Nazdar releases 184 Series solvent inkjet ink Nazdar Ink Technologies has announced the 184 Series, a newly developed digital imaging ink formulated specifically as a high-performance ...

September 06 2018

Nazdar releases 184 Series solvent inkjet ink

Nazdar Ink Technologies has announced the 184 Series, a newly developed digital imaging ink formulated specifically as a high-performance alternative for Mimaki JV150/300 and CJV150/300 digital printers using Mimaki BS4 ink.

Nazdar 184 Series users will benefit from low odour and enjoy the convenience of a range of packaging options, including 600ml bags and 2000ml bags compatible with MBIS.

"The new Nazdar 184 Series exhibits outstanding performance, with excellent outdoor resistance to colour fade and chemical attack caused by UV degradation or environmental pollution," said Stephen Woodall, Nazdar Ink Technologies' Global Segment Manager - Aqueous & Solvent Digital. "We've developed an ink with excellent performance and adhesion on flexible and pressure sensitive vinyl, banner material, blue back paper and backed mesh."

For more information and technical data, visit the 184 Series web page or email product questions to InkAnswers@nazdar.com

Epson Introduces Dye-Sublimation Solution Optimised for Rigid Photo Applications Epson today announced a new solution designed for creating dye-sublimation photo panels and other rigid...

August 29 2018

Epson Introduces Dye-Sublimation Solution Optimised for Rigid Photo Applications

Epson today announced a new solution designed for creating dye-sublimation photo panels and other rigid substrates. New Epson DS Transfer Photo Paper, a high-quality, lightweight dye-sublimation transfer paper, combined with Epson SureColor® F-Series dye-sublimation printers, inks and Wasatch RIP support, creates a complete solution designed to produce rigid photos with advanced print quality and vibrant images with minimal grain, consistency and reliability.

Universal Woods, the world’s leading manufacturer of hard surface products for sublimation, has been using the new Epson solution – DS Transfer Photo Paper with the Epson SureColor F6200 printer on its ChromaLuxe panels. “The new DS Transfer Photo Paper was manufactured with ChromaLuxe in mind, and it addresses some of our main concerns with sublimating – texture and lack of sublimation dye around the outer areas of the aluminum photo panel,” said Josh Bender, sublimation specialist, ChromaLuxe. “This complete Epson dye-sublimation solution achieved a WIR Display Permanence Rating of 65 years1, the highest we’ve seen to date with ChromaLuxe prints.”

In addition, Image Wizards, the inventors of metal prints, has been using the new Epson transfer solution to create rigid photo prints. “The new Epson DS Transfer Photo Paper is the best dye-sublimation paper for rigid applications I have used,” said Roger K. Laudy, founder and president, Image Wizards. “In particular, the ink transfer onto metal prints on aluminum is amazing, with virtually no grain, as well as high ink transfer. This is easily the paper of choice for my customers.”

The new DS Transfer Photo Paper delivers excellent color gamut and black density, with reduced grain and mottling for smoother flesh tones and cleaner, lighter colors. In addition, it offers superb handling with almost no curl and warping under the heat of a flat press. The paper offers high ink transferability with slight transparency, which helps register the printed paper to the rigid substrate. Best used with the SureColor F6200, Wasatch SoftRIP version 7.6 offers full support for the DS Transfer Photo Paper for color management, print cost estimation and color profiles.

“This new paper is especially beneficial for the SureColor F6200 user who is producing high-quality photographic prints on ChromaLuxe plates,” said Tim Check, senior product manager, Professional Imaging, Epson America, Inc. “There are a lot of multipurpose transfer paper solutions available; this is one of the first that is specifically designed for rigid photo print quality – reducing grain to provide a more dynamic range of color.”

Pricing and Availability

The new DS Transfer Photo Paper is available now through Epson authorized Professional Imaging Resellers in three roll sizes for the following MSRPs:

- 17” x 300’ – $65

- 24” x 300’ – $89

- 44” x 300’ – $165

For additional information, visit www.proimaging.epson.com

Hop Industries Releases Hop-Syn GO Synthetic Paper Exclusively for HP Indigo Digital Presses Hop Industries, manufacturer of the durable Hop-Syn synthetic paper today announces the imm...

August 29 2018

Hop Industries Releases Hop-Syn GO Synthetic Paper Exclusively for HP Indigo Digital Presses

Hop Industries, manufacturer of the durable Hop-Syn synthetic paper today announces the immediate availability Hop-Syn GO, a new grade specifically designed for all models of the HP Indigo digital press. Environmentally-friendly and 100% recyclable, the Hop-Syn GO grade is a surface-treated, clay-coated, calendered polypropylene substrate. Its unique composition offers superb ink adhesion and high-quality graphic imaging unlike any other synthetic paper for the HP Indigo press.

Hop-Syn GO is 100% waterproof and is extremely scuff resistant, ideal for menus, identification cards, P-O-P signage, retail tags, and more. Competitively priced, Hop-Syn GO provides the durability, tear resistance, and weather resistant properties of polypropylene plastic with the print performance and efficiency of conventional paper.

