See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

March 14 2023

Fujifilm has confirmed that the Acuity Prime L flatbed printer is now commercially available. The printer, which was unveiled at FESPA 2022, is a larger version of the award-winning Acuity Prime 20 and 30 models.

Offering a maximum print area of 3200mm x 2000mm and a headline print speed of 202m2/hr, the Acuity Prime L is easy to operate, and produces high quality results at high speed. It features six vacuum zones and 16 media location pins, as well as the ability to print side by side jobs with its dual zone function, for maximum flexibility.

Uvijet HM – an ink system formulated specifically for the Acuity Prime series – provides excellent adhesion to a broad range of substrates while also producing a wide colour gamut. The new ink range is optimised to produce high quality, vibrant images day-in, day-out.

A new jettable primer improves adhesion still further for particularly challenging substrates. This removes the need for the offline pre-treatment of substrates before printing, saving time and money.

Available with up to seven ink channels (CMYK, plus white, clear and primer) the Acuity Prime L with Uvijet HM inks offers the ultimate versatility and value by providing the flexibility for print businesses to customise it to their own needs.

In January 2023, German graphics arts business Tom Fox became one of the first companies in Europe to invest in the Acuity Prime L. The company purchased the machine just a few months after adding an Acuity Prime 30 to its production line.

Anda Baboi, Marketing Manager, Fujifilm Wide Format Inkjet Systems says: “Following the success of the Acuity Prime 20 and 30 printers, we are pleased to announce the commercial availability of the Acuity Prime L. Larger in size, it enables businesses to increase their productivity without compromising on speed or quality."

“Tom Fox is one of the first companies to have invested in the Acuity Prime L and we look forward to seeing how it boosts business for them and other print service providers in the sector.”

March 14 2023

Meteor Inkjet Ltd, leading supplier of electronics, software, tools and services for industrial inkjet, further expands its product portfolio with drive electronics and software for Ricoh’s TH6310F industrial inkjet printhead.

The TH6310F is Ricoh’s latest printhead to use highly-integrated MEMS technology, enabling precise jetting even with a large gap. Compatible with aqueous, UV and solvent inks, and incorporating a unique ink recirculation system, the TH6310F is ideal for single-pass packaging and textile applications, as well as high-end scanning systems requiring many printheads.

Meteor’s HDC-2R26 drive electronics for the TH6310F are easily scalable to systems of any size and, coupled with Meteor’s comprehensive software, OEMs can significantly reduce the effort and risk associated with the design and delivery of industrial inkjet printers. The HDC-2R26 fully supports the new Dual VCOM capability offered by the TH6310F printhead, allowing the selection of two different printhead drive waveforms per nozzle. This feature delivers superior jetting frequency and print productivity by shortening the drive cycle. Also available for the TH6310F are Meteor’s DropWatching System and printhead waveform development services, essential tools to accelerate time to market for new inkjet applications.

Jonathan Wilson, Meteor’s Vice President of Business Development comments, “Meteor electronics and software have been driving Ricoh printheads since 2011 and we are proud to add the TH6310F to our line-up. Among many benefits, our ability to manage multiple printhead waveforms per nozzle means that Meteor solutions allow OEMs to take advantage of all that the TH6310F printheads have to offer.”

Graham Kennedy, Ricoh’s Director of Industrial Print Solutions adds, “Ricoh is delighted that Meteor is supporting the TH6310F. Meteor drive electronics provide the easiest and most reliable way for OEMs to unlock the potential of these printheads.”

Meet with Meteor to discuss solutions to drive the Ricoh TH6310F at InPrint in Munich, 14-16 March (Meteor stand 2420).

Durst Group, the leading solution provider in the digital print industry, has announced its premier partnership with the EcoPrint Summit, taking place on 6-7 June 2023 in Geneva, Switzerland. Durst’s commitment to sustainability in print, coupled with the support of industry leaders, reflects the growing importance of ecological responsibility within the sector.

"As Durst Group, we are committed to using our technology to drive sustainability and promote a better future for all,” said Christoph Gamper, CEO of Durst Group. “Our partnership with the EcoPrint Summit is an exciting opportunity to bring together experts and innovators in the print industry to work towards a shared goal."

The EcoPrint Summit will feature plenary sessions, roundtable discussions, learning workshops and Eco-Innovations Awards, providing inspiration, participatory discussions, and learning opportunities for those interested in making sustainable changes within their businesses.

"Partnering with Durst Group brings a powerful message to the print industry. Its commitment to sustainability and driving innovation aligns perfectly with the EcoPrint Summit's mission to promote sustainable practices within the sector," said Frazer Chesterman, Director of FuturePrint.

Durst Group has been at the forefront of promoting sustainable technology within the digital print industry. With a focus on commercial, label, packaging, and wide format printing, the company has developed solutions for high-end additive-manufactured technical ceramics components, printed signage, labels, advertising, and textile and product decoration.

"At Durst Group, we believe the print industry can and will be a part of a better tomorrow, and we are proud to be shaping this future through our commitment to sustainability and innovation," said Gamper.

Those interested in joining Durst Group and the EcoPrint Summit in Geneva can sign up for updates, news, and analysis viahttps://www.ecoprint.events.

