Xeikon is launching into the corrugated printing market with Idera, a new fully integrated digital solutions platform for corrugated packaging converters. The new platform is a post-pr...

June 15 2020

Xeikon is launching into the corrugated printing market with Idera, a new fully integrated digital solutions platform for corrugated packaging converters.

The new platform is a post-print, single-pass printing press, using certified food-safe water-based inks on coated and uncoated corrugated sheets, up to 1.6 m wide x 2.8 m long at up to 150 linear m/min. The inks are manufactured by Xeikon itself.

It has been designed as a solution for a corrugated box market with decreasing lot sizes, shorter lead times, and ever-increasing demand for high-quality packaging.

Xeikon says Idera will deliver higher print quality than flexography and enable printing of both short and long runs with all the benefits of a digital print-on-demand solution, including reduced waste. Idera also has the ability to customise and version.

From September onwards, the Idera solution will be available at the Global Innovation Center in Lier, Belgium for customer evaluation and testing.

“It is no secret that we are seeing rapid changes in the behavioural patterns of consumers, brands and retailers,” Sebastien Stabel, market segment manager for Carton Packaging at Xeikon, said.

“The exponential growth of e-commerce and the increasing pressure on sustainability are underlying forces that drive creative innovation in the digitisation of packaging to higher levels of productivity. Ever rising consumer expectations for instant, unique and entertaining products continue to set the bar higher within the supply chain for decreased lead times and even faster delivery,” Stabel said.

Xeikon enters a market that has EFI with its Nozomi and HP with its Pagewide leading a field that will also soon include other industry heavyweights such as Screen, Domino, and others. However, Xeikon is owned by Flint, which is the world's biggest supplier to the flexo industry, giving it unrivalled entry to the market. Xeikon also already develops and supplies flexo platemaking equipment.

Xeikon points to the McKinsey report from a year ago, No ordinary disruption – winning with new models in packaging 2030, which warns, “This is the time for companies in the packaging industry to buckle up and get ready. They have less than two years to prepare”. With that in mind, companies need to change their focus with an intuition reset and review their business models and markets.

Xeikon believes that migrating from corrugated post-print to digital corrugated printing is the optimal way for forward-thinking businesses to set themselves up for future success.

It says its Idera solution “provides the winning combination of a best-in-class, single-pass digital press for the corrugated sector, food-safety patented ink technology, and an open architecture system for third-party integration.”

To develop Idera, Xeikon relied on its long established in-house digital expertise, and on the experience and manufacturing footprint of its parent company, Flint Group. As the number one supplier of inks for corrugated packaging, Flint has a deep understanding of the corrugated market.

Stabel said, “We are working closely with Flint Group, our partners, and most importantly our customers, to customise the software, hardware and ink sets and address more closely the needs of the corrugated market. At the same time, we add our digital expertise to what is already a solid base product.”

Lode Deprez, VP Digital Inks & Imaging Technology said, “In our R&D Competence Center for digital inks, our engineers develop, formulate and produce our own high-performing, food-safe, water-based inks. This includes our new and patented technology used for pigment dispersion that guarantees the best performance and a cost-efficient solution.”

Filip Weymans, Xeikon vice president of marketing, said, “With more than 30 years of innovation and experience in digital printing, we are still leading the way. Xeikon is recognised as an advisor in many key markets, such as graphic arts and labels, and now in the corrugated market. Xeikon is a technology-agnostic advisor in the digital transformation that print manufacturing processes are undergoing. We are excited to be bringing Xeikon and Flint Group knowledge and expertise to the corrugated market with Idera and our broad range of consulting and advisory services.”

Esko, a global supplier of integrated hardware and software solutions for the print and packaging sectors, has unveiled its fastest single head imager, the new Optics 100v2, delivering a 25% increa...

June 01 2020

Esko, a global supplier of integrated hardware and software solutions for the print and packaging sectors, has unveiled its fastest single head imager, the new Optics 100v2, delivering a 25% increase in productivity for corrugated plate imagers. The speed and quality option is the latest addition to the Esko CDI range featuring unique and patented ‘single head’ split laser technology.

Exclusive to the CDI Crystal and CDI Spark platforms, the innovative Optics 100v2 features a new imaging setup that enables plate makers to obtain one 5080 (50in x 80in, or 127cm x 203cm) full sheet more per hour from their CDI and achieve a remarkable 100% increase in productivity on partial plates.

“We have developed Optics 100v2 to address the major pain points faced by the industry,” said Pascal Thomas, Director of Flexo Business at Esko. “Cost pressure is increasing across the board and a lot of skilled labor and expertise is involved in flexo plate making for corrugated print production.

“This latest innovation means that prepress operators can now work faster, producing one more plate per hour, and importantly improve the efficiency of operation by 20 per cent,” explained Pascal. “Not only that, but we all know that since plate materials can be very expensive, it is necessary to use as much of the offcut material as possible to minimise waste.

“Traditionally it has taken 15 or more minutes to image a partial plate to avoid machine imbalance, but now with Optics 100v2 it is significantly faster at less than seven minutes for a 1m2 offcut. Plate makers can reduce waste, use less energy and minimise operator input to lower costs and boost operational efficiency.”

The overall increase in productivity leads to a 20% improvement in operating efficiency, while the ability to obtain a full 5080 sheet more per hour means an additional eight 5080 sheets per typical shift.

“This is by far the fastest single head optics system on the market today,” said Pascal. “The single head system removes the problem of gluing or linking two heads together in the middle of an image, and additionally the new imaging setup enables the use of full speed on partial plates regardless of the thickness, unlike when using multiple heads. The design also reduces vibration and optimises thick plate imaging, which are the typical for the corrugated industry.

“This enables significantly faster imaging on thick partial plates and creates freedom for operators to prepare the next plate while waiting, increasing productivity and efficiency further still,” said Pascal.

Optics 100v2 is just one of a host of new innovative features and updates Esko has unveiled as part of its integrated software portfolio, Esko Software 20. The significant new developments bring even more innovation and functionality to the Esko suite of best-selling software solutions as part of its continuing drive to deliver operational efficiency improvements to the packaging value chain in tandem with outstanding value to customers. Available from 15 June 2020 onwards – and free to Esko Software Care Plan customers - the latest software release incorporates solutions such as ArtiosCAD 20, Automation Engine 20, Studio 20 and efficiency-driving updates to Share & Approve and the award-winning Print Control Wizard.

Canon has launched significant upgrades and optional configurations to its digital label press, the LabelStream 4000 series. Addressing the needs of label converters, new improvements include an op...

May 18 2020

Canon has launched significant upgrades and optional configurations to its digital label press, the LabelStream 4000 series. Addressing the needs of label converters, new improvements include an optional orange colour channel, a screen-like high-opacity white ink, and enhanced usability for greater production efficiencies.

With the LabelStream’s expanded colour capability, users can add optional orange and white ink channels. Match a wider range of brand colours and achieve highest white opacity without compromising on quality or reliability.

The new white ink channel achieves up to 80 percent opacity at 36 m/min in a single pass. Users can eliminate lengthy set-up times and expensive screens, as well as increase cost efficiencies. With additional opacities of more than 70 percent at 50 m/min and more than 65 percent at 75 m/min, a wide range of performance levels are available.

Using Xaar 2001 printhead technology, which offers high pigment load, and increased ink laydown capability, the LabelStream inks attain a colour gamut of 96 percent with the spot-colour swatch book at a Delta E 2000 value of less than two.

LabelStream 4000 Core unit is the first step into the world of high performance, UV inkjet printing. Built on a cost-efficient, yet powerful base unit, users have the option to expand the press set-up to meet their needs.

With its UV inkjet technology and a robust web transport system, the press offers print speeds of up to 75m/min and two print width set-ups of 330mm or 410mm, resulting in an industry-leading output speed of 1,845 sqm/hr, providing quicker turnaround times. Users can also complement digital production printer with UV flexo units for spot colours, varnishing and coating.

For more complex applications, the LabelStream 4000 hybrid configuration offers a custom mix of UV flexo, embellishment and finishing units, turning it into a fully integrated, single-pass label conversion line. This mix of conventional and digital technologies enables a complete inline production of high-quality self-adhesive labels.

