The new Avinci CX3200 is a dye-sublimation roll-to-roll printer that can print either directly to textile or on transfer paper. It delivers high productivity and a consistently vibrant print qualit...

June 22 2021

The new Avinci CX3200 is a dye-sublimation roll-to-roll printer that can print either directly to textile or on transfer paper. It delivers high productivity and a consistently vibrant print quality on a wide range of polyester-based fabrics.

The Avinci CX3200 engine enables sign printing companies to create textile prints of up to 3.2 m wide at a production speed of up to 270 m²/h. The engine uses eco-friendly, odourless water-based dye sublimation inks to print either directly to fabric or to transfer paper.

Being able to print directly to fabric is easy and ideally suited for fast handling of soft signage applications such as banner displays, wall graphics and point-of-sales or trade show displays, as well as for special applications requiring print-through, such as flags. Transfer paper, in turn, allows for super sharp prints, eliminates any set-off, and limits media waste to a minimum. In addition, it extends the application scope to sportswear and fashion garments, as well as home décor prints on non-coated polyester fabrics.

The Avinci CX3200 guarantees a wide and vibrant colour gamut, outstanding tonal rendering and fine detail reproduction. The dedicated dye-sub inks stand out through their flexibility, and outdoor resistance. They deliver a stable jetting performance and the same first-rate quality batch after batch. An offline calendering unit effectively fixes the colours after printing.

Philip Van der Auwera, Wide-Format Marketing Manager at Agfa, states: “The market demand for soft signage keeps growing, as it is lightweight, resistant to wrinkles and folding, and easy to transport and reuse. The Avinci CX3200 will meet the needs of existing textile printing companies, as well as enable sign & display printers to diverge into textile printing and bring in new business. We designed it to be fit for high productivity and maximum uptime. It is extremely robust and reliable, as well as easy to operate.”

Reliability and convenience guarantee high productivity

The new Avinci CX3200 is a solidly built, reliable engine that can handle any job from a single print to sizeable runs in a 24/7 setup. It is equipped with Kyocera water-based print heads that will cover the printer’s entire life cycle. The strong pre-heater limits drying time and reduces set-off, while the vacuum make sure that thin transfer papers are kept perfectly wrinkle-free.

Changeover between jobs is fast and easy. Loading a new roll can be done in less than seven minutes by a single operator, thanks to the automatic media transport with pinch rollers.

Asanti warrants colour consistency and low ink consumption

The Avinci CX3200 is driven by Agfa’s intuitive Asanti workflow software, which streamlines all preparation, production and finishing steps of the printing process. Its smart algorithms guarantee high print quality and colour consistency, as well as low ink consumption.

In addition, Asanti features a number of options that facilitate soft signage production, such as the automated positioning of cutting marks and grommets, and the easy design of canvas extensions for the creation of flag pole pockets. It also lets printers nest and tile artwork to optimise media use.

With Asanti StoreFront, Agfa’s web-to-print software solution, soft signage printing companies can automatically manage incoming web orders or set up online stores.

SureColor F10060H combines efficient high-speed production with outstanding image quality Epson has announced a new 76-inch high speed dye sublimation printer with support for...

May 31 2021

SureColor F10060H combines efficient high-speed production with outstanding image quality

Epson has announced a new 76-inch high speed dye sublimation printer with support for media up to 76” wide – the SureColor F10060H. This new model features a total of six ink lines including the traditional CYMK along with two more that can be configured for either Light Cyan (Lc) and Light Magenta (Lm) or Fluorescent Pink (Fp) and Fluorescent Yellow(Fy).

The CYMKLcLm configuration is aimed at customers who seek to produce premium quality output with maximum image quality. It enables more precise and accurate colour with fine gradation and reduced grain. It is particularly suited to output that include images of people, product and locations and environment. Skin colours are outstanding, equipment is vibrant and beaches, trees and skies look rich and captivating.

The FpFy configuration is aimed at customers producing sportswear, work and emergency clothing, merchandise and soft signage which require a fluorescent component.

Images produced with fluorescent ink are bright and intense with high reflectivity. While traditional dye sub printers only apply fluorescent inks as a spot colour, the SC-F10060H can also apply them as a continuous tone mixed with other colours to provide a full rainbow of brilliance.

The new printer features a total of six next generation PrecisionCore printheads, each with 3200 nozzles. The heads support Variable Sized Dot Technology (VSDT) and feature active inkless nozzle status monitoring. To ensure maximum image quality with minimum wastage the printer undertakes auto nozzle replacement and incorporates advanced self-cleaning.

The new printer supports production speeds up to 245m2/hr on rolls up to 1950mm (76”) wide and 60kg in weight. To ensure cost-effective operation it supports ultra-thin media, incorporates a high-precision auto-take-up and features a bulk ink system that holds up to 120L with dual storage and auto hot-swap.

Like its 4-colour siblings, the SureColor F10060H is a sophisticated, dye-sublimation machine for textile production aimed at high volume producers. It combines speed, efficiency and production-cost minimisation with the ability to produce superior output quality .

In the dye-sublimation sector, customers demand fast turnaround and reliable operation. They also expect consistent and accurate output. With these requirements in mind, Epson has developed a machine that sets new standards in terms of standards in quality, reliability and durability.

The SC-F10060H is designed for easy operation. It features a large 9” colour touch panel display and a transparent platen window with integrated lighting. Downloadable EMX profiles facilitate rapid set-up with common media types. An integrated RGB camera enables easy profile adjustment and fast configuration with new medias.

When developing the original 4-colour SC-F10060 and now the new 6-colour SC-F10060H, Epson carefully considered workflow. The printer can be loaded by single operator, care of an integrated media lifter and dual front and rear feed controls. It also features an industrial style signal lamp and an ink system with automatic hot swap. The SC-F10060H ships complete with Epson Edge Print and Edge Dashboard software and also supports a new service called Epson Cloud Solution PORT (ECSP) that enables detailed production monitoring and advanced status analysis.

As with all Epson Large Format Printers, the SC-F10060H is backed with a comprehensive service package that offers cover up to five years. The new ECSP system enables Epson to offer remote support and accelerated repair; problems can be directly analysed and service agents dispatched complete with appropriate parts.

To ensure maximum up-time, the optional User Self Replacement of printheads have been enabled, clearly demonstrating Epson has raised the benchmark for production equipment.

The SureColor F10060H is available for ordering now from authorised Epson Large Format fabric printing solutions resellers.

To find out more go to: https://www.epson.com.au/Prographics/products/Fabric_Merchandise/?groupid=88&grouptypeid=19

Canon Production Printing Australia have today announced the Colorado 1630, a new modular addition to their portfolio of 64” UVgel roll-to-roll printers. The ind...

May 20 2021

Canon Production Printing Australia have today announced the Colorado 1630, a new modular addition to their portfolio of 64” UVgel roll-to-roll printers.

The industrial grade printer is said to be a smart investment choice for large format graphic providers such as sign makers, PSPs and in-house printers producing smaller volumes by giving them access to all the proven advantages of UVgel technology, at a lower investment level.

The Colorado 1630 delivers superior print quality of 1,800 dpi and highly durable, odourless and instantly dry prints on a wide range of media. In its fastest print mode, for applications such as outdoor banners and billboards, the Colorado 1630 can attain a maximum print speed of 111 m²/hour.

The modular architecture of the Colorado 1630 allows customers to start with the base model, and depending on business needs, choose from a range of additional modules such as FLXfinish, easy-double sided printing or a second media roll. For example, if the printer is installed with one media roll but run lengths are increasing, a second media roll option can be easily added.