“Our customers have been asking for a Hop-Syn grade made specifically for the HP Indigo press, and we delivered a substrate that outperforms all other synthetic papers in the market, both in quality output and price,” comments Jack Smith, Senior Vice President of Hop Industries. “Hop-Syn GO grade has been put through our rigorous R&D and field-tests. The feedback has been overwhelmingly positive. HP Indigo customers rave about the Hop-Syn GO’s high quality and boast about how easy it is to run.”

Hop-Syn GO synthetic paper produces vibrant imaging with 85-90% opacity. Its smooth matte finish is printable on both sides. Hop-Syn GO is UV resistant up to 3 months outdoors and can be scored and grommeted. Hop-Syn GO is available in stock sheet sizes including 12 x 18 in, 13 x 19 in, 20.5 x 29.5 in, and 55 in stock roll width.

Hop Industries stocks its full line of Hop-Syn synthetic paper in its NJ warehouse; all grades can be shipped within 24 hours. The company also offers In-house converting, slit rolls from 1-in up to 54-in, and custom sized sheets and quantities.

For questions or more information visit www.hopsyn.com

SAi Receives Software Certification for HP DesignJet Z6610 and DesignJet Z6810 Printers Salt Lake City, Utah, USA – SA International (SAi), the leading provider of softwar...

August 29 2018

SAi Receives Software Certification for HP DesignJet Z6610 and DesignJet Z6810 Printers

Salt Lake City, Utah, USA – SA International (SAi), the leading provider of software solutions for the signmaking, digital printing and CNC machining industries, today announces that its market-acclaimed SAi Flexi software solution is certified for use with both the HP DesignJet Z6610 and DesignJet Z6810 printers. The certification helps ensure print providers and sign & display companies to streamline their workflow, increase their throughput and guarantee premium quality output for their customers.

Applicable to FlexiPRINT, FlexiSIGN & PRINT, FlexiPRINT SE and HP FlexiPRINT edition v12, the certification officializes the software with HP’s stamp of approval and confirms that these Flexi solutions fully comply with its rigorous performance requirements for both DesignJet printers

Efficiency-Enhancing Tools

For users, this provides the assurance that the software will seamlessly integrate with their HP DesignJet printer without disruption to their print line.

The certification also offers those users who require advanced production tools – such as nesting, tiling and color management options – access to a catalogue of efficiency-enhancing tools. These include the ability to minimize material waste and maximize profit margins using Flexi’s new contour cut true shaping nesting tool. Users can precisely match the job spot colors with ease using Flexi’s spot color swatch tools.

Commenting on the certification, Eyal Friedman, Vice President, Technical Services at SAi, says, “As this certification demonstrates, our software solutions continue to perform at the highest level to equip print providers and sign & display companies with a multitude of business-enhancing tools.”

Designed as the world’s first and only all-in-one design, print and cut software solution, Flexi provides users with a comprehensive design-to-output workflow under one roof. Users have the choice to either purchase the software outright or via SAi’s subscription model. Subscribers have the financial flexibility to add extra licenses during peak periods as well as enjoy instant access to the latest upgrades.

Lexmark Launches Enhanced Retail Print and Digital Signage Solution Lexmark, a global imaging solutions leader, today introduced a new version of Lexmark Print and Digital Signage, a u...

August 16 2018

Lexmark Launches Enhanced Retail Print and Digital Signage Solution

Lexmark, a global imaging solutions leader, today introduced a new version of Lexmark Print and Digital Signage, a unique and powerful solution that automates the store signage and labeling processes, allowing retailers to easily print and publish quality, on-demand signs, labels and tags, freeing store staff to interact with customers. The latest version features enhanced mobile capabilities that allow store associates to make signage without leaving the sales floor, so customers get the attention they need to make buying decisions.

"Generating engaging and accurate in-store signage is a challenge for retailers across the globe, as stores struggle with price changes, pricing integrity, template management and waste," said John Linton, director, Lexmark Retail Industry Solutions. "We developed the Lexmark Print and Digital Signage solution to automate the in-store signage process, helping retailers quickly and easily develop engaging, accurate and on-brand signage so store staff can be on the sales floor with customers."

The Lexmark Print and Digital Signage solution is a proven enterprise solution for printing and publishing shelf-edge signs, labels and tags used in retail stores. The Lexmark Publishing Platform, which evolved from AccessVia software, uses one system to print paper signs from laser printers in the store, produce volumes of press-ready output for high-speed printing at a central location, and print electronic shelf labels, allowing brand consistency across all signs and reducing IT costs.

Solution benefits include:

New EFI Fiery DFE for Konica Minolta AccurioPress 6136 Series Delivers Best-in-Class Quality, Productivity and Workflow Integration Electronics For Imaging, Inc. (Nasdaq:EFII), and Kon...

August 16 2018

New EFI Fiery DFE for Konica Minolta AccurioPress 6136 Series Delivers Best-in-Class Quality, Productivity and Workflow Integration

Electronics For Imaging, Inc. (Nasdaq:EFII), and Konica Minolta Business Solutions U.S.A., Inc. announced a new EFI Fiery digital front end (DFE) designed to drive the AccurioPress 6136 series of monochrome digital presses from Konica Minolta.

