High productivity, high image quality, and ability to print on various media MUTOH INDUSTRIES LTD., a leading manufacturer of wide-format inkjet printers, affil...

August 01 2023

High productivity, high image quality, and ability to print on various media

MUTOH INDUSTRIES LTD., a leading manufacturer of wide-format inkjet printers, affiliated with MUTOH HOLDINGS CO., LTD. today announces the release of the XpertJet 1462UF, a flatbed UV-LED printer with a table size of 1,420 mm (55.9”) x 700 mm (27.5”), which combines high productivity and high image quality to meet diverse user needs.

The XpertJet 1462UF is equipped with two newly developed 4-inch UV-LED lamps and staggered dual print heads with independent CMYK and white/varnish for faster two-layer printing.

The highly rigid and precise chassis and MUTOH's unique alluminum rail mechanism deliver high ink dot placement accuracy.

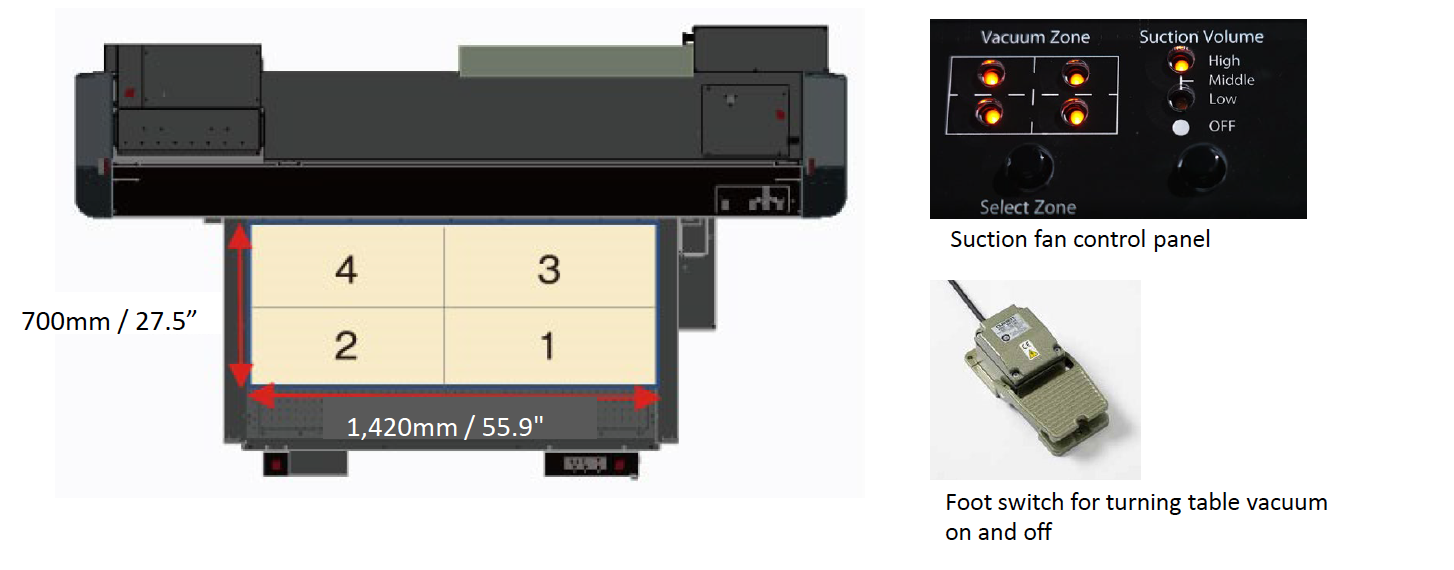

The printer supports media up to 1,420 mm (55.9”) x 700 mm (27.5”), 150mm (5.9”) thick, and 50 kg/m2 in weight. The table unit is equipped with a 4 zone vacuum table with 4-stage suction force control, and service holes for fixing jigs, allowing greater flexibility in media selection.

The XpertJet 1462UF brings the best "Made in Japan Quality" to various markets such as personalised items, store decoration, sign, industrial products and more.

Key Features of the XpertJet 1462UF

Both high productivity and high image quality in bi-directional printing enable faster 2-layer printing

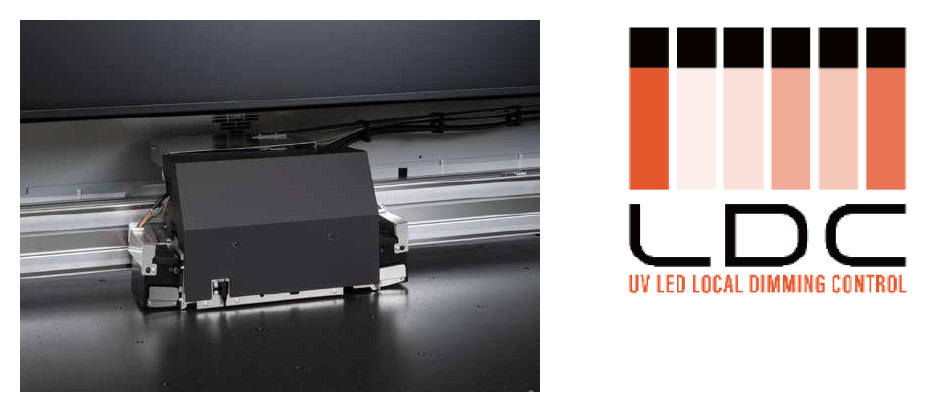

- Two new 4” wide UV LED lamps

Newly developed 4-inch wide UV-LED lamps are placed on both sides of the print head. Combined with "UV-LED local dimming control technology," which individually controls the UV-LED lamp irradiation for each segment according to the printing conditions, it achieves optimal ink curing even in bi-directional printing.

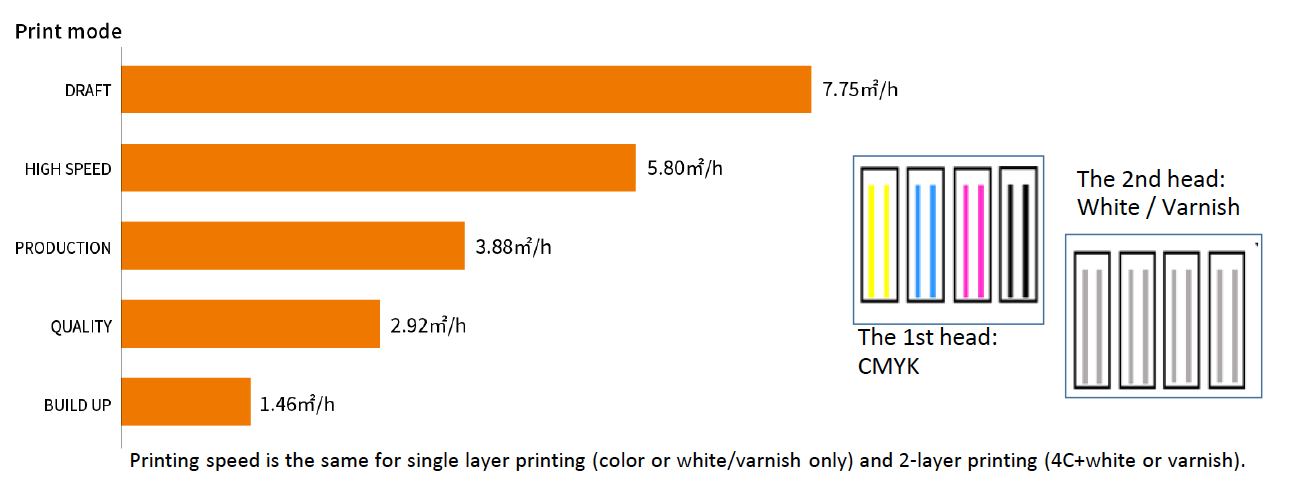

Dual print heads in a staggered setup

Staggered dual printheads ensure high-productivity. The first head prints CMYK, the second head prints white/ varnish, which enable 2-layer printing without speed loss. It is ideal for braille and 2.5D structure prints.*ADA-compliant Braille printing will be supported in NorthAmerica.