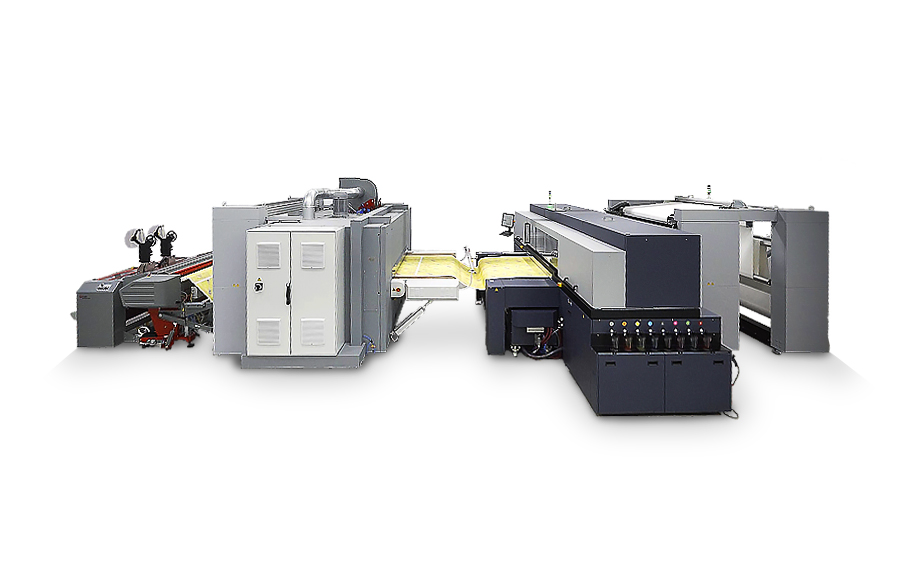

Graham & Brown has invested in more “absolute game-changing” Alpha Wallpaper Edition technology from Durst in what has become the central pillar in the international wallpaper brand’s drive to total carbon neutral production.

“The potential is enormous,” said Sam Dobson, Operations Director for Graham & Brown, of Blackburn, Lancashire, UK. “Digital is an extremely important technology for the wallpaper industry. It’s really about print-on-demand, reducing print run-lengths and giving a more bespoke offering to customers. At the moment, this industrial-scale digital production has filled the gap between high run lengths of conventional printing and the low volumes on our previous digital machines.

“We see the Durst as a complementary technology that has many environmental and other benefits. As one example, the main resource we need to power the machine is electricity, and all of that is renewable. For the last year all of our digital production – representing 35% of the Graham & Brown brand offer – has been carbon zero.”

Graham & Brown’s digital journey ran in parallel with its e-commerce proposition to create unique wallpaper, more flexibility and reduce its warehouse stock by becoming more of a print-on-demand brand to meet evolving customer demands. The installation of the first Durst Alpha Wallpaper Edition production printer in January 2022 was so successful that a second machine was installed a year later.

Martin Winkler, Durst Group wallpaper specialist and Business Development Manager, Textiles, said: "The move to digital production in the wallpaper industry is accelerating as buying habits change. We are proud to have partnered with Graham & Brown as it expands digital printing volumes to provide carbon neutral production, which only digital can deliver. The installation of a second Durst Alpha Wallpaper Edition is underpins our belief that wallpaper has since ceased to be just a ‘renovation object’ and has now become a lifestyle product with which customers express their individuality and create a feel-good atmosphere.”

Durst, manufacturer of digital printing and production technologies, has adapted its digital printing technology in the wallpaper printing to initiate a digital disruption. A shift from conventional printing presses to more sustainable production processes using less water and energy consumption, enabling smaller volumes to be produced inexpensively without warehousing costs is accelerating. Other important drivers are the use of new environmentally friendly materials that are odour-free and can be made from recycled raw substrates.

The Durst Alpha Wallpaper Edition is the most productive digital printing system on the market, with a production capacity of over 1,500 rolls per day or up to 1.2 million linear meters per year. In addition to productivity and outstanding color consistency across the entire print width or run length, total cost of owner (TCO) is also important for producers. This is where Durst has another advantage with its expertise in print quality and ink consumption. With Durst Alpha Pigment Inks, Durst also offers fully water-based inks in eight colors that enable “Healthy Sustained Wallpaper”, with a natural and high-quality look.

March 07 2023

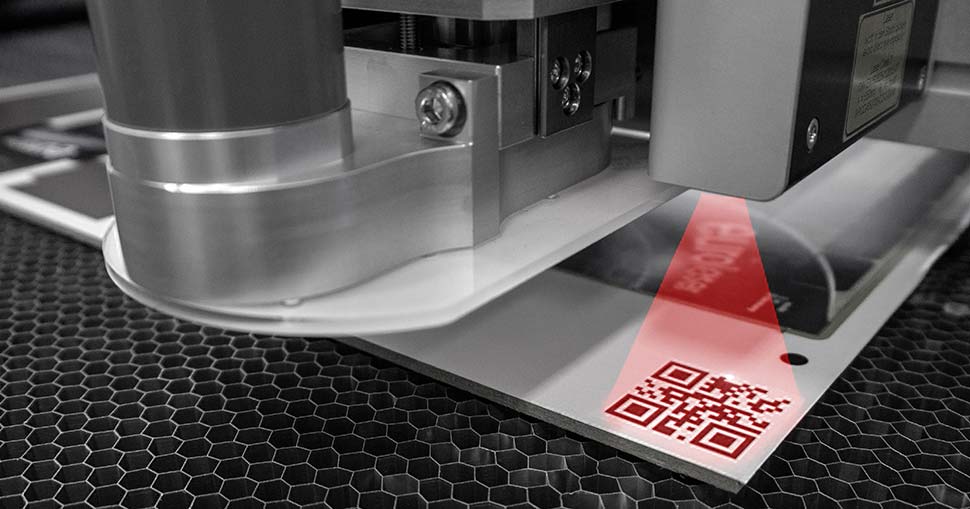

Precise, automated and consistently high cutting quality - by meeting these requirements the laser cutting systems from the German manufacturer eurolaser have been scoring points with users worldwide for many years.