Craig Nethercott, Managing Director, Canon Production Printing Oceania, says, “Enabling our customers and partners to expand their application possibilities and grow their business is essential for us.

“In Australia we have seen some of the highest utilisation rates and volumes per machine on a global scale, however, increasingly we’ve seen the demand for a 1.6 m UVgel printer that can serve customers with lower volume requirements.

“We hope that with the introduction of the Colorado 1630, more print service providers can benefit from a highly automated, robust and stable printer with a modular architecture that offers remarkable flexibility at an attractive investment level”, he says.

Further enhancing its efficiency, the precise media handling of the Colorado 1630 ensures near perfect registration for double-sided printing. A ‘print side in’ option also allows customers to print on both the inside and outside of the roll for maximum media versatility. All options can be enabled remotely, without the need for a service visit.

Adding flexibility for a matte or gloss finish to each print, the optional FLXfinish module uses a unique LED curing technique designed to add visual impact to applications such as banners, wall coverings and point of sale materials without the need to change the inks or media. This technology also supports printing on porous substrates, such as uncoated papers and soft signage materials, further expanding new market opportunities.

The new versatile printer offers the same high productivity features, output quality and media versatility as the Colorado 1650. Using the same unique Canon UVgel 460 inks used by the Colorado 1650, the Colorado 1630 produces razor-sharp prints with a wide colour gamut.

Extremely reliable and easy-to-use, this robust workhorse is built for maximum uptime and quick turnarounds. Operating costs are also minimised thanks to the efficiency of the printer, combined with reduced waste consumption.

Users can benefit from uninterrupted production with on-the-fly ink replenishment which, combined with unprecedented automation for features such as nozzle monitoring, printhead maintenance and media feed winding, allows users to avoid unnecessary downtime.

In addition, Canon’s Remote Control app is now available to monitor all Colorado printers. This will allow users to check the printer status remotely, enabling 24/7 unattended printing. The Remote Control app sends alerts to the users’ mobile devices with printer status updates, warnings and errors, offering the reassurance that the printer is running smoothly to meet deadlines.

anz.cpp.canon

HP Inc. announced the latest addition to its HP Stitch portfolio to help print service providers (PSPs) diversify their soft signage and interior décor offerings, as well as meet more challe...

May 11 2021

HP Inc. announced the latest addition to its HP Stitch portfolio to help print service providers (PSPs) diversify their soft signage and interior décor offerings, as well as meet more challenging customer needs. The updated 126-inch HP Stitch S1000 is designed to offer high quality with greater versatility and smooth operation.

"The new HP Stitch S1000 will allow PSPs to expand their dye-sub production versatility even further and say yes to ambitious projects, as well as demanding and innovative applications,” said Oscar Vidal, Large Format Global Business Strategy Director, HP. "With the large format industry set for a progressive year, HP’s latest Stitch device ensures soft signage and interior decoration professionals are able to handle a diverse range of customer needs, safe in the knowledge they have the technology to deliver.”

Take on more

The highly versatile new HP Stitch S1000 gives users the option to print directly to fabric or onto transfer paper, simplifying workflows without compromising on results - while 1200 native dpi printheads and HP’s Drop & Dry system ensure deep blacks, vivid colours and extreme resolution to deliver work of the highest-quality.

A newly incorporated contact heater offers enhanced backlit saturation performance on direct-to-fabric jobs, meaning colours appear brighter and more vivid than ever before.

Work faster

HP Stitch S1000 is designed to provide rapid turnaround production start-up times and speeds of up to 2370 ft²/hr (220 m²/hr). Additionally, it also offers the possibility to double the through put on substrates of up to 63 inches (1.6m) with dual roll accessory.

The Smart Nozzle Compensation system and Optical Media Advance Sensor Plus work together to ensure reliable image quality while operating at pace. With an additional integrated aerosol and vapour extraction system, meeting tight deadlines has never been easier.

User-replaceable printheads and HP preventative maintenance support helps increase uptime, while spreader rollers, 10-litre ink supplies and rolls up to 600lb (300kg) allow print professionals to confidently leave the device to print unattended.

Take control

Combined with the HP PrintOS app, print operations are easily controlled anywhere, anytime – while also allowing PSPs to make data-driven decisions . If working with a fleet, the HP Configuration Center ensures jobs are distributed efficiently for maximum productivity, with a built-in spectrophotometer providing colour consistency across fleet.

Tests show that in 40% less time, a single operator can easily load both transfer and textile rolls - enabled by features including automatic media tension adjustment, simple media path, automatic and optimised printhead cleaning, and a device warm-up process that occurs in parallel with loading.

Gain a sustainability edge

The updated HP Stitch S1000 uses ECO PASSPORT certified dye sublimation inks, a standard that verifies the safety of chemical products used in the textile and leather industry. The device also benefits from HP’s free and convenient printhead recycling scheme, via the HP Planet Partners initiative. Meanwhile, the outer carton of a S1000 ink cartridge is made from cardboard and can be recycled locally - part of HP’s goal of creating a more circular, low-carbon economy.

Pricing and Availability

Information on country availability, pricing, and retail destinations for the HP Stitch S Printers Series Portfolio vary region by region.

A first-look at the product can be found via this video

Xaar, has launched its latest printhead – the Xaar Nitrox – that provides users with greater print speeds and uniformity to deliver unparalleled performance across a wide variety of pri...

May 04 2021

Xaar, has launched its latest printhead – the Xaar Nitrox – that provides users with greater print speeds and uniformity to deliver unparalleled performance across a wide variety of print applications.

The new Xaar Nitrox is the next printhead to come from ImagineX which sets the roadmap for Xaar’s bulk inkjet innovations and printhead developments.

Speed is integral to the Xaar Nitrox, with firing frequencies of up to 48kHz enabling print at up to 100 metres per minute. Set-up time and installation are also fast, with drop in printhead alignment and Xaar’s AcuChp Technology allowing for a more automated process that is quick, easy, and reliable.

With its ‘plug and print’ capability, printer uptime is maximised, and superb print uniformity also delivered. Xaar’s TF Technology recirculation minimises any temperature changes within the printhead, virtually eliminating print density variations and controlling viscosity to provide consistent printing across the swathe throughout each job.

Maintaining a constant flow of fluids directly past the back of the printhead nozzles enables instant priming of the Xaar Nitrox and avoids the need for costly and wasteful purging before printing can start. The very high flow rate also prevents sedimentation and nozzle blockages, particularly in heavily pigmented inks, radically improving reliability in even the harshest printing environment.

The Xaar Nitrox supports the widest range of applications and handles the broadest range of fluids. Its open printhead architecture and TF Technology facilitate printing in multiple orientations. Consequently, the Xaar Nitrox prints extremely reliably, whether in vertical or horizontal mode, or even when being positioned by a robotic arm with accelerating and decelerating speeds.

High Laydown Technology delivers very high volumes of ink in a single pass and combined with Xaar’s TF Technology allows fluids with higher particle loading and sizes, even those with viscosities of up to 100 centipoise, to be used. This enables the Xaar Nitrox to print an increased colour gamut and special effects for applications in the ceramic, glass and packaging sectors as well as jetting higher molecular weight materials for Advanced Manufacturing and 3D printing.

Backwards compatible with the Xaar 1003, the three variants of the Xaar Nitrox – Core, Pro and Elite – provide customer choice and flexibility for a range of print needs.

The Nitrox Core is designed for applications using oil-based inks, such as in ceramic tile decoration, while the Nitrox Pro can handle more demanding fluids including soluble salts and frit used for printing glass. The Nitrox Elite delivers printing at up to 48kHz and its exceptional drop placement and accuracy make it perfect for functional fluids and 3D applications, alongside more traditional display graphics and label printing solutions.

Graham Tweedale, General Manager of Xaar’s printhead business unit said: “We are delighted to be launching the next printhead from our ImagineX platform.

“Whether using the latest highly viscous fluids for 3D printing or High Laydown for packaging and labels, the speed, performance and productivity of the Xaar Nitrox means you can use it to print right the first time and every time.”

Kornit Digital, worldwide market leader in digital textile printing technology, announced today the release of its new MAX technology, establishing a new standard for on-demand fashion and apparel ...

April 27 2021

Kornit Digital, worldwide market leader in digital textile printing technology, announced today the release of its new MAX technology, establishing a new standard for on-demand fashion and apparel production.

One technology, highest quality, endless design possibilities – all waste-free

MAX technology surpasses industry norms for retail quality on multiple fabric types and breaks new grounds of versatility with previously unattainable print applications, significantly expanding the reach of digital on-demand textile production into the centre of mainstream fashion and apparel.

A key feature of Kornit’s MAX technology is XDi, which delivers revolutionary 3D capabilities for new, high-density graphic decoration that can simulate embroidery, vinyl, and heat transfer in a single, waste-free digital process. The new XDi, which is based on Kornit’s patents, allows fulfillers and brands to expand their offerings to include new-to-market, innovative decorations without the inefficiencies and cost of operating analog technologies.

Introducing Kornit Atlas MAX and ActiveLoad Automation

Kornit also debuted the ActiveLoad Automation technology, a new robotic system to significantly ease the burden of manual and labor-intensive media handling in the textile decoration industry. This increases total output per shift while ensuring minimal downtime and exceptional reliability. The new patent pending ActiveLoad Automation technology ensures continuous production and consistency, while decreasing human error and fatigue, regardless of employee experience and training, for ultimate results and best operational efficiency.

The first product with MAX technology is now commercially available in the Kornit Atlas MAX, a carbon-neutral, industrial-scale DTG production system, providing unsurpassed retail quality, exceptional colour-matching capabilities, and a wide, vivid colour gamut, with exceptional durability. The Atlas MAX is delivered with the new XDi technology built in, for 3D printing capabilities. An upgrade to the Kornit Atlas systems will be available during the first quarter of 2022.

“Kornit’s new MAX capabilities bring sustainable on-demand production to the mainstream. We plan to roll out the MAX technology to additional lucrative market segments such as team sports, athleisure, diverse categories of fashion, and home décor applications,” said Omer Kulka, Kornit Digital CMO. “Kornit innovation arrives at just the right moment to match supply to demand – demand that requires freedom of design for self-expression, quality, and sustainable practices; and supply that expands on-demand capabilities enabling the direct-to-consumer vision.”

Delivering on the promise of digital production

“There’s a growing realisation and acceptance that on-demand production is the answer to meet the demands of today’s consumer,” said Ronen Samuel, Kornit Digital CEO. “Kornit’s MAX technology defines the future of on-demand, sustainable textile production, and the future is here now. MAX offers a rare sustainable symbiosis, more creativity, less waste. I am excited to experience what’s possible once the collective brilliance of our industry begins to create digitally, without limits. A world of opportunity awaits us.”

“Our customers have a strong, growing need for retail quality and additional applications, and we are confident the Kornit Atlas MAX will equip us to meet that demand,” added Scott Valancy, COO, Monster Digital, which beta-tested the new system.

To learn more please join a special industry event hosted in partnership with FESPA on April 28-29, 2021. More details can be found on the Kornit website.

Mimaki Engineering Co. Ltd. (Headquartered in Nagano Prefecture, Tomi City; President / Kazuaki IKEDA), manufacturer of industrial inkjet printers, cutting plotters and 3D printers, announced the r...

April 20 2021

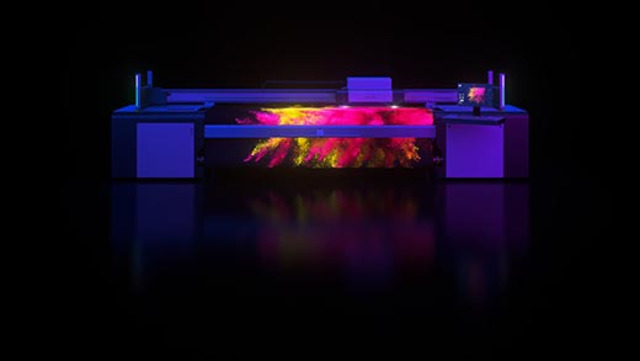

Mimaki Engineering Co. Ltd. (Headquartered in Nagano Prefecture, Tomi City; President / Kazuaki IKEDA), manufacturer of industrial inkjet printers, cutting plotters and 3D printers, announced the release of “JFX600-2513” and “JFX550-2513”, large flatbed UV inkjet printers.

The JFX600-2513 and JFX550-2513 are successor models of JFX500-2131, a large flatbed UV inkjet printer on sale from 2012.

Equipped with drastically increased number of print heads, the JFX600-2513 and JFX550-2513 enable highly efficient printing and can improve productivity by approximately 300% for the JFX600-2513 and 150% for the JFX550-2513 compared to the JFX500-2131. In addition, the number of colours that can be installed has been increased from 4 colours in the previous JFX500-2131 to 6 colours, and a wide variety of ink sets can be selected to lead printing with vivid colours and higher expressive power. It really creates to print more eye-catchy signage graphics at higher speeds than ever before.

The maximum printable size is 2,500 mm x 1,300 mm, with a thickness of up to 60 mm. It supports 4'×8’ boards (1,220 mm x 2,440 mm), which are often used for signboard production. Since direct printing on media is possible, they can print on a variety of media such as resin, glass, and metal, not to mention large sign boards, which makes them perfect printers for a wide range of applications such as large decorations, sign displays, and interior materials. Enable of direct printing on media up to 60mm thick, the printers are capable of 2.5D printing (Emboss print), which creates an uneven surface by printing with multiple layers of UV ink, offering high value-added printing applications.

Mimaki in-house developed UV inks used in JFX600-2513 and JFX550-2513 are environmentally harmonised product with extremely low VOC content that are friendly to humans and the environment. They have been certified as “GREENGUARD Gold” because they meet the world's most stringent standards for volatile organic compound (VOC) emission measurement tests specified by UL, a U.S. third-party safety science organisation, which guarantees their safety to the environment.

Mimaki Engineering is developing “Connected Digital Printing,” a system that connects inkjet printers to peripheral devices such as robots, conveyor belts, inspection equipment, various sensors, and pre- and post- processing systems through intercommunication to enable integration into production lines, unattended on-demand production, and mass customisation.

The new models JFX600-2513 and JFX550-2513 support our original “MDL command” that allows users to control the printers from their production system or peripheral devices. By utilising MDL commands, it is possible to acquire information such as the amount of ink remaining in the printer and error information, as well as possible to control the table position and height where the print media is set, and printer operations such as the start of printing to deliver the unmanned, labor-saving, and automated printing of workpiece transfer. It contributes to the realisation of digital transformation (DX) including pre and post processes of print and provides digital on-demand printing solutions for a new added value.

The JFX600-2513 and JFX550-2513 are scheduled to start sales in the summer of 2021 and will be targeted at sign graphics applications including large indoor and outdoor signs and advertisements.

"Mimaki Australia is really excited to launch these 2 NEW LED UV Flatbed printers by July this year," says Btad Creighton, National Marketing Manager, Mimaki Australia. "The JFX550 and JFX600 performs a significant increase in productivity which is up 300% (JFX600 model) compared to our previous JFX500 production model. These 2 NEW models are perfect for 8x4 boards (1,220 mm x 2,440 mm) with a thickness of up to 60mm. With features including 2.5D printing (Emboss Print), Greenguard Gold certified inks and “MDL command” that allows users to control the printers from their production system or peripheral devices. The JFX500 and JFX600 is a must view for Australian sign and print producers looking for their next investment."

Overview

1. Up to 300% faster print speed than JFX500 for improved productivity

2. The UV inks for the both models are certified as GREENGUARD Gold due to their environmental friendliness.

3. High value-added printing available, such as 2.5D print by UV printing

4. “MDL command” for printer control to support automation of workpiece transfer

*Specifications, designs, dimensions, and other information described in this document are subject to change without notice due to technical improvement etc.

Mutoh Europe nv, EMEA business unit of Mutoh Industries Co. Ltd., Japan, today announced release of a new 64” (162 cm) wide, high quality 8 channel piezo drop-on-demand roll fed dye sublimati...

April 13 2021

Mutoh Europe nv, EMEA business unit of Mutoh Industries Co. Ltd., Japan, today announced release of a new 64” (162 cm) wide, high quality 8 channel piezo drop-on-demand roll fed dye sublimation inkjet printer, called XpertJet 1682WR.

Engineered and designed in Japan, this new dye sub printer model is the successor to Mutoh’s award winning ValueJet 1638WX dye sub printer.

The XpertJet 1682WR printer has been developed for high quality graphics for transfer onto all possible types of polyester coated or polyester based rigid substrates, gadgets and flexible materials. Applications encompass in-store textile displays, personalised interior décor, custom apparel, soft signage, sportswear, customised promotional products, giftware and more.

Featuring a high level of print production efficiency, the XPJ-1682WR accommodates two gold plated piezo variable drop print heads producing stunning results in 4, 6, 7 or 8 colour ink setups. The piezo print heads are capable of firing drops from 2.8 picolitres up to 33.9 picolitres.

Cleverly designed, the XpertJet 1682WR combines multiple product enhancements which will deliver optimum quality results and an excellent user experience. A newly developed multi-stage pressure roller system will enhance media feed stability for a wide range of sublimation papers. Rolls can be easily installed thanks to a new enhanced roll off system and newly developed media flanges. Continuous printing is made possible with the different motorised take-up systems, for rolls weights up to 30, 40 or 100 kg and roll diameters from 150 to 250 mm.

The XPJ-1682WR printer also integrates Mutoh’s new “Media Tracker” technology. With this new feature, the user can print a barcode on the roll of media in use before it is removed from the printer. When reloading the same roll of media, the XPJ-1682WR will read the barcode and will automatically detect how much media is left on the roll.

Available immediately, this dual head high quality dye sublimation printer will fit both startup and established businesses wanting to extend their product portfolio.

The new XpertJet 1682WR model will be sold exclusively through Mutoh’s channel of certified & trained distributors throughout Europe, the Middle East & Africa.

Mutoh XpertJet 1682WR – Highlights

• Successor to Mutoh’s popular and award winning ValueJet 1638WX

• Transfer sublimation printing up to 1625 mm (63.97”)

• Two gold plated piezo drop on demand heads on board, drop sizes from 2.8 pl to 33.9 pl

• Typical production speeds between 10 m²/h and 48 m²/h

• Up to 8 colour setup

• New multi-language & intuitive OLED operation panel

• Easy access illuminated print platform

• Enhanced media handling & transport

• Ready for volume printing : 30, 40 or 100 kg motorized take up systems

• “Media Tracker” feature to easily track remaining media left on a part-used roll

• Environmentally friendly printing - high level of operator safety

Mutoh Australia will have stock available in May.

swissQprint is launching Karibu S – the speed version of its Karibu UV roll to roll printer. S stands for speed – and that means increased productivity combined with astonishingly good ...

March 25 2021

swissQprint is launching Karibu S – the speed version of its Karibu UV roll to roll printer. S stands for speed – and that means increased productivity combined with astonishingly good print quality. Another plus: both Karibu and Karibu S are capable of automatic double-sided printing.

Karibu, the UV roll to roll printer from swissQprint, now has a powerful big brother: the new speed model. Created for print service providers who run multiple shifts to produce large volumes of items such as banners, non-durable poster prints and XL billboards. Karibu S combines an output of up to 330 square metres per hour with impressively sharp images and edges.

Special print head configuration

Karibu S features a defined print head configuration: four print heads are in operation for each process colour – and that explains the high throughput rate. What is more, all swissQprint large format printers have nine dual-configurable colour channels, so one channel is left free. Typically, this channel is configured with white to print items such as transparent films.

Universal and highly flexible ink

swissQprint's portfolio includes an optimised ink for its dedicated roll to roll printers. It features a broad adhesion profile and is very flexible. This means that print service providers can use almost every conceivable type of roll media. And the ink can stand up to everything that the material has to take: cutting, folding, stretching, and so on.

Automatic double-sided printing

As a new feature, both Karibu and Karibu S can handle automatic double-sided printing. Thanks to a camera system and QR codes, the process takes place automatically – with high efficiency and reliability. Supported by the Lory output software – developed in-house by swissQprint. Managing print jobs is made very simple thanks to intuitive graphic user guidance.

A profitable investment

Both Karibu models feature the same robust design as all swissQprint products – ensuring lifespans well above the average. With their low operating costs, the versatile UV roll to roll printers offer the promise of high added value throughout their long lifetimes. And the high standard of quality that is typical of swissQprint.

More information: www.swissqprint.com

The Jeti Tauro H3300 UHS LED is Agfa’s new flagship, targeted to the high end of the sign & display market. This UV LED inkjet engine prints media up to 3.3 m wide in four or...

March 09 2021

The Jeti Tauro H3300 UHS LED is Agfa’s new flagship, targeted to the high end of the sign & display market.

This UV LED inkjet engine prints media up to 3.3 m wide in four or six colours at a speed up to 600 m²/h. Like its siblings, it combines industry-leading print quality with all-round versatility, extreme productivity and cutting-edge automation, yet it is even sturdier and up to 30% faster. And just like the other members of the award-winning Jeti Tauro H3300 family, it is a true hybrid that can handle boards and sheets as well as flexible materials – in different configurations.

Built for 24/7 performance

Every component of the new Jeti Tauro H3300 UHS LED (UHS for ‘ultra-high speed’) is geared towards sustaining highly productive, reliable print operations with low maintenance requirements and high uptime. Examples include the high-speed autoloader for fast media processing and the large ink tanks for greater autonomy.

Thanks to the extended vacuum zones and media guides, it is also well-suited for corrugated cardboard packaging printing, thus enabling sign & display printers to expand their offering and cover all deliverables for their customers’ marketing campaigns.

The master roll-to-roll configuration can handle both single- and dual-roll printing, and features an optional camera for accurate double-sided printing of block-out media.

Sustainable inks with the lowest consumption

The Jeti Tauro H3300 UHS LED uses Agfa’s GREENGUARD Gold certified Anuvia UV LED inks, characterised by a wide colour gamut and high colour vibrancy. Ink consumption is the lowest on the market thanks to Agfa’s patented ‘Thin Ink Layer’ technology – which relies on the exceptional colour strength of the pigments in Agfa’s inks, the smart algorithms in the Asanti software, and perfectly matched printer components. White ink and primer are optional.

Powered by Asanti workflow software

The Jeti Tauro H3300 UHS LED is powered by Agfa’s Asanti workflow software, which controls and automates the entire printing process from prepress to finishing, while guaranteeing colour consistency and optimising ink consumption. The smart Asanti Production Dashboard displays ink and media consumption and printing time for each job and printer. Calibrated Print Modes (CPMs) are personalised production templates that control all parameters for a particular substrate and enable automatic job creation.

More about the Jeti Tauro H3300 range

Agfa introduced the first Jeti Tauro H3300 in the spring of 2018. These high-end hybrid large-format inkjet engines have since helped print service providers around the world to make their business more efficient and to acquire new business. The Jeti Tauro H3300 range now includes:

Summa nv, a leading manufacturer and supplier of high-end cutting solutions, is proud to introduce the Tray One Sheet Feeder, specifically developed for the desktop models of its new S One roll cut...

March 09 2021

Summa nv, a leading manufacturer and supplier of high-end cutting solutions, is proud to introduce the Tray One Sheet Feeder, specifically developed for the desktop models of its new S One roll cutter Series. Tray one not only benefits large volume industries but focuses equally on small volume businesses such as copy shops and retailers. Tray One represents the ideal sheet/label cutting solution specifically engaging in optimal ease-of-use in the cutting workflow.

Automating the cutting workflow as much as possible can make a real impact on many business’ productivity, efficiency and ultimately on the company’s bottom line. The more advanced the automation, the fewer redundancies, waste of time and material. Summa is, therefore, constantly on the search to optimise automation into its entire cutting equipment gamut.

The new Tray One Sheet Feeder is yet another step in Summa’s pursuit to enhance automation, facilitate media handling and save the S One roll cutter operator a lot of time.

Tray One is compatible and retrofittable with S1D60, S1D75 models from the Summa S One Series.

Christof Van Driessche, Chief Commercial Officer, Summa explains: “Evolving with industry trends and developing our machines tailored to customer needs are two key Summa drivers. The demand for an efficient sheet and label processing add-on for our desktop roll cutters was quickly picked up and led to the development of this ultra easy-to-use Tray One Sheet Feeder – tailored perfectly to the desktop S One roll cutters. We are convinced Tray One will uplevel many business’ workflow in the digital press, retail, copier and screen printing industries.”

Advantages of the Tray One sheet feeder are multifold, ranging from the possibility to process a wider range of material types, straightforward workflow built-up via plug-ins, easy cutting of vectorial PDF files, compatibility with different print technologies, support of common copier sizes, and so on. By using Tray One, workflows will be facilitated considerably, from copy to cut.

Furthermore, perfectly integrated in-house Summa GoSign software – available on all Summa roll cutters, S One included - ensures automatic contour cutting of printed sheets thanks to advanced OPOS registration. The many intelligent features of the GoSign software guarantee the cutting workflow to be managed flawlessly and with great flexibility. Tray One combined with the reliable Summa desktop vinyl cutters controlled by the GoSign software is the perfect match to obtain accurate, easy-to-use label and sheet cutting solutions for many years to come.

Side note: SummaCut D60 models in the field can also be retrofitted with the sheet feeder, Tray SummaCut.

These three new developments will be launched via web streaming on 24 March 2021 at swissQprint's factory in Switzerland, with an initial event followed by two repeats. swissQ...

March 09 2021

These three new developments will be launched via web streaming on 24 March 2021 at swissQprint's factory in Switzerland, with an initial event followed by two repeats.

swissQprint is presenting three new innovations: first, the speed model of the Karibu UV roll to roll printer. Second, the option for automatic double-sided printing with Karibu. And third, neon inks for UV printing – an absolute world first.

These three new developments will be launched via web streaming on 24 March 2021 at swissQprint's factory in Switzerland, with an initial event followed by two repeats. For details and registration, visit www.swissqprint.com/en/launch. From the launch date onwards, visitors are welcome to discover these new innovations around the clock on the company's website, www.swissqprint.com. swissQprint will also be exhibiting at the virtual.drupa from 20 to 23 April 2021, when these new developments will be showcased.

www.swissqprint.com/en/launch

Meteor Inkjet Ltd, leading supplier of electronics, software, tools and services for industrial inkjet, further expands its product portfolio with the introduction of a set of products for Epson&rs...

March 02 2021

Meteor Inkjet Ltd, leading supplier of electronics, software, tools and services for industrial inkjet, further expands its product portfolio with the introduction of a set of products for Epson’s I3200 range of PrecisionCore printheads. These products join Meteor’s previously launched solutions for Epson S3200, S1600 and S800 printheads.

Epson PrecisionCore printheads embody technology that enables outstanding image quality, productivity, durability and printhead scalability. With a compact form factor accommodating four separate colours at 600dpi, the I3200 is easy to carriage-mount, making it ideal for low-cost, multi-pass printers such as those used in direct-to-garment textile printing. The head is also attractive in single-pass applications requiring ultra-low cost without sacrificing print resolution, including on-demand, colour book printing and direct-to-shape product personalisation. Compatible with water-based, UV or eco-solvent inks, the heads can also be used in any number of functional inkjet applications.

Meteor’s new PDS-3EI3200Z Print Driver Stack (PDS) for the I3200 is designed with space and cost efficiency at its heart. Supporting three printheads per PDS, the electronics are easily scalable to systems of any size and, coupled with Meteor’s comprehensive software, OEMs can significantly reduce the effort and risk associated with the design and delivery of superior industrial inkjet printers. Moreover, Meteor’s DropWatching Systems and printhead waveform development services are essential tools to accelerate time to market for new inkjet applications.

Jonathan Wilson, Meteor’s sales director, comments, “Through successful cooperation with Epson, Meteor is proud to present a solution which allows our mutual customers to take advantage of all the I3200 has to offer. Meteor’s electronics and software provide the fastest and easiest way for OEMs to unlock the potential of these printheads.”

Paddy O’Hara, business development manager, Epson Europe adds, “At Epson we work with market leading partners to provide the printhead driver solutions that our OEM customers demand. With the introduction of Meteor’s system for driving the I3200 series of printheads, our customers will have access to extremely versatile hardware and software, allowing them to develop printers for a wide range of applications.”

High-volume sign and graphics businesses can achieve a new, higher level of productivity with the first single-pass inkjet printer from Electronics For Imaging, Inc. dedicated to display graphics. ...

February 17 2021

High-volume sign and graphics businesses can achieve a new, higher level of productivity with the first single-pass inkjet printer from Electronics For Imaging, Inc. dedicated to display graphics. The new EFI™ single-pass for display graphics UV LED inkjet printer, part of EFI’s super-high-speed series of devices, leverages the proven capabilities of the market leading EFI Nozomi C18000 Plus printer for direct-to-board corrugated packaging production. With this new 63-inch wide single-pass solution, users can reach truly breakthrough speeds, running through skids of synthetic media and paper-based materials at speeds up to 1,000 sheets or boards per hour. A future upgrade for the printer will also allow for conversion to roll-to-roll production.

“When EFI announced EFI Nozomi single-pass technology at drupa 2016, the company was surprised at the level of interest expressed in this printer by display graphics customers, and we have been able to respond to demand with the most productive solution dedicated to that market,” said Ken Hanulec, vice president of worldwide corporate marketing, EFI. “Single-pass technology, done right, has the potential to change every print vertical it touches and give our customers unprecedented new opportunities. As the leader in advanced UV LED digital production solutions, we are excited to bring the very important efficiencies and throughput advantages of EFI’s proven single-pass technology to the display graphics market.”

Operating at speeds that are up to three to four times faster than the most productive shuttle-based/multi-pass printers, the EFI single-pass for display graphics printer delivers high-end output on a wide range of media in quantities other digital solutions cannot match, giving customers a lower total cost of ownership, and higher profit potential, for high-volume demand.

Driving the analog to digital transformation

This breakthrough printer can give users the lowest cost per square foot in the market, while also giving them the greatest application range and extreme efficiency. Users can handle even challenging burst capacity demands with the printer’s remarkable throughput. Plus, the 7-colour printer delivers a wide colour gamut with six colours: CMYK with optional orange and violet inks, plus white.

The printer’s on-board quality inspection system checks for colour uniformity, as well as for nozzle out and other defects to further ensure optimum print quality.

All of these factors make EFI’s single-pass for display graphics printer the digital competitor on a cost basis to many analog print applications. Display graphics producers can bring digital print’s versatility advantages, such as seamless versioning and design change capabilities, to long-run work.

As a very high volume digital printer, this new single-pass solution delivers the benefits of digital to new quantity levels that some print providers traditionally approached with analog methods. Users can eliminate the significant waste associated with analog screens and production make-readies, bringing a significant environmental advantage to digital display graphics printing.

Efficiency and uptime with EFI Fiery server and Professional Services

The EFI Fiery® digital front end (DFE) used to drive the printer provides outstanding print and colour quality, with a scalable blade-server architecture with HyperRIP performance, Adobe PDF Print Engine, and variable data support. The DFE also features Smart Ink Estimator – an advanced solution that accurately analyses image data for more-precise estimates of ink costs. Fiery Edge™, EFI’s next-generation profiling technology, is included as well, delivering even better out-of-the-box colour and quality enhancements.

Scheduled to be available later this year, the printer is designed for robust productivity and high uptime, thanks to its proven, award-winning single-pass platform and an enhanced program of professional services from EFI. The professional services program also provides extensive remote support to deliver faster, effective service. New remote solutions include innovative data and intelligence offerings centred around EFI IQ™ cloud platform applications that help users glean greater management insights about their production operations to further improve productivity, efficiency and profitability.

The new single-pass printer is one of three solutions – including the VUTEk® h5 UV LED hybrid flatbed/roll-to-roll printer with three-quarter automation and the new EFI VUTEk XT hybrid – that comprise EFI’s super-high-speed portfolio of advanced, high-volume display graphics products designed to drive the analog-to-digital transformation in printing. For more information on EFI’s portfolio of solutions for display graphics production, visit www.efi.com.

Global printing industry leader Inkcups announces the release of the newest addition to the Helix line of products: the Double Helix. The Double Helix features two side-by-side print s...

February 16 2021

Global printing industry leader Inkcups announces the release of the newest addition to the Helix line of products: the Double Helix.

The Double Helix features two side-by-side print stations that are able to simultaneously print the same artwork on two of the same vessels. These print stations have the ability to print superior quality, full-colour (CMYKWW+V) images on straight-walled and tapered cylinders. With this high-speed printing system, customers can focus and target medium to higher-volume print runs.

Fast and flexible just like the flagship Helix, the Double Helix can print full-colour seamless graphics at around 6 to 8 parts per minute depending on artwork size. This new machine is ideal for use with drinkware, barware, spirits, craft beer, candle holders, and many other industrial cylinder printing applications. In these fields, typical end products include high quality graphics on stainless steel tumblers, pint glasses, beer cans, wine and spirit bottles, sports bottles and much more.

“We are really excited to launch the Double Helix to the drinkware and industrial markets, and expect that it will be a major success. Our Helix printer is an amazing product for digitally printing with full colour images but it’s speed does not satisfy all the needs in the market. The Double Helix will help our customers generate more revenue by getting increasing throughput and opening up new profit opportunities for higher volume printing,” said Ben Adner, CEO of Inkcups.

The Double Helix is compatible with Inkcups’ full line-up of UV digital ink. With a printable area of 8.6 inches, this machine can print on items up to 12 inches in length with a diameter of 2-5 inches using design techniques such as spot varnish, tip-to-tip printing, mirror print, contour print and more. Other highlights of this machine include the ability to add the new and patented Transparent Pin Curing (TPC) system for transparent drinkware items as well as integrating pre-treatment processes.

Delivered as a turnkey package with Inkcups world-class InkcupCare warranty and service coverage, the Double Helix is engineered and manufactured in the U.S. and available for order now.

inkcups.com

In the sign & digital industry and beyond Summa is known to be one of the forerunners when it comes to roll cutting technology. To date, the company has provided many sign-making c...

February 09 2021

In the sign & digital industry and beyond Summa is known to be one of the forerunners when it comes to roll cutting technology.

To date, the company has provided many sign-making companies infinite and reliable cutting solutions with its roll cutter series. But standing still is not an option and product development and innovation are highly regarded purposes for Summa.

Therefore, Summa is proud to announce a brand new roll cutter product line which is called S One. The S One Series is the next step in Summa’s mid-level roll cutting machines and replaces the former SummaCut roll cutter Series. To optimise quality, ergonomics as well as efficiency, the S One Series is built completely from the base, using the experience and knowhow acquired over years of developing roll cutters. The name S One refers to the core idea behind its development:

The One to change the game

Increased productivity, quality and capabilities

The S One Series not only showcases a new, sleeker and more modern look. It also embodies add-ons and enhanced features for better quality, improved ergonomics and higher productivity. The improvements and additions include:

• User-friendly GoSign software to manage cutting workflows with great flexibility

• Efficient drag cutting head, allowing up to 600 grams of cutting force

• Ergonomic touchscreen, allowing for effortless navigation

• Robust OPOS Sensor, increasing the speed at which registration marks are read

• Improved internal intelligence, minimising human errors and operator intervention

• Excellent tracking performance for ultimate accuracy

• OPOS Xtra functionality for flawless processing of very small sticker jobs

• Smart FlexCut feature, enabling to perforate material to remove the design out of its carrier easily

Future-proof cutting solution

The products developed by Summa stand out for their reliability, longevity and versatility. Faithful to this tradition and conviction, also the new S One product line is built according to strict requirements, specific to Summa products. The S One Series is, therefore, designed with premium up-to-date components for long durability. Moreover, its combination of innovative features makes the S One roll cutter a flexible and future-proof unit, able to grow along with the customer’s business aspirations and goals.

Christof Van Driessche, Chief Commercial Officer, Summa adds: “With the experience and dedication on board, Summa continues to show true leadership as a supplier of high-end cutting solutions. The introduction of the S One roll cutter series is yet another milestone in Summa’s large history of legendary performance. The S One Series will unquestionably bring added value and innovation to many sign makers’ cutting workflows.”

HP Inc. has introduced a range of new Latex large format print solutions to help print service providers diversify their offerings and meet more challenging customer needs. After a yea...

February 03 2021

HP Inc. has introduced a range of new Latex large format print solutions to help print service providers diversify their offerings and meet more challenging customer needs.

After a year of business disruption across the large format industry, the HP Latex 700 and 800 series brings a suite of features that enable PSPs to be more agile, tackle ambitious projects and take on the highest value work. The new portfolio also delivers fast workflows that help businesses hit deadlines, while sharpening their sustainability edge.

“When you think about HP Latex, imagine the unique ability to say yes to every customer request, regardless of fast-changing schedule or application demands. Help meet deadlines with indisputable operator and environmental safety, as, with HP Latex, every signage & decor decision becomes a sustainable one,” said Guayente Sanmartin, General Manager, Large Format Business, HP. “The new Latex 700 and 800 portfolio will allow PSPs to win big by navigating customer challenges in the next normal and embracing more ambitious projects - safe in the knowledge their work will deliver.”

The new HP Latex range consists of four devices – the HP Latex 700 and 800, and the HP Latex 700W and 800W which offer white ink capability for the first time in this category. It is the whitest white ink available on the market that does not yellow over time , enabling print businesses to produce neater outlines and add more contrast to darker supports.

Meanwhile, updated printheads possessing more nozzles and producing speeds of up to 36 m2/hr (388 ft2/hr) allow the HP Latex 800 and 800W to offer 50% higher productivity levels compared to previous HP models. Print jobs executed on the new 700/800 Series will deliver with vivid colours and finer image and text details, even at faster print speeds. Operationally, HP PrintOS also enables PSPs to monitor and control their print fleet using a cloud-based interface they can use virtually anywhere, anytime.

Recent HP research reveals that 85% of PSP customers now demand sustainable products and practices. To meet this requirement, the new Latex products continue to build on HP’s long-lasting commitment to sustainable printing. All four devices in the HP Latex 700 and 800 series use the HP Eco Carton – a cartridge made with cardboard material, reducing the amount of plastic used by 80%. HP’s water-based inks are also kinder to the environment.

Improved HP Latex Print and Cut Plus

In related news, HP has also introduced an updated Latex Print and Cut portfolio that is fully compatible with the Latex 700 and 800 Series. Equipped with the latest Raster Image Processor (RIP) software and completely new contour cutters, the devices allow for improved usability - making jobs easier and more intuitive than ever for signage and decorative printed applications.

The HP Latex Print and Cut Plus Portfolio includes the following products:

• HP Latex 335 Print and Cut Plus Solution

• HP Latex 315 Print and Cut Plus Solution

• HP Latex 115 Print and Cut Plus Solution

• HP Latex 64 Plus Cutting Solution

• HP Latex 54 Plus Cutting Solution

• HP Latex 54 Basic Plus Cutting Solution

Updated features include optimised cutting accuracy through the enhanced Optical Position System (OPOS) configurations. As part of this improvement, the HP cutter reads the black inner lines along the job and carries out additional measurements, further aided by new HP barcodes located on the printed sheets to identify jobs. Cutting on the new Latex 64 and 54 Plus Cutting Solutions is enhanced by a higher cutter downforce of up to 600gr. This provides the necessary pressure to deliver accurate cutting performance even on thicker media.

The user experience on the coloured touch screen interface is highly responsive and includes an improved menu, making the entire solution simple to work with. The media basket also features a refined design and now has a smaller footprint when folded, enabling businesses to make better use of space.

Revamped HP PageWide XL

Completing the announcements from HP are the new additions to the HP PageWide XL suite of large format print solutions. Aimed at enterprise and mid-market companies, as well as printers serving the architecture, engineering and construction industries, the new HP PageWide XL devices provide fast, simple, and secure solutions.

The new range includes the following printers:

• PageWide XL 3920 MFP

• PageWide XL 4200 Printer and MFP

• PageWide XL 4700 Printer and MFP

• PageWide XL 5200 Printer and MFP

• PageWide XL 8200 Printer

The new HP PageWide XL printers deliver on the productivity needs of users while offering an improved experience. With the 4200, 4700 and 5200 models boasting a larger front panel - increased to 15.6 inches (from 8 inches) - it is easier for users to preview real-time scans and undertake more complex printing tasks. Additionally, for the first time, users can carry out post-editing tasks, including crop, contrast, brightness, and rotation directly from the panel.

For IT managers and CAD designers at enterprise and mid-market businesses, security is a major priority. The new PageWide XL solutions respond to this with new features to protect businesses in an increasingly connected world; including HP SecureBoot, Whitelisting and HP Connection Inspector - making the new PageWide XL range the world’s most secure large format printers.

Availability

The HP Latex 700 and 800 Series, the updated HP Latex Cut and Print Plus Solution, as well as the new additions to the PageWide XL portfolio, are expected to be available from all major markets starting February 2, 2021.

The new EFI™ VUTEk® XT hybrid flatbed/roll-to-roll display graphics printer from Electronics For Imaging, Inc. brings world-class innovations – including the next generation of mult...

February 02 2021

The new EFI™ VUTEk® XT hybrid flatbed/roll-to-roll display graphics printer from Electronics For Imaging, Inc. brings world-class innovations – including the next generation of multi-pass pin-and-cure imaging, ink delivery and dot placement technologies – to signage and graphics providers looking to address higher-volume needs with a reliable, premium-quality print solution offering a lower total cost of ownership (TCO).

The highest throughput ever for a VUTEk hybrid printer

Announced during EFI’s Engage global users conference and available mid-year, the new VUTEk XT model is the redesigned, next-generation successor to the EFI VUTEk HS series of hybrid high-volume printers and will deliver an unprecedented productivity boost, printing more than 375 boards per hour – nearly twice the throughput of the VUTEk HS125 F4 printer.

“Print businesses need the next level of capability with a lower TCO, and EFI has focused our global R&D expertise to meeting those goals with this printer and a complete EFI technology offering that together make super high speed inkjet display graphics a profitable reality for customers,” said Ken Hanulec, vice president of worldwide corporate marketing, EFI. “The new VUTEk XT printer – with its outstanding quality, superior substrate capability, robust productivity and almost unheard-of ink yield – delivers greater versatility and value in the display graphics market.”

Design innovation in hybrid pin-and-cure production

The new VUTEk XT represents the next-generation hybrid architecture for EFI’s proven pin-and-cure technology, which sets UV ink using LED lamps for sharp definition and accurate placement, followed by a full UV cure at high production speeds.

The printer includes a new media transport that eliminates the need for material edge guides, ensuring highly accurate registration and smooth transport of even thick boards. The printer’s new vacuum belt and vacuum table ably handle a wide range of materials. As a result, printing even difficult types of materials can be easy and accurate, reducing waste and improving overall throughput.

The VUTEk XT also features superior front-to-back registration, within 1 mm, and produces boards in up to three printing lanes that can be the same or different files.

CP5G – the best technology in ink delivery

Another advantage, the XT model’s unique CP5G ink system, delivers complete ink circulation, superior dot placement, 5-picoliter drops and grayscale imaging – a robust combination of features that provides fine text imaging and near-lithographic quality without expanding beyond four-colour CMYK ink sets. CP5G also expands users’ capabilities further in media compatibility, providing improved adhesion to a broader range of substrates.

In addition to the VUTEk XT setting a new image quality standard with its 4-colour grayscale printing, thanks to CP5G, the printer also gives customers the significant economic advantage of a 30-50% ink yield increase compared to other display graphics inkjet printers.

Customers can choose from a number of automation options to configure the printer to their exact needs. This includes the ability to feed one or two large rolls of media, as well as three-quarter in and out and full pallet-to-pallet automation options. All options minimise the need for operator intervention and speed work through the printer.

The EFI VUTEk XT is part of a new super high speed class of printers from EFI designed to drive the analog-to-digital transformation of display graphics into newer, even higher volumes. The super high speed portfolio also includes EFI’s successful VUTEk h5 hybrid UV LED printer with three-quarter automation and a new single-pass for display graphics UV LED printer that leverages EFI’s industry leading, award-winning Nozomi direct-to-board corrugated printing technology.

More than a print device offering

EFI addresses the growing market need for high-volume digital production with outstanding image quality, transport optimisation, and software performance on its super high speed display graphics solutions. In addition, EFI’s highly talented Professional Services team stands ready to assist customers with installation and training, along with additional offerings including development of new applications and business opportunities.

EFI also leads the way with its integrated solutions platform to meet ever-changing market needs. That is where the company’s technology shines – from Fiery® digital front ends (DFEs), to the industry’s leading MIS/ERP workflow and web-to-print/eCommerce software offerings, EFI’s complete portfolio helps customers grow profitably, attract and retain new business, and provide a better, safer working environment for employees. The outstanding, versatile production and colour management capabilities of Fiery DFEs used to drive EFI super high speed printers optimise performance and colour management. And, new EFI IQ™ cloud solutions, including EFI Go for remote printing support, provide customers with stronger production management, data reporting and more.

For more information on EFI’s portfolio of innovative solutions for display graphics production, visit www.efi.com

Electronics For Imaging, Inc. is setting new levels of production and efficiency for customers at the higher-volume end of the superwide-format signage and display graphics market. The new EFI&trad...

February 02 2021

Electronics For Imaging, Inc. is setting new levels of production and efficiency for customers at the higher-volume end of the superwide-format signage and display graphics market. The new EFI™ VUTEk® Q series product line delivers superior quality and a complete system solution with advanced roll-to-roll LED technology. The new EFI VUTEk Q3r and Q5r UV LED printers produce a wide range of challenging applications, like the most demanding premium POP with multi-layer white and cosmetics displays that demand the highest print quality to the highest volume campaigns that requires the lowest cost of production. The fastest, most productive roll-to-roll display graphics printers in their class, the 198-inch wide VUTEk Q5r printer runs at speeds up to 7,233 square feet (672 square meters) per hour, and the 138-inch wide VUTEk Q3r model prints up to 6,006 square feet (558 square meters) per hour.

The VUTEk Q3r and Q5r printers, launched this week during EFI’s Engage virtual users event, take users beyond in many aspects including productivity and application reach and more so in its full system solution from file submission to finished print which is already cut to size and rolled and marked for the designated display location. Users benefit from throughput that can be up to a few times faster than existing models in the market.

The world’s first VUTEk Q5r installation site, Yahav Digital Print, is a large wide-format print production company currently with four EFI roll-to-roll printers and many more throughout its history. Zevik Nur, CEO of Yahav Digital Print, found the new capabilities of the Q5r go above and beyond just faster print to also deliver a complete full system solution from file submission to finishing.

“Our new VUTEk Q5r was installed in October of 2020, and we have been running it in full production ever since,” Nur said. “It has exceeded all our expectations in terms of reliability, production speeds, print quality, ink consumption, media utilisation and ease of use. We can shift a lot of jobs to the new Q5r, and our customers are highly satisfied with our ability to shorten lead time and produce even higher quality prints at faster speeds.”

Premium quality with UltraDrop Technology and LED imaging

The new printers feature up to nine ink colours (standard CMYK and optional lc, lm, lk, white and clear coat), enabling exact customisation of each printer to users’ needs and strategies. They also boast EFI UltraDrop™ Technology, featuring native 7-picoliter printheads with multi-drop addressability for high-definition image quality. Users gain outstanding smoothness in shadows, gradients and transitions, as well as precise and sharp 3-point size text with a true resolution of up to 1,200 dots per inch. Their UV LED curing ensures not only cost savings but also a more environmentally friendly printing solution, consuming less energy and enabling the use of thinner, heat-sensitive substrates.

The printers also feature EFI’s “Power Tool” options for advanced productivity and capabilities, including in-line quality inspection, in-line slitting and cutting, roll and tape collection, auto-calibration, automated backlit printing, automated blockout printing and much more.

David Aloni, CEO of Xtreme dpi, sees significant advantages in the printers’ efficiency and high-speed operation. “As part of our due diligence in selecting a new roll-to-roll printer, we ran the EFI VUTEk Q5r through its paces, including full production,” said Aloni. “It is the fastest printer in its class, achieving a record production speed. We have found its print quality to be second to none, even for the most challenging files and media types. It certainly surpass our production requirements in a high-quality, fast and consistent way.”

New cloud connectivity, robust Fiery RIP and colour capabilities

Newly designed mobile operator touch screen stations for the VUTEk Q3r and Q5r printers offer operators maximum convenience. The touch screen stations also direct users to new EFI IQ™ optional cloud-based applications for easy monitoring and analysis of production activity, resulting in actionable data that can help operations be even more efficient and profitable.

Both printers include EFI’s industry-leading Fiery proServer Premium digital front end (DFE) with Fiery FAST RIP for accelerated file processing, maximising the printer investment by eliminating idle printer time. The printers’ Fiery DFE systems also include robust options such as Fiery Spot Color, Fiery Color Profiler Suite and Fiery Color Verifier for the ultimate in easy-to-use, proof-grade color management.

“We designed the EFI VUTEk Q3r and VUTEk Q5r to go beyond printing to provide a complete print to finished graphic workflow – from RIP to finished product – on the same platform,” said Ken Hanulec, vice president, Worldwide Marketing, EFI. “This new printer series is one big competitive edge for our customers, bringing unprecedented speed to our portfolio and a host of valuable features and options that take profitable roll-to-roll print production to a new, higher level.”

Mimaki has released the new TS100-1600 sublimation transfer inkjet printer for textile and apparel applications, as well the upgrade of its Tiger-1800B textile inkjet printer, all scheduled for ava...

February 02 2021

Mimaki has released the new TS100-1600 sublimation transfer inkjet printer for textile and apparel applications, as well the upgrade of its Tiger-1800B textile inkjet printer, all scheduled for availability from February 2021.

The TS100-1600 is the latest addition and entry-level model to the Mimaki 100 Series and offers an excellent balance of operation performance, image quality, speed, and cost.

The 1.600 mm printer achieves high productivity with a print speed of 70-sqm per hour and uses Mimaki’s SB610 ink, available in one-litre bottles which is said to reduce running costs (compared to the standard 440 cc cartridges) and enables stable, long-term operation due to the reduced frequency of ink replacement.

The printer is also equipped with a variety of features, including the Nozzle Check Unit (NCU), Nozzle Recovery System (NRS), and Mimaki Advanced Pass System (MAPS4) to ensure stable, high-quality prints. Its new Dot Adjustment System (DAS) function is useful for automated dot position correction and media feeding, which drastically reduces the workload of the operator.

The TS100-1600 is compatible with Mimaki’s original RIP software – the TxLink4 Lite and the RasterLink7.

As well as the new TS100-1600, Mimaki has also upgraded its Tiger 1800B industrial textile printer and belt conveying system. The new MkIII is available in two models, one for printing direct to textile (with 16 printheads) and the other for printing to sublimation transfer papers (with 8 printheads).

The ‘Mimaki printer controller’ touchscreen is a new feature, designed to enhance the stability and accuracy of the printer.

The Tiger-1800B MkIII achieves a maximum print speed of 385 sqm/h, includes a 10kg ink tank for low running costs, and is compatible with Mimaki’s TXLink4 RIP software. Upgraded from 8-bit to 16-bit rendering for smoother gradations, the printer also includes a 10GB Ethernet controller for faster data transfers.

The Mimaki TS100-1600 and Tiger-1800B MkIII printers will be available worldwide from February 2021.

www.mimaki.com