Eclipse is a process-free printing plate for sheet-fed commercial printers that combines all the benefits of process-free technology with effortless printing. Eclipse is a process-free...

October 29 2019

Eclipse is a process-free printing plate for sheet-fed commercial printers that combines all the benefits of process-free technology with effortless printing.

Eclipse is a process-free printing plate for sheet-fed commercial printers that combines all the benefits of process-free technology with effortless printing.

Inherent to the nature of a process-free plate, Eclipse eliminates the need for a processor using chemicals. It thus reduces printers’ capex and prepress costs. Agfa’s latest innovation, however, distinguishes itself from other process-free plates as this drop-in is just as easy to use as a conventional plate:

First of all, the plate keeps the press as clean as can be. Patented process-free technology supports the transfer of the plate coating to the first few printed sheets, instead of to the press as is the case with other process-free plates.

In addition, Eclipse is the only process-free plate to provide excellent and stable image contrast, enabling quick visual image inspection as well as recognition by a punch & bending system. That way – even after a week of storage – there will be no mix-ups on press or costly plate remakes. Eclipse keeps its great contrast even after 24 hours in office light, which makes an enormous difference compared to the two hours of other process-free plates. During this period, print quality will be fully preserved in terms of dot gain, toning, start-up time…

Another reason that makes Eclipse an outstanding choice for those desiring to go process-free, is its high scratch resistance. When loading, storing, transporting or mounting this robust plate, printers need not worry about damaging it. The new plate is flexible too, as it can be used with either conventional or H-UV/LED-UV inks.

A balanced proposition

Eclipse complements Agfa’s offset printing plate portfolio, which meets printers’ needs in different ways. “We are continually looking for ways to stay ahead of the curve and to provide the highest added value to our customers,” said Guy Desmet, Head of Marketing Offset Solutions. “There is no ‘one-size fits all’ when it comes to printing plates. Our portfolio consists of conventional, low-chem, chem-free, and process-free plates. We will always discuss the ideal solution with printing companies, based on their needs and preferences.”

Eclipse is part of Agfa’s ECO³ approach of sustainable innovation, which encompasses hardware, software and consumables that make prepress and printing operations cleaner (ECOlogy), more cost-effective (ECOnomy) and easier to operate and maintain (Extra Convenience). ECO³ extends from the prepress environment into the press room with unparalleled ink saving and press standardization software packages that reduce make-ready time and paper waste.

Next-generation bizhub i-Series seamlessly connects the dynamic office Konica Minolta Australia, a leader in delivering world-class business transformation solutions and technolo...

October 29 2019

Next-generation bizhub i-Series seamlessly connects the dynamic office

Konica Minolta Australia, a leader in delivering world-class business transformation solutions and technologies, has unveiled the new bizhub i-Series, the next generation multifunction device product line from the award-winning bizhub legacy portfolio. Born from the company’s continuing ambition to create value for customers and driven by the desire to rethink the way multifunctional devices work for them, the i-Series is a smart technology hub that fully embraces the way businesses are evolving and sharpens their competitive edge.

The smart device technology augments office connectivity, optimising the way the office works while preparing it to be future-ready from operational improvements to digital transformation. Powering new opportunities for productivity and innovation, the i-Series provides the necessary tools for an effective communications network. It simplifies complexities to improve productivity and streamline business processes, for better decision-making and, ultimately, enable smarter business. Breaking through traditional office limitations, it helps navigate quickly to demands and changing conditions.

Shane Blandford, director of marketing and innovation, Konica Minolta, said, “As office documents become more digitised and data volumes increase, document management and access assume more importance than ever. Remote access and cloud integration also heighten the need for security.

“Multifunctional devices and printers are now expected to connect people, places and devices simply and safely and create a new way of working. Konica Minolta wanted to provide a new-value office tool that could be used intuitively by digital natives. That intent gave rise to the second generation bizhub, the bizhub i-Series. The consistent and simplified usability of the new i-Series range, along with class-leading performance and connectivity enhancements make these our most productive multifunction devices.”

Simple design and usability

The stylish, contemporary design boasts an intuitive smartphone style user interface with a tiltable, floating 10” touchscreen panel, rounded edges, and LED status indicators. The interactive user experience provides ease-of-use through reduced wait times, vibration feedback, and customisation. Conveniently, both the A3 and A4 multifunction models function in precisely the same way so users can be productive, regardless of the specific device.

High-quality performance, enhanced efficiency and seamless connectivity

The i-Series multifunction models house a powerful engine, a quad-core Central Processing Unit with up to 8GB of memory and 256GB SSD, for quick-response, high-performance operations. And, the additional combination of full-speed media printing range, high-speed one pass double feed, digital skew correction, and large capability trays for the A3 models, expertly blends reliable functionality with versatile serviceability. Further extending the capabilities of the i-Series and adding flexibility, Konica Minolta MarketPlace gives the freedom to personalise the user interface and provides direct access to apps that boost business productivity. Efficiently integrating work processes and connections, it caters to all types of changing needs and fully accommodates evolving workstyles.

Smart service and next-level security

Minimising downtime and ensuring uninterrupted use, the i-Series intelligently collects data for self-diagnosis and for optimum replacement time predictions of parts and consumables. The exceptional service comes with an outfitted layer of top-grade security, which gives businesses one less thing to worry about. With bizhub SECURE services (optional) and self-encrypting SSD, the i-Series fosters a secure work ecosystem where data is protected and reliably accessible. Additionally, the optional BitDefender anti-virus extension automatically scans all transmitted and received data in real time, so data remains protected from external threats. All i-Series models are compliant with General Data Protection Regulation (GDPR), and ISO 15408 certified HCD-PP, so data privacy standards and security requirements are met in order to stay productive.