The LabelStream provides faster syncing between flexo and digital print units, so users can benefit from reduced operator intervention, increased uptime and high-quality output. The seamless interplay of the two technologies, driven by LabelStream’s central control panel, allows for easy recalling of job settings and automated job set-up. The central control panel enables job changes to take effect on-the-fly without halting the press to adjust digital and analogue elements.

Canon’s service proposition has grown and evolved, with more than 1,600 high-volume inkjet presses and 8,500 UV-based large format printing systems worldwide, enabling LabelStream customers to benefit from proven, diversified and tailored service models.

With the LabelStream 4000, users can reduce operator intervention, increase uptime and produce high quality output, all with one device with minimal set-up time, the flexibility to mass customise contents and artwork, and the quicker time to market.

Known for its innovative auto feed cutting solutions, Intec Printing Solutions Limited, releases an ultra-fast label cutter for busy print departments. The new ColorCut LC...

May 18 2020

Known for its innovative auto feed cutting solutions, Intec Printing Solutions Limited, releases an ultra-fast label cutter for busy print departments.

The new ColorCut LC600 ‘on demand’ digital sheet label cutter is designed to provide automatic sheet label cutting for digital print production users. With NO die’s or setup costs users can cut any shape label, in an instant, making this ideal solution for the label and packaging market sectors.

Targeted at busy print departments, seeking complete unattended cutting production, the LC600 combines reliable label sheet feeding with an instant job retrieval system - this ensures effortless, yet precise, kiss cut labels at lightning-fast speeds.

Offering an unparalleled production capability to cut a mixed batch of label jobs, the LC600 can load a sheet of labels and read a QR code to instantly recognise the associated cut file, on every sheet, on the fly. The feeder/stacker can take up to 250 sheets of a varied stack of jobs and cut one after the other, in a seamless and uninterrupted flow and with SmartMark registration, the cutter ensures superb accuracy, every time.

The LC600 is powered by Intec’s renowned ColorCut Pro software that integrates with Adobe Illustrator or CorelDRAW with plug in support. When users create their job, ColorCut Pro applies an auto assigned (editable) QR code to each of the designs and saves the cutting file to the ColorCut Pro Job Library which is automatically retrieved when cutting.

The digital cutting head can apply up to 750g of pressure and cut at up to 960mm per second enabling users to produce either one or indeed hundreds of sheets and thousands of labels. And with its 'Dual Grip' feed system, holds the media during cutting on BOTH sides of the cutting head, enabling it to cut closer to the media edges than most other types of cutter.

Designed with space saving in mind the LC600 sports a retractable media catch tray that slides away when not in use, ensuring that it can easily be accommodated in any print shop.

Mark Baker-Homes, director of product development states, “Intec has developed this really exciting product at a time when label suppliers need to offer an incredibly quick turnaround to companies requiring much needed health and safety labelling”.

Product video of machine in operation https://youtu.be/I1ZsTp8szJI

Mark Andy has released a suite of new features on its digital press line, Digital Pro. The production digital machine launched in August 2019 with Digital Pro 1, a roll to roll solution and Digital...

May 12 2020

Mark Andy has released a suite of new features on its digital press line, Digital Pro. The production digital machine launched in August 2019 with Digital Pro 1, a roll to roll solution and Digital Pro 3, an inline digital hybrid press with a single flexo station and die cutting. This product line was built to tackle short run work, and is now capable of additional converting functionalities, reinforcing the OEM’s commitment to profitable digital printing.

First to market was a second optional print station, available before the print engine on both Digital Pro 3 and Digital Pro 1 models. Chandler Davis, Market Manager- Digital, Mark Andy explains “Digital Pro’s base hybrid configuration supports over 80% of prime label applications. However, the ability to reverse print or lay flexo inks and coatings prior to digital opens up a lot of opportunity. This especially rings true when you look at the added opacity on clear and metallised films, or jobs that may use multiple spot colours in a single run.” The print station adds 30 inches of machine footprint and uses UV LED curing technology. A private label ink, performance certified by Mark Andy and powered by Siegwerk, ProWhite, is available through Mark Andy Print Products for order.

Alongside the print station, three unique conveyor packages were released to Digital Pro customers and are backwards compatible with over 140 Digital One machines in operation globally. The conveyors perform basic to advanced roll-to-sheet applications, which Mark Andy reports a surge in demand for from end users. Operators can cut 2-14”sheets, convey into an output receptacle or shingling table, and batch sheets into set quantities.

Label manufacturers also now have the option to outfit a bypass module to their Digital Pro 3. With this feature, printers can web the press to bypass the digital engine and use the machine as a standalone finishing machine in addition to a digital label press. The bypass boosts press speeds by 35% to 110 fpm (33.5 mpm) and reduces cost of operation and consumable wear when the digital module is not printing.

The last option in this wave of updates is a crush knife assembly for slitting. Crush knives are ideal for many applications and the primary benefit is faster set-up time and cleaner edge slitting The system supports up to 8 knives in the cartridge and achieves a minimum lane size of ½ inch. (12.7 mm).

All features are available on future press builds, and can be added to existing machines in the field. Davis closes with "When we said this platform was future proof, we meant it. Our team is constantly listening, learning, and pushing the limits of what Digital Pro can tackle. We've done a lot in the last 8 months of product commercialisation and have much more on our road map into the future."

For more information, visit www.markandy.com.

The new book signature solution for high speed digital presses Tecnau announces general availability of the StreamFolder 5152 cut and stack line for high-speed web fed color inkjet fin...

May 04 2020

The new book signature solution for high speed digital presses

Tecnau announces general availability of the StreamFolder 5152 cut and stack line for high-speed web fed color inkjet finishing. The system efficiently produces short-run digital book printing jobs of varying run lengths including ‘books of one.’ Available with a tack-gluing option, the StreamFolder 5152 operates, in-line or near-line, at speeds up to 750 fpm / 230 mpm to take full advantage of the emerging generation of high-speed inkjet presses.

StreamFolder 5152 plow-folds the web once or twice along the travel direction, enabling efficient use of a web-fed press at its maximum print width. This folded web is very strong as the paper is up to three times thicker for system reliability (especially for lighter weight papers) feeding through the cutter and stacker. In addition, all modules operate in taut web to generate the exceptionally smooth paper ?ow required for high-speed operations. Curl is canceled out as the web is folded back onto itself, for reliably flat books. The StreamFolder 5152 also features “north/south job offsetting”, offsetting sets/book-blocks back & forth in the direction of travel to maintain full speed even for multiple consecutive small sets.

The system includes Tecnau’s StreamFolder f50 plow-fold module, Cutter c51 single-cutting cutter, and shingling Stacker s52. StreamFolder f50 is based on Tecnau’s popular and proven StreamFolder f20 product, with a next-generation controls package enabling Internet of Things connectivity, offering features such as remote monitoring and diagnostics and automatic software updates. Stacker s52 offers a tack-gluing option to keep loose sheets or signatures together for automated conveying to an inline perfect binder or other finisher, or to maintain book block integrity and registration during manual handling. An optional signature jogger also may be added for excellent signature registration.

The StreamFolder 5152 is a member of Tecnau’s Revolution 50 series, a family of products featuring top speeds, Internet-of-Things (IoT) compatibility, and media ?exibility as required in today’s most demanding digital print environments. The complete Revolution 50 series is designed for reliable, continuous non-stop production and lower maintenance costs.

Building on the success of its predecessor, the Ricoh Pro C5200, the Pro C5300 is ideal for small to medium size PSPs, print on demand environments, Corporate Reprographics Departments (CRDs) and p...

April 14 2020

Building on the success of its predecessor, the Ricoh Pro C5200, the Pro C5300 is ideal for small to medium size PSPs, print on demand environments, Corporate Reprographics Departments (CRDs) and print shops.