At this year's FESPA in Munich, eurolaser is presenting a new camera system for the efficient and precise processing of printed materials. The new technology increases process speed and expands processing possibilities. The camera system will be presented on the large-format laser system 3XL-3200, on which printed textiles are automatically cut live. In addition, the cutting of plastic sheets on a smaller laser system and the processing of cardboard on a Zünd cutter will be demonstrated.

Since its foundation in 1994, eurolaser has specialised in cutting non-metallic materials. These include plastics such as polyester or acrylic, wood and MDF, textiles and composites as well as many other materials. Today, the universal cutting systems are used, among other things, for cutting large-format textiles in the soft signage sector, for technical control elements made of plastic films or printed acrylic displays for shop fitting. In particular, the demand for large processing areas and automation solutions is increasing across all industries. With the new, optional camera system, called POSITIONplus professional, eurolaser picks up on this trend and offers exciting competitive advantages especially for processors in the printing industry.

Many applications require precise cutting to existing fiducial marks or other material references. For this purpose, eurolaser offers a smart solution consisting of a camera and evaluation software. Using reference points, the optical recognition system allows printed materials to be cut out precisely along the print contour. The new camera technology considerably reduces the time needed to read in the fiducial marks. The entire working area is quickly captured via area scan, thus optimising the process time. In addition, this process expands the range of possible applications. For example, contours on materials can be detected, whereupon suitable cutting data is created under software control. Pattern matching is also possible. Material patterns are detected so that the positioning of the cutting data is done taking the pattern into account. Useful functions that save time and money in further processing.

Working without contact means more than you might imagine at first glance. No influence of force on the material, no material distortion, no clamping of the material, better material utilisation, less waste, no re-sharpening of the tool are only some of these benefits. The thermal cutting process of the laser is very advantageous in many applications. Fringe-free, slightly fused cut edges in synthetic textiles, sealed multi-layer foils or crystal-clear, smooth cut edges in acrylic are just a few examples. The laser processing is carried out with the highest precision, even very filigree details are cut exactly. Since the laser beam itself is wafer-thin (approx. 0.2-0.3 mm), even inner contours are cut radius-free, without taking the tool diameter into account. Unlike other machining processes, the laser does not become blunt over time. The quality of the cuts remains consistently high for years, from the first to the last workpiece.

Of course, there are also machining requests that cannot be optimally implemented with the laser, such as mitre cuts or milling and V-grooves. In this case, eurolaser offers unique flexibility. Additional mechanical tools can be installed on all laser systems. For this purpose, the user has access to well designed eurolaser solutions as well as the entire high-quality tool range of Zünd Systemtechnik AG from Switzerland. For example, milling and marking tools can expand the processing possibilities. Materials that are not suitable for the laser, such as PVC, can also be processed on the same cutting system.

eurolaser will be presenting its cutting solutions at FESPA in Hall B2, Stand D16.

March 07 2023

March 07 2023

UK headquartered narrow web printing ink specialist Pulse Roll Label Products is helping printers beat rising energy bills with the launch of its new dual cure UV LED ink range, PureTone DC®.

The new high-performance ink from global supplier Pulse Roll Label Products can be cured with UV LED lamps, meaning the curing process uses just a fraction of the power of traditional UV lamps. Being fully Food Packaging Compliant, new PureTone DC is suitable for label converters supplying industry sectors that require compliance to food packaging regulations and guidelines, and the range also includes CMYK+OGV for extended colour gamut printing.

LED lamps used with PureTone DC not only deliver a more stable light ensuring consistency of curing and print, but they can also be switched on and off instantly – unlike traditional UV lights, which must be left running – and they also last many times longer.

Crucially, PureTone DC’s dual cure formulation means printers can use just one set of inks with both UV and LED curing presses, delivering further efficiency gains through avoiding unnecessary and costly inventory and ink management complexity, as well as being able to convert across press by press. The new ink also matches the impressive strength of others in the Pulse range, making it easy to compare and match colours as necessary.

Gary Seward, Managing Director of Pulse Roll Label Products, said: “LED curing is looking like the future of the industry – and PureTone DC puts Pulse Roll Label Products squarely at the forefront. Offering increased performance compared with other suppliers, and with a dual cure formulation, this new solution gives printers the versatility and freedom they need to switch to LED ink at their own convenience.

“At a time when our customers’ energy bills are soaring, solutions like PureTone DC that help cut costs with rapid, energy-efficient curing can make all the difference. As well as needing less energy to run, the UV LED lamps that cure this ink last many times longer than traditional UV equivalents, with output remaining consistent over the bulb’s lifespan. What’s more, disposal is also significantly less complex with UV LED bulbs,” he said.

“We’ve even seen improved cure and adhesion over the existing ranges during extensive beta testing, so this really is the next generation of PureTone ink,” added Gary. “The message is clear – UV LED technology like PureTone DC is better for your business, your staff, your customers and the planet.”

Unlike some LED inks, PureTone DC’s dual cure formulation means the initiators within the ink are activated when exposed to either traditional UV lamps or UV LED light. This feature is designed to help printers gradually phase out their existing mercury-based curing equipment without the need for expensive initial investments. As an LED curing ink, PureTone DC can also cure at lower temperatures, making it suitable for a wider range of substrates including heat-sensitive thin films.