Running on the latest EFI Fiery FS300 Pro software platform, the new EFI Fiery MIC-4160 external DFE is the first Fiery server for black-and-white print engines to launch on the new NX One server platform with Fiery QuickTouch. The new DFE is almost 50% faster than previous generations and is compatible with the innovative new Konica Minolta IQ-501 Intelligent Quality Optimizer for automated density control and accurate front-to-back registration. The latest Fiery Command WorkStation used with the DFE delivers a true unified job management interface for all Fiery Driven printers including cut-sheet, wide-format, superwide-format and high-speed inkjet devices.

“In-plants and commercial printing businesses need greater efficiencies to streamline their monochrome high-volume production operations and this new EFI Fiery DFE helps users get the most from their advanced AccurioPress 6136 investment,” said Kevin Kern, senior vice president, business intelligence services and product planning, Konica Minolta. “The DFE’s features help make users monochrome digital print workflows just as advanced as those found in high-end digital color print production.”

Free Fiery DFE training from EFI, found at the Learning@EFI site, will give AccurioPress 6136 series customers information to ensure they can use all the Fiery product features to the fullest extent possible.

New, bi-directional communication provides synchronized, real-time paper catalog updates that can be entered from either the press or the Fiery Command WorkStation interface, bringing operational flexibility to users, along with new paper tray assignment tools. Plus, the DFE’s Fiery QuickTouch display provides easy, automated backup and restore features. Optional EFI Fiery JobMaster software available with the DFE simplifies the process for creating manuals and other long documents with visual tools for tab insertion, scanning, image editing and media assignment.

End-to-end integration for greater efficiency

The new Fiery DFE also integrates into existing print production workflows through JDF implementation, which seamlessly connects with automated estimating, scheduling, job ticketing, accounting and other processes managed by EFI's suite of industry-leading MIS and web-to-print products, including EFI PrintSmith, Premium Pace and Enterprise Pace bundles for Konica Minolta.

In addition to built-in, industry-standard and certified JDF connectivity, Fiery API enables print service providers to rapidly develop live, bidirectional integration with their internally developed software or web services for their unique workflow automation needs. Fiery API is a REST (Representational State Transfer) application programming interface, allowing easy development regardless of application or software platforms including web browser, Windows, Mac, Linux, iOS, Android.

“We are pleased to continue our relationship with Konica Minolta in bringing this outstanding DFE to the AccurioPress 6136 series of monochrome printers,” said John Henze, vice president of Fiery marketing, EFI. “It not only gives users our latest production enhancements, it brings users all the efficiencies of our new NX One touchscreen display, giving users faster views of job status information and quick access to server management tools.”

The new Fiery DFEs run on Windows 10 and are available from Konica Minolta and authorised Konica Minolta resellers. For more information about EFI Fiery Driven products, visit www.efi.com

NESCHEN expands the colour range of the bestseller easy dot NESCHEN supplements its solvoprint easy dot colour range with the colours red, yellow, green, blue and a black variant. The ...

August 07 2018

NESCHEN expands the colour range of the bestseller easy dot

NESCHEN supplements its solvoprint easy dot colour range with the colours red, yellow, green, blue and a black variant. The company now offers its customers an extensive colour range for every design style, extending the easy dot range by the variants gold and silver.

This new range of colour foils is characterised above all by strong colour tones which create loud advertising messages on glass surfaces both in transmitted and incident light. The 100 µm PVC films are equipped with the special dot adhesive coating from NESCHEN. The structure of acrylate adhesive dots and air ducts running between them enables even inexperienced users to easily apply large motifs without bubbles and to subsequently correct the them. Solvoprint easy dot red, yellow, green, blue and black can be plotted and die-cut very well. The new colour films are therefore also ideal for e. g. lettering. In contrast to "normal" colour films, these coloured easy dot® media can be adhered quickly and easily. It does not require any drying time which would otherwise be urgently necessary for wet application. We recommend the application on the inside of the shop window which does not cloud the colour impression in any way.

Solvoprint easy dot can also be printed with (eco)solvent, latex and UV-curable inks if required. The new colour variants are now available in 137.2cm x 30m.

NUtec launches EFI GS & QS range of UV curable inks NUtec Digital Ink, a leading ink manufacturer producing water-based, UV curable and solvent printing inks, recently announced it...

August 07 2018

NUtec launches EFI GS & QS range of UV curable inks

NUtec Digital Ink, a leading ink manufacturer producing water-based, UV curable and solvent printing inks, recently announced its latest UV inks suitable for the EFI range of GS and QS printers.

NUtec’s Amethyst UV inks for EFI printers are available for roll to roll printers as the A50-RTR-EF or for hybrid printers as the A50-HYB-EF. Both ink versions offer superior colours, great reliability, excellent image quality and continued operating functionality.