Key benefits of the enhanced system include:

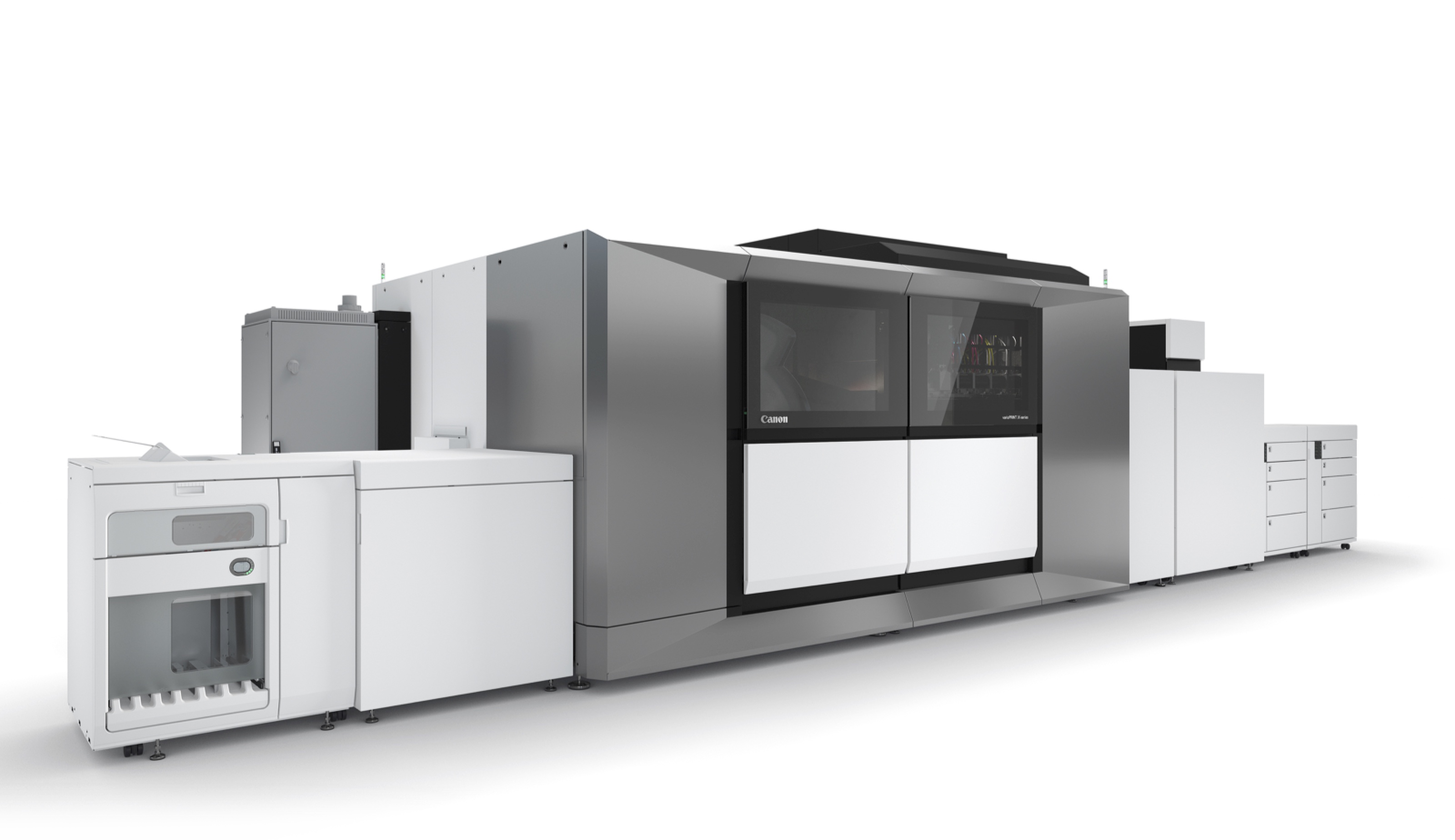

Leading supplier Canon Production Printing Australia announces the new varioPRINT iX-series, an advanced sheetfed inkjet press featuring iQuariusiX technology. Built for those with producti...

April 07 2020

Leading supplier Canon Production Printing Australia announces the new varioPRINT iX-series, an advanced sheetfed inkjet press featuring iQuariusiX technology. Built for those with production volumes of 1-to-10 million A4 images per month, this revolutionary new full spectrum press combines the image quality and media range of offset or liquid toner systems, with the productivity and cost efficiency of inkjet.

This latest addition to the Canon Production Printing Australia portfolio promises over 9,000 SRA3 images per hour, or 320 A4 images per minute, on a wide range of media including offset coated paper from 90 to 350gsm. This significant advancement to the sheetfed world enables high-volume and full spectrum production of commercial print applications, from marketing collateral and premium direct mail to catalogues, magazines and books.

With more than 90% average uptime and no need for daily calibration and maintenance, the varioPRINT iX-series enables substantial productivity gains and measurable improvements in overall running costs, compared with other cutsheet production print technologies.

The company has drawn upon the significant expertise within its ranks to create a result that, according to Managing Director, Craig Nethercott, will provide significant advantages for commercial printers interested in improving profits across Australia and New Zealand.

“The appeal of inkjet is its excellent productivity in the face of ever tighter deadlines and higher volumes of short-run jobs needing quick changeovers. With the varioPRINT iX-series, there’s no longer a need to compromise between quality and media range, or between productivity and cost efficiency,” said Mr Nethercott.

“Commercial printers can now say “yes” to virtually any order, with confidence that print quality is flawless, media options are vast, and quick turnarounds are no problem. Customers wanting to offer the broadest portfolio of high-quality applications now have a sheetfed inkjet press that helps them to grow their volumes, as well as manage smaller, more diverse jobs flexibly and profitably.”

The revolutionary new press builds on the success of the varioPRINT i-series platform introduced in 2015. With over 250 installations to date worldwide, the varioPRINT i-series has established Canon Production Printing as a leader in sheetfed inkjet production printing for transactional applications, books and high-quality direct mail.

The latest iQuariusiX technology at the heart of the new iX-series combines three key innovations:

• A breakthrough drying system combines air and heat with humidification to protect the paper. This ensures robust prints on a wide media range, perfectly flat and ready for immediate finishing.

• New proprietary polymer pigment water-based inks and ColorGrip for outstanding, vibrant and robust colour on a variety of media, including coated stock up to 350gsm.

• iQuarius quality control technologies for high-end image quality, thanks to true 1200 dpi image processing and 1200 dpi co-developed Kyocera print heads for printing razor-sharp text and line details, smooth gradients and perfect skin tones. Advanced nozzle uniformity control technology uses an inline scanner to automatically check and align single nozzles during the production run to eliminate streakiness. Nozzle activity control offers the capability of detection and auto-compensation of the nozzles during the job and thus reduces downtime and waste, and ensures high image quality.

Media handling is improved with auto-detection, discard of flawed sheets before printing and precision paper transport further optimising quality and productivity. Together, these innovations deliver a balance of excellent image quality, media and application versatility, reliable productivity and cost efficiency - all in a single inkjet press. Handle short runs profitably, switch jobs quickly, and confidently produce finished documents with mixed media, while meeting demanding customer deadlines with ease.

Powered by a high-performance, media-driven workflow, the PRISMAsync print server optimises productivity by automatically setting the appropriate printing parameters for the media selected as well as enables advance scheduling of up to eight hours of production. Combined with PRISMA software, a completely automated and highly intuitive solution can be integrated into any existing workflow, covering every stage of production, from creation and print management through to finishing and delivery tracking.

Christian Unterberger, Chief Marketing Officer & Executive Vice President from Canon Production Printing adds “The introduction of the varioPRINT iX-series is a significant enhancement of our product portfolio for the graphic arts market. With the varioPRINT iX-series sitting alongside Canon’s Colorado UVgel technology and ProStream continuous feed printer, commercial printers now have a broader range of Canon solutions to choose from to meet their specific business needs.”

HP has announced a raft of new print solutions with eight new presses that include a 6000sph B2 press, an entry level SRA3, and software for its new range of label and packaging presses that will e...

March 17 2020

HP has announced a raft of new print solutions with eight new presses that include a 6000sph B2 press, an entry level SRA3, and software for its new range of label and packaging presses that will enable them to hit any spot colour within three minutes.

Phillip Rennell, sales and marketing director at ANZ distributor Currie Group said, “HP Indigo has really shown their leadership in the graphic arts market, producing an enhanced portfolio for our customers, continuing to deliver digital print solutions for today and showing how they are creating the future. Again.”