With the United Nations (UN) having committed to phasing down mercury use in a wide range of products and processes due to the substance’s harmful environmental and health effects, the ease of disposal of UV LED lamps is also another benefit to printers.

“There are already significant restrictions in place on disposal of mercury and introducing it into the waste stream, and these regulations are only tightening,” said Gary. “With different rules and procedures across different countries around the world – particularly with regard to landfill – printing businesses are looking to transition away now, to get ahead of the changes on the horizon.

“The ongoing uncertainty over the future of mercury regulations in flexo printing, coupled with the enormous cost and energy benefits, means there’s never been a better time to make the change to UV LED ink,” he said.

To find out more about the wide-ranging benefits of LED curing from Pulse Roll Label Products please contact sales@pulserl.com or visit www.pulserl.com/ink-product/puretone-dc

Mimaki has announced its first ‘direct to film’ (DTF) inkjet printer, the TxF150-75, at its Global Innovation Days event.

Utilising a heat-based transfer method, the printer is ideal for creating premium, customised merchandising, sportswear and various other promotional textile applications.

DTF printing provides an easy and affordable process for decorating apparel, and is commonly used for decorating T-shirts. The design is printed directly onto a special transfer film, which is then sprinkled with hot-melt powder, and once heated and dried, the transfer sheet is ready to be applied to the fabric using a heat press.

Based on Mimaki’s best-selling 150 Series, the new TxF150-75 responds to the market need for a reliable, stable DTF technology. A built-in ink circulation system and degassed ink pack design help prevent common DTF issues, and by utilising proprietary Core Technologies, which include a nozzle check unit and nozzle recovery system, the printing process is carried out efficiently with minimal user intervention.

Mark Sollman, Sr. Product Manager EMEA, Mimaki Europe comments, “Apparel decoration is a hugely popular and dynamic sector, one which we are already operating in with our other textile technologies. However, we could see the impact DTF technology has had on the industry in recent years, with its significant advantages over existing technologies. Namely, DTF avoids the time intensive process of plate creation in screen printing and the required weeding in traditional vinyl heat transfer. The technology can also create vibrant designs with its full colour printing capabilities. We’re excited to bring a solution to the market that is designed for those already active in the decorated apparel sector and those looking to enter it, which excels in usability, reliability and quality.”

DTF printing is a printing method that has become widespread in the textile and apparel industry, especially in the wear printing market typified by T-shirts. In DTF printing, the design is first printed directly on a special transfer film by a printer. Next, the printed film is sprinkled with hot-melt powder, which is then heated and dried to form a transferable ink layer on the film. The formed ink layer is then transferred to a fabric such as a T-shirt by a heat press to complete the finished product.

As the company’s first entry into a new segment, Mimaki has created its own range of water-based pigment inks (PHT50) especially for this solution. As of March 2023, these inks are OEKO-TEX ECO PASSPORT certified, guaranteeing that safety and environmental standards are met in line with Mimaki’s sustainability pledges. Unlike sublimation heat transfer printing, DTF is much more versatile when it comes to materials, able to work with more than just polyester and polyester blended materials, and on light or dark coloured fabrics.

The TxF150-75, developed by Mimaki Engineering, is an inkjet printer with a maximum printing width of 80 cm for producing DTF print transfer sheets. The PHT50 heat transfer pigment ink for DTF, consisting of five colors (CMYK and white), is scheduled to obtain the ECO PASSPORT certification by the end of March which is essential for obtaining the international safety standard for textile products “OEKO-TEX”.

The DTF printers have been plagued by ink ejection defects and white ink clogging. To overcome these issues, Mimaki has adopted a degassing ink design that uses aluminum packs as the printer's ink packaging form, as well as a white ink circulation function MCT (Mimaki Circulation Technology)*1. The new printer also features Mimaki's NCU (Nozzle Check Unit)*2 and NRS (Nozzle Recovery System)*3 technologies that support stable operation. They ensure continuous printing without stopping the operation to support customers' productions.

Currently, silk screen printing is widely used in the wear printing market, but this printing method requires the preparation of plates, making it unsuitable for small-lot production. Moreover, full-color printing requires time and labor to create plates for each color. The heat transfer method using rubber sheets is also commonly used, but it involves manual labor for "weeding," which is the process of manually removing unnecessary portions of the transfer when fixing the printed design on the fabric. In recent years, there has also been a growth of direct-to-garment (DTG) printing, which uses inkjet printers to print designs directly on garments and fabrics. DTG printing does not require plates and can be used for full-color printing, but it does require fabric preprocessing and manual handling by the operator at each printing steps.

Under these market circumstances, DTF printing eliminates the need for plate preparation and weeding, which have been difficulties in conventional printing methods. Since it enables unattended printing process operation, it is rapidly being adopted in the market as a technology that contributes to labor savings.

The printer is supplied with Mimaki’s RasterLink7 RIP software, allowing users to have full oversight and the ability to streamline the process from the design to the final product. Distributed in the UK and Ireland by Hybrid Services, the TxF150-75 will be commercially available via its network of specialist resellers from April 2023.