Highly rigid & high-precision chassis

Highly rigid and precise chassis and adjustment of MUTOH’s high precision alluminum rail mechanism deliver high ink dot placement accuracy.It enables stable and high-quality printing.

4 zone vacuum table

The XpertJet 1462UF has both sufficient table area and strength, it is capable of printing on heavy or thick media. The media size of 1,420mmx700mm (55.9”x27.5”) supports a wide range of applications from large signage to small print runs . It improves productivity and shortening delivery time. The 4-zone vacuum table can be configured for single or multi area vacuum suction securing virtually any media in place. Select from four levels of suction force (strong, medium, low, and off).

Designed for ease of use to improve operability

Table function for easy media fixation

Suction holes and pre-drilled holes outside the print able area can be used to secure custom jigs. In addition, unique ferro magnetic table easily secures a variety of products with magnets.

The simple nozzle check function

Even after the jig and media to be printed are set on the table, nozzle check can be performed at anytime in a dedicated area next to the print table.

Other key features of the XpertJet 1462UF are as follows.

Ease of use Signal tower light - The status of the printer can be checked at a glance from a distance.

Automatic nozzle checking unit - Automatically detects missing nozzles and performs nozzle cleaning.

Nozzle area select - Nozzle area select temporarily prints using selected areas of active nozzles when clogged nozzles fail to recover.

Automatic media detection - The onboard laser sensor automatically detects media thickness.

Ink circulation system - Three circulating pumps for white, black and yellow inks are installed to ensure stable colour reproduction.

Ionizer (optional) - Optional ionizer neutralises static charges on the media surface to support stable printing.

MUTOH genuine RIP software VerteLith - Genuine RIP software that achieves unmatched image quality and workflow efficiency.

Megnajet has launched the JetSource HFR Core, a new fluid management system designed to meet the challenges of high-volume, inkjet printing and additive manufacturing applications....

July 25 2023

Megnajet has launched the JetSource HFR Core, a new fluid management system designed to meet the challenges of high-volume, inkjet printing and additive manufacturing applications.

Developed in response to the increasing industry demand for jetting large volumes of fluid, Megnajet’s latest fluid management system recirculates fluid at up to four litres per minute across up to five independent ports for printheads.

In addition, the JetSource incorporates an impressive system architecture which minimises any restrictions and enables peak flow rates to be achieved, thereby maintaining print system productivity.

This innovation in inkjet fluid management systems helps OEMs and integrators to overcome the common challenges in jetting large volumes of fluids. The system provides accurate, high-quality results across a range of applications including labelling and packaging embellishments, special varnish effects, braille and high-build 3D printing.

Optimised tank volumes ensure continuous availability of conditioned fluids with the advanced dual heating and sensing system providing precise temperature regulation for jetting.

Pressure stabilisation is also guaranteed with the JetSource HFR Core, providing a fast response to changes in print duty and maintaining control when ejecting large volumes of fluid. Thanks to a compressed air venturi system, it can react quickly and accurately to deliver high quality print regardless of the duty cycle.

Easily integrated to customers’ inkjet systems, its compact nature and ease of use make the JetSource HFR Core the ideal fluid management solution in high volume applications. Units can also be customised to suit specific fluid types, including the use of alternate body materials such as FDA approved food grade acetal or a choice of gasket materials and customisations to user software.

The launch of the JetSource HFR Core opens up the opportunity for OEMs to take advantage of the benefits of high productivity printheads and printbar-based architecture, without having to invest in developing their own solution.

Mike Seal, General Manager at Megnajet said, “We’re delighted to launch the JetSource HFR Core as it meets the growing demand to precisely and accurately control large volumes of fluid across high productivity printheads.

“JetSource will help our customers to access the many opportunities of high-volume inkjet applications, delivering print quality that is essential to their success, while saving them time, effort and resources in having to develop their own standalone solution.”

May 09 2023

Print service providers can benefit from increased flexibility with the Flex RTR module, which doesn’t need undocking when transitioning from rolls to boards or sheets. This improves printer uptime and maximizes print production efficiency. The module marks the next step in the Tauro’s automation story, focusing on the optimal utilisation of this hybrid printing solution’s versatility.

“Automation is at the core of our inkjet printing solutions development track,” says Dieter Jancart, Segment Manager for high-end inkjet systems at Agfa. “Depending on a company’s specific job types and printing requirements, we will offer a tailored solution that will ensure the most efficient handling of their workload, regardless of whether it involves rigid or flexible substrates, or a combination of both.”

The Flex RTR was developed to match the one-pass printing mode on the Tauro H3300 UHS LED, up to a printing speed of 905 m²/h. It has a compact footprint and is ergonomic and user-friendly. With the simple press of a button, the dancer rolls controlling media tension move upward, enabling quick and effortless loading of the media by a single operator.

With the ability to handle both single- and dual-roll printing, the Flex RTR module can accommodate widths of up to 3.3 m and 1.6 m, respectively, with a maximum roll diameter of 400 mm and a weight of 450 kg for each roll. Switching from single- to dual-roll printing and back is a quick and straightforward process that can be accomplished by a single operator. The dancer rolls do not need to be removed or reinstalled but can remain in place during the changeover.

To ensure accurate double-sided printing, the integrated camera system reads QR codes generated by the printer’s user interface to pinpoint the exact image location and adjust the print position at the start of each job. If printing on the back side is unexpectedly halted, the camera system will identify which image needs to be printed, so that production can resume rapidly and flawlessly.

The new Flex RTR module is available as of this moment for all Tauro H3300 LED printers.

Vastex International have expanded their line of l...

April 25 2023

Vastex International have expanded their line of low wattage, high efficiency dryers for curing of DTG-printed inks and pretreatment, and water-based screen-printed inks and discharge, at high rates using 20 percent less energy than comparable dryers.

The new Lo-E1D model with 46 cm long heating chamber and 2.85 kW of power draws 12.5 amps at 230V, curing up to 23 garments/h printed with digital white ink at 3 minutes dwell time, or 64 garments/h with DTG pretreatment only or water-based inks at one minute dwell time.

The new Lo-E3D model with 132 cm long heating chamber and 6.35 kW of power draws 38 amps at 230V, or just 10 amps at 400V, 3 phase, and cures up to 64 garments/h with digital white ink at 3 minutes dwell time, or 180 garments/h with DTG pretreatment or water-based inks at one minute dwell time.

"We engineered the new models for energy conscious-printers having lower or higher capacity requirements than satisfied by our first Lo-E2D dryer, which gained immediate acceptance following its 2022 introduction," says Vasilantone. With a 89 cm long heating chamber and 4.6 kW of power drawing 22 amps at 230V, that model cures up to 45 garments/h with digital white ink at 3 minutes dwell time, or 88 garments/h with DTG pretreatment or water-based inks at one minute dwell time.

All Lo-E models are equipped as standard with a 76 cm wide conveyor belt that runs true by means of a low friction belt aligner patented by the company, with belt speed controls allowing infinitely adjustable dwell times from one to five minutes.

The Lo-E2D and Lo-E3D models come equipped with a 224 cm conveyor belt length and a 10.5 m3/min. exhaust system that evacuates moisture and air contaminates from the heating chamber, and cools the enclosure's outer skin and control panel. The Lo-E1D has a 122 cm conveyor length and a 7.9 m3/min. exhaust system.

Height-adjustable heaters offer dual zone temperature control with a boost zone to quickly reach cure temperatures, and carry an industry-leading 15-year warranty.

As with all Vastex floor-standing conveyor dryers, the modular design of the low energy models enables users to add one or more heating chambers and extend the conveyor belt, multiplying capacity in direct proportion to each heating chamber added. Conveyor extensions can also be added to the infeed or outfeed of the dryer to optimize loading and cooling/unloading of garments.

The company also produce mid- and high-capacity dryers for DTG, DTF and screen-printing applications, as well as commercial-grade and entry-level manual screen printing presses, flash cure units, screen exposing units, screen drying cabinets, washout booths and complete screen printing shop systems, and offers a comprehensive range of training classes for entry level, intermediate and advanced screen printers.