Alon Bar-Shany, general manager at HP Indigo said the new press line-up was designed to work in what he called 'the new normal' of the online world where same day delivery, no minimum orders, evidential sustainability and consumers willing to pay premium prices for outstanding experiences were facts of life. He said the current coronavirus crisis was an opportunity to look at things in new ways.

The commercial presses are now Series 5, the SRA3 line-up will now include three systems: the enhanced top-of-the-range HP Indigo 7K, a new entry level HP Indigo 7eco and the remanufactured HP Indigo 7r. The B2 line up is now in two versions: the HP Indigo 15K for premium market, and the new 6000sph HP Indigo 100K for high-volume work.

In labels and packaging HP Indigo is launching a new spot colour matching system SpotMaster across the range, which it says will enable any spot colour to be reproduced accurately within three minutes. Label presses will include the HP Indigo 6K with inline varnishing, the HP Indigo 8K which is the duo version. There is a new flexibles press, the HP Indigo 25K which supersedes the 20000.

The new folding carton press is the HP Indigo 35K which supersedes the 30000, and, says Indigo general manager Alon Bar-Shany, has 'hundreds of improvements under the hood'. For larger cartonboard printing the company is launching the HP Indigo 90K for B1 plus sized sheets.

HP also previewed a new narrow web label press the Series 6 V12, which will print at 120 metres a minute in 12 colours at 1600dpi, and is based on a new LEPX technology. It is due for release in two years' time.

Global head of Graphic Solutions Business Santi Morera said the new print systems would offer 'high growth opportunities to printers' and said the launch was 'unprecedented'.

Beyond the presses HP is developing its PrintOSX cloud-platform applications with an AI-driven service and support infrastructure to enable printers to get the most out of their press investment.

Based on PrintOSX advanced technology, tools and know-how, HP says printers can start building the “print factory of the future” and reach operational excellence, automate production, and innovate with high-value applications.

Launched at drupa 2016, some 12,000 HP customers are now connected on HP PrintOS, using a range of applications that leverage big data on the cloud in real time for all types of production challenges.

HP is launching a B2 6000sph duplex press that pumps out up to a million sheets a month, as it identifies two key markets for B2 printing – premium quality, and high volume, and releases two ...

March 17 2020

HP is launching a B2 6000sph duplex press that pumps out up to a million sheets a month, as it identifies two key markets for B2 printing – premium quality, and high volume, and releases two presses for those two markets.

The new 6000sph HP Indigo 100K is designed for non-stop printing, while the HP Indigo 15K is aimed at the premium printing market. HP Indigo currently dominates the B2 digital market, its own estimates claim it has 95 per cent share, with in excess of 1000 in the market.

Alon Bar-Shany, general manager at HP Indigo said, “Our analysis of the B2 market revealed two winning strategies: premium printing, and high-volume printing from the likes of the online ganging printers. The new HP Indigo B2 digital press solutions will enable printers in both these markets to optimise their businesses and take them to new levels of productivity.”

Phillip Rennell, sales and marketing director, Currie Group said, “With this news, HP Indigo has continued to innovate and increased the ability to meet changing customer demands for our Australian and New Zealand customers.”

Bar-Shany said the new presses were not intended to replace offset printing, saying they would complement it, although offset to digital transfer is one of the key strategies with most commercial B2 in the 5000 sheets or less bracket. He did describe the HP Indigo 100K as a "digital offset press" saying printers "will recognise the sound it makes from feed and delivery".

The HP Indigo 100K Digital Press offers uninterrupted duplex digital printing, enabling printers to deliver more than one million B2 duplex sheets per month. Printing at 6000 sheets per hour, the new four-colour HP Indigo 100K press delivers significantly higher productivity compared with the HP Indigo 10000 series, along with the look and feel of offset. It has the capacity to print on different substrates non-stop.

HP says the high performance is enabled by advanced paper handling and offset-like gripper-to-gripper design for precision registration, as well as Indigo digital advantages, including colour automation, calibration, fast switchover between jobs and media, and five-input source feeder.

Aimed at the premium print market the new B2 HP Indigo 15K Digital Press brings new quality with high-definition printing and FM screens, and versatility enabled by a wider range of substrates, now offering additional options with up to 600 microns (24 pt.). New inks include ElectroInks Premium White and Invisible Yellow. New high definition FM stochastic screens support increased sharpness for halftone text.

Existing HP Indigo 12000 presses are upgradeable to new features of the HP Indigo 15K through a new Value Pack that is available now.

In the SRA3 market the new HP Indigo 7K supersedes the 7000 series, it is a 19-inch (SRA3+) digital press that offers a broader range of high-value digital applications with a media gamut up to 550 microns, with special inks such as HP Indigo ElectroInk Silver, high opacity Premium White, Invisible Yellow for security or other applications and ElectroInk Easy Release ink for scratch-off applications. New features will be upgrade options to the HP Indigo 7000 series, again through the Value Pack.

The new HP Indigo 7eco is an entry-level press with Indigo quality and productivity offering what HP says is an economical and sustainable choice to sprint into digital printing. Bar-SHany said, “This is an aggressively priced HP Indigo for those looking for lower cost entry into Indigop printing. It has the same platform as the 7K, but not all the bells and whistles, it prints in five colours, and doesn't print on plastics for instance, but it keeps the Indigo quality and capabilities.”

HP is also launching the HP Indigo 90K web-fed press, which supports single sided applications including banners, oversized B1 posters and wallpaper, incorporating new and patented algorithms for continuous print.

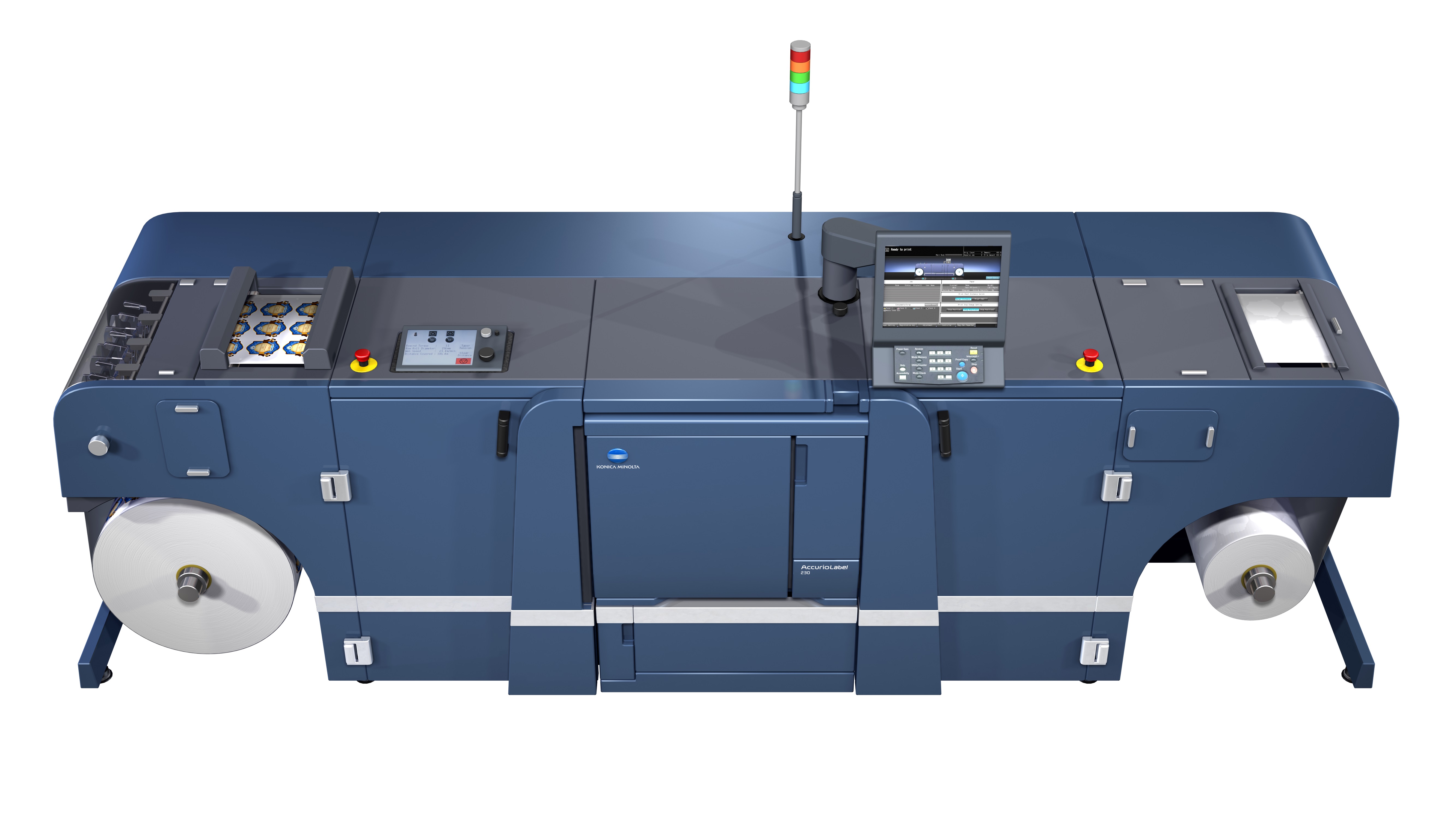

Konica Minolta is pleased to announce that the AccurioLabel series marked another important milestone: the 500th unit shipped since launched in 2016. The Konica Minolta AccurioLa...

March 10 2020

Konica Minolta is pleased to announce that the AccurioLabel series marked another important milestone: the 500th unit shipped since launched in 2016.

The Konica Minolta AccurioLabel series was designed for small to mid-size label converters by offering affordable entry to high-quality digital printing. It was developed to manage and deliver an increasing number of small to medium print jobs in ever-shorter processing times. Contrary to traditional conventional flexo and offset printing, the highly flexible digital presses can process jobs that require variable data printing, numbering or barcode printing easily and efficiently.

Toshitaka Uemura, general manager, industrial print business unit, Professional Print Business Headquarters, Konica Minolta, Inc. said, “Konica Minolta entered the digital label press market in 2016 and has quickly hit the milestone of 500 units sold. We drove the growth of the overall digital label press market by creating a new market of the mid-range digital label press. Last year, we had one of the largest shares of the global market.

“This has been achieved by widespread support from customers for the AccurioLabel series as a solution to various issues faced by the label printing industry, including the growing demand for small to medium print jobs with fast delivery.

“Many label converters, which used analogue printing alone, have entered digital printing for the first time using AccurioLabel. We will continue to help customers expand their businesses as their partner in the industrial printing business.”

Locally, the Australian label market offers huge potential with a number of key players now considering digital. Since launching its first label press to the Australian market at PacPrint in 2016, Konica Minolta has had great success and is looking to build on this with the AccurioLabel 230.

Tatjana Ferguson, product marketing manager, industrial print, Konica Minolta Australia, said, “As a company, we are always looking at options that can add further value for our clients includingin the label market. We know that label converters are looking for shorter runs and shorter turnaround times and with the AccurioLabel 230 jobs that were difficult to produce efficiently on analogue presses can now be produced quickly and easily.

“The AccurioLabel series is also designed to deliver stable printing quality. It is clearly hitting the mark with label converters who want to be able to deliver high quality and consistent results, repeatedly.”

Features of the AccurioLabel 230

The latest model of AccurioLabel series, AccurioLabel 230 is a highly flexible system for on-demand job needs and runs most tack papers and films at speeds of up to 23.4 mpm. The output is high quality and high precision, with the printing resolution of 1,200x1,200 dpi and 256 gradations. The touch panel monitor enables intuitive operation and is easy to use for operators, eliminating the need for extensive user training. Tasks that were time-consuming on analogue machines can be performed quickly and accurately.

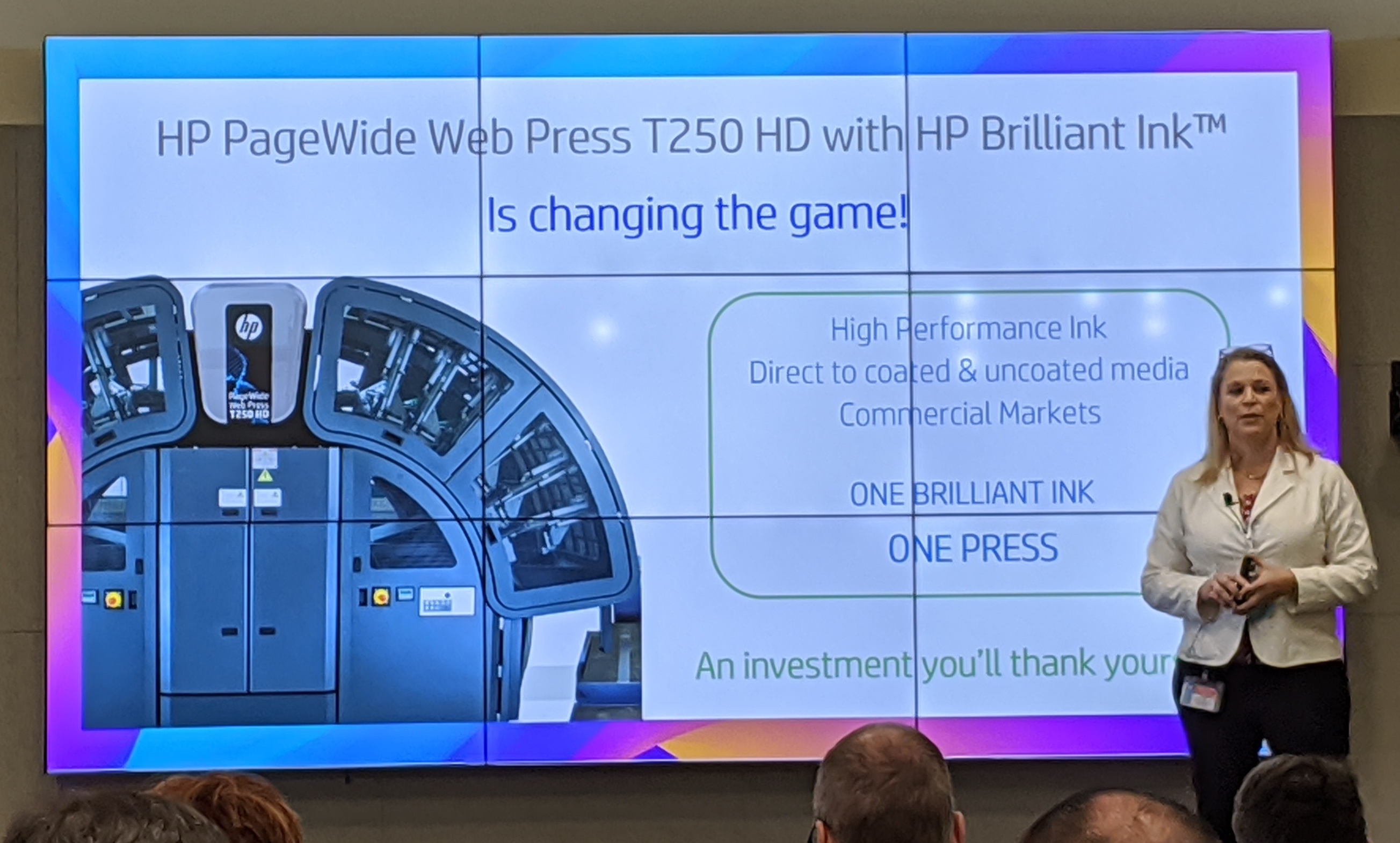

This week in San Diego, HP previewed the PageWide Web Press T250 HD, which will launch officially at drupa in Düsseldorf, Germany, this June. An upgrade to its popular T240 press, the new vers...

March 07 2020

This week in San Diego, HP previewed the PageWide Web Press T250 HD, which will launch officially at drupa in Düsseldorf, Germany, this June. An upgrade to its popular T240 press, the new version is aimed squarely at capturing more of the commercial print work traditionally run on offset litho presses.

First, what hasn’t changed: it still runs at 500 colour fpm, and can handle up to 62 million letter-size pages per month. It still has a 22˝ web, and still offers three modes — Performance, Quality, and Performance HDK, which blends the two. It is completely upgradeable from any of the T200 series PageWide presses, and will continue to be supported and upgraded as future innovations are released.