March 01 2023

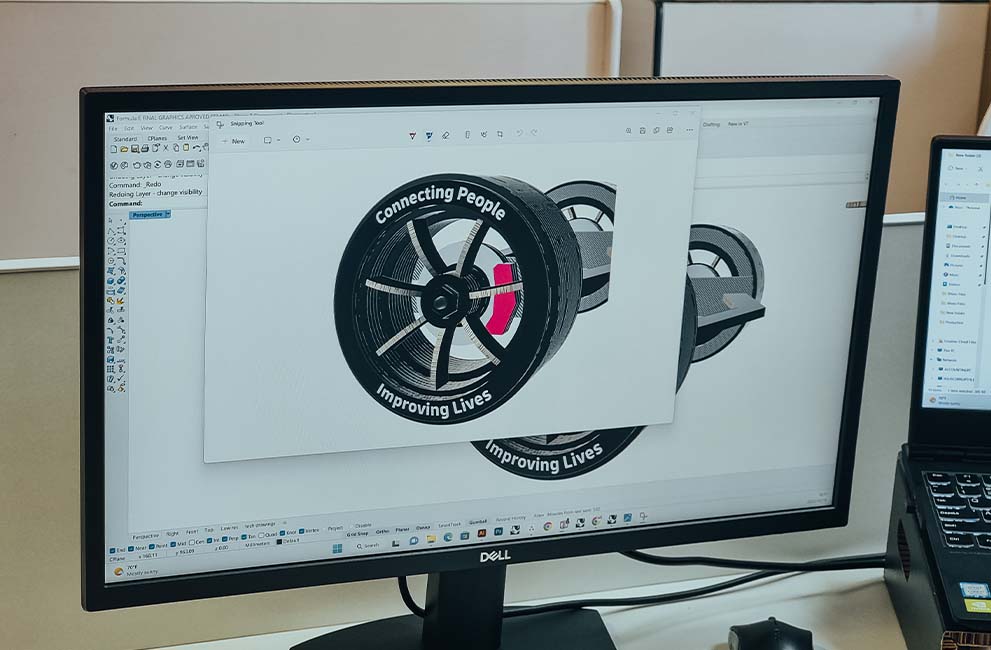

Towards the end of 2022 we were approached by DHL with a grand idea to build a full scale replica of the Formula E Gen 3 vehicle as part of the fanfare for the first ever Formula E race in Cape Town. The proposed idea was so outlandish, that we immediately figured DHL couldn’t be serious and it would never happen, so we gladly accepted the challenge.

However, DHL being the Official Founding and Logistics Partner of the ABB FIA Formula E World Championship, were very serious about the idea and more significantly had the clout to make it happen.The brief itself was simple; make a full scale replica of the Formula E Gen 3 vehicle out of a sustainable paper based material (Xanita board).

At the time we knew very little about the impending Formula E event and even less about the Gen 3 vehicle, let alone if it was even possible to deliver on the brief. What followed from the initial brief was five weeks of some of the most challenging and significant engineering advances with Xanita board to date.

It is not over-stating things when we say that this has been the most technical challenge that has ever been presented to the Xanita team. In over 15 years of pioneering with Xanita board and thousands of design jobs having passed through our design studio, nothing has presented a challenge quite like this.

And it required a team to make it happen…

Another advantage of Xanita board is its lightweight nature, which makes it easy to handle and install. This is especially beneficial for exhibitions and visual merchandising applications, where displays and stands need to be set up quickly and easily. Additionally, Xanita board is incredibly strong and durable, making it an ideal choice for shopfitting applications where the board is able to mimic materials such as wood, MDF and chipboard for certain applications.

We look forward to seeing you at Euroshop 2023 and showcasing the many benefits of Xanita board to the retail industry. With its eco-friendly and sustainable properties, Xanita board offers a responsible and cost-effective solution for exhibitions, visual merchandising and shopfitting applications.

At this point you might be wondering why that is? Well, imagine you have a flat sheet of A4 paper (or letter size US) and you have to turn that into a believable replica of a racing car with corresponding printing. The Japanese refer to the art of folding paper into decorative shapes and figures as origami. So think of this as life size origami, with the added need for industrial design, engineering and factoring real world physics into the equation.

Remember that Xanita board is a rigid paper product, it is produced in flat sheets and to create three dimensional finished products, it needs to be direct printed and CNC cut. This requires a fundamental understanding of the board, the equipment used to “convert” it and the subsequent limitations of both. (See our post on industrial design which dives a little deeper into this).

For this project we tested some of those limitations with Xanita board, we were forced to think differently and change our approach. To create the DHL box car our design team needed to take the actual Gen 3 Formula E car, break it down (virtually) into its individual elements and design a way for those to be engineered back into their 3D forms from flat the sheets and then ultimately assemble them into a believable replica of the Gen 3 car.

All of this, concept to delivery, was required in little over 5 weeks.

So what is Formula E?

Formula E is the world’s first international, fully-electric street racing series aimed at bringing the latest innovations in electric vehicles and alternative energy solutions to the world’s major city centres by creating a motorsport experience that will excite generations to embrace clean energy, for a cleaner, faster future. Learn more about the ABB FIA Formula E at www.fiaformulae.com

The 2023 Cape Town E-Prix was the first Formula-E Event to be hosted in Sub-Saharan Africa and the first major open-wheel race hosted in South Africa since 1993 when the last Formula-1 Race was hosted at Kyalami.

Making the impossible possible.

Firstly it starts with a partner who dreams big and is willing to take the risk. In this instance DHL believed in us and gave us the opportunity to work on a project that 9 times out of 10 would never happen. A project that most designers dream of, a project that tests your abilities and once completed rewards you in a way that cannot be adequately described in words.

For that we are grateful to the team at DHL africa for giving us this opportunity and believing in us to deliver on this mad idea.

Secondly and ultimately, it comes down to the team, our team. The willingness to take on challenges, to learn, to grow and to find a way to make **it happen. The design and production team that worked on this project, literally lived it for the past 5 weeks. They owned it and embraced it in a way that made those of us looking in from the outside immensely proud to be part of Xanita.