Commitment to sustainability

Konica Minolta is committed not only to innovation but to environmental sustainability. The fruition of the new i-Series reflects upon this strong commitment. As part of the top energy-saving bizhub product line, each model conforms to globally recognised standards from such organisations as EPEAT and Blue Angel. The new fusing unit and low-temperature fixing toner help achieve lower energy consumption in operating and sleep modes. Environmental impact is reduced further through the new packaging design, as traditional cushioning material has been replaced with lighter air cushions, still ensuring safety during transport. Best of all, operating sounds are quieter due to improvements made to the cooling fan and the document feeder mechanism resulting in fewer distractions for a better-focused work environment.

Shane Blandford said, “Konica Minolta recognises the i-Series as the next step; the innovative technology that lets businesses perform at their best and achieve high-quality work, all while providing the peace of mind for them to focus on more important matters. And, as businesses continue to evolve, the bizhub i-Series will grow with them.”

The new i-Series models available now are the bizhub C250i, C300i, C360i, (A3 colour MFPs), C3350i, and C4050i (A4 colour MFPs), C4000i and C3300i (A4 colour printers) and the C3320i (A4 colour MFP). Additional models to the i-Series product lineup will be released in the coming months.

iSeries will be on display at Stand E38 at CEBIT at the International Convention Centre Sydney from October 29-31.

SCREEN Graphic Solutions (SCREEN GA) has added the Truepress Jet520HD AD to its Truepress Jet520HD series of roll-fed high-speed full colour inkjet presses. The new system features an Advanced Drye...

October 22 2019

SCREEN Graphic Solutions (SCREEN GA) has added the Truepress Jet520HD AD to its Truepress Jet520HD series of roll-fed high-speed full colour inkjet presses. The new system features an Advanced Dryer unit that further enhances drying performance and will be released worldwide in late October.

The introduction of the Internet has triggered rapid diversification in the information media field. Likewise in the printing industry, the active use of digital printing technologies has led to an increasing need to create new added value for printed materials via approaches including mixed, small lot and personalized production.

In recent years, progress in inkjet technologies has enabled related systems to achieve both the quality to rival offset printing and outstanding throughput. SCREEN has been a leader in this new technology segment, launching its Truepress Jet520HD in 2015 and Truepress Jet520HD+ in 2018, and has made a major contribution to the development of new business models for the printing market.

The Truepress Jet520HD series offers high-precision printing at resolutions of up to 1200 dpi and the ability to output directly onto offset coated papers using SCREEN’s independently developed Truepress SC Ink. However, there are remaining challenges and demands from users who require both even greater productivity and further improvements in the volume achievable for images in printed materials.

The Truepress Jet520HD AD, featuring an Advanced Dryer unit that delivers enhanced drying performance, is specifically designed for users who require improved density and performance when printing on coated papers. The new addition to the Truepress Jet520HD series lineup is expected to further expand the business areas supported by inkjet presses.

SCREEN has an impressive track record of creating inkjet technologies that provide outstanding speed and quality as well as advanced production line automation and other solutions designed to solve customer needs. The company intends to use these and future developments to pioneer new markets and contribute to the continuing expansion of the printing industry.

Note: Truepress and Truepress SC Ink are registered trademarks and/or trademarks of SCREEN Holdings Co., Ltd. in Japan and/or certain other countries.

At Labelexpo Europe 2019 (stand 9A34, Brussels Expo, 24 - 27 September), Fujifilm is showcasing a range of new products designed to help label converters optimise their existing flexo presses, unde...

September 30 2019

At Labelexpo Europe 2019 (stand 9A34, Brussels Expo, 24 - 27 September), Fujifilm is showcasing a range of new products designed to help label converters optimise their existing flexo presses, under the slogan "Protect the planet and your profits". Consisting of enhancements to the company's water-washable flexo plate and processing systems, together with new LED UV curing and imprinting solutions, Fujifilm will be highlighting just how efficient and eco-friendly the production of high quality labels can be.

On show for the first time will be Flenex FW-FP, Fujifilm's new water-washable plate for flexible packaging, joined by the upgraded SB-938 FLW water-washable plate processor and the brand new Aquarius Water Treatment System. New Sericol JJ LED UV flexo ink and JF indirect food packaging compliant UV cured inks are also being displayed alongside Fujifilm's established Illumina cold cure LED UV system and additional new ACTIV LED UV system, while a new industrial imprinting system will also be showcased at the exhibition.

Nills Gottfried, Segment Product Marketing Manager at Fujifilm Graphic Systems Europe says: "This year's Labelexpo promises to be an exciting one for Fujifilm. We're delighted to be presenting a range of new products for the labelling market, alongside established products many visitors may still wish to learn more about. All are designed to ensure the highest quality label production achieved in the most efficient, profitable and eco-friendly way possible.

Water-wash plate and plate processing equipment Fujifilm's new Flenex FW-FP plate features all the quality benefits of the established FW-L2 plate as well as added solvent resistance, reduced curling effect and a thicker polyester base of 188µm.

SB-938 FLW is Fujifilm's easy access, all-in-one, semi-automatic water-washable plate processor designed to provide efficient plate handling. In combination with Fujifilm's Flenex FW plates, the SB-938 FLW processor offers the fastest platemaking times in the industry - under 40 minutes. This is 3 times faster than leading solvent systems and 1.5 times faster than current thermal and water technologies. Says Gottfried: "Our upgraded SB-938, with its best-in-class waste water capabilities, is a prime example of Fujifilm's desire to manufacture products that support the ever evolving environmental requirements demanded by the industry. It has an array of new features, including a washing section which minimises water use during rinsing, a liftable brush frame providing easier access for cleaning and a unique remote diagnostic service, to name a few."

Rounding off Fujifilm's new flexographic equipment is the new Aquarius Water Treatment System. Used in combination with either the C-Touch or SB-938 water-wash flexo plate processors, Aquarius reduces water usage, prolongs the bath life and reduces waste water and processor cleaning times.

In combination, Fujifilm's newest Flenex plate, processor and water treatment system can help label converters reduce water use while also ensuring that their equipment functions effectively for as long as possible.