What has changed — and it’s a big one — is the inks.

Launching alongside the T250 are the new HP Brilliant inks. The new formulation is specifically designed for commercial markets, with the ability to print directly to both coated and uncoated media without needing an extra step. HP has replaced the primer station that was needed to run multiple stocks on the T240 with a new HP Optimiser that runs in-line with the rest of the printheads.

The Optimiser is automated, and lays down the exact amount of coating needed, exactly where it is needed on a page to ensure ink adhesion every time, no matter what the surface of the paper actually looks like. HP bills it as a universal laydown to build the perfect surface for the inks every time, virtually eliminating the need to have specially treated papers, or limited options.

The inks also boast upgraded colour, with 30-50% higher gamut than most industry standards, as well as offering a glossier look and feel, especially when printed on a glossy stock. According to HP, the HP Brilliant inks produce “deep reds and dazzling blues,” and are “designed to meet or exceed the sheet gloss of the paper."

The press uses the latest HDNA thermal inkjet printhead, also launching at drupa, which is more finely tuned than previous iterations, promising smoother colour transitions, with good shadows and highlights. The press will come with the Colour Vision system as well, which has been upgraded to include colour cameras and a new lighting system, so “what you see is what you get,” allowing operators to see in real time what the press is doing at full speed, and manage any faults or errors on-the-fly, without needing to stop the press.

Kris Albee, global marketing manager, noted that HP designed the T250 to simplify the process, providing one ink across coated, uncoated, quality, and production on a single press, in-line. “This is one press that does it all,” she said.

A New Era in Coating

Launching alongside the HP PageWide Web Press T250 HD is the ExcelCoat ZRW Web Coater from partner Harris & Bruno. This is said to be where the T250 goes from a great production inkjet device to a full-scale commercial printing powerhouse.

The coater simultaneously runs both aqueous and UV coatings, with changeout between the two done is as little as 10 minutes. It has also been simplified and automated, making it easy for a single operator to handle the entire operation from white paper to coated stock. The gloss level can be adjusted to capture the exact look that the piece requires, from a soft touch to a high gloss, and it is robust enough to withstand the abuses of the traditional mail stream, reportedly making it perfect for capturing direct mail operations.

Everything from the cylinders to the dryers are modular, making it very easy and quick to change out, without needing tools or equipment. It can also feed directly into existing finishing lines, with the combination of press and coater playing well with all of the major finishing equipment, including winders, cutters, creasers, and more.

For commercial printers looking to expand into new growth areas without sacrificing applications such as direct mail or transactional jobs, this is a pretty compelling piece of equipment. It solves many of the challenges of earlier inkjet options, while still providing all of the benefits of a fully digital product.

All in all, this is an exciting step forward for high-speed production inkjet for the commercial space. The press will get its first beta installations in July after drupa wraps, with orders anticipated worldwide.

Konica Minolta Australia has announced it will release the MGI JV 3D One press, an entry-level MGI UV Varnish solution, in April this year. The new press offers commercial printers an accessible an...

March 03 2020

Konica Minolta Australia has announced it will release the MGI JV 3D One press, an entry-level MGI UV Varnish solution, in April this year. The new press offers commercial printers an accessible and affordable option for 2D and 3D varnish effects that will add more value to what printers can offer their customers.

The MGI JV 3D One digital embellishment press was first introduced to the market at PRINTING United in October, 2019. The new press is a part of MGI’s JETVarnish range available from Konica Minolta and was designed to be complimentary with its AccurioPress and AccurioPrint digital print systems or as a standalone embellishment system.

The MGI JV 3D One press can be used for a variety of applications, including packaging, books, magazines, business cards, menus, photobooks and greeting cards. It is simple to use, compact, and has a smaller operational footprint than previous MGI models. It is highly efficient and can process up to 3500 A4 sheets per hour on a range of sheet sizes up to of 364 x 750mm.

Sue Threlfo, general manager, production and industrial print, Konica Minolta Australia, said, “The MGI JV 3D One will give all commercial printers access to an embellishment press regardless of their size, offering them a way to differentiate themselves and stand out from competitors. Rather than outsourcing embellishment printing, commercial printers can leverage the MGI JV 3DOne to do embellishment in-house. Digital embellishment offers printers the opportunity to add value to the printed page and subsequently achieve margins.

The MGI JV 3DOne press features include:

• digital print embellishment with UV coating and embossing

• spot varnish editor for job modification

• varying varnish thickness, between 21 and 116 micron in one pass

• AIS SmartScanner registration technology which will minimise crop marks, waste and set-up time

• a job cost calculator with job management tool

• both 2D and 3D tactile effects.

Sue Threlfo said, “Konica Minolta and MGI work very closely to meet the needs of customers with the right solutions and products for the right applications. For Konica Minolta, service and support are paramount, so customers can rest assured their presses will be reliable and, when maintenance is required, they’ll be up and running again with minimal disruption.”

The MGI JV 3DOne digital press is expected to be released in April, 2020.

Contiweb, a specialist in state-of-the-art technologies for printing, advanced drying and web-handling, announces today the launch of its Digital Fluid Applicator (DFA), a standalone remoistening a...

February 26 2020

Contiweb, a specialist in state-of-the-art technologies for printing, advanced drying and web-handling, announces today the launch of its Digital Fluid Applicator (DFA), a standalone remoistening applicator for digital web presses, developed to significantly improve the quality of digitally printed products.

Based on the popular Contiweb Fluid Applicator for heatset web offset applications, the DFA is an innovative and user-friendly system, which uses tap water and a surfactant to intelligently and very precisely remoisten the paper on digital web presses. Silicone can also be added as an option, decidedly advantageous if inline finishing is being employed.

“Common quality issues such as loss of signature flatness, growth of cut books, curling and broken folds are overcome with our new DFA system. Furthermore, damage on the printed surface due to friction from inline finishing modules can be overcome by the integrated siliconizer,” explains Rutger Jansen, CEO at Contiweb, adding: “There may be a perception in the market that digital inkjet printing does not require remoistening, however the process generates high temperatures during drying, resulting in significant loss of moisture and diminished quality of the printed matter, a difficulty we’ve been determined to resolve.”

The Contiweb DFA mixes tap water and a surfactant within the system, which is then continuously circulated, rather than using specially treated deionized water. The amount of remoistening can be adjusted quickly to suit requirements, and due to a sophisticated control system, are steadfastly consistent. The system ensures constant coverage, even with changing press speeds, and can be set differently for each side of the paper if desired. Settings can also be saved, slashing set-up times for repeat jobs.

“The Contiweb team has developed a Plug and Play system that is compatible with digital web presses from all well-known manufacturers. Using economical, easy-to-access tap water, with high performance pure silicone, the Contiweb DFA will provide a step-change in the quality of digitally printed products. I’m very much looking forward to seeing the results for our customers,” concludes Jansen.

Epson has further reinforced its commitment to sustainable business solutions with the launch of 7 new WorkForce devices, all powered by its innovative, ultra-efficient PrecisionCore heat-free prin...

February 26 2020

Epson has further reinforced its commitment to sustainable business solutions with the launch of 7 new WorkForce devices, all powered by its innovative, ultra-efficient PrecisionCore heat-free print technology.

WorkForce Pro WF-C878R

The new range starts with the compact WorkForce Pro WF-878R desktop printer, ideal as either the main print device for smaller businesses or as a workgroup device for larger business and culminates with the WorkForce Enterprise

WF-C21000, an ultra-fast 100 ppm device designed to easily handle large print volumes and tight deadlines.

WorkForce Pro WF-C879RTC

Epson Australia MD Craig Heckenberg said, “Business inkjet is expected to account for over 40% of developed business print solutions within the next five years[1]. As a result Epson has taken steps to now to help the market with its requirements in this area, placing particular emphasis on heat-free and energy efficient solutions. These new products perfectly position us and our channel partners for future growth as they provide a sustainable, economical print solutions for organisations that are becoming increasingly aware of their carbon footprint, while at the same time seeking ways to reduce operating expenses.”

WorkForce Enterprise WF-C21000

The WorkForce Pro WF-C878R, WF-C878RTC, WF-C879R and WF-C879RTC models deliver enviable price performance. Extraordinarily high ink yields delivering up to 86,000 pages in black and up to 50,000 pages in colour mean minimal staff disruptions to attend any of the devices and, combined with aggressive price points, present a very compelling lower cost of ownership proposition.

WorkForce Enterprise WF-C21000 with finishing options

Where time and deadlines are important or finishing options are required, the WorkForce Enterprise WF-C20600 (60 ppm), WF-C20750 (75 ppm) and WF-C21000 (100 ppm) models come into their own. Comprehensive finishing options that include offset finishing and stapling, booklet-making and automatic hole-punch complement a total print solution that supports any busy work environment.

Where organisations are looking to reduce their carbon footprint, meet their corporate social responsibility objectives, or just play their part in reducing CO2 emissions, these new Epson devices are the ideal choice to help address all of these goals and more.

Epson PrecisionCore Heat-Free print technology uses no heat in the printing process and up to 87% less energy to print a page than a comparable laser-based device2. This energy saving translates into reduced CO2 emissions and directly reduces printer-related electricity costs.

Availability and pricing

The new range of Epson WorkForce Pro and Enterprise business print devices will be available to Australian customers from April 2020. Purchase prices start from $4,995 ex. GST. All models are available as part of managed print service plans and flexible finance arrangements through Epson Premium Partners nationally.

For further information on Epson WorkForce Pro solutions go to: https://www.epson.com.au/products/A4_Colour_Printers/

Leapfrog Machinery is excited to announce that it is the exclusive Australian Distributor for the Adelco Automatic Screen Printing Presses! Director of Leapfrog Machinery, Howard...

February 11 2020

Leapfrog Machinery is excited to announce that it is the exclusive Australian Distributor for the Adelco Automatic Screen Printing Presses!

Director of Leapfrog Machinery, Howard Debney is excited by the news, saying “The high quality Adelco Automatic Textile Presses are ideal for Aussie Screenprinters. Their advanced features, the ability to expand and grow with the business along with digital capability fulfils a need within the screen printing market”

Adelco have long been synonymous with world class manufacturing, durable, high quality, automatic screen printing presses. Their focus on Research & Design alongside the latest manufacturing techniques, enables Adelco to produce screen printing equipment “Designed to Survive”

Two of the key Automatic Textile Printing Presses Leapfrog Machinery will bring into Australia are the Adelco Cyclone and Matrix:

The Adelco Cyclone Carousel runs at pin point accuracy at extreme speeds. Designed for the most challenging screen & digital printing, the Cyclone achieves a pin-point registrations of <+-0.02mm. With an advanced touchscreen control system, tool free quick release pallets and a variety of setups: from 6 Colour, 8 Stations to 14 Colour, 16 Stations; the Adelco Cyclone brings a powerful tool to your screen printing business.

The Adelco Matrix offers an efficient use of space while fulfilling high production requirements, with rates in excess of 900 prints per hour. The Matrix offers a printing press that is both Modular & Expandable; enabling it to grow with your business. With a strong stable structure, smooth quiet operation and chainless pallet indexing system, the Adelco Matrix is perfect for the printer looking for speed, precision and versatility.

While excited at the prospect of selling the Automatic Textile Preses, Mr Debney is jubilant at Leapfrog’s ability to offer a complete solution for screen printers. Mr Debney says “The Adelco range of Gas & Electric Dryers along with their Manual and Automatic Flash Cure machines paired with the Vastex Screen Printing Machinery Leapfrog currently sells; enables us to confidently advise, source and supply our customers with the Right Machinery for their individual needs.”

The Adelco Machinery is now available in Australia.

For information contact Leapfrog Machinery (0)2 9482 4999 www.leapfrogmachinery.com.au

Focus Label Machinery has announced a cooperation with TS Converting Equipment, manufacturer of the Elite Cameron range, to develop a hybrid coating and printing press. The new unit, w...

January 21 2020

Focus Label Machinery has announced a cooperation with TS Converting Equipment, manufacturer of the Elite Cameron range, to develop a hybrid coating and printing press.

The new unit, which is due to launch in the spring this year will have options to apply release coatings, hot melt coat, print, laminate, die cut, slit and rewind materials in one pass.

‘We have known Focus for many years and are excited to be developing the new press together,’ said Tim Self, director of TS Converting. ‘The new machine has huge potential in the self-adhesive laminate, tape and label industries.’

David Lee of Focus Label Machinery, added: ‘Our partnership brings together years of design expertise in different industries and the development will open some exciting new avenues for our printing technology.’

The new machine is said to be designed as a modular press with the ability to print on both sides of the web in one pass using UV Flexo or digital inks. Further details regarding the new machine are expected to be released in spring this year when both companies will proceed with the testing phase.

Xaar has launched a five-step service for the evaluation of fluids for use in new product development and advanced manufacturing applications. The service aims to help companies establ...

January 14 2020

Xaar has launched a five-step service for the evaluation of fluids for use in new product development and advanced manufacturing applications.

The service aims to help companies establish the suitability of inkjet technology and fluids in new applications without incurring large upfront costs. To support the new service, Xaar has invested in a dedicated laboratory. This is equipped with a number of custom test rigs for sample production and fluid testing, such as a Notion Systems n.jet 3D printer.

Each new project starts with the initial fluid evaluation where guidance is provided on issues such as ink development and material compatibility as well as options for complex rheology testing and fluid physicals measurement. Stage two covers jetting optimisation encompassing printhead waveform configuration, alongside application and fluid optimisation. Stage three involves actual sample production utilising one of the custom test rigs. Once samples have been produced, the process moves on to upscaling the development application, focusing on the provision of the relevant Xaar inkjet system. The fifth and final then completes each project through providing continued support and delivering application improvements, testing and advice.

The five-step service is currently enabling companies to evaluate the jetting of fluids with high viscosities. Most inkjet printheads are capable of jetting materials with viscosities with a range of 10-25 mPa.s (10-25 cP). Now, thanks to improvements in Xaar’s TF technology, fluids that have significantly higher viscosities can be successfully jetted through its printheads.

Mike Seal, Xaar business development manager, advanced manufacturing and 3D printheads, commented, ‘Inkjet technology is now highly relevant across a multitude of new product development applications, and we wanted to enable companies to be able to review the suitability of inkjet printing in their product development programmes without the need for significant capital investment or upfront costs.’

Mr Seal continued, ‘Providing access to our inkjet development expertise through our five-step service helps clients get to market quicker by reducing their own development timelines and costs. From 3D printing through to functional fluid applications such as optics and flat panel displays, the possibilities and applications for inkjet printing are extremely diverse, and our dedicated team and five-step service is here to support throughout each development project.’

Investment comes following Onset X1 and Acuity EY installations as the company's partnership with Fujifilm goes from strength to strength Fujifilm today announces that it has installed...

November 19 2019

Investment comes following Onset X1 and Acuity EY installations as the company's partnership with Fujifilm goes from strength to strength

Fujifilm today announces that it has installed the first Acuity B1 in Asia at leading Filipino retail marketing solutions company, 11FTC. The investment signals 11FTC's intention to diversify its product offering into high-quality, short-run packaging.

Founded in 1996 and based in Quezon City, 11FTC employs 265 staff and offers a fully integrated retail marketing solutions service to its clients, who include major retailers and global FMCG brands. Its product offering involves the production and installation of a variety of high quality sign and display and other print products.

11FTC is always on the lookout for the latest technology to help it meet changing customer demands. Renowned for its innovation and the speed with which it can turnaround high quality wide format work, the company saw in the Acuity B1 the opportunity to add production capacity to its factory and diversify its product offering into quality, short-run packaging.

John Mandarang, CEO at 11FTC, explains: "Fujifilm invited us to visit their showroom in Bangkok and it was there that we first saw the Acuity B1 in action. We've had a very successful working relationship with Fujifilm for several years now - operating an Onset X1 to produce high-quality large format display materials, and an Acuity EY flatbed with Uvijet KV inks for the production of vacuum formed products. We're always looking to grow as a company and broaden our offering, and in the Acuity B1 we believe we've found a machine with the necessary quality and versatility to help us to break into short run quality packaging - particularly for localised, targeted promotions.