The conversion from EFI original inks to one of the NUtec alternative inks is a smooth, hassle-free process due to NUtec’s specially designed bottle and adaptor. Developed in-house, the exclusive bottle design offers the unique ability to work across both 5 litre and 3 litre configurations for the GS and QS machines.

Neil Green, Sales and Marketing Director at NUtec notes, “EFI customers who have converted to our inks are particularly impressed with the colour and the physical properties of the inks especially as far as the adhesion and flexible attributes are concerned. These easy-to-install cost-effective UV inks, packaged exclusively for EFI printers, are fast gaining traction with satisfied customers around the world.”

NUtec’s alternative inks for the EFI GS and QS range of printers precede a comprehensive range of optimised UV inks soon to be launched by NUtec Digital Ink.

The new digitally printable HP Satin Wrapping Paper They say gift giving is an art, but with HP Satin Wrapping Paper, it means business! Print Service Providers can now cr...

August 07 2018

The new digitally printable HP Satin Wrapping Paper

They say gift giving is an art, but with HP Satin Wrapping Paper, it means business!

Print Service Providers can now create custom gift wrap with their HP PageWide XL, HP Latex or HP DesignJet Z series printers with little to no investment. Technology is making personalization widespread for a vast array of products and services. HP Satin Wrapping Paper allows consumers to personalize their gifts with photos, text and images for every occasion from Christmas, to weddings and birthdays, to Valentine’s Day and anniversaries. HP Satin Wrapping Paper provides a new profitable market opportunity.

Zach Ulivarri, General Manager of Color Reflections, Orlando, FL, believes there is a huge market for customizable wrapping paper. "We have tried in the past to emulate gift wrap, so having a product specifically designed for this application is really great and HP Satin Wrapping Paper runs beautifully on our Latex printers."

HP Satin Wrapping Paper provides excellent image quality at production speed. Not just for personal use either, HP Satin Wrapping Paper is perfect for corporate gifts, point-of-sale displays or posters. This recyclable*, FSC-certified* paper also meets environmental goals.

MACTAC LAUNCHES EASY TO USE JT 8300 DOT SERIES FOR SHORT TERM DECORATIONS Mactac, a leading brand of pressure sensitive graphic and decorative products from Europe, today announced the...

July 18 2018

MACTAC LAUNCHES EASY TO USE JT 8300 DOT SERIES FOR SHORT TERM DECORATIONS

Mactac, a leading brand of pressure sensitive graphic and decorative products from Europe, today announced the launch of the new JT 8300 Dot Series specially designed for short-term indoor advertising in Australia and New Zealand.

“Many frustrated employees of commercial spaces struggle to apply promotional graphics and we wanted to design an improved, easy-to-handle adhesive to solve this problem,” said Jordan Leach, business manager, Avery Dennison Graphic Solutions in Australia and New Zealand. “The Mactac JT 8300 Dot Series is the perfect choice for short-term promotions in commercial spaces as it offers quality in terms of creating striking designs without incurring extra costs related to professional installation.”

The Mactac JT 8300 Dot Series monomeric calendered PVC has a special dotted adhesive that allows fast application and removability while achieving a highly professional result. It has good adhesion power on glass, smooth flat surfaces as well as smooth door or painted surfaces and requires no water and application tools. It offers greater flexibility as it provides good printability on all main platforms.

This series is highly suitable for companies doing short term communication or advertising campaigns during festive seasons, or for discounts, promotional activities, product launches, exhibitions or trade shows.

With a reputation spanning over 50 years, Mactac products undergo strict quality control and are highly appreciated for their proven consistent product quality. Mactac has the strong backing of prestigious brands in areas ranging from architecture, interior design, signage and marking, transport to advertising.

www.mactacgraphics.eu

.png)

NUtec to introduce GBL-free solvent ink range Global supplier, NUtec Digital Ink is expanding its Diamond eco-solvent product offering with new GBL-free ink versions. This move s...

July 13 2018

NUtec to introduce GBL-free solvent ink range

Global supplier, NUtec Digital Ink is expanding its Diamond eco-solvent product offering with new GBL-free ink versions. This move supports NUtec’s new product strategy which includes the introduction of more environmentally and operator- friendly digital ink alternatives for its worldwide customers.

The Diamond GBL-free range will include the D10-GF-MS21 which will be chemically & colour matched to Mimaki® SS21 and designed as a back to back replacement, while the D10-GF-ESM will be chemically & colour matched to Roland Eco-Sol MAX™ inks.

A key feature of the GBL-free Diamond ink range is that no flushing or profiling will be required when converting from OEM inks. It will also be a low smell ink with excellent outdoor durability, superior abrasion and chemical resistance.

The Diamond range will provide excellent media compatibility across a broad range of self-adhesive and flexible substrates. All NUtec’s ink products are supported by NUtec Digital's Ink Delivery System Warranty.

NUtec also offers its customers a HAPs-free ink alternative through its Emerald range of Environment Responsible Product or ‘ERP’ inks. Both the Diamond GBL-free and the Emerald solvent ink ranges eliminates the use of controlled or restricted substances as defined in specific regions and countries.