A small company at the tip of Africa, doing big extraordinary things.

The final lap

When the time comes to finally retire the DHL box car, it is not destined for the dump or rubbish heap. Xanita board is 100% repulpable and the box car will be recycled and returned to the paper stream perhaps returning as the cardboard box you receive a DHL delivery from one day.

For now though, the DHL box car will be proudly displayed in the foyer at the DHL Cape Town stadium.

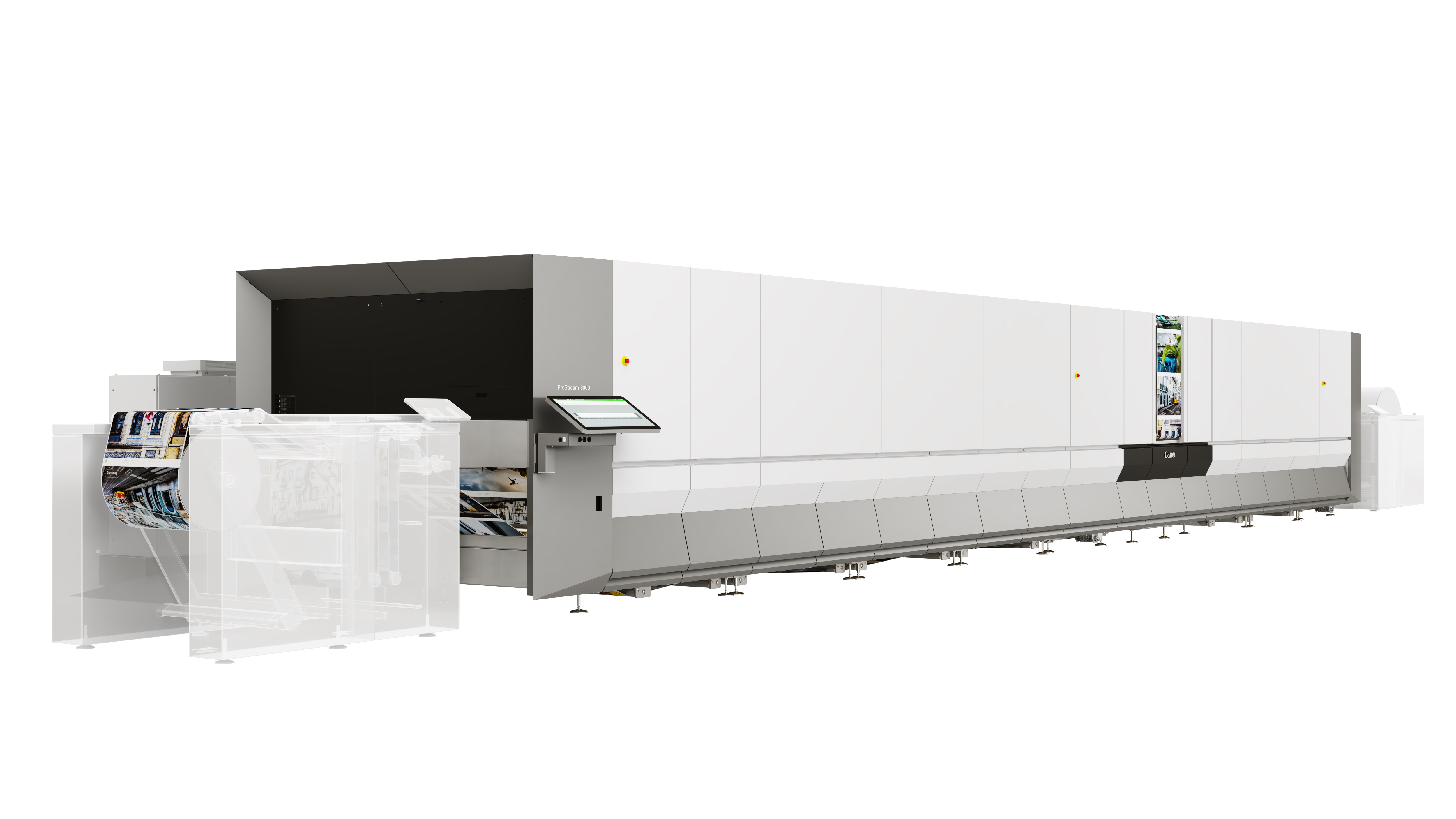

HUNKELER INNOVATIONDAYS, Switzerland, 27TH February 2023 – Canon today announces the launch of the ProStream 3000 series, the next generation of its high-speed, web-fed inkjet presses for commercial print. Built on the established ProStream technology platform, the new ProStream 3000 series delivers consistent offset print quality at industrial speed on a wider selection of substrates including heavyweight paper, enabling ultra-fast digital production of a broader range of commercial print jobs.

This extended media capability makes it even easier for print businesses – including general commercial and online printers, book producers and photo product specialists – to migrate high-volume, high-value work from offset. With ProStream, customers can now reap the full end-to-end productivity benefits of inkjet production across the majority of applications, from direct mail and books, to postcards, posters and calendars.

Available in two models – the 80m/262ft per minute ProStream 3080 and the 133m/436ft per minute ProStream 3133 – the new press produces ProStream’s renowned high print quality on web widths up to 558mm/22in and for page lengths up to 1524mm/60in. The new ProStream series can duplex print up to 1790 four-colour A4 impressions per minute or 11300 B2 sheets per hour, equating to 62 million US letter/58 million A4 impressions per month, on a wide range of substrates and weights, including standard offset coated, uncoated and inkjet-optimised papers up to 300gsm, without the need to slow down significantly for heavier media weights.

To deliver offset quality at the highest possible speed across a wider range of substrates, the ProStream 3000 series incorporates an enhanced drying system. This uses air floatation throughout the paper path – including the turning bar – to protect the surface quality of the printed output at all stages. The system’s asymmetric design dries all jobs evenly and in a controlled way without coming into contact with the paper, ensuring exceptional quality even on the most scratch-sensitive media.

Consistently high quality with accurate, vibrant colour is delivered by native 1200dpi piezo drop-on-demand print heads in combination with proven polymer pigment inks and Smart ColorGrip, a new version of Canon’s paper conditioning solution. With Smart ColorGrip, which is also now available as an option for the ProStream 1000 series, the amount of ColorGrip solution can be customised to specific areas of the page to adjust for heavy or light ink coverage, delivering optimal printed results. Canon’s Inline Quality Control, a high-performance camera system, also provides automatic print quality assurance, so operators can spend less time on quality control.

Thanks to the increased efficiency of both its drying system and cooling unit, the new ProStream’s energy consumption is lower than the 1000 series for most applications. The new press can be connected to less power supply, which makes the ProStream 3000 series a feasible choice for smaller print businesses via reduced electrical infrastructure. The drying and cooling units and the power supply have also been relocated in the new product’s architecture, improving accessibility for ease and speed of servicing.

Craig Nethercott, Managing Director, Canon Production Printing Australia, comments, “At Canon, we share our customers’ passion for print and we’re driven to create technology solutions that accelerate their progress towards their business goals. Customers worldwide have already embraced ProStream’s exceptional productivity for everything from high-margin books to premium direct mailing jobs, while benefiting from minimal waste and very high uptime.“

“With the launch of the new ProStream 3000 series, we’re building on this success to power our customers faster and further, delivering the speed, efficiency and media versatility they need to energize their growth. The scope to print virtually any job at full ProStream speed means that customers can now confidently migrate even more offset work to digital on-demand, reducing turnaround, slashing makeready time and waste, making today’s shrinking run lengths more profitable and meeting brand owners’ demands for shorter time to market.”

The first ProStream 3000 will be installed in the Pixartprinting Group in Italy, joining the company’s existing line-up of three ProStream 1800 printers, which have served to bridge the ‘margin maximisation gap’ between the company’s existing offset and digital B2 toner technologies, without compromising quality. Chief Manufacturing Officer Alessio Piazzetta, remarks: “Our products are printed using only the most advanced machinery. Since the first installation in 2018, the ProStreams have allowed us to further optimise production by choosing the most cost-effective system based on the variables of the job in question. The main benefits have been higher productivity and efficiency, and the fact that the technology is so user friendly.”

Based on the significant commercial impact of the ProStream technology, Pixartprinting has chosen to boost its inkjet firepower further by investing in the next-generation press, aiming to fulfil the company’s OEE (overall equipment effectiveness) requirements and raise digital break-even points above those of offset for even more products and papers.

The ProStream 3000 series has its global debut at Hunkeler Innovationdays (27 February – 2nd March 2023, Lucerne, Switzerland), where it is being exhibited in live production workflows of a broad range of commercial print applications. The new press is available immediately, either directly from Canon or from its accredited channel partners, depending on the territory.

To find out more about the Canon ProStream 3000 series, visit https://www.canon-europe.com/business/products/production-printers/digital-presses/prostream-3000-series/?utm_content=pr&utm_medium=social

HUNKELER INNOVATIONDAYS, Switzerland, 27TH February 2023 – Since its launc...

February 28 2023

HUNKELER INNOVATIONDAYS, Switzerland, 27TH February 2023 – Since its launch in 2020, the Canon varioPRINT iX-series sheetfed inkjet press has proven its value as a high-quality, highly reliable production system for its users, with 275 global orders and installations and 30% of all varioPRINT iX users worldwide opting for a second press or more. In line with Canon’s focus on innovation through rigorous research and development, and in close collaboration with customers, Canon is launching a new release to the successful series, enabling the varioPRINT iX-series to deliver even higher performance in terms of image quality, efficiency and productivity.

The varioPRINT iX-series offers a high level of automation and multiple efficiency features that support PSPs in saving labor costs and reducing maintenance activity, resulting in an improved return on investment and cost efficiencies. Its innovative iQuariusIX ink and printing technology deliver high output quality, achieving a 91% reproduction of Pantone spot colors, which has been verified by certifications from Fogra and Idealliance.

varioPRINT iX users have also reaped the benefits of its media versatility. With more than 1,000 approved substrates, including standard offset coated, uncoated and creative media, varioPRINT iX-series customers have been printing a wide range of applications, ranging from brochures, premium direct mails and books, to flyers and calendars. With the fastest print speed in its class, unparalleled productivity and a proven uptime of over 90%, the top ten varioPRINT iX-series users are printing, on average, over six million images per month.