LED UV systems and inks

Fujifilm is also launching a new LED UV retrofit curing system called ACTIV, which allows any traditional UV flexo press to be converted to LED UV curing, bringing major improvements to label production. "ACTIV takes advantage of the very latest LED UV curing technologies, along with Fujifilm's ink expertise, to deliver an industrial, reliable curing system with none of the disadvantages of higher power and higher temperature conventional UV lamps," says Gottfried. "ACTIV accelerates productivity, as well as offering quality improvements, greater application versatility, cost and material savings, and reduced environmental impact."

This new LED UV curing system will be demonstrated alongside the established Illumina LED UV curing system, presented at Labelexpo in 2017.

Launched in tandem with ACTIV is Fujifilm's new high performance, Sericol JJ LED UV flexo ink and Sericol JF indirect food packaging compliant UV cured ink. Both are designed for use with the Illumina and ACTIV LED UV curing systems, as well as most other LED UV curing systems. The Sericol JF flexo UV ink is formulated to comply with Swiss Ordinance SR 817.023.21 and Nestle Guidance Note on Packaging Inks 02-2014 and EC Regulation on GMP 2003/2006, making it suitable for indirect food packaging, in accordance with EuPIA guidelines.

Finally, as a technical preview, Fujifilm's new Industrial Imprinting System offers variable data printing at industrial production speeds. In an era of mass customisation, imprinting provides a great opportunity to add value and help to increase the range of solutions companies can offer. Fujifilm's new imprinting solution is highly productive and can be fully integrated easily into existing packing or filling line equipment. Using Fujifilm's inkjet technology, the imprinting system can print images or information as text, logos, QR or barcodes, or any other customised data.

Gottfried concludes: "If label converters want to find out more about how they can optimise their existing flexo presses with the latest innovative solutions, we recommend they visit the Fujifilm stand at Labelexpo. With new products across the stand, Fujifilm will be demonstrating how label production can be made more flexible, efficient, profitable and ultimately more eco-friendly."

Mark Andy is highlighting four product releases at Labelexpo Europe, including a new flexo press. Mark Andy has introduced the Evolution Series to its suite of flexographic offerings. ...

September 30 2019

Mark Andy is highlighting four product releases at Labelexpo Europe, including a new flexo press. Mark Andy has introduced the Evolution Series to its suite of flexographic offerings.

A simple-to-operate platform powered by proven Mark Andy engineering and technology, the Evolution Series provides converters a scalable production solution designed to serve their business needs today while providing adaptability to the needs driving future business growth.

The Evolution Series, demonstrating live at the show, is available in 13” and 17” (330 and 460 mm) web widths with production speeds up to 750 fpm (230 m/m) and is available for immediate order.

Tom Schelmbauer, chief business officer, Mark Andy Flexo, says the Evolution Series is a strategic addition to the company’s flexo solutions by providing full servo technology previously unattainable to this wide of a range of the market. “Full servo flexographic printing is now within reach for all converters,” explains Schelmbauer. "This technology, with the highest possible quality and engineering, has been a longstanding – and noticeably absent – request in the industry. Building on the success of our existing technology, we’re able to bring the Evolution Series to market as a solution for converters that need a label or film press with the capability to grow as their business grows. “

In addition, Mark Andy’s Digital Pro line is making its European debut. This modular entry- to mid-market digital system is running live at the stand– specifically the Digital Pro 3, the advanced inline converting model fitted with semi-rotary diecutting.

The roll-to-roll configuration, Digital Pro 1, is also on display on stand 8A60, extending Mark Andy’s presence to the “Digital Hall” for the first time. Printing at 77 fpm (23.4 m/m), the new product line provides production-level speed for all applications in addition to a low cost to print, giving companies priced out of production systems the opportunity to benefit from digital.

Digital Series HD, a 7-colour UV inkjet press with QCDC-SR, Live VDP and StitchAI, is making its first appearance in Brussels since launching in spring of 2018. Mark Andy’s full-production true hybrid digital inkjet system is now available in 17” (430 mm) web-width, and is being demonstrated four times daily, with special demonstrations highlighting its high-speed shrink sleeve capabilities.

Representatives from Mark Andy Print Products Europe are on-stand during the show, as well. Mark Andy Print Products, now supporting European converters and customers, offers all essential flexo pressroom consumables, including, plate mounting tape, doctor blades, anilox rolls, splicing tape, pressroom chemistry, and more.

RISO Kagaku Corp. has launched a new brand of high-speed production inkjet printers. The brand’s first product, the VALEZUS T2100, is a high-speed, 320-ppm full-color cut-sheet printer....

August 27 2019

RISO Kagaku Corp. has launched a new brand of high-speed production inkjet printers. The brand’s first product, the VALEZUS T2100, is a high-speed, 320-ppm full-color cut-sheet printer.

One of RISO’s commanding strengths is the development of inks optimized for high-speed paper feeding and high-speed printing. This expertise enables RISO to deliver unique printing solutions serving the demand for high-volume printing.

By connecting printer engines to print the front and back sides respectively, the VALEZUS T2100 achieves a fast double-sided printing speed of 320 ppm. The VALEZUS T2100 offers a compact footprint for a production printer as well as superior ease of use and maintenance.

With these features, the VALEZUS T2100 increases productivity and dramatically improves work efficiency in high-volume printing. In high-volume printing applications, such as transactional printing at print service providers, in-house printing at financial institutions, insurance companies and government offices, the VALEZUS T2100 opens a world of new possibilities in cut-sheet printing.

The VALEZUS T2100 will be available in the fall, and RISO Inc. will show the inkjet printer at PRINTING United, October 23 - 25 in Dallas.

Main features of the VALEZUS T2100:

The VALEZUS T2100 can print 320 ppm (continuous printing of A4-sized paper with long-edge feed on standard settings) or 19,200 pages per hour (not including cleaning time), based on full-color, double-sided printing of A4-sized paper. Because the VALEZUS T2100 is a cut sheet printer, it can easily handle short-run jobs as well, enabling speedy processing of a diverse range of jobs.

The VALEZUS T2100 is equipped with two high-capacity feeder/stacker units, each capable of feeding and stacking up to 4,000 sheets (total of 8,000 sheets). The two units can be switched while the printer is active, allowing users to load/unload paper without stopping the job. Also, the stacker unit is equipped with a jogger mechanism and dedicated cart, enabling smooth transition to post-processing after printing. The feeder/stacker units are scheduled to be available in the spring of 2020.

The VALEZUS T2100 can fit in existing workflow of customers. It supports PDF and Postscript, generally used in an open system environment as well as AFP/IPDS, which is used as an industry standard for mission-critical production print applications.

The VALEZUS T2100 incorporates an inkjet system that adopts oil-based inks ensuring energy-saving operation. Oil-based inks contribute to energy-saving because there is no need for ink-drying heaters required for water-based inks, and unlike toner-based technologies, there is no heat-fixing process required.

Mark Andy has announced the launch of Digital Pro, the latest development to its digital product offerings. The new product line comes to market with 77 fpm (23.4 m/m) production speed for all appl...

August 12 2019

Mark Andy has announced the launch of Digital Pro, the latest development to its digital product offerings. The new product line comes to market with 77 fpm (23.4 m/m) production speed for all applications and low cost to print, allowing businesses priced out of production systems the opportunity to benefit from digital.

Available for immediate order, the CMYK dry toner Digital Pro line includes a roll-to-roll press, Digital Pro 1, and a configurable inline hybrid model, Digital Pro 3. The systems are priced starting at $199,000 USD and $295,000 USD, respectively, and will be initially showcased at regional events throughout North America starting August 2019.

The product will make its European debut at Labelexpo Europe this September in Brussels.

Digital Pro 1 is a roll-to-roll machine, fitted with an unwind, state of the art print engine and rewind, providing 12.5" digital print width. The introductory Digital Pro system is important for plants with established converting and finishing workflows, simplifying digital print for operators to a click of the button. As business and workflows evolve, the modular nature of Digital Pro 1 provides an upgrade path with scalable inline printing and converting options.

Digital Pro 1 is joined by the advanced inline hybrid model: Digital Pro 3. This system includes a multi-purpose flexo station for inline embellishment and is fueled by a robust DFE that supports variable data printing and versioning needed in the short- and micro-run market segment.

Digital Pro 3 can be configured with a single slot die station or with a semi rotary die module to finish labels inline. The semi-rotary system reduces die inventory and comes with a standard 19" magnetic cylinder to accommodate most repeats without tool changeover.

Digital Pro system is fueled by a high-yield toner and supports a wide range of substrates and applications with no priming or coating required. Additional media capabilities supported by the product line include vinyl, PVC, foil.

Joe Calmese, chief business officer, Mark Andy Digital, says, “Printing digital at high speeds with inline converting is at the top of many converters' wishlists. Same with roll-to-roll devices. We’ve been listening. The end result is the Digital Pro line with configurable hybrid print systems that provide a powerful path to profitability, both now and in the future as we continue to push the envelope in digital innovation”

Digital One press owners are eligible for a field upgrade of the new Digital Pro engine into their existing machine to optimize production and help increase margins with a substantially lower cost to print structure. The Digital Pro engine upgrade provides a 70% increase in speed and a 30% lower cost to print over the previous generation Digital One press. Current Digital One customers will continue to receive the high level of support and service they have come to expect from Mark Andy.

A new LED back-lighting kit from Vastex illuminates the translucent acrylic back panel of screen washout booths, improving visual inspection of the screen surface being reclaimed. Offe...

July 30 2019

A new LED back-lighting kit from Vastex illuminates the translucent acrylic back panel of screen washout booths, improving visual inspection of the screen surface being reclaimed.

Offered in two sizes, in 120 or 240V, the kit is optional on new equipment and can be retrofit to all existing Vastex washout booths and certain other makes. Both the light and switch are IP65-rated as being dust- and water-tight.

Model VWB-LK2 measures 24 x 2 in. (610 x 51 mm) for booth chambers ≤4 ft (1219 mm) wide, while Model VWB-LK4, at 48 x 4 in. (1219 x 102 mm), is sized for chambers ≥4 ft (1219 mm) wide.

The units attach to the washout booth upper frame with mounting brackets supplied.

Vastex washout booths feature stainless steel construction, frosted acrylic back panels, squeegee shelves and a screen stand-off that holds screens in place during wash-down. An optional vacuum tool removes excess water from screens for quick drying.

The company also manufactures screen printing presses in one to 10 colours and one to 10 stations, athletic numbering accessories, flash cure units, infrared conveyor dryers, heat presses, screen exposing units, screen drying cabinets, screen registration systems and complete screen printing shop systems, and offers a comprehensive range of training classes for entry level, intermediate and advanced screen printers.

MPS has released its next-generation flexo press technologies: the EFS and EFA, replacing the former EF series. ‘With a beautiful design, new colours and even more operator...

July 17 2019

MPS has released its next-generation flexo press technologies: the EFS and EFA, replacing the former EF series.

‘With a beautiful design, new colours and even more operator-friendly innovations, the EFS and EFA flexo presses are the next level that this market demands,’ said Atze Bosma, CEO of MPS Systems.

The EFS and EFA are both multi-substrate presses designed for printing labels and flexible packaging on any material, varying from thin unsupported films, self-adhesive labels, shrink sleeves and cartonboard up to 450μm.

The highly automated EFS enables operators to maximise press performance with ease of operation, high productivity and reliability. The automation on the EFS includes the automatic loading of job settings using job memory, AutoTeach for quick and automated register settings, and iStop for job changes with minimum waste.

The EFS is designed with high-quality print sleeves and many MPS innovations as standard, such as iControl, Crisp.Dot, Quick Change Die station. EFS is suitable for the ‘Talk to me’ connectivity platform for data exchange, performance monitoring, pre-loading of job settings and remote support.

The EFA press provides servo-controlled pressure settings for the print sleeves and aniloxes at each print station.

‘Our EFA is the best option for any printer looking to achieve maximum performance capability from their press,’ said Bosma. ‘With full automation of all print pressure settings and the ergonomic slide-out ink drawer as a standard feature, this press is the ultimate in operator-friendliness. With all options for connectivity, it is the most future-proof solution for a printer’s business.’

With the introduction of the EFS and EFA press lines, the existing press colour scheme is also adjusted. The main part of the of the presses will come a darker anthracite for a high-quality look and feel. The new colour design featured in the EFS and EFA presses will be reflected in production builds of the hybrid EF Symjet, EXL-Packaging and EXL-Offset presses as well.

The hybrid EF Symjet press, with the name unchanged, is now available with the EFS and EFA platforms.

Xante' today announced the EnVite Multi-Media Digital Press, its newest innovative digital press designed for the demanding stationery and specialty printing markets. Stationery stores serve custom...

July 15 2019

Xante' today announced the EnVite Multi-Media Digital Press, its newest innovative digital press designed for the demanding stationery and specialty printing markets. Stationery stores serve customers who have very high standards and so does Xante', said Robert Ross, President and CEO. The EnVite delivers extremely high-quality, fast and fully automated prints on specialty media and does so at a very affordable price.

The EnVite produces stunning 4800 dpi colour quality on an extensive range of media types and sizes. Well-suited to fast production of invitations, envelopes, stationery, business cards and greeting cards, EnVite boasts speeds of up to 3,500 full-colour, fully-addressed A7-size envelopes per hour and media sizes from 3.5x3.5 up to 13x49. The digital press includes the Enterprise SP, a radical new design high-speed feed system that fits comfortably in the limited floor space of stationery stores. With the EnVite, stationery stores will be able to print on a wide range of media including vellum, linen, sueded, pearlised, and foil-lined envelopes. EnVite print markets include small poster printing, menus, postcards and so much more.

Powered by Xante's iQueue workflow software, the EnVite provides stationery stores with rich personalisation and customisation tools to satisfy any requirement.

We designed a product that greatly expands the capability of the typical stationery shop, said Mark Priede, Xante's Vice-President of Global Sales and Marketing. The extensive variable data printing tools included at no extra charge in iQueue make each print job unique and personalized. Customers can bring their own designs or use any of iQueue's more that 1,000 free design templates and specialty fonts. EnVite and our iQueue workflow software make outstanding personalised print jobs incredibly easy.

The Xante' EnVite Multi-Media Digital Press is available immediately direct from Xante' or its reseller partners around the globe.

July 02 2019

Xerox has unveiled a new entry-level cut-sheet production inkjet by press that it says will leapfrog the competition with new advantages of value, volume, and velocity — a combination that could help to open up inkjet to more in-plants.

Xerox announced the launch of its Baltoro HF Inkjet Press on June 26 in Rochester, N.Y., noting that it will succeed the Brenva as the company’s cut-sheet production inkjet platform. Baltoro will print on a range of uncoated plain, inkjet treated, and coated paper without priming or pretreating, increasing its productivity.

The press will print at speeds up to 18,000 images per hour. It boasts a 13.76x20.25˝ maximum image area and true 1,200x1,200-dpi resolution. Among its features for high productivity and quality are Xerox Automated Intelligence and Advanced Image Controls (AI) and inline spectrophotometry by X-Rite. It also is available with a dynamic perforator from Tecnau plus other inline finishing options.

Xerox says that Baltoro enables clients to print high-volume, transactional work and high-quality direct mail and catalogs on a single press with superior image quality and productivity. The Baltoro HF is Xerox’s first product built on this platform.

“We engineered the Baltoro HF by leveraging the best of our iGen and High Fusion inkjet technologies,” said Tracey Koziol, senior VP of Global Offerings at Xerox. “The result is a breakthrough platform that expands into the commercial print environment and supports high-quality production with economics similar to offset printing.”

“Designing and manufacturing the Baltoro HF from the frame to the engine gives us a greater ability to continuously advance the platform at a faster clip,” Kozol continued.

The Baltoro HF Inkjet press is the first Xerox press to use this type of technology. Xerox claims the Baltoro HF is the only press in the entry-level class to use automated intelligence to optimize and maintain color and image quality as well as self-correct in real time.

The automated intelligence of the press, together with its High Fusion ink and Xerox High Fusion W-Series Inkjet Heads, reportedly delivers true, high-definition 1,200x1,200-dpi image quality without the need to condition media with priming solutions or precoats. Xerox notes that eliminating the priming solution reduces press size, power consumption and total cost of ownership while increasing productivity.

The Baltoro HF also offers additional time-saving advantages. Its speed, paired with having the widest print area in its class, enables the press to increase client productivity by more than 115%. On the front end,Xerox FreeFlow Core automates the time-consuming prepress work, while Xerox FreeFlow Print Server allows clients to add new jobs while the press is running.

SCREEN GP Australia has announced availability of its PlateRite Ultima 24000N series of thermal plate recorders capable of up to 24 x A4 pages on a 1632mm x 1325mm plate. The series features the la...

May 28 2019

SCREEN GP Australia has announced availability of its PlateRite Ultima 24000N series of thermal plate recorders capable of up to 24 x A4 pages on a 1632mm x 1325mm plate. The series features the latest GLV (grating light valve) imaging heads and delivers high throughput of up to 35 full-sizeplates per hour (Z model), with an outstanding cost performance.

“VLF, or very large format, CtP is experiencing an upswing in Australia and New Zealand as the demand for faster plate changes on both wide web and oversize sheetfed litho machines increases,” says local Managing Director Peter Scott. “Markets include publishing, packaging, POS and platemaking where several jobs are ganged up on one plate. We already have very strong interest in the new Ultima 2400N and expect installations to happen this year.”

PlateRite Ultima 24000N series

Several plate sizes are possible on the new Ultima 24000N series and Screen has optimized the plate sizes series to suit these presses. Two new versions offer significantly more compact footprints than the existing models with even greater productivity and cost performance.

The PlateRite Ultima 24000N series incorporates the latest GLV imaging heads with an upgraded optical system. These heads support the output of Screen’s proprietary Spekta 2 hybrid screening, enabling richer, high-resolution results. The 24000N-Z model is equipped with a 1,024 channel head that boosts output up to 35 VLF plates per hour, or 45 plates per hour when making B1 1030mm x 800mm sized plates.

The 512 channel 24000N-S model also improves throughput to 24 plates per hour, from the 22 plates offered by its predecessor. Both models are able to handle plates from 650 x 490 mm up to 1,652 x 1,325 mm, comprehensively covering the sizes used by large-format presses. In addition, the new series can be used with Screen’s MA-L40000 multi-cassette autoloader, capable of automatically supplying up to 300 plates, to achieve extended continuous operation. Screen also plans to develop a new model of its Skid autoloader, which is able to deliver a larger number of uniformly sized plates.

The whole system can be linked to TRUST Network Service, the company’s sophisticated online maintenance support service, helping to ensure trouble-free operation.

Screen CtP thermal platesetters are available through plate suppliers such as Fujifilm, WRH Global/Xingraphics and, for flexographic CtP, Jet Technologies. The company will be at PrintEx 2019, Sydney August 13-16 on stand B08.

www.screenaust.com.au

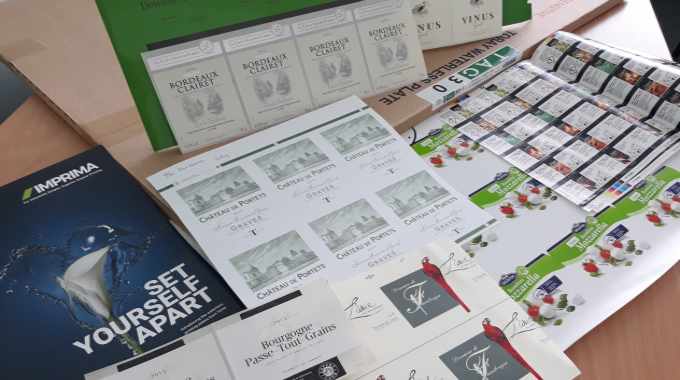

Toray Graphics, a manufacturer of waterless offset plate technology based in the Czech Republic, has introduced a new waterless offset printing plate, Imprima LJ. Toray described the n...

May 28 2019

Toray Graphics, a manufacturer of waterless offset plate technology based in the Czech Republic, has introduced a new waterless offset printing plate, Imprima LJ.

Toray described the new water-washable plate as having high quality and durability. Its printing resolution is up to 175 LPI.

The thermal negative CTP printing plate uses a standard imaging wavelength of 830 nanometers. It is suitable for label production but can also be used for a wide range of other applications, including CD/DVDs, loyalty cards, metal decoration and for printing on non-absorbent substrates.

These plates are also suited to printers using UV curable inks as well as for sheet-fed and on web presses that require production quality such as density stability during the print run,’ said the company in a statement. ‘Its high resistance to chemicals and UV inks makes it an extremely durable plate. It also offers excellent screening at 1-99 percent with 36 micron FM or hybrid screening, and 2-98 percent with AM screening at 175 LPI.’

Since it is a water-washable plate, it requires no chemicals in the developing process, and can be processed in most available waterless processors. It also does not require post-baking. This makes it easy to insert into any offset workflow and results in low-cost processing.

Other benefits of this new plate are said to include:

- Stable dot reproduction

- High ink coverage

- Up to three hours daylight resistance under standard safe-light conditions

- Long shelf life, suitable for archiving

- Compatible with all waterless inks

Following this launch, Toray said ‘in the near term’ it will introduce a new plate type for other printing segments: the Imprima WJ high resolution and high durability water-washable plate.

SCREEN Graphic Solutions has finalised development of a new blue ink intended for use in its high-end Truepress Jet L350UV+ digital label printing system. The ink will be released worldwide in June...

May 21 2019

SCREEN Graphic Solutions has finalised development of a new blue ink intended for use in its high-end Truepress Jet L350UV+ digital label printing system. The ink will be released worldwide in June.

In recent years, the growing awareness of corporate and product brand image has led to a continuous increase in demand for higher quality product labelling and packaging. At the same time, there has been a growing need for the ability to use the blue colours often required for corporate designs and product packaging with digital label presses to provide greater flexibility and impact.

In response to these trends, SCREEN GA has developed ‘Truepress ink for L350UV Blue’. This new blue ink is designed for use with the company’s Truepress Jet L350UV+ system, a high-end UV inkjet label printing model that also offers features including industry-leading print speeds of up to 60 metres per minute, wide media compatibility and outstanding operability. SCREEN GA’s exclusive expertise has enabled it to successfully extend the blue colour gamut to its maximum potential.

The system’s ability to handle blue ink in addition to conventional CMYK and white inks allows it to faithfully reproduce blue colours in corporate designs that were previously difficult using process colours alone. It is also able to precisely output a wide range of blue tones frequently used on the packaging of items such as cosmetics, toiletries and body care products. These expressive capabilities help to improve brand image and create products that truly stand out from competitor items in the marketplace.

Screen Europe will be showing the Truepress Jet L350UV+ with the new blue ink at the inaugural LabelFest Open House event at its Amstelveen showroom in the Netherlands on 15th & 16th May 2019. Partners joining Screen at the event include CERM, Hybrid Software, Avery Dennison, Rotocon Europe, SEI Laser, CGS and Kurz. Carlo Sammarco, Screen Sales Director Packaging Solutions EMEA, said; “Visitors to LabelFest will be able to see a fully integrated digital label production system in operation and will have the opportunity to discuss their requirements with members of the Screen team and with our partner vendors.”

SCREEN GA intends to continue its efforts to provide solutions to the diverse market needs connected to label printing. It will also continue to promote the creation of new applications and business models as it works to support the expansion of the label and packaging industry.

Global printing industry leader Inkcups announced the release of its newest product, the Helix Hi-Fi, a 7-colour rotary digital printer that delivers photorealistic skin-tone matching with the addi...

May 14 2019

Global printing industry leader Inkcups announced the release of its newest product, the Helix Hi-Fi, a 7-colour rotary digital printer that delivers photorealistic skin-tone matching with the addition of three new colour pockets.

The Helix Hi-Fi is an evolution of the Inkcups Helix, the industry’s best-selling printer in its class. In addition to Helix’s standard CMYKWV, the Helix Hi-Fi has three additional colours: light cyan, light magenta and light black. While the standard Helix already delivers the best image quality in the industry, the addition of the light colours brings output quality to a new level. The benefits are most dramatic in printing skin tones where true photorealistic images are generated with smoother shade transitions, less graininess, and higher-resolution edge effects.

The Helix Hi-Fi’s unique skin-tone matching function is increasingly in demand for personalised printing, which often requires one-off production of facial images. Helix Hi-Fi can import a series of unique image files and produce high-resolution printed products of stunning quality. Typical applications include personalised images on glass candle holders, drinkware including stemless wine glasses, stainless steel tumblers, pint glasses and many more.

Ideal for promotional and retail markets, the Helix Hi-Fi prints multi-colour graphics on straight-walled cylinders, tapers, and objects with limited wall curvatures. The system features a built-in programmable tilt to reduce change-over time and eliminate the need to optimise print recipes for each SKU change. The Helix Hi-Fi uses UV LED ink and prints 360 degrees with a maximum resolution of 1200 dpi. The machine’s printable area is 8.6 inches (218 mm); the system can print on items up to 12 inches (305 mm) in length with a diameter ranging from 2-5 inches (51-127 mm).

The Helix Hi-Fi is delivered as a turnkey package that includes software to integrate with web-based production solutions, as well as Inkcups world-class InkcupCare warranty and service coverage. The company offers multiple pre-treatment options (including newly released MagiCoat), inks and other supplies, along with application testing and sample prints upon request. Metals, glass, plastics, and ceramics are all validated for image durability from handling and washing.

“The Helix Hi-Fi is unmatched in price and performance,” said Ben Adner, CEO of Inkcups. “The addition of these three inks is a game changer for customers looking to achieve high-quality personalised results. Inkcups has always had a strong business with promotional printing, and we are pleased to lead the industry in the personalisation category.”

Meteor Inkjet, the leading independent supplier of electronics and software to drive industrial inkjet printheads, further enhances its portfolio with the launch of a tiered collection of services ...

April 02 2019

Meteor Inkjet, the leading independent supplier of electronics and software to drive industrial inkjet printheads, further enhances its portfolio with the launch of a tiered collection of services for ink characterisation, print reliability analysis and printhead waveform development and optimisation.

Customers can now choose from an extensive menu of waveform optimisation services which includes real-time evaluation of drops in flight; process mapping of drop volume and velocity response to drive voltage and frequency; visualisation and image capture of drop and ligament formation; analysis of a fluid’s rheology; determination of printhead open time and latency; assessment of jetting reliability, fluid build-up and misting; and print reliability testing using both standard images and customer-provided application-specific images.

Matthew Pullen, Meteor’s product manager for DropWatching Systems comments, “Our new service offering fills a significant gap in the market. Ink manufacturers and print system developers can now access Meteor’s committed team of technical specialists to optimise fluid and printhead combinations for specific application requirements and progress ink formulation efforts in a time efficient way.”

The updated Hans-Gronhi LC330RE Roll to Roll Laser Die Cutter from Hans-Shinohara Canada saves time and money while allowing users to offer exciting new short-run printing and finishing products to...

March 19 2019

The updated Hans-Gronhi LC330RE Roll to Roll Laser Die Cutter from Hans-Shinohara Canada saves time and money while allowing users to offer exciting new short-run printing and finishing products to their clients faster and more cost-efficiently. Its popular 13″ width can accommodate most narrow-web flexo printers, as well as the HP Indigo 6900 and 8000 digital presses. The fully automated, computer driven, roll-to-roll laser cutter/engraver is also ideal printers who want to improve cutting precision compared to traditional mechanical die cutting.

Its Optical Laser Tracking Systems ensures precise positioning while its Automatic Tension Control improves stability. Adjustable laser-powered cutting speeds can be used for different jobs and with different materials. Additional laser heads can be added as needed. Built-in technology also includes laminating, slitting and waste discharge capabilities, as well as a manual feeder for special materials.

The LC330RE can also laser-engrave quickly and accurately on a wide variety of traditional and difficult substrates with ease. This opens up exciting new product and revenue opportunities for printers. Common applications include multi-shaped digital labels and security printing (can generate barcodes, numbering, etc.). Cutting speed is from 1 foot up to 196 feet per minute (depending on the specific application). Maximum roll diameter is 19.7” with sheet widths from 2” to 12.9” and a maximum scan capability of 12.59.” The LC330RE includes a colour code sensor and auto deviation correction technology for consistent and accurate positioning.

Ricoh introduced the new Ricoh Pro VC20000 color continuous feed inkjet press. The compact, versatile system is now available across EMEA. It brings competitive color production ...

March 19 2019

Ricoh introduced the new Ricoh Pro VC20000 color continuous feed inkjet press.

The compact, versatile system is now available across EMEA. It brings competitive color production to existing users of continuous feed printers, as well as sheetfed users who are looking to consolidate the output of multiple devices to a single machine. With a footprint of just 4.3 square meters, it can fit into almost any production environment.

The Pro VC20000 inkjet printer is compatible with a wide variety of papers.

The Pro VC20000 joins the mono 75 meters per minute, 600 x 600 dpi Ricoh Pro V20000 and the mono 150mpm, 600 x 600 dpi Ricoh Pro V20100.

“The Pro VC20000 further enhances our fast-growing portfolio of colour continuous feed inkjet printers that includes the Ricoh Pro VC60000, and of course, the groundbreaking Ricoh Pro VC70000," said Eef de Ridder, VP, commercial and industrial printing group. "As the system is so easy to run clients can quickly enjoy improved operational efficiency, increased running speeds and significantly lower running costs enabling them to competitively elevate their service delivery and explore new markets.”

The Ricoh Pro VC20000 is supported by Ricoh’s fast-growing software portfolio. It includes the new cloud-based Ricoh Supervisor, a remotely accessible Internet of Things solution that supports informed decision making by collecting, securely storing and analysing operational data; and Ricoh Communications Manager that delivers and deploys Customer Communications Management services with end to end visibility from source system to the final delivery for both print and digital communications.

There is also the newly updated Ricoh ProcessDirector that controls and manages print production processes, TotalFlow BatchBuilder for intelligent and optimised production processes and FusionPro for the design and production of personalised communications.

SCREEN Graphic Solutions has finalised the development of its PlateRite Ultima 24000N series of thermal plate recorders designed for plates up to 24 A4 pages. The series features the latest GLV&tra...

February 21 2019

SCREEN Graphic Solutions has finalised the development of its PlateRite Ultima 24000N series of thermal plate recorders designed for plates up to 24 A4 pages. The series features the latest GLV™ imaging heads and delivers high throughput of up to 35 plates per hour with an outstanding cost performance. SCREEN GA plans to release the new systems to the international market in March.

In recent years, as printing companies seek to improve the production efficiency of printed materials, the international market has shown a growing requirement for the use of large-format presses capable of easily handling multiple jobs in a single run. The need has affected both sheet-fed and web offset presses. In response to this trend, SCREEN GA has adapted and optimised the plate sizes supported by its PlateRite Ultima 24000 series to suit these presses. These efforts have now led to the development of the PlateRite Ultima 24000N series. Its two new systems offer significantly more compact dimensions than the existing models with even greater productivity and cost performance.

The PlateRite Ultima 24000N series incorporates the latest GLV™ imaging heads with an upgraded optical system. These heads support the output of SCREEN GA’s proprietary Spekta 2 hybrid screening, enabling richer, high-resolution expression of printing themes. The series’ Z model is equipped with 1,024 channel heads that boost output to 35 plates per hour, up from the 27 plates possible with the current system. The 512 channel S model also improves throughput to 24 plates per hour, from the 22 plates offered by its equivalent system. Both models are able to handle plates from 650 x 490 mm up to 1,652 x 1,325 mm, comprehensively covering the sizes used by large-format presses.

In addition, the new series can be used with SCREEN GA’s MA-L40000 multi-cassette autoloader, capable of automatically supplying up to 300 plates, to achieve extended continuous operation. SCREEN GA also plans to develop a new model of its Skid autoloader, which is able to deliver a large number of uniformly sized plates. The whole system can likewise be linked to TRUST Network Service, the company’s sophisticated online maintenance support service, helping to ensure trouble-free operation.

SCREEN GA will continue to use its position as a leading international supplier of CtP systems to meet the constantly evolving needs of printing companies. It remains fully committed to the long-term growth of the industry.

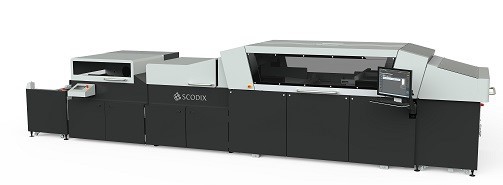

Scodix, a provider of digital enhancement solutions for the graphic arts industry, announced the commercial launch of the Scodix Ultra 101 and the Scodix Ultra 202 Digital Enhancement Presses. The ...

February 12 2019

Scodix, a provider of digital enhancement solutions for the graphic arts industry, announced the commercial launch of the Scodix Ultra 101 and the Scodix Ultra 202 Digital Enhancement Presses. The Scodix family of presses, including the Scodix Ultra 101 and the Scodix Ultra 202, was developed to meet the increased demand for business-generating digital enhancement and allow print service providers of all sizes to target new revenue opportunities.

Designed as a stepping stone into the world of digital enhancement, the Scodix Ultra 101 is fully compatible with offset and HP Indigo presses. Seamless integration ensures print providers can maximize their uptime and crucially, expand their throughput. The Scodix Ultra 101 offers six Scodix enhancements including Scodix Sense, Scodix Foil, Scodix Metallic, Scodix VDE, Scodix Glitter and Scodix Cast&Cure, plus combinations of all of the above, offering users a competitive business differentiator. The Scodix Ultra 101 solution is making its worldwide debut at the HP Indigo Global VIP customer event on February 12th. The full capabilities of the Scodix Ultra 101 will be demonstrated with HP Indigo 12000 HD Digital press.

“Delivering visually striking and tactile enhancements, Scodix adds great value to HP Indigo prints,” states Alon Bar-Shany, General Manager, HP Indigo Division, HP Inc. adding, “The introduction of the new Scodix Ultra 101 is further testament to the company’s innovation and will increase applications and business opportunities for HP Indigo customers.”

The Scodix Ultra 202 ‘full feature’ Digital Enhancement Press provides customers with the largest array of enhancement capabilities in the industry today. This press produces unmatched quality – quickly and cost-effectively – enabling print providers to increase their throughput and creating business opportunities. Users have the freedom to print enhancements on paper, lamination, a variety of water-based coatings, PVC and carton, opening the door to a succession of new applications.

All nine of the Scodix applications run efficiently on the Scodix Ultra 202 press, replacing the need for separate systems on the production floor and preserving a small footprint. By incorporating digital enhancement, print providers can expand their service offering with attention-grabbing applications. These include premium business/greeting cards, folders, head-turning book covers, audience-engaging brochures, stand-out labels and packaging.

Scodix brings numerous benefits to a range of industries, including commercial print, direct mail, folding cartons, point of display, web2print, security markings and many more with a focus on fine details.

Adina Shorr, CEO at Scodix, concludes, “By adding these new systems to our portfolio, we are increasing the number of customers that can employ Scodix and ‘turn print into an experience’.

“The Scodix Ultra 202 promises to be our flagship product, with the widest range of applications and substrate compatibility in the market, while the brand-new Scodix Ultra 101 provides a taste of that, allowing smaller printers to add luxurious embellishments and personalisation that sells brands, whilst protecting profitability.”