For information contact Vastex International, Inc., +1 610 625 2702, sales@vastex.com, www.vastex.com

Roland DG Corporation, a leading manufacturer of wide-format inkjet printers and printer cutters worldwide, announced today the launch of a new VersaOBJECT brand of products capable of printing brilliant colour directly on a wide variety of three-dimensional objects. The lineup adds six CO models to its series of large-format UV-LED flatbed inkjet printers, four with fixed flatbed tables and two with belt systems, providing users with a host of options.

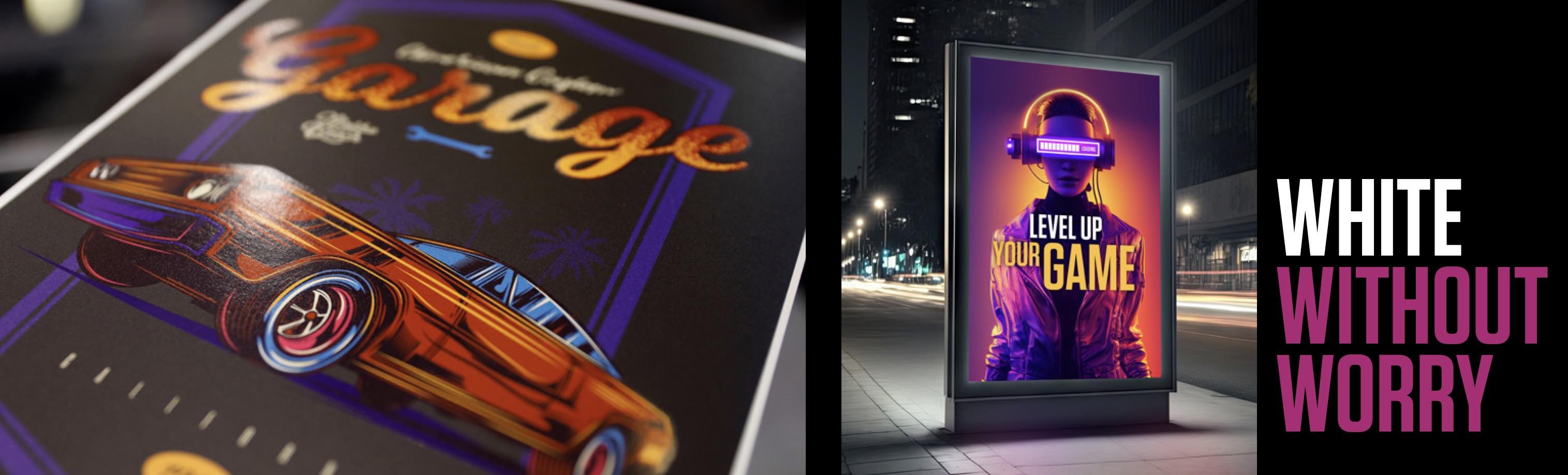

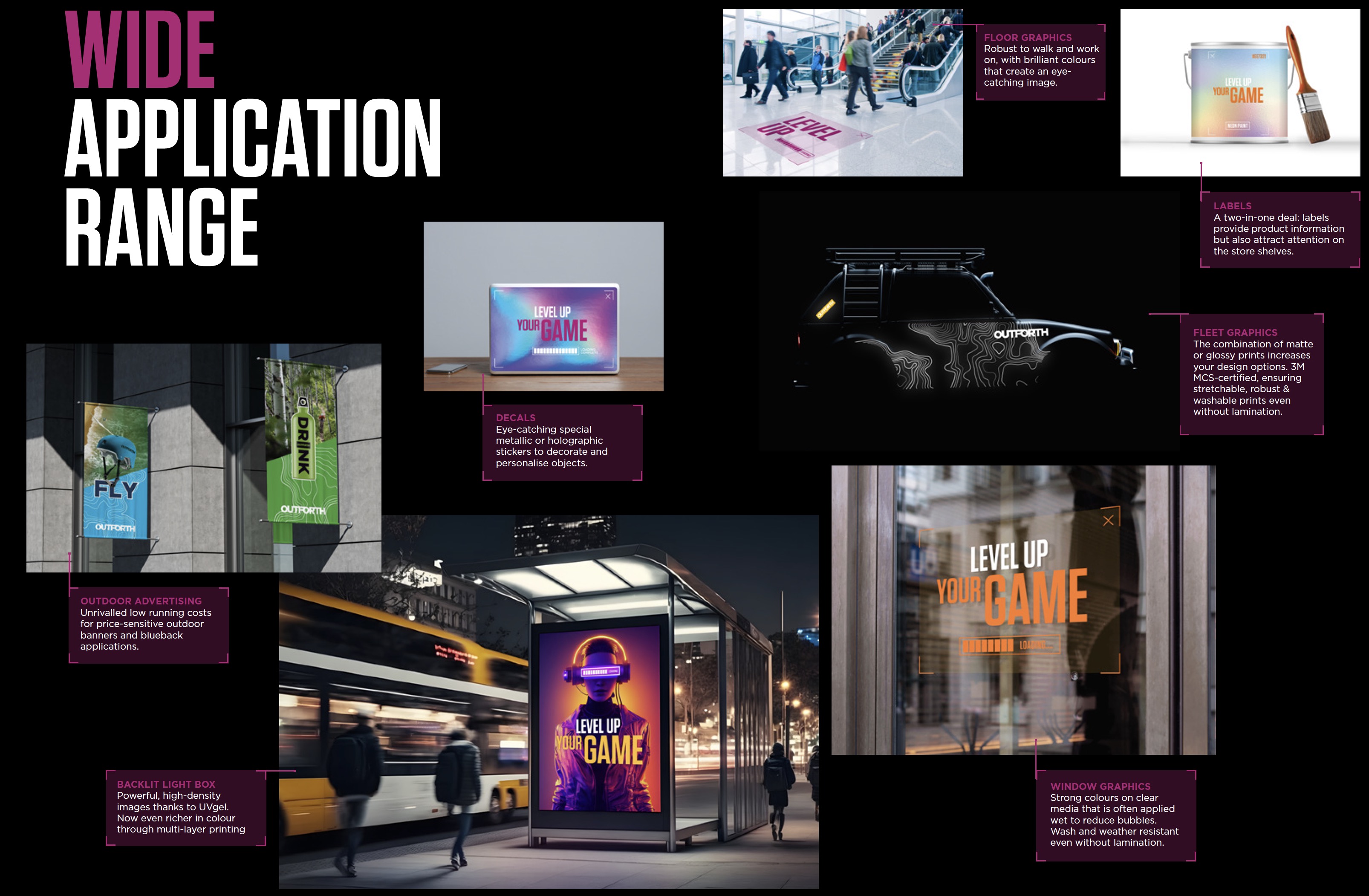

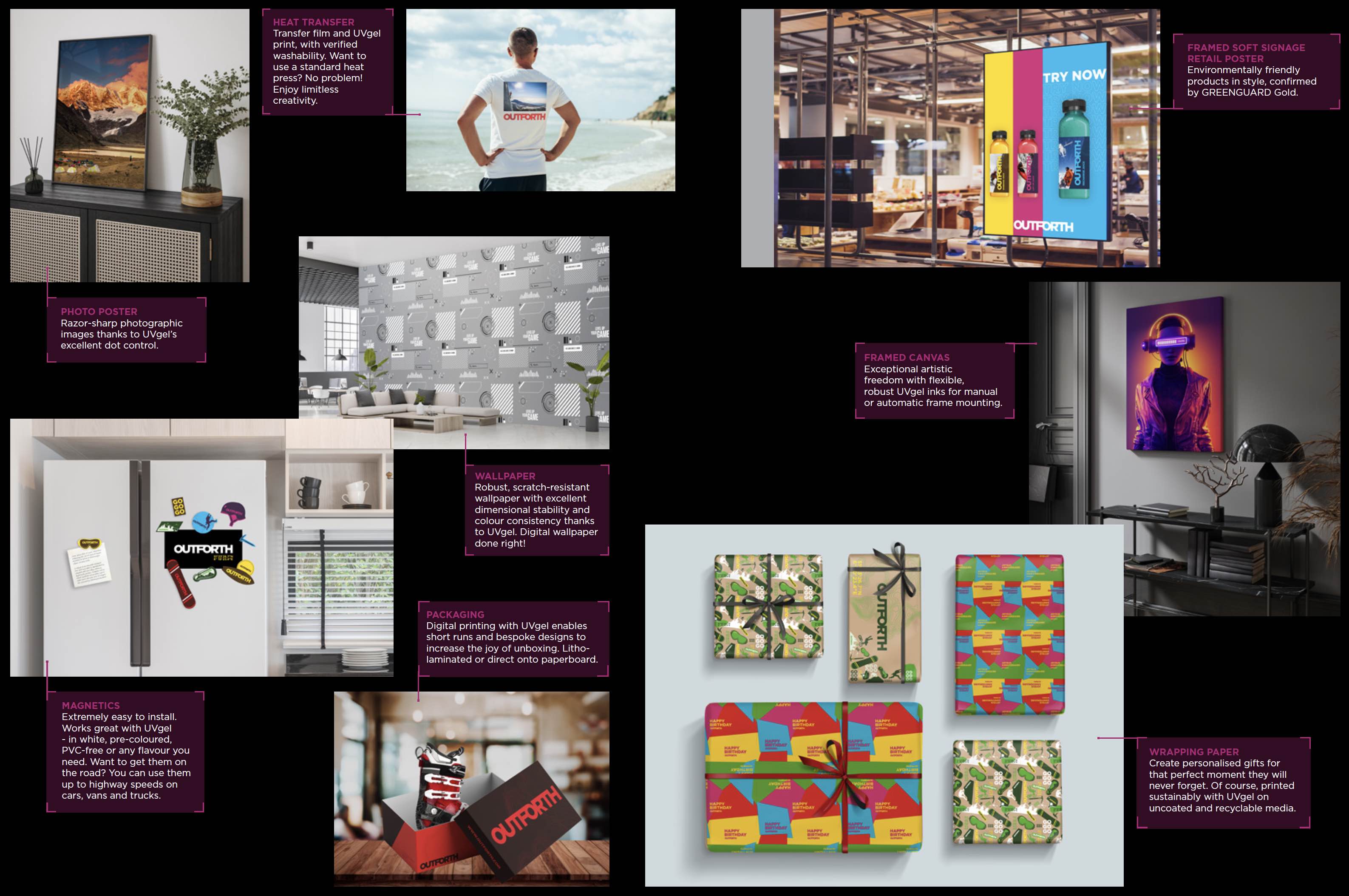

Canon Production Printing today launches the new Colorado M-series, a modular 1.6m roll-to-roll printer with two speed configurations and now also with Canon UVgel white ink, boosting the printer’s unmatched productivity and substantially expanding the range of applications that customers can create.

Retaining Colorado’s industrial build quality, the new M-series design is based on a single platform that can be configured to customers’ needs and grow with their business, with easy in-field upgrades. The scalable series includes two base models (M3 and M5) offering a choice of output speeds (cruising speed of 29m2/hr [312ft²/hr] and 40m2/hr [427ft²/hr] and maximum print speed of 111m2/hr [1,195ft²/hr] and 159m2/hr [1,709ft²/hr] respectively), with the option to upgrade from one model to the other. Both printers can be easily upgraded to ‘W’ versions for white ink (M3W and M5W).

The introduction of a white UVgel ink maximises the scope for customers to benefit from UVgel’s renowned performance advantages for a full spectrum of premium graphics and décor applications – for example window graphics, labels and wallpaper. With this addition, and with new media detection sensor technology for easy media handling, Colorado M-series customers can expand their typical product offering using heavy structured, transparent, coloured, reflective and magnetic materials.

The unique gel formulation of Canon UVgel ink translates to fast build-up of dense and opaque white images in fewer passes than with conventional printing technologies, and printed output maintains its original whiteness over time. UVgel’s particular properties also eliminate many of the production, nozzle-cleaning and maintenance issues commonly associated with white ink, offering smooth, error-free printing, minimising ink usage and waste, and maximising productivity.

Customers can also choose the popular FLXfinish+ option with their Colorado M-series printer, allowing them to add matte, gloss or mixed matte and gloss on the same print, without additional varnish. High-volume customers can automate the print-to-finish process with a UVgel Print Factory or UVgel Wallpaper Factory configuration, which seamlessly integrates the Colorado M-series printer with cutting, rewinding, taping or sheet stacking to manage volumes of at least 50,000m2 (500,000ft²) per year with minimal operator time.

Craig Nethercott, Managing Director, Canon Production Printing Oceania says: “Ever since they burst onto the market, Colorado printers with UVgel ink have set the highest bar for speed, quality and all-round productivity. On top of these business-critical performance criteria, customers today want to make smart, environmentally-responsible investments in large format graphics printing solutions that can evolve with them and help them tap into lucrative creative applications, products and markets. With the addition of an easy-care white ink option, the new modular Colorado M-series is the growth engine that businesses need to level up their capabilities and turn ideas into reality.”

Canon UVgel ink delivers pin-sharp image quality and consistent colour, while its instant drying properties enable immediate cutting and finishing, and its ultra-durability removes the need for lamination. Like previous Colorado models, the M-series is designed to handle the workload of multiple legacy roll-to-roll printers, with industrial-grade round-the-clock reliability and unattended printing with minimal operator intervention. The new M-series Colorado printers are supported by PRISMAguide XL, the easy and powerful make-ready software which results in effortless production runs with consistently high quality.

Compared to other ink technologies such as latex or eco-solvent inks, UVgel technology consumes up to 40% less ink to build up the same image quality and colour intensity. The low-heat, energy-efficient LED curing system and ‘instant-on’ operation results in reduced energy use compared to other technologies. Furthermore, with UVgel technology, customers can print on environmentally responsible materials such as PVC-free and paper-based media, even uncoated. This means the Colorado M-series printer fits perfectly in a sustainability-conscious organisation.

The Colorado M-series is designed with low total cost of ownership and rapid return on investment in mind, thanks to the lowest operating costs in its category, the ability to produce high-value applications, and the unique modular upgrade options.

The Colorado M-series is available immediately via accredited partners as well as Canon’s direct sales organisations.

Designed to deliver high speed print, scan, copy and share functionality

Epson’s multifunction models, SureColor T-Series T5760DM 36-inch and T7760DM 44-inch dual-roll, have joined the newly released production-class T-Series, taking the total in the range to 6 printers. All printers are available now from authorised Epson dealers.

New SureColor T7760DM dual-roll MFP printer

Developed from the ground up, the all new SureColor T-Series MFP models embody the philosophy of high-speed printing, scanning, copying and sharing across an even wider range.

New SureColor T-Series compact form factor in-situ

All SureColor T-Series MFP models share the same key features as the other models in the range which include Epson’s latest 2.64-inch PrecisionCore™ printhead providing outstanding image quality. There’s also improved usability, streamlined workflows and media handling, Adobe’s Embedded Print Engine as standard, dual rolls, built-in take-up reel for roll-to-roll printing, complete front operation and easy automatic roll loading.

The new MFP models like the other models in the range also share the same compact industrial design with flat top providing a small footprint for space-constrained production environments.

The new SureColor T-Series range’s many save options

The SureColor T5760DM 36-inch and T7760DM 44-inch models incorporate an advanced high speed integrated 36” scanner for scan and copy functionality. The scanner flat opens automatically when selecting either copy or scan mode and the printer conveniently allows for printing to continue when these modes are selected and in use. The scanner supports scan and copy functionality with network and direct USB and included is a 960GB SSD for file storage in a variety of formats. It features a dual light source to ensure the best possible imaging even on aged and creased documents. It also incorporates advanced CIS with RGB filters to reproduce accurate colours and recognise highlighter and pen-based markings even with fluorescent ink.

The SureColor T5760DM 36-inch and T7760DM 44-inch delivers posters and POP displays at speeds over 27 m2/h and CAD and technical drawings at production-class speeds over 130 m2/h, for fast cost-effective production with lower power consumption.

More about the new SureColor T-Series MFP

The new line delivers a range of features designed to revolutionise business productivity, including:

-Enhanced security features and IT tools – 28 IT security features to assist with data production, communication security, and access control, including IC card option for user control and tracking, and SSD encryption.

As a further update to the original T-Series line-up, the SureColor T7760DL 44-inch dual-roll printer with large cost-effective 1.6L ink pouches, T3760D 24-inch and T5760D 36-inch dual-roll printer versions are also available now.

The SureColor T5760DM 36-inch and T7760DM 44-inch dual-roll MFP models are available in Australia and New Zealand now for the following RRP (ex-tax):

Australia

T5760DM Printer with 5-year CoverPlus – $16,995

T7760DM Printer with 5-year CoverPlus – $20,295

New Zealand

T5760DM Printer with 5-year CoverPlus – $18,495

T7760DM Printer with 5-year CoverPlus – $21,995

Picture credits

New SureColor T7760DM dual-roll MFP printer

New SureColor T-Series compact form factor in-situ

The new SureColor T-Series range’s many save options

Follow Epson on social media:

Facebook: @EpsonAustralia

Twitter: @EpsonAust

Instagram: @EpsonAust

March 14 2023

Fujifilm has confirmed that the Acuity Prime L flatbed printer is now commercially available. The printer, which was unveiled at FESPA 2022, is a larger version of the award-winning Acuity Prime 20 and 30 models.

Offering a maximum print area of 3200mm x 2000mm and a headline print speed of 202m2/hr, the Acuity Prime L is easy to operate, and produces high quality results at high speed. It features six vacuum zones and 16 media location pins, as well as the ability to print side by side jobs with its dual zone function, for maximum flexibility.

Uvijet HM – an ink system formulated specifically for the Acuity Prime series – provides excellent adhesion to a broad range of substrates while also producing a wide colour gamut. The new ink range is optimised to produce high quality, vibrant images day-in, day-out.

A new jettable primer improves adhesion still further for particularly challenging substrates. This removes the need for the offline pre-treatment of substrates before printing, saving time and money.

Available with up to seven ink channels (CMYK, plus white, clear and primer) the Acuity Prime L with Uvijet HM inks offers the ultimate versatility and value by providing the flexibility for print businesses to customise it to their own needs.

In January 2023, German graphics arts business Tom Fox became one of the first companies in Europe to invest in the Acuity Prime L. The company purchased the machine just a few months after adding an Acuity Prime 30 to its production line.

Anda Baboi, Marketing Manager, Fujifilm Wide Format Inkjet Systems says: “Following the success of the Acuity Prime 20 and 30 printers, we are pleased to announce the commercial availability of the Acuity Prime L. Larger in size, it enables businesses to increase their productivity without compromising on speed or quality."

“Tom Fox is one of the first companies to have invested in the Acuity Prime L and we look forward to seeing how it boosts business for them and other print service providers in the sector.”

Mimaki has announced its first ‘direct to film’ (DTF) inkjet printer, the TxF150-75, at its Global Innovation Days event.

Utilising a heat-based transfer method, the printer is ideal for creating premium, customised merchandising, sportswear and various other promotional textile applications.

DTF printing provides an easy and affordable process for decorating apparel, and is commonly used for decorating T-shirts. The design is printed directly onto a special transfer film, which is then sprinkled with hot-melt powder, and once heated and dried, the transfer sheet is ready to be applied to the fabric using a heat press.

Based on Mimaki’s best-selling 150 Series, the new TxF150-75 responds to the market need for a reliable, stable DTF technology. A built-in ink circulation system and degassed ink pack design help prevent common DTF issues, and by utilising proprietary Core Technologies, which include a nozzle check unit and nozzle recovery system, the printing process is carried out efficiently with minimal user intervention.

Mark Sollman, Sr. Product Manager EMEA, Mimaki Europe comments, “Apparel decoration is a hugely popular and dynamic sector, one which we are already operating in with our other textile technologies. However, we could see the impact DTF technology has had on the industry in recent years, with its significant advantages over existing technologies. Namely, DTF avoids the time intensive process of plate creation in screen printing and the required weeding in traditional vinyl heat transfer. The technology can also create vibrant designs with its full colour printing capabilities. We’re excited to bring a solution to the market that is designed for those already active in the decorated apparel sector and those looking to enter it, which excels in usability, reliability and quality.”

DTF printing is a printing method that has become widespread in the textile and apparel industry, especially in the wear printing market typified by T-shirts. In DTF printing, the design is first printed directly on a special transfer film by a printer. Next, the printed film is sprinkled with hot-melt powder, which is then heated and dried to form a transferable ink layer on the film. The formed ink layer is then transferred to a fabric such as a T-shirt by a heat press to complete the finished product.

As the company’s first entry into a new segment, Mimaki has created its own range of water-based pigment inks (PHT50) especially for this solution. As of March 2023, these inks are OEKO-TEX ECO PASSPORT certified, guaranteeing that safety and environmental standards are met in line with Mimaki’s sustainability pledges. Unlike sublimation heat transfer printing, DTF is much more versatile when it comes to materials, able to work with more than just polyester and polyester blended materials, and on light or dark coloured fabrics.

The TxF150-75, developed by Mimaki Engineering, is an inkjet printer with a maximum printing width of 80 cm for producing DTF print transfer sheets. The PHT50 heat transfer pigment ink for DTF, consisting of five colors (CMYK and white), is scheduled to obtain the ECO PASSPORT certification by the end of March which is essential for obtaining the international safety standard for textile products “OEKO-TEX”.

The DTF printers have been plagued by ink ejection defects and white ink clogging. To overcome these issues, Mimaki has adopted a degassing ink design that uses aluminum packs as the printer's ink packaging form, as well as a white ink circulation function MCT (Mimaki Circulation Technology)*1. The new printer also features Mimaki's NCU (Nozzle Check Unit)*2 and NRS (Nozzle Recovery System)*3 technologies that support stable operation. They ensure continuous printing without stopping the operation to support customers' productions.

Currently, silk screen printing is widely used in the wear printing market, but this printing method requires the preparation of plates, making it unsuitable for small-lot production. Moreover, full-color printing requires time and labor to create plates for each color. The heat transfer method using rubber sheets is also commonly used, but it involves manual labor for "weeding," which is the process of manually removing unnecessary portions of the transfer when fixing the printed design on the fabric. In recent years, there has also been a growth of direct-to-garment (DTG) printing, which uses inkjet printers to print designs directly on garments and fabrics. DTG printing does not require plates and can be used for full-color printing, but it does require fabric preprocessing and manual handling by the operator at each printing steps.

Under these market circumstances, DTF printing eliminates the need for plate preparation and weeding, which have been difficulties in conventional printing methods. Since it enables unattended printing process operation, it is rapidly being adopted in the market as a technology that contributes to labor savings.

The printer is supplied with Mimaki’s RasterLink7 RIP software, allowing users to have full oversight and the ability to streamline the process from the design to the final product. Distributed in the UK and Ireland by Hybrid Services, the TxF150-75 will be commercially available via its network of specialist resellers from April 2023.

swissQprint flatbed and roll to roll printers are highly energy efficient as certified according to ISO standard 20690. Economical in power consumption, the printers thus con...

February 28 2023

swissQprint flatbed and roll to roll printers are highly energy efficient as certified according to ISO standard 20690. Economical in power consumption, the printers thus conserve resources.

The swissQprint range of printers, has undergone tests as specified by the ISO 20690 standard – and earned excellent grades. Fogra experts certify the printers’ Kudu, Nyala and Karibu "top in class” energy efficiency".

The large format printers consume little electricity in relation to their productivity, which bears positively on operating costs and the environmental balance. The average consumption is 2,2 kWh. swissQprint is the only manufacturer who can provide this certification.

The Swiss UV LED large format printers consume an average of 2.2 kilowatt-hours of electricity, exactly the same as an average kettle.

Another comparison: A two-hour video streaming session on a 65-inch 4K TV requires about the same amount of power, calculated from the data centre to the end device.

Epson has announced that, from the first half of the 2023 fiscal year beginning April 2023, it will launch sales of two new models of inkjet printheads that support solvent inks. The new I3200(8)-S1HD and S800-S1 are compatible with a wide variety of inks used for industrial applications. In addition to aqueous, UV-cured, and eco-solvent inks, they support oil-based, solvent, and other types of inks for digital printing applications in production printing.

-S1HD.jpg)

I3200(8)-S1HD

The I3200(8)-S1HD can handle up to eight colours of ink and deliver resolutions up to 1200 dpi, enabling the rendering of high-resolution images in a variety of situations.

S800-S1

The S800-S1 is equipped with only one chip. Its compact design helps to improve productivity in printing environments where space is limited.

These new products will expand Epson's offerings in the PrecisionCore printhead series and enable the company to support an even broader range of industrial and other digital printing environments, for applications such as marking/coding, signage, and printed electronics.

The two new products will enable the implementation of inkjet printing technology in new fields, particularly in industrial printing applications. Epson will continue to develop original technology to contribute to the expansion of its customers' businesses and further accelerate inkjet innovation.

Product features

I3200(8)-S1HD

• Solvent compatibility

Compatibility with solvents with high solubility gives this printhead the ability to meet the requirements for printing things such as displays and photovoltaic cells.

• Prints with up to eight colours and easily equips printers for high-quality output

Up to eight different colours of ink can be used-and not just CMYK colour inks. Liquids of different types can also be jetted, enabling this printhead to flexibly adapt to industrial printing applications. It also delivers 1200 dpi high-definition image quality, making it ideal for high-speed single-pass as well as multi-pass printing.

S800-S1

• Compact design

The S800-S1 is compatible with the same inks as the I3200(8)-S1HD, but the single-chip design enables it to print where space is limited, as well as print in close proximity to substrates with a 3D surface.

For more information about PrecisionCore printheads, please visit:

• Micro Piezo inkjet technology

corporate.epson/en/technology/search-by-products/printer-inkjet/micro-piezo.html

• Micro Piezo printhead manufacturing technology

corporate.epson/en/technology/search-by-products/other/precision-core.html

February 14 2023

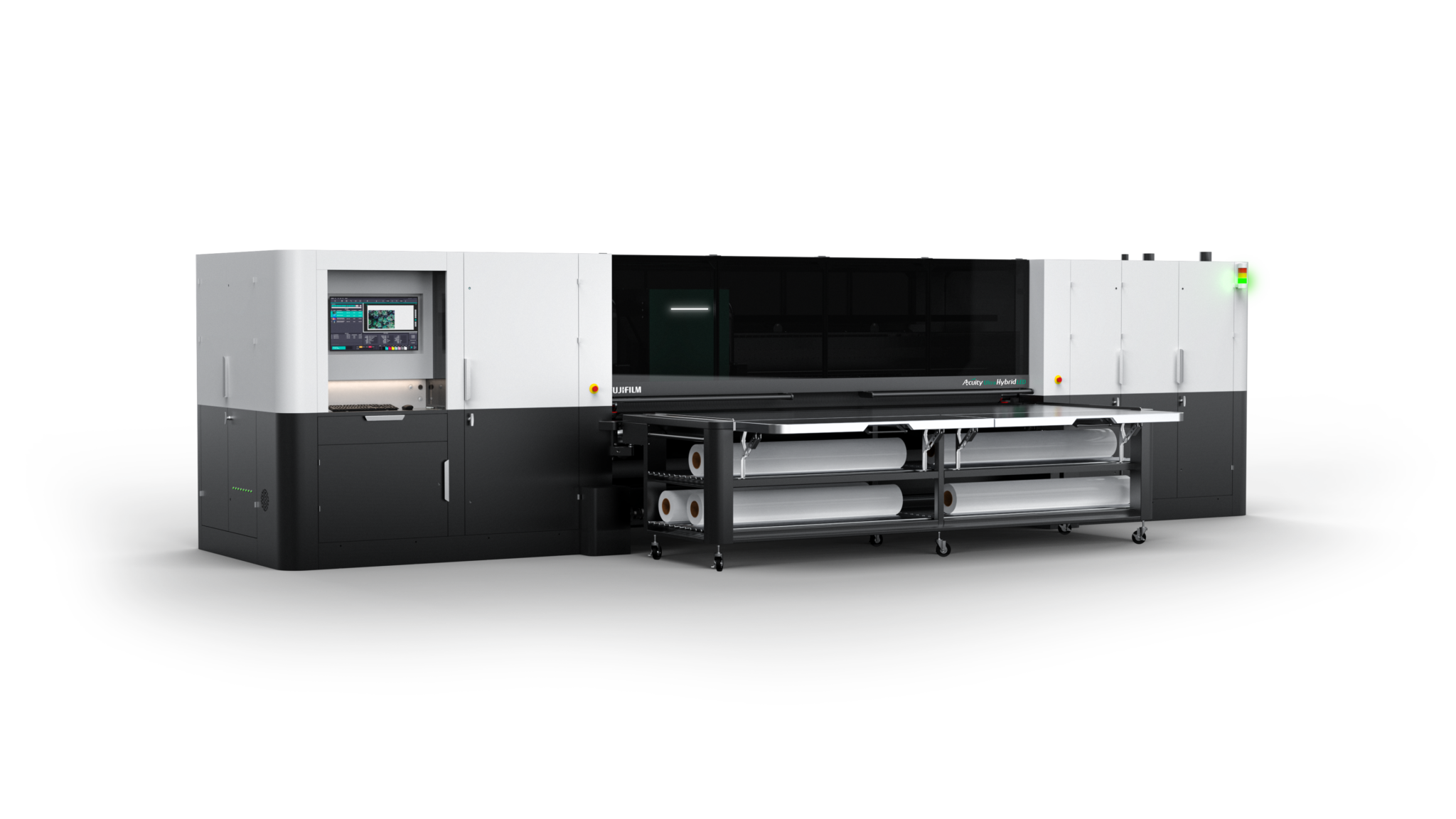

Fujifilm announces that the installation of the world’s first Acuity Ultra Hybrid LED got underway at Echo House in Surbiton, UK on Friday 27th January.

The highly-respected design and sustainable creative production company has a long and successful history of partnering with Fujifilm – having installed an Acuity Select flatbed press in 2014 and, more recently, the world’s first Acuity Ultra in 2018.

The Acuity Ultra Hybrid LED was Fujifilm’s big reveal at Fespa 2022 – the latest development in its ‘new blueprint for wide format’ concept that introduced an all-new Acuity range redesigned from the ground up for maximum ease of use and ROI.

A 3.3m high-end printer offering exceptional print quality and performance on both rigid and flexible substrates, the Acuity Ultra Hybrid LED prints at speeds of up to 218 m²/hr (RTR), and delivers a print resolution of up to 1200 x 1200 dpi. It is unique in being able to combine ultra-high quality and a competitive return on investment, for both rigid and flexible applications, all in one platform.

The machine features a range of intelligent design features to ensure unrivalled ease-of-use and excellent overall performance and Fujifilm has also created an entirely new ink range, Uvijet UH, especially for the new machine, with six colours (CMYK, Lm, Lc) available as standard and white ink also available as an optional extra. The new ink range has both Greenguard Gold and AgBB certification.

Peter Onyskiw, Director of Operations at Echo House, comments: “We’ve built a collaborative and trusting relationship with Fujifilm over the many years we’ve worked with them – that’s what led us to be the first company in the world to install a 5m Acuity Ultra back in 2018. That machine is still going strong – though we did have to move it to a new spot to make room for the new one! We’re excited to be first again. We work in a rapidly innovative and highly creative sector, serving some of the largest companies in the world, with brands who set extremely high expectations for us. The Acuity Ultra Hybrid LED combines exceptional quality with greater flexibility through its hybrid capability – giving us even more creative potential to continue to meet, and exceed, our customers’ expectations. The technological efficiencies, flexibility and reliability further extend our sustainable credentials to boot.”

David Burton, Director, Fujifilm Wide Format Inkjet Systems says: “We’ve had a long and successful partnership with Echo House over many years – they’re never afraid to be first – so they were a natural fit to be the first to trial the latest press in our all-new Acuity range.

“We’re delighted to be starting a new chapter in our journey with them – and we look forward to working with them as they look to harness the considerable potential of this hybrid press to target new business opportunities.”

Roland DG Corporation, a leading manufacturer of wide format inkjet printers and printer cutters, announced today the worldwide launch of six new models in the best-selling TrueVIS Series of large format inkjet printers and printer-cutters: the AP-640 Resin Printer, the LG-640/540/300 high productivity UV printer cutters, and the versatile, cost effective MG-640/300 UV printer cutters.

November 29 2022

| ||

November 29 2022

Xaar, the leading inkjet printing technology Group, has launched its revolutionary printhead – the Xaar Aquinox – delivering exceptional reliability, creativity, and sustainability for printing aqueous fluids.

The Aquinox is the latest development from Xaar’s ImagineX platform, and its revolutionary aQ Power Technology provides a radically new approach to how water-based fluids are jetted reliably, delivering a truly transformational industrial printhead.

Xaar’s aQ Power is a combination of ground-breaking technologies designed to optimize the Aquinox’s lifespan and robustness when handling aqueous fluids. These include a redesigned internal architecture, new water compatible materials capable of coping with an extended working range of pH levels, and a revolutionary new drive system enabling optimum drop ejection. This, together with Xaar’s TF Technology ink recirculation, ensures the Aquinox delivers significantly increased nozzle open time compared to typical aqueous printheads.

Water-based inkjet printing has never been more effective or versatile thanks to the Xaar Aquinox’s unique technologies, exceptional print speeds and compatibility with multiple aqueous fluid types. Speeds of over 100m/min can be achieved, and a high native resolution of 720dpi and firing frequency of up to 48kHz, enables high fluid laydown, with maximum productivity. And with Xaar’s High Laydown Technology the drop size capability is extended, making the Aquinox ideal for printing textiles, highly absorbent substrates, or thick film coatings.

Thanks to Xaar’s Ultra High Viscosity Technology the Aquinox is capable of jetting fluid viscosities of up to 100cP. By enabling a wider color gamut and fluids with larger particles and more pigment for higher opacity, colors are more vibrant and whites and blacks stronger ensuring the Xaar Aquinox can bring the latest imaginative designs and finishes to life.

Being able to handle the latest aqueous inks means the Xaar Aquinox not only delivers the impact and creativity demanded, but also helps users future-proof their business in a more environmentally friendly way. Xaar’s technology and its chevron architecture provides a very energy efficient operation, reducing the power required for printheads, printers and end users alike. In addition, the Aquinox’s improved nozzle open time and latency reduces maintenance and ink waste, helping to minimize the total cost of ownership for users.

John Mills, CEO of Xaar, said: “The introduction of the Xaar Aquinox, powered by our ImagineX platform, is our most significant product launch in recent years.

“The Aquinox demonstrates our commitment to driving the future of inkjet into new and ever more sustainable applications, and we are proud of this revolutionary transformation in aqueous inkjet printing.”

Supported by the robust and proven Hydra ink supply system, with its ‘plug and print’ capability and easy to use, intuitive user interface each Xaar Aquinox printhead is easily integrated into new print machines.

The Aquinox comes with development kit that gives OEMs everything they need to get up and running. This includes the ink supply system and printhead drive electronics.

Having collaborated with leading developers and manufacturers of aqueous inkjet inks to rigorously assess and improve performance, the Xaar Aquinox is equally capable of handling dye-based and pigmented fluids and inks, across a wide range of applications.

John concluded: “The Aquinox seamlessly combines all Xaar’s proven technologies and innovations into a truly transformational and reliable aqueous printhead, providing a real step change in reliable aqueous inkjet printing.

“From textiles to ceramics and packaging, we see the Xaar Aquinox breaking new ground, enabling new water-based print applications, many of which were previously not possible with inkjet. “The Xaar Aquinox will revolutionize aqueous printing, helping to deliver a world where you can truly print anything you imagine.”

October 25 2022

HP Inc. has today announced new solutions to help Print Service Providers (PSPs) meet high levels of demand, optimise work processes and grow their businesses by delivering innovative applications.

“To reach higher margins, PSPs are always on the hunt for efficiency gains, and technology that allows them to say yes to more jobs with the confidence to deliver exceptional results,” said Daniel Martinez, General Manager, HP Large Format. “Our latest offerings are designed to enable this. The HP Latex 2700 family delivers increased print quality, raw speed and white ink capabilities that will amaze customers. Meanwhile, our new Professional Print Service Plans give PSPs a range of ways to manage fleets and operations - improving workflow and maximising the potential of their business.”

Designed to tackle pressing issues facing print service providers today, the HP Latex 2700 wide-format printer ensures high-quality printing at a pace that is difficult to match. Get a full overview of the printer in the forthcoming online HP webinar, click here for details and to reserve your place.

The new 3.2m (126-in) wide HP Latex 2700 printers take production efficiency to the next level, offering vivid colours at up to 89 m2/hr (958 ft²/hr) via symmetrical double printheads, which come equipped with automatic printhead cleaning technology. Users can take on high-margin jobs with 30% wider gamut at high speed, preserving media gloss and feel across a range of signage and décor applications – including thin films, vinyl and paper.

“With the investment in the HP Latex 2700, the increased white ink capabilities allow us the opportunity to go after so many new layers and finishes which offers us new techniques,” says John Mark Watson, MD of John Mark Ltd. “We have been blown away by the results we are getting and have been showing those to designers who have been impressed by the outcome. The new white ink changes the game and takes digital wallpaper printing into a whole different dimension.

In the long term, we see that this will lead to a new trend in design, and it accelerates our position in offering quality digital printed wallcoverings. The machinery and the ink that HP supplies are not only eco-friendly but are leading in the market which also gives us a competitive edge.”

Meanwhile, the HP Latex 2700W printers offer the whitest white ink on the market at speeds of up to 54 m2/hr (581 ft²/hr), allowing PSPs to produce high-margin applications on pre-coloured and transparent media. Automatic ink recirculation and white printheads that can be stored in an offline rotating chamber eliminates waste between white jobs.

All devices in the Latex 2700 series run on fourth generation HP Latex ink - bringing UL ECOLOGO certification , while also meeting UL GREENGUARD GOLD and Toy Safety requirements. This allows PSPs to embrace jobs in even the most sensitive environments.

Additionally, the whole portfolio takes HP Eco-Carton - cardboard-based ink cartridges that reduce plastic by using 100% recycled and recyclable cardboard containers, as well as recycled plastics from HP’s closed-loop recycling process, including post-consumer beverage bottles and U-validated ocean-bound plastics.

HP Professional Print Service Plans are designed to enable business agility, maximise uptime and productivity, and to provide learning opportunities and support.

PSPs have a choice of two different HP Professional Print Service Plans – Basic and Plus – with each containing a portfolio of service and software solutions tailored to business needs. New and enhanced features include:

For further information about HP Professional Print Service Plans and its features, please visit the website here.

The HP Latex 2700 portfolio will be available in all major markets from October 19th, 2022 with pricing available on request from local HP teams and partners.

HP Professional Print Service Plans will be available globally from October 19th, 2022.

October 25 2022

Karibu 2, the dedicated roll to roll printer from swissQprint, uses the latest print head technology. It achieves up to 1350 dpi resolution, so Karibu 2 delivers top quality even at high output. The machine accommodates rolls up to 3.4 metres wide and prints using UV inks that are flexible, NVC-free and Greenguard Gold certified. Unique features ensure high efficiency and reliability as well as outstanding versatility. “We took these proven and popular features from the first generation and have now augmented them with the latest print head technology”, explains Carmen Eicher, Chief of Sales and Marketing Officer.

Easy roll handling for single and dual rolls

Thanks to the cassette system, rolls are loaded and ready to print within minutes. swissQprint offers a dual roll option capable of handling two rolls each up to 1.6 metres wide. This doubles productivity. The roll holders are split into two sections with each half of the shaft driven individually to ensure optimum web tension and perfect results on both rolls.

Tip Switch vacuum

The Karibu vacuum plate is divided into 136 individually operable segments. Within four seconds, the vacuum can be selectively adjusted, whatever the roll width. Hence there can be no air leakage, even through the space between dual rolls.

Convenient backlit and mesh printing

Karibu features a Light Box right next to the printing area, for immediate and continuous quality control of backlit prints. As a result, neither much material nor time is lost should optimisations prove necessary. A Mesh Kit is also integrated right next to the Light Box. This makes clean and simple work of processing permeable substrates, as well as full bleed printing. There is neither additional set-up work beforehand nor cleaning afterwards. A mouse click by the operator sends the beam from its standard position to the mesh position. Printing can then start immediately.

Automatic double-sided printing

For media that needs to be printed front and back, swissQprint offers an automatic double-sided printing function. Karibu controls the process with the help of an integrated high-resolution camera system and QR codes printed next to the image. This ensures that subjects printed on the reverse side are positioned with perfect registration, and matching the correct image on the front. Lory, the intuitive output software, guides operators through the process – so they have less work (and less thinking) to do, and the risk of errors is minimal.

October 11 2022

FUJIFILM North America Corporation, Graphic Systems Division, proudly announces its entry into the high-end wide format hybrid market with the unveiling of the new Acuity Ultra Hybrid LED printer.

The Acuity Ultra Hybrid LED expertly handles both rigid and flexible media, all in one platform, delivering an extremely versatile solution with maximum speeds of up to 2,346 ft²/hr. (roll-to-roll) and resolution of up to 1200 x 1200 dpi.

The printer, which will be commercially available the beginning of 2023, will be available for demonstration at PRINTING United Expo 2022 in Las Vegas, October 19-21, in the Fujifilm booth (#825, North Hall, Las Vegas Convention Center).

“The Acuity Ultra Hybrid LED wide format printer is a high-end printer for rigid and flexible media for the sign and display market, offering superb, high-quality printing in a 3.3m platform,” said Shaun Holdom, marketing manager, Ultra products, FUJIFILM Corporation, WFIJ System Business Headquarters. “The printer features new Fujifilm Uvijet UH inks, designed to produce both exceptional near-photographic quality for close viewing applications including interior graphics, signage and decor as well as the speed and durability for long distance viewing applications including short- and long-term exterior signage and industrial applications."

The Acuity Ultra Hybrid LED features media loading and unloading tables with a unique textured table surface designed to optimise the feeding and alignment of rigid media. A strong catch mechanism protects against accidental damage, and secure locking allows for media feed accuracy throughout every print run.

The Graphic User Interface (GUI) features the same design features found on the Fujifilm Acuity Ultra R2 and includes additional functionality to handle rigid media production—up to six sheets simultaneously.

An intelligent vacuum control system automatically turns on the correct vacuum zones needed for any print job based on the width of the media, and the vacuum motor power constantly adjusts to maintain optimal media hold down, regardless of media type and size, ensuring an accurate and high-quality print finish.

A tailored designed airshaft allows dual roll functionality, two media rolls of different diameters (each up to 14 in.) that can run at the same time.

Fujifilm has developed an entirely new inkjet ink series, Uvijet UH, designed specifically for the Acuity Ultra Hybrid LED printer, with six colours (CMYK, Lm, Lc) available as standard and white ink available as an option. The new ink has both GREENGUARD Gold and AgBB certifications.

Uvijet UH has been designed to adhere to a broad range of rigid and flexible media types, delivering the same exceptional high quality of the Uvijet GS and AU inks used in the Acuity Ultra R2, while also minimising ink usage and waste, helping to reduce running costs.

“Our new blueprint for wide format printer offering, announced last year, will provide our customers with greater flexibility, ease-of-use and even better ROI,” said Holdom. “The development of the Acuity Ultra Hybrid LED showcases Fujifilm’s commitment to continually meet our customer changing needs.”

For additional information on the new Acuity Ultra Hybrid LED wide format printer, go to https://print-us.fujifilm.com/products/wide-format-printers/acuity-ultra-hybrid-led/

For additional information on FUJIFILM North America Corporation, Graphic Systems Division, go to www.fujifilmgraphics.com

September 27 2022

Key features of the SC-F6460 and the SC-F6460H

The SC-F6460 and the SC-F6460H have been specifically designed by Epson for dye sublimation printing. They combine single source design, manufacture, service and support resulting in a fully integrated solution with optimum image quality and maximum reliability. Both models enable configurable and flexible output to suit a variety of applications ranging from custom clothing and décor to soft-signage, hard signage and merchandise.

The new printers have been designed to be quick to install, easy to operate and easy to maintain. They produce predictable, accurate and repeatable output quickly and efficiently to deliver cost-effective production with low running and minimum labour costs.

Dye sublimation has increasingly replaced traditional screen printing in recent years as it produces images that are bright, colourful and extremely durable. The process, combined with the technology underpinning the SC-F6460 and the SC-F6460H, means jobs can be turned around quickly and efficiently and the digitisation of workflow enables easier image creation, editing and customisation.

As mentioned, the SC-F6460 and the SC-F6460H feature a new PrecisionCore printhead that is 33% larger than the previous model for faster ‘raw’ output. Its ultra-fine nozzles support up to 600 x 1200 dpi with Variable Size Dot Technology (VSDT). Upgraded precision dot technology enables superior quality to be achieved at lower pass rates.

Epson UltraChrome DS ink provides another advantage for the new printers as it is designed to provide consistent output with a wider gamut. The ink set incorporated with these new models features an HDK formulation for blacker blacks with a more neutral tone and deeper, more accurate colour. The ink is fast drying for rapid production and sublimates well ensuring even more cost-effective production.

Both the SC-F6460 and the SC-F6460H enjoy Epson’s most advanced image processing with the latest generation Epson LUT, HTM and print modes enabling faster imaging with better gradation. Epson Edge Print also facilitates streamlined production with a simple yet highly functional interface that accurately renders images on screen so what you see is what you get.

Flexible comprehensive service with enhanced backup and support

Epson provides a comprehensive ‘heads and all’ on-site warranty. Epson also provides optional additional cover that can be matched to individual leasing and operational requirements at an extremely cost-effective price point. Multiple CoverPlus packs can be combined with the base warranty to provide up to five years of total cover. While extending on-site parts and labour cover, they also provide additional component protection for your investment during the cover period.

For even greater peace of mind, the SC-F6460 and SC-F6460H feature integrated support for Epson’s Cloud Solution PORT service. Once activated this service not only provides enhanced reporting and management functions for the user, but also enhanced support capabilities. If a printer breaks down Epson can directly interrogate the machine, analyse the fault, attempt to remotely rectify it and if necessary, dispatch a technician with the parts required to get the machine up and operating again quickly and efficiently.

Availability

The SC-F6460 and SC-F6460H are expected to be available in November 2022. They will ship complete with a 4-colour ink set and a roll of media. The SC-F6460H will come complete with an auto take up, which is also available as a separate option with the SC-F6460.

Follow Epson on social media:

LinkedIn: @Epson-Australia

Facebook: @EpsonAustralia

Twitter: @EpsonAust

YouTube: @EpsonAustralia

Instagram: @EpsonAust

Roland DG Australia, a leading manufacturer of wide format inkjet printers and printer cutters, announced today the launch of the VersaUV LEC2 S-Series Flatbed Printers, designed to maximise direct-to-object printing options to deliver unsurpassed graphic results.