Richard Kampert, Managing Director at the Dutch commercial online printer, Kampert-Nauta comments, “Since we installed our first varioPRINT iX3200, we’ve been very impressed with the high print quality and productivity we’ve been able to achieve, especially when printing on thicker substrates for our greeting cards, for example. And as our online business generally requires quick turnarounds, the high uptime of the varioPRINT iX has also been an important benefit for us. We therefore increased the volume we were printing on the iX, generated from new business and moving small jobs from our offset presses. As a result, we needed to invest in a further device to fulfil the increasing demand and made the decision to install a second varioPRINT iX3200 on our premises in 2022. Looking to the future, we see inkjet as the technology that is going to best meet our needs —producing great quality on a wide range of stocks and being very reliable and cost-efficient, it really has everything a commercial printer requires”

Setting a new benchmark for quality, productivity and efficiency

Listening closely to customer requirements and with its focus on continuously pushing the boundaries, Canon is launching a new software release R4.3, which delivers an exceptional level of image quality, efficiency and productivity. It gives customers the ability to bring the advantages of short-run or personalized digital printing to even more applications, such as demanding premium direct mail and high-quality, image-rich books. This is achieved through a new, automatic image quality verification system, which scans every sheet to check the quality and dynamically makes system adjustments as needed.

Other performance advances include the automatic customer media validation process (MVP) for the easy set-up of new media with the support of a wizard, as well as improved detection of potential multi-sheet feeds in the paper input module (PIM), which diverts detected sheets to the sentry bin. No operator intervention is required and production continues uninterrupted.

The update also brings a host of workflow benefits with the Canon PRISMAsync controller such as SMB hot-folder support, subset support via JDF, media handling for two-sided media with different front/back treatment and improved encrypted disk support.

Peter Wolff, Chief Marketing Officer and Senior Vice President, Canon Production Printing, comments, “Due to its high quality and exceptional productivity, even on heavy media up to 350 gsm, the varioPRINT iX has proved to be a popular investment option within the commercial print market and feedback from customers has been extremely positive. As with all our technologies, we are continuously investing in research and development to ensure they are delivering to their maximum and supporting users with their changing needs, enabling them to future-proof their businesses. Both existing and new users will now benefit from the new benchmark we are setting in high-quality, efficient and productive print manufacturing with release R4.3.“

The software-driven release is retrofittable to all varioPRINT iX devices and will be rolled out to our customers starting in March 2023.

To find out more about the Canon varioPRINT iX-series, visit: https://cpp.canon/products/varioprint-ix-series/

uge influx of enquiries as small businesses and growing brands discover ‘three-in-one’ solution

Mox, the new software solution that combines project management with digital proofing and DAM in one cloud-based solution, has been hailed a resounding success by users just weeks after its release to market.

Developed to help growing brands and small businesses increase their speed, simplify go-to-market processes and launch SKUs, Mox – launched on January 25 – delivers real-time project and task visibility, improves collaboration, and ensures teams produce right-first-time packaging and marketing content on time.

“The response to our launch last month has been better than we could have imagined,” said Mox general manager, Adrian Fernandez. “We’ve already received some fantastic feedback from users, and the website (https://moxsoftware.com/) has been inundated with visitors and enquiries from businesses wanting to understand how it works and how it can save them time and money.”

Created by Esko, Mox is the new best-practice software tailored to the needs and budget of growing consumer brands, turbo-charging businesses in terms of increased productivity, reduced costs, and saved time in their packaging and content creation process.

“We’ve been working with a number of companies both in the run-up to and following the wide release, and as we’ve been collating feedback the dominant opinion has been ‘where have you been all my life?’,” said Adrian. “Whenever you launch a new product, you’re always hopeful the target user will immediately see the benefits it can deliver to their business. We’re all thrilled that Mox seems to have hit the bullseye.”

Mox was specifically developed to help small-to-medium sized consumer brands (SMB) meet the challenges of today’s omnichannel market, work more efficiently, and bring quality products to market in a consistent, fast, and sustainable way.

“Some of the early feedback has been incredible,” added Adrian*. “One cosmetics company director has called it life-changing, citing how everything is clearly accessible and how the visual design of the platform gives complete oversight of a project - as well as how easy it makes searching for and finding specific assets, approvals or workflows.

“Another retail outlet’s brand leader commented that not only was everything attractively and easily organized, but it made his job easier by allowing him to keep his boss looped in on approvals processes,” he said. “Similarly, a head of product content was amazed that Mox provided the capabilities of their various platforms, but all in the one solution.”

Mox was developed as a collaborative, scalable solution for marketers, packaging and project managers, creatives, and all internal and external stakeholders who create and distribute product packaging content. “It delivers real-time project and task visibility, improves collaboration, and helps accelerate speed to market,” said Adrian. “One VP of content and creative said they loved how Mox ‘speaks the language of different engines of the business’, and that’s a great way of looking at it. Mox enables users to find all the information in one place and at the same time – everything from specific color codes and requirements through to details of workflow and processes all at once.

“We are absolutely thrilled by the reception we’ve had since unveiling Mox, and we’re looking forward to working with so many new companies to help them connect teams, content, and consumers like never before.”

Mox delivers a host of benefits to businesses, including:

• Collaboration - Bring internal and external contributors together with the right information to create and review before product launch

• Review & Approve - Get feedback in real-time, make revisions, and obtain approval before content distribution with automated notifications

• Workflow Templates - Configure and build standardized templates to use consistently every time

• Track & Audit - Fully understand your content process, including when, how, and who approved it

• Advanced Proofing Capabilities – View content for proofing with deep zoom, visual comparisons, ink type and density, and font usage for most popular file formats

• Digital Asset Management – Tag and organize content, leveraging metadata with 100 GB of storage per user

• Permissions & Roles - Manage who has access to projects and assets, including fast external sharing

Want to see for yourself? Try a free 30-day trial of Mox by clicking here

To explore the benefits of Mox for your business, click here and complete the simple form to be put in touch with a Mox expert.

February 28 2023

They provide a deep dive into tomorrow’s print and packