polycarbonate, acrylic, thermoplastic, silicone and other plastics.

Safe to operate, with no debris or gas leakage, the fully enclosed machine is operated via the included METAZAStudio Software for effortless control. The program is easy to use, so don’t worry if you're not an expert in graphic design. It's as simple as uploading your vector graphic or entering the personalised text and selecting your holographic, metallic or gloss foil finish. The internal vise holds your objects perfectly in place and with the touch-of-a-button, a laser pointer reveals the origin point on the media for precise positioning. And with that, your unique designs and personalisation are precisely transferred onto your gifts, promotional giveaways, merchandise and so much more.

The LD-80 is suitable for a huge variety of production environments. It's a compact, light-weight, desktop device and doesn't require special electricals, making it an ideal solution for anyone with limited space or would benefit from a more mobile solution. Pack it up and take it to different locations or events to produce on-site and on-demand personalisation like never before!

Feature summary:

Class 1 laser decorator device

Loadable material size 100 x 200 x 20mm

Printable area 80 x 80mm

Suitable for plastic (ABS, PC, Acrylics)

Includes easy-to-use METAZAStudio software

Vector graphics, text and variable data

Portable production weighing only 12kg

Have you subscribed to our YouTube channel yet? We’ve just put up a brand new CorelDRAW step by step tutorial and walkthrough. Laser Engraving expert Jordan shows you how to ...

April 08 2018

Have you subscribed to our YouTube channel yet?

We’ve just put up a brand new CorelDRAW step by step tutorial and walkthrough.

Laser Engraving expert Jordan shows you how to set up artwork in CorelDRAW so you can laser engrave your city map using a laser! You can even use this to engrave on furniture and make custom side tables with your favourite city map.

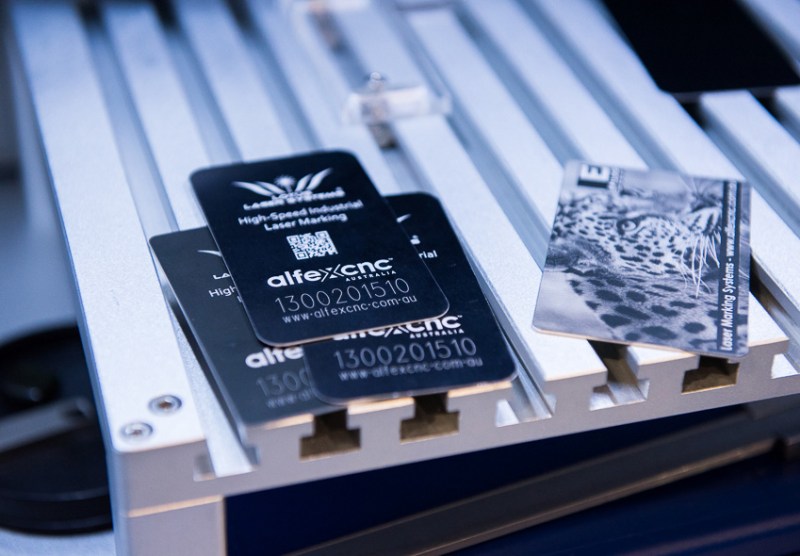

Leading machine tool supplier Alfex CNC Australia, which celebrates its 40th anniver...

April 03 2018

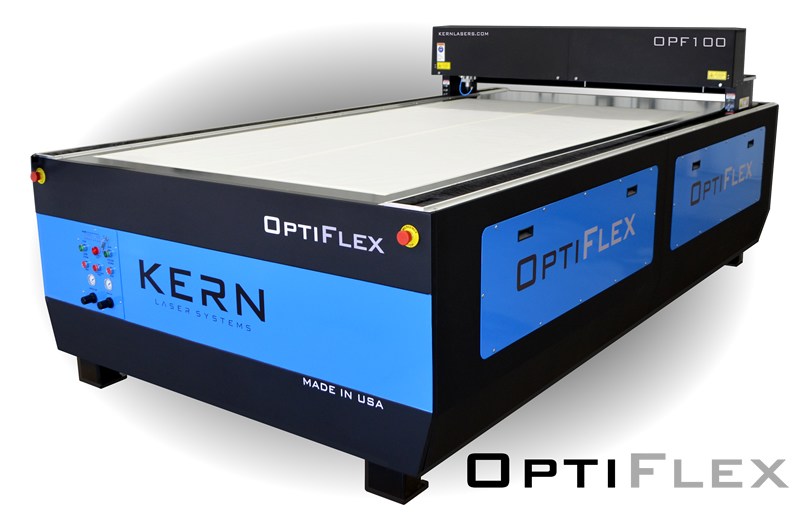

Leading machine tool supplier Alfex CNC Australia, which celebrates its 40th anniversary this year, has announced it will be unveiling the all-new Kern OptiFlex Laser on stand #G14 at the Visual Impact expo in Brisbane next month.

The OptiFlex is Kern’s flagship high-performance laser system, with a HyperDual motion package which Alfex says ‘sets the standard’ for large format laser cutting and engraving machines.

“This new system provides powerful, accurate cutting and engraving with cut acceleration rates up to three times faster than its competitors and work areas of up to 2,000mm x 3,000mm,” says Alfex CNC Business Development Manager, Christian Buhagiar.

“We’ll be showing the 1320 x 2540mm OPF 100 model on the Alfex stand, and demonstrating how its 400 watt laser enables it to cut metal as well as acrylic and plastic substrates, with ease.”

While the OptiFlex is sure to pull the crowds, Buhagiar says it will be just one of the highlights of the Alfex display. The company’s experienced staff will also be showcasing:

“We are excited to be able to showcase the latest solutions on our stand at Visual Impact, and we’re looking forward to giving visitors an introduction to how we can help them build their business via improved production processes and efficiency,” Buhagiar says.

Alfex CNC will be on Stand #G14 at Visual Impact Brisbane, which will run from 18-21 April at the Brisbane Convention & Exhibition Centre. Find out more at www.visualconnections.com.au or register online today to skip the queues.

Alfex CNC Australia Director George Buhagiar announced earlier this month the expansion of the laser and CNC company’s service department, creating new jobs and facility upgrades to their gro...

March 22 2018

Alfex CNC Australia Director George Buhagiar announced earlier this month the expansion of the laser and CNC company’s service department, creating new jobs and facility upgrades to their growing list of customers.

“2017 was a record year of growth for Alfex CNC and we are excited to see this growth continue in 2018. We’ve always been primarily service focused, and to maintain our reputation as having the best machine service we are expanding our service team.“

Alfex CNC was established in 1978 with the primary goal and a strong commitment to not only offer the finest machine tools available at that time but to also back them with some of the best support in the machine tool industry.

Haas Factory Outlet – Australia (A Division of Alfex CNC Australia) is the exclusive Australian distributor for Haas Automation. Today, Haas manufactures four major product lines: vertical machining centers (VMCs), horizontal machining centers (HMCs), CNC lathes and rotary tables, as well as a number of large five-axis and specialty machines. All Haas products are manufactured at the company’s expansive facility in Oxnard, California – the largest, most modern machine tool manufacturing operation in the United States. With around 1,200 Haas machine installations in Australia, it is no wonder that the team of Haas certified service technicians continues to grow.

With this growth and coinciding with our 40 year anniversary, we are pleased to announce the return of Marshall Philp to our Brisbane operation. Philp joined the team in early February as Haas CNC Service Coordinator. Philp previously workedfor Alfex CNC Australia where he became a Haas certified technician at the Haas Automation headquarters in the United States. “Marshall returns to the team with a great deal of experience to improve, strengthen and build our customer service/support efforts in Queensland and interstate”, says George Buhagiar.

“Our investment in our service department is significant and illustrates our commitment to our customers. We are proud to support our customers with their growth and look forward to continuing all of our new and long-term relationships.”

For further information on Alfex CNC Australia, visit www.alfexcnc.com.au

For more information on Haas Factory Outlet – Australia, visit www.haas-australia.com

Q: I HAVE A MAC, CAN I USE IT TO RUN MY LASER? A: Yes, but there are some caveats. If you are lucky enough to own an Epilog Fusion M2 Laser then th...

March 13 2018

Q: I HAVE A MAC, CAN I USE IT TO RUN MY LASER?

A: Yes, but there are some caveats. If you are lucky enough to own an Epilog Fusion M2 Laser then these come with a dedicated Mac driver which can run your laser directly from your Mac computer without the need for any additional programs. If your machine does not provide a dedicated Mac driver then you still have a couple of options; (1) Boot Camp for Mac – after loading Windows on to your Mac you then have the ability to choose between running Windows or Mac OS when you first boot up. (2) Parallels for Mac – similar to Boot Camp however with Parallels you can run both Windows and Mac OS simultaneously so you don’t need to reboot each time you want to change between operating systems

Q: HOW DO I GET A MARK ON BARE METAL PLATES WITH MY CO2 LASER?

A: Commonly used materials like stainless steel and aluminium can be best marked with a CO2 laser by utilising one of the many different metal marking solutions available today to achieve a near permanent, high contrasting black mark. It is critical that the stainless steel or aluminium is raw and has no coating (make sure it doesn’t have a clear coat) and that the surface is clean and free from oils and grease before you apply a thin coat of the marking solution. Use a slow-to-medium speed and high power for best results when laser engraving. You will need to use a slower speed for aluminium. We recommend MarkSolid 114 Aerosol.

For anything to do with laser engraving, click on the link below.

Q: WHAT ARE THE BENEFITS OF HAVING MORE LASER POWER? A: Generally speaking, the more laser power you have the faster you can engrave or the thicker you ...

March 13 2018

Q: WHAT ARE THE BENEFITS OF HAVING MORE LASER POWER?

A: Generally speaking, the more laser power you have the faster you can engrave or the thicker you can cut. Keep in mind that not all materials require a lot of power – if you are only engraving materials like anodised aluminium or cast acrylic you do not need much power however if you plan on predominantly using your laser to cut then you’ll need to consider a suitable power depending on your specific application.

Q: HOW DO I KNOW WHICH DPI SETTING TO USE?

A: As a general rule you will want to use a mid-to-high dpi for engraving text or other items with fine details, and a lower dpi for photographs or large block-style objects. Again this is a general rule and you should experiment with the different settings to understand the different results you can achieve. The higher the dpi the more dots the laser will mark (basically more details) however this also increases the overall marking time. A lower dpi will provide for faster marking times but is not suitable for all jobs. One thing to keep in mind is that the lower the dpi you use the more laser power will be required in order to achieve the same depth/darkness of mark.

Q: WHAT IS THE BEST WAY TO REMOVE SMOKE RESIDUE AFTER LASER ENGRAVING?

A: If engraving wood you have a couple of options

(1) If the wood has been sealed/lacquered you should be able to remove most or all of the residues with a damp cloth, however, if the wood is raw you may need to use some fine sandpaper to remove the residue – we recommend having some 220 grit sandpaper on hand in case you ever need it

(2) Alternatively, you can be proactive and use a light to medium tack masking paper first and then engrave it into the wood, allowing the residue to settle on the mark instead of your part. Then after the job simply remove the mask to reveal your perfectly clean engraved design

For materials other than wood

(1) You can try using Isopropyl Alcohol (IPA) to clean away any leftover residue

(2) Another tip is to use the Bottom-Up engraving feature found in your print driver (a standard feature on Epilog Lasers). In standard top-down engraving, there can be a large amount of engraving debris generated and as that debris is pulled towards the exhaust ports at the rear of the machine, some of it will collect in the areas that have just been engraved. The Bottom-Up function reduces the amount of smoke and residue so that it is not dragged across freshly engraved marks. This feature is particularly useful for two-ply engraving plastics where you are engraving through a colour like red/blue/green into white underneath.

Regardless of the material you are engraving it is also a critical factor to make sure you have sufficient extraction otherwise the smoke and residue will hang around and settle on your material instead of being immediately sucked away after engraving.

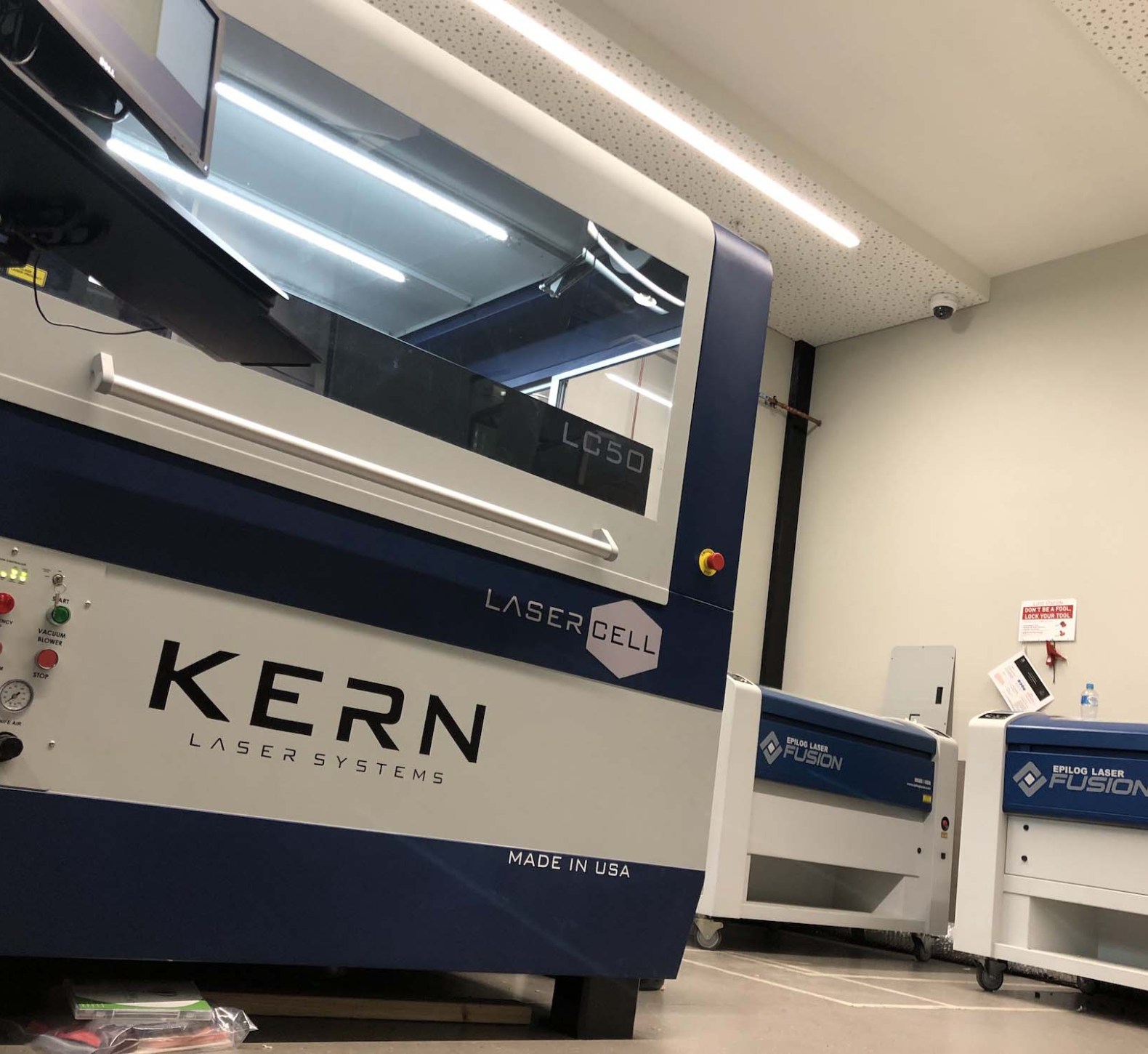

The Melbourne School of Design at University of Melbourne initiative for 2018 was to expose students to relative industry machinery and processes that they would potentially use as designers and...

March 13 2018

The Melbourne School of Design at University of Melbourne initiative for 2018 was to expose students to relative industry machinery and processes that they would potentially use as designers and architects after graduation. A complete laser cutting and engraving system that was safe to use in the classroom as well as flexible enough to have all the features needed inside a workshop meant the LaserCELL by Kern Laser Systems was the perfect solution.

Australia’s leading university, The University of Melbourne, is known to help graduates become thoughtful and skilled professionals. With their distinctive curriculum, the Melbourne Model, The University of Melbourne continues to seek ways to give students a wider understanding of the world beyond their degree.

Dr Jas Johnston, Manager of the Fabrication Workshop at the Melbourne School of Design, University of Melbourne, explained that the university wanted to expose students to relative industry machinery and processes that they would potentially use as designers and architects. “Industrial laser scale equipment was part of that initiative, to get the students hands-on in the industrial design field”.

Whilst their existing range of lasers allowed students to create projects made of plywood, MDF and acrylic, Dr Johnston and the University were looking for a solution that would allow students to cut and work with metal. “We find that once the students have access to the machinery and its capabilities, it opens up their creativity,” says Johnston.

The University required a laser system that was capable of cutting stainless steel, aluminium and other metals whilst still offer the ability to engrave and cut acrylic, plywood, MDF materials and also pipe/tube. This eliminated many vendors, especially when combined with the need for expert local support. “We felt confident with Kern and Alfex CNC Australia because of their commitment to supporting Australian customers. We got to speak with not only several members of the local team, but also Kern Laser Systems CEO Derek Kern, which you just don’t get with other companies.”

Issues with equipment usually stem from incorrect setup, which can lead to students to lack confidence in using the machinery again. “Having the Kern engineers come in from the USA and the local Alfex CNC engineers to set up the LaserCELL really boosted our confidence in knowing that the LaserCELL would be set up properly from the get-go and we would have expert support here in Melbourne.”

Another reason why we went with the Kern LaserCELL over other systems, is that it will still process all the other materials our students use. We needed the variety of materials as well as metals.”

The LaserCELL is perfect for educational settings due to the blend of performance and safety. The fully enclosed (Class 1) design is devised for high traffic areas such as University workshops and classrooms where safety is of the utmost importance”, said Christian Buhagiar, Business Development Manager of Alfex CNC Australia.

Now that students have access to industry machinery, Dr Johnston says their first project with the LaserCELL is an augmented reality workshop. The workshop will see students use the LaserCELL to cut flat sheets of metal to create hologram instructions. The LaserCELL will also be heavily used for Furniture Design projects.

The LaserCELL is Kern’s fastest and most productive machine to date and is compatible with Pipe Rotary, K-Vision Camera Registration and Metal Cutting options.

Our goal was to get students more access to machinery in the industry. With the Kern LaserCELL we’re confident that we’ll see new and innovative ideas in the classroom” said Dr Johnston.

We’re very proud of the relationship that Alfex and the team at Melbourne University have built over the years. It’s always a pleasure working with Jas, Sean and the guys, and we’re really excited to see them put the Kern LaserCELL to good work. There will no doubt be many impressive projects come from this new installation”, said Buhagiar.

For more information on the Kern LaserCELL and how you can use it in your organisation, call or email the team on 1300 20 15 10 or sales@alfexcnc.com.au today.

Epilog Laser, the largest manufacturer of popular engraving and cutting systems, is excited to celebrate their 30th anniversary in 2018. The company plans to host an anniversary bash in the Denv...

March 07 2018

Epilog Laser, the largest manufacturer of popular engraving and cutting systems, is excited to celebrate their 30th anniversary in 2018. The company plans to host an anniversary bash in the Denver metro area on August 11 to celebrate their successes over the past three decades.

“As I look back on the past three decades I am incredibly proud of what we have accomplished as a company, but also humbled by the undying support we have received from everyone who touches this business – our employees and distributors, our customers and fans, our vendors and other associates – everyone we’ve met along the way has had some sort of impact,” said Steve Garnier, CEO and one of Epilog’s founding members. “The past 30 years have been an unforgettable journey filled with triumphs and challenges, growth, and innovation. I can’t wait to see what lies ahead for us.”

Epilog Laser got its start in 1988 when two Georgia Tech buddies – Garnier and John Doran, Epilog’s vice president of engineering – combined their talents to create the industry’s first small-format, computer-controlled laser engraving and cutting system.

Mike Dean, Epilog’s vice president of sales and marketing, came on board not long after and the trio set out to become game-changers in the engraving space. As the company has grown over the past 30 years, they’ve seen their lasers used in a wide variety of markets, from guitar customization to cabinetry design to medical device marking. The combination of industrial-quality engraving speeds and quality with an affordable price have allowed everyone from makers to engineers to artists to add lasers to their businesses and find real success.

“It has been and continues to be an amazing ride,” Garnier said, “and we’re so thankful to everyone who has taken it with us. We can’t wait to see what the next 30 years brings!”

For more information, visit www.EpilogLaser.com.

ULTRA platform-based laser systems are designed and ideally suited for precision laser cutting, laser ablation, and laser surface modification in manufacturing, research and development, academi...

February 28 2018

ULTRA platform-based laser systems are designed and ideally suited for precision laser cutting, laser ablation, and laser surface modification in manufacturing, research and development, academic research and prototyping environments. Major features of the series include rapid, high-accuracy laser beam positioning, and the flexibility to be configured with 9.3 and 10.6 µm CO2 lasers and 1.06 µm fiber lasers. All lasers are air-cooled in a range of power from 10 to 150 watts for CO2 and 40 to 50 watts for fiber lasers.

The variety of wavelengths and power ranges make the ULTRA platforms highly effective in the areas of organic material modification, including plastic films, industrial fabrics, engineering plastics, laminating adhesives, composite materials, and many others utilized in Aerospace, Automotive, Electronics, Medical Devices and Battery Manufacturing.

Key features of the ULTRA series include MultiWave and MultiWave Hybrid™ processing capabilities, precision focusing with autofocus, adjustable laser power density, an automation interface, camera registration, an integrated, touchscreen user interface, and support for fire detection and suppression.

The ULTRA 9MW platform offers MultiWave processing for thin materials and supports one interchangeable CO2 or fiber laser source.

For ultimate materials processing flexibility, the ULTRA 9MWH, equipped with MultiWave Hybrid technology, can process the broadest range of compatible materials. This unique technology uses a combined beam of laser power containing up to three wavelengths – 9.3 µm, 10.6 µm, and 1.06 µm – in a single coaxial beam. Each spectral component of the beam is independently controlled and can be modulated in real time.

Rowmark LLC continue to innovatively expand its product offering to meet the demands of the market with the first real “Rose Gold” 2ply laserable Laminates. Rose gold is quic...

February 24 2018

Rowmark LLC continue to innovatively expand its product offering to meet the demands of the market with the first real “Rose Gold” 2ply laserable Laminates.

Rose gold is quickly becoming one of the sought after finishes in the awards and signage markets… and we are excited to now offer this colour option to you!

Laser and rotary engravable, UV-LED printable, Rose Gold is ideal for interior signage, personal identification, trophies, awards, plaques and more. Now is stock, Rose gold is offered in a premium brushed metal finish and comes in a 610mm x 1225mm sheet sizes.

Colour trends come and go, but Rose Gold continues to be as popular finish that won’t be fading anytime soon.

For more information about Rose Gold, and to request your sample piece or place an order, contact sales@rowmark.com.au or phone 1300 023 370.

Alfex CNC installed the Epilog Legend Elite Mini 18 Laser at St Aidan’s Anglican Girls School in Brisbane. Their very own Haydn Brown walked through the setup of the system with the teache...

January 15 2018

Alfex CNC installed the Epilog Legend Elite Mini 18 Laser at St Aidan’s Anglican Girls School in Brisbane. Their very own Haydn Brown walked through the setup of the system with the teachers explaining various parts and how to maintain the system.

Jackie Child from St Aidan’s commented “We were so impressed and watched with eyes glued to the cutting table.” Watch the video of the first design cut with their new laser.

The Mini 18 is ideal for classroom environments as its compact size is suitable for smaller spaces. A Class 1 laser system, the Legend Elite Series has been designed to be safe under all conditions of normal use, making it suitable for students to use in a classroom environment.

Students at St Aidan’s will now be able to prototype ideas and inventions, expanding their skillset on this compact and safe laser.

Learn more about the Epilog Legend Elite Series here.

We’re delighted to announce that BOFA have been awarded the Queen’s Award for Enterprise: Innovation. This accolade is in recognition of the revolutionary

January 01 2018

We’re delighted to announce that BOFA have been awarded the Queen’s Award for Enterprise: Innovation. This accolade is in recognition of the revolutionary Intelligent Operating (iQ) system which was first launched in 2012.

BOFA’s range of Advantage laser fume and filtration extraction systems are designed for applications that generate particulate and gaseous organic compounds within the laser marking, cutting, coding and engraving industries.

The Queen’s Awards are the UK’s most prestigious business awards to celebrate and encourage business excellence in the UK.

Managing Director Tony Lockwood commented: “At BOFA, we are very proud of being a successful British manufacturer, and to receive this recognition in what is our 30th year is a fantastic achievement and testament to the hard work of everyone at the company.”

iQ has introduced many performance enhancements, including independent filter monitoring and remote data analysis, to improve extraction efficiency, reduce the risk of production downtime and lower the lifetime cost of technology ownership.

Already acknowledged as number one in the industry, know that while you’re selecting which BOFA product to buy from Alfex CNC, any that feature ‘iQ’ in the name includes award-winning technology as standard.

Learn more about BOFA laser fume extraction systems here.

Alfex CNC Australia is proud to announce their partnership with American company, Kern Laser Systems. As the eminent manufacturer of laser cutting systems in North America for sign makers, plast...

December 28 2017

Alfex CNC Australia is proud to announce their partnership with American company, Kern Laser Systems. As the eminent manufacturer of laser cutting systems in North America for sign makers, plastic fabricators, visual graphic facilities, Kern Laser Systems has installed more than 1,000 laser systems worldwide. Alfex CNC’s broadened equipment distribution will give Australian companies the ability to use world-class laser systems that can be maintained locally.

Kern Laser Systems is a family owned and operated company that has been manufacturing laser cutting systems for the visual graphics industry since 1982. With a footprint across America, the United Kingdom, Middle East and now in Australia, Kern Laser Systems offers a range of work area solutions ranging from 600mm x 600mm right up to 3000mm x 2000mm and laser powers up to 400watts CO2 and soon to be released 1.5kW fiber machine.

Kern’s distribution partnership with Alfex CNC Australia is fitting given that both companies are established in the field and have extensive knowledge and expertise in laser equipment.

“The opportunity to work side by side with another family owned and operated business is especially appealing and fits solidly with our company values,” said Derek Kern, President, Kern Lasers.

Over the years Alfex CNC has extended its range on providing reliable products with exceptional customer service.

“Kern manufactures some of the best laser equipment in the world, and for Australian companies to have access to our extensive product range through Alfex CNC, is a perfect fit,” added Mr Kern.

The move broadens Alfex CNC’s reach in Australia by further establishing the credentials of being a distributor that offers only world class products backed by exceptional customer service in the Australian marketplace.

Alfex CNC’s team is welcoming the addition of Kern products to the company’s product range, along with the training and maintenance facilitation provided by Kern said Business Development Manager, Mr Christian Buhagiar.

For almost 40 years, Alfex CNC Australia has supplied the industry with the latest equipment and technologies from the world’s leading CNC machinery manufacturers. With a team of industry-leading service and technical support, Alfex CNC’s highly trained and dedicated staff have a proven track record for performance, reliability and exceptional after sale support.

“Our technicians are well trained and we anticipate the Australian market to welcome the Kern product range with open arms”, added Mr Buhagiar.

To learn more about Kern Laser Systems and other products offered by Alfex CNC Australia please click here