Technical Director of NUtec, Paul Geldenhuys notes, “NUtec is continually working on alternative versions of traditional ink chemistries to ensure a healthier, cleaner environment for its customers. The Diamond GBL-free and Emerald ERP ranges are prime examples of these developments which are being welcomed by NUtec customers worldwide.”

For more information on the company, its products and its people, visit www.nutecdigital.com

.png)

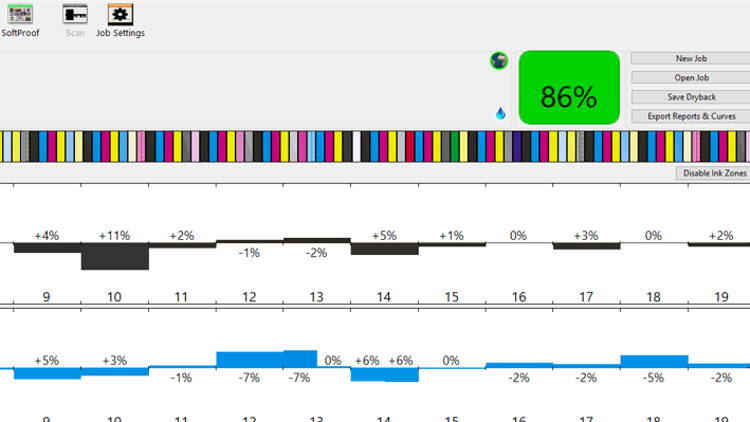

Agfa Graphics announces the release of InkTune and PressTune software to reduce the production costs. These intelligent tools are part of Agfa Graphics’ ECO³ offering and gi...

July 10 2018

Agfa Graphics announces the release of InkTune and PressTune software to reduce the production costs.

These intelligent tools are part of Agfa Graphics’ ECO³ offering and give print houses complete control over all printing elements, from ink use to compliance with ISO, G7 and client-specific standards, while reducing production costs. Real-time data insights into print quality drive these capabilities, independent of printing technology and press manufacturer.

InkTune and PressTune are crucial elements of Agfa Graphics’ ECO³ program. In designing and creating solutions based on hardware, software and consumables, Agfa Graphics focuses on ecology, economy, and extra convenience (ECO³) to make prepress and printing operations cleaner, more cost-effective and easier to manage and maintain. The ECO³ solutions drive extra value to printing businesses.

InkTune: cost savings plus quality boosts

Building on grey component replacement (GCR) technology, InkTune dynamically substitutes CMY inks with black ink. As an intuitive software solution that is fully integrated into the prepress workflow, InkTune uses Agfa unique technology such as Dynamic Ink Limit Control and Dynamic Device Link Generation to maximize ink reduction up to 30%, while maintaining color fidelity. The reduction of ink not only has a positive cost savings impact, it also increases overall production efficiency as the drying time is reduced. Furthermore, quality levels increase as rosette structures disappear and color deviations become less visible.

“InkTune eliminates the choice between the reduction of ink, time, and drying powder on the one hand, and high-quality prints on the other hand. Customers can achieve all these benefits through the software’s built-in intelligent adjustment of ink consumption. InkTune allows them to shorten press setup times, as well as to cut costs of all print-related resources, achieving the lowest total cost of ownership on the market. It is easily set up and requires no additional investment in training or hardware,” asserts Erik Peeters, Global Marketing Manager Software Solutions at Agfa Graphics.

PressTune: a new benchmark in smart print process control

As a print production tool, PressTune drives consistency, productivity and the ability to print to exacting standards. As the required print quality standard is reached faster by means of dynamic ink density adjustment and a data-driven scoring mechanism incorporating dry-back compensation, make-ready times get reduced by up to 40% – which in turn leads to less waste.

Through intelligent analytics capabilities applied to print and color data obtained from the press, PressTune also reports in real time across printing technologies to each stakeholder, for full transparency of the print production process. It enables issue identification and optimized press maintenance scheduling. Even more, the solution’s easy-to-read dashboard makes it simple to generate print quality reports for brand owners in packaging and commercial print and allows for remote quality assurance.

“Together, PressTune and InkTune enable significant cost savings by reducing ink use, boosting quality and accelerating your production workflow,” continues Erik Peeters. “In fact, PressTune provides InkTune with the perfect foundation to optimize ink consumption by delivering quality consistence. Both PressTune and InkTune are central to our ECO³ offering, embodying sustainable innovation that focuses on ecology, economy, and extra convenience for the customer.”

Complementary solutions in action

Imprimeries et Editions Henry, a print house in Montreuil-sur-Mer with a 120-year history, recently worked alongside consultants from Agfa Graphics to take its print processes to the next level. Already relying on an Avalon system, Azura plates and Agfa Graphics’ Apogee workflow, the firm recently installed both PressTune and InkTune.

“PressTune and InkTune have enabled us to obtain a higher consistency throughout our print runs,” says Marc Henry at Imprimeries et Editions Henry. “We have reduced our make-ready times, we use less paper and ink, and we can adapt printer calibration curves according to paper, print job or customer-specific demands. Agfa Graphics’ solutions have brought us a more convenient way of working.”

.png)

NUtec to introduce GBL-free solvent ink range Global supplier, NUtec Digital Ink is expanding its Diamond eco-solvent product offering with new GBL-free ink versions. This move s...

June 29 2018

NUtec to introduce GBL-free solvent ink range

Global supplier, NUtec Digital Ink is expanding its Diamond eco-solvent product offering with new GBL-free ink versions. This move supports NUtec’s new product strategy which includes the introduction of more environmentally and operator- friendly digital ink alternatives for its worldwide customers.

The Diamond GBL-free range will include the D10-GF-MS21 which will be chemically & colour matched to Mimaki® SS21 and designed as a back to back replacement, while the D10-GF-ESM will be chemically & colour matched to Roland Eco-Sol MAX™ inks.

A key feature of the GBL-free Diamond ink range is that no flushing or profiling will be required when converting from OEM inks. It will also be a low smell ink with excellent outdoor durability, superior abrasion and chemical resistance.

The Diamond range will provide excellent media compatibility across a broad range of self-adhesive and flexible substrates. All NUtec’s ink products are supported by NUtec Digital's Ink Delivery System Warranty.

NUtec also offers its customers a HAPs-free ink alternative through its Emerald range of Environment Responsible Product or ‘ERP’ inks. Both the Diamond GBL-free and the Emerald solvent ink ranges eliminates the use of controlled or restricted substances as defined in specific regions and countries.

Technical Director of NUtec, Paul Geldenhuys notes, “NUtec is continually working on alternative versions of traditional ink chemistries to ensure a healthier, cleaner environment for its customers. The Diamond GBL-free and Emerald ERP ranges are prime examples of these developments which are being welcomed by NUtec customers worldwide.”

For more information on the company, its products and its people, visit www.nutecdigital.com

Roland DG's Dye Sublimation Inks Earn ChromaLuxe Certification for Outdoor Durability Roland DG Australia, a leading manufacturer of wide format inkjet printers and 3D devices, ...

June 29 2018

Roland DG's Dye Sublimation Inks Earn ChromaLuxe Certification for Outdoor Durability

Roland DG Australia, a leading manufacturer of wide format inkjet printers and 3D devices, has announced that its Texart™ SBL3 dye sublimation inks have earned certification from ChromaLuxe® for outdoor durability. This certification assures users that they can expect optimum quality and durability when transfer graphics are printed with Texart SBL3 inks and sublimated to ChromaLuxe EXT (Extended Life) UV-resistant photo panels.

In addition to the certification, Chromaluxe is backing up the UV resistance and expected outdoor life of graphics printed with Texart inks and transferred to ChromaLuxe EXT with a two-year warranty on photography-based output and a three-year warranty on signage-based output.

This certification from ChromaLuxe applies to all standard Texart SBL3 inks, which are available in 4-colour or 8-colour configurations with CMYK, Light Cyan, Light Magenta, Orange, and Violet. Designed to bring out the best in Roland DG’s advanced Texart RT-640 and XT-640 dye sublimation printers, SBL3 inks are ideal for creating vibrant sublimated signage, apparel, accessories and hard goods. In addition to producing rich, durable graphics, these water-based, fast-drying inks contain a high concentration of dyes, which allows for reduced ink usage while retaining maximum vibrancy.

“The ChromaLuxe certification and warranties provide assurance to Texart series users that their graphics sublimated to ChromaLuxe EXT panels will stand up to powerful UV rays and the elements,” said Lily Hunter, Roland DGA Product Manager, Textiles and Consumables. “They get the best of both worlds – colourful, vibrant graphics and the very best outdoor durability possible.”

For additional information on Roland Texart SBL3 dye sublimation inks, visit

https://www.rolanddg.com.au/products/inks/roland-texart-sbl3-dye-sublimation-inks

Océ Launches New Touchstone Dimensional Printing Software Realizing the appeal that dimensional printing can have in the graphics market, Canon U.S.A., Inc. announced the...

June 25 2018

Océ Launches New Touchstone Dimensional Printing Software

Realizing the appeal that dimensional printing can have in the graphics market, Canon U.S.A., Inc. announced the launch of Océ Touchstone dimensional printing software, positioned for large-format print solutions to streamline dimensional printing on the company’s Océ Arizona Series UV flatbed printers. Until now, creating these dimensional prints tended to be a laborious process involving significant file manipulation and iterative testing performed by the print provider. As a result, few end users are aware that this is even possible, let alone request this type of printing. To simplify this labor intensive workflow, Canon has tailored specific solutions to meet the needs of the two parties involved in the process: the designer who creates the files and the print provider that prints them.

Utilizing the highly-accurate ink drop placement and repetition provided by Océ Arizona UV curable flatbed printers, resourceful print providers have been able to print multiple layers of ink and produce dimensional effects ranging from common textures such as woodgrain to special effects such as varnish highlights, embossed type and logos or even braille.

“Our commitment to our customers and the drive to expand our large format capabilities, has led to the development of the Océ Touchstone Dimensional Printing Software,” says Toyotsugu Kuwamura, EVP and general manager, Business Imaging Solutions Group, Canon U.S.A., Inc. “We are thrilled to introduce this simple solution that will help print providers improve their workflow and create new possibilities for both their organizations and their customers.”

Through Canon-created Adobe CC Photoshop and Illustrator extensions, graphic designers can build the dimensional effects quickly and easily, preview and refine these effects on screen and then export the file as a single PDF file that can be sent to an Océ Touchstone enabled print provider for final print production.

To help streamline the process on the print production side, Canon worked closely with graphics RIP provider ONYX, a Canon group company, to marry the patented Océ ALPS (Advanced Layer Printing System) technology with a special ONYX Thrive printer driver so that the RIP could now interpret the height map contained within the PDF, convert that data into separate print layers and send it to the Océ Arizona printer as a single batch file containing all the layers in the correct print sequence. This provides the print provider with a familiar print workflow where they can print the entire job essentially with one push of the print button. Carriage height adjustment is automated and the multiple layers can be left to print unattended, thus enabling print providers to make additional revenue after business hours.

The commercially licensed Océ Touchstone software is offered exclusively by Canon Solutions America and available now. The software requires ONYX Thrive 12.2 or a newer edition and an Océ Arizona 1260, 1280 or 2200 series printer to use. The Adobe CC Océ Extensions are available for both Microsoft Windows and Mac OS operating systems.

Orafol has introduced a number of new printable films They are: - Orajet 3952F - a cast and highly transparent film with long-term durability and easy application.&...

May 31 2018

Orafol has introduced a number of new printable films

They are:

- Orajet 3952F - a cast and highly transparent film with long-term durability and easy application.

- Orajet 3851 - a digitally printable etched glass film for long term applications.

- Oracal 970 Premium Special Effect Cast - now with eight colours

- Oracal 351 - rose gold has been added and is available in 50 micron thickness.

- Oracal 7710 Fluorescent Premium Cast Plus - developed for application onto emergency services vehicles, this film comes in fluorescent yellow and red.

- Oraguard 244G Anti-Graffiti Film - UV resistant and can be cleaned without reducing its effectiveness.

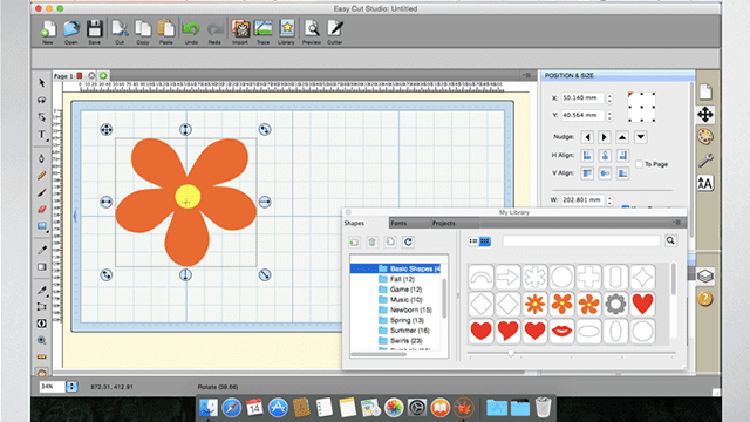

Worldwide availability of Easy Cut Studio version 4.1.03. EasyCut Studio, the leading provider of vinyl cutting software solutions dedicated for the professional sign making and...

May 31 2018

Worldwide availability of Easy Cut Studio version 4.1.03.

EasyCut Studio, the leading provider of vinyl cutting software solutions dedicated for the professional sign making and sign production processes, has announced the launch and worldwide availability of Easy Cut Studio version 4.1.03. the latest version of Easy Cut Studio includes many new vinyl cutters supported, like Mutoh ValueCut Series, Fenta, Roland GS and etc.

In addition, The new version features enhanced SVG support , Text to Outlines conversion capabilities, and the ability to work on multiple layers at once among its improvements.

Complete layout, design, text and production features for all of your sign making needs, Easy Cut Studio is the top-of-the line sign design & cutting software for macOS and Windows on the market today. Includes professional cutting tools to design, print and cut all types of graphics. Comes with many features for fast cutting. It supports many popular vinyl cutting plotters of well-known brands. Fully compatible with Windows 10 and the latest macOS 10.13. New cutting plotter drivers are being added continuously in Easy Cut Studio.

Easy Cut Studio v4.1.03 includes dozens of new features including the following:

Added support for Mutoh ValueCut Series;

Added support for Fenta SL440, SL740 and SL1320 vinyl cutters;

Added support for Roland GS cutter;

Fixed FCM batch convert error;

Fully compatible with the latest macOS 10.13.4.

Other improvements and bug fixes.

Pricing and availability:

Easy Cut Studio version 4.1.03 is compatible with both macOS and Windows. The upgrade is available to all current Easy Cut Studio users at no charge. New users can get all the features and updates for $59.95 ($10 off) for a limited time with lifetime free upgrades.

Andretti Autosport wins with ONYX Thrive Watch how ONYX RI{ software products help Andretti Motorsport.

May 27 2018

.jpg)

Sun Chemical marks 200th anniversary Throughout the remainder of 2018, Sun Chemical will celebrate its 200th anniversary. Sun Chemical claims itself as the f...

May 27 2018

Sun Chemical marks 200th anniversary

Throughout the remainder of 2018, Sun Chemical will celebrate its 200th anniversary.

Sun Chemical claims itself as the first to develop UV inks, water-based inks, pigmented flexo inks and flexo inks for polyethylene films, as well as the creator of the four-color wet process ink system in 1906, now commonly known as CMYK printing.

Sun Chemical has been manufacturing pigments since 1907. Today, the Performance Pigments division offers an array of pigments, effects and preparations for the coatings, cosmetics, plastics, inks and specialties markets. Continuous innovation in new color space and providing unique colors and effects into a variety of existing and new markets, has enabled global growth.

With DIC Corporation’s acquisition of the company in 1987, Sun Chemical became a truly global company, with growth within the Latin American and Middle Eastern markets and the formation of the Advanced Materials division, which delivers compounds, polymers and application materials to broad markets.

‘Beginning with the inspiring legacy of Lorilleux and Samuel Morris in the early 1800s, Sun Chemical has delivered 200 years of color expertise, innovative technology and an ongoing commitment to quality and service for our customers,’ said Rudi Lenz, Sun Chemical president and CEO. ‘Having held close to 10,000 worldwide trademarks and over 3,000 granted patents in various global jurisdictions in its history, Sun Chemical takes pride in producing solutions tailor-made to meet the individual needs of our customers.

‘Sun Chemical’s vision has been and will always be to help customers take on the global challenges of the future by providing quality, service and innovation in every solution we deliver. For the future, we are committed to pursuing research and development that will bring our customers new innovative and sustainable solutions. We look forward to celebrating this ongoing commitment to excellence as a company and with our customers this year.’

Esko has announced a new release of its packaging management solution, WebCenter. WebCenter 18 streamlines and speeds up the ...

April 21 2018

Esko has announced a new release of its packaging management solution, WebCenter. WebCenter 18 streamlines and speeds up the packaging development workflow by delivering extra features that give brand owners and converters more control and visibility of their packaging preproduction specification, approval and project life cycle.

When CMO Council asked packaging professionals how long it takes to make a packaging change, they reported that changes take an average of about 198 days. Marketing leaders think it takes 90 days or less, but consumers don’t understand why packaging changes and other physical media can’t be made in one day. WebCenter 18 helps its users to get much closer to that one-day standard.

The review and approval process with WebCenter has been improved, enabling more visibility into project status and reviewer input. With WebCenter 18, brand owners now understand the root causes of any bottlenecks, as it now captures the reasons for rejection and the number of approval iterations, allowing for ongoing process improvement. It can also automatically involve the right stakeholder after a rejection, speeding up the revision process.

What’s more, reviewers can now review the product exactly as it would be on the shelf. This improves the accuracy of the review feedback and so further reduce approval times and number of iterations. The 3D packaging models can then also be used to clearly communicate internally, but also to populate and market with retailers and consumers online.

WebCenter 18 content management now includes built-in and custom templates, so users efficiently comply with regulations such as Nutrition Fact Tables and Over the Counter Drug Facts. The Graphic Content Management functionality allows brand owners to centralize artwork data, and merging it into templates, including the logging of symbols, logos and bar codes, as well as packaging copy and graphics. These elements must be perfect for branding and regulatory compliance, and this process completely removes manual processes that lead to mistakes. Translations within and outside of the system can be managed systematically, as well.

The new WebCenter is designed to give converters an edge by including exactly those new features that give them valuable insights into their processes. Capturing data around the number of approval iterations and the reasons for rejections are two examples of how WebCenter 18 uncovers bottlenecks and root causes of delays in the process. These insights provide a basis for continuous improvement of the processes to further speed up turnaround times.

WebCenter 18 also comes with a social media-like instant messaging function, which can be utilized inside the context of a specific project. All communication is therefore stored inside the project for full traceability and transparency. This further streamlines communication between stakeholders and results in a greater reduction of errors and increased efficiency.

In addition, reviewers now review the product exactly as it would be on the shelf. This 3D review process significantly reduces approval time and iterations and lets converters catch more errors.

Deploying in only five days delivers immediate business impact after The “QuickStart” versions of WebCenter are available to allow organizations to implement the tool in less than five days with proven and expert workflows ready to use. This way, the “QuickStart” versions deliver instant benefits in project management, data management, the approval process and data automation.

“Packaging is an ever more important part of almost all consumer goods, from food to electronics, and it plays an even greater role as consumer awareness and demand increases. WebCenter is already the leading packaging management platform used by Fortune 500 companies that are active in the CPG and pharma industries, as well as converters and packaging printers. The feedback from our early users has been overwhelmingly positive. With this new version, Esko has the most powerful solution that ties the entire supply chain together,” says Udo Panenka, president of Esko.