"Our customers demand high quality at a competitive price and often at very short notice. They also trust us to advise them on innovative ways to maximise shopper engagement. Fujifilm has proven to be a consistently reliable partner since the installation of our Onset X1 and Acuity EY in 2015. We've learnt that we can depend on both the technology and the support that Fujifilm provides, to provide an excellent level of service and an extremely high level of quality to our customers. This first-hand experience was a major factor in our decision to invest in the Acuity B1.

"We're delighted to be in partnership with a company as reputable and forward thinking as 11FTC," says Fujifilm's Andrew McDuffie. "As they continue to grow and drive their business forward, we look forward to working with them to provide the technological and advisory support they need to continue to meet their future business goals."

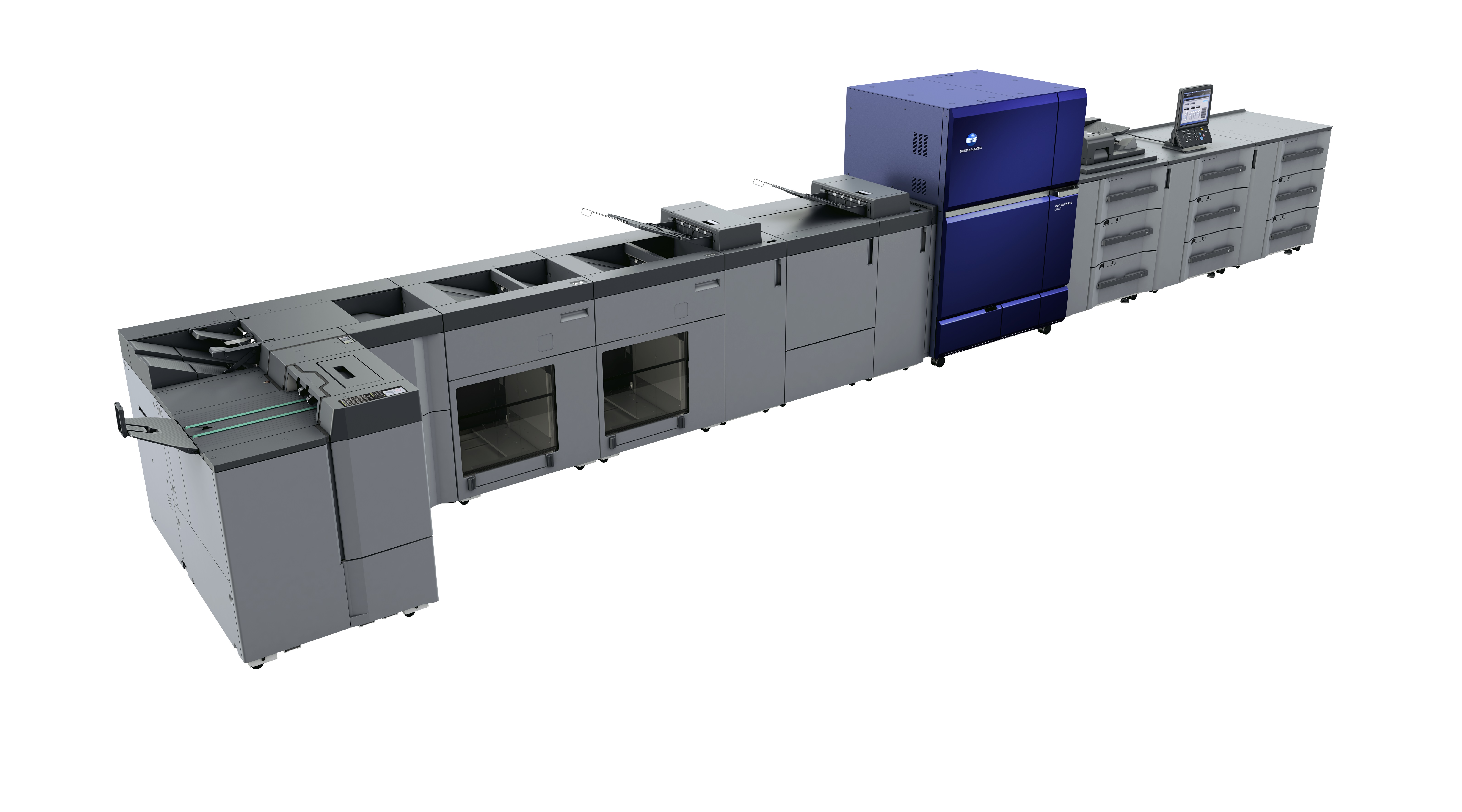

Konica Minolta Australia has announced the release of the AccurioPress C14000 series high-volume production presses, which will be available locally early next year. The presses offer higher total ...

November 12 2019

Konica Minolta Australia has announced the release of the AccurioPress C14000 series high-volume production presses, which will be available locally early next year. The presses offer higher total productivity and efficiency that will really change the game for commercial printers.

The 140 ppm AccurioPress C14000, along with the 120 ppm AccurioPress C12000, were designed from the ground up to be digital print factories. These presses really demonstrate Konica Minolta’s mission to support the transformation of its clients, with a number of advanced automation features and accessories that will help printers expand and streamline their operations to deliver increased, high-quality output with less waste.

The AccurioPress C14000 series offers the new TU-510 versatile trimmer unit for advanced operational efficiency. The TU-510 is a truly unique inline, four-edge trimmer and creaser that allows full bleed finishing support for banners, booklets, direct mail and a dedicated business card cutting option. In addition, the AccurioPress C14000 series is equipped with the Intelligent Quality Optimiser (IQ-501) as standard, which can also improve labour efficiency by as much as 30 per cent.

Sue Threlfo, general manager, production and industrial print, Konica Minolta Australia, said, “The new AccurioPress C14000 series will be a game-changer for the industry. With the TU-510 inline trimmer unit and advanced automation features designed to maximise efficiency these presses will provide significant value to those in high-volume printing environments where deadlines are tight, quality is key and efficiencies must be gained. We are really looking forward seeing these new presses arrive in Australia early next year.”

Mark Brown, national product marketing manager, Konica Minolta, said “The AccurioPress C14000 series is ideal for helping Australian printers attract and retain new customers, providing exceptional quality output at high speeds. This will let printers be more productive and turn high-quality jobs around faster, delivering an outstanding customer experience.”

Opportunities for business expansion

The unique features of the AccurioPress C14000 series make them ideal for customers looking to increase productivity through efficiencies and speed to grow their business. With resolution equivalent to 3600 x 2400 dpi and enhanced media capability up to 450 gsm, they offer breathtaking speeds with outstanding image quality and unparalleled media flexibility.

New duplex banner printing up to 900 millimetres and simplex banner length capability of 1300 millimetres combined with envelope and embossed media capability gives customers the opportunity to offer new types of work, such as four-panel gatefold brochures and book covers for finishing offline. To further improve efficiency and output, envelope printing can be accomplished using the standard fuser. Finally, new technology used in the print engine dramatically improves image quality on textured paper stocks.

Operational efficiency

Paired with Konica Minolta’s enhanced IQ-501, the new presses automatically and continuously measure and manage colour to ensure the first print in a run matches the last. Two-dimensional registration correction has also been improved through the higher output resolution. The automatic media detection sensor comes standard on these models, detecting the stock and assigning the appropriate tray, eliminating time consuming paper settings and operator error, reducing waste and increasing productivity.

The LS-507 large stacker supports higher speed, permits banner bypass and offers operators the advantage of offloading while the machine is still running, another new benefit added to Konica Minolta’s AccurioPress expanded line.

Convenient colour management and job management utilities are available with the Konica Minolta’s proprietary controller. A customisable operation screen makes the products extremely easy to operate. Other third-party controller options include the latest Fiery and Creo models.

Stability, high durability and reduced downtime improve total cost of ownership

Konica Minolta’s IQ-501 enhanced auto inspection options offer expanded inspection performance, verifying print quality and now detecting streaks and spots as well as blemishes. The high-quality prints mean maximum stability even during long-run jobs, while better registration and quality increases total usable print volume. The new presses offer a highly reliable duty cycle of 2.5 million, up from 1.8 million with the AccurioPress C6100, with double the toner capacity of earlier models.

The new AccurioPress C14000 and C12000 will be available in Australia in March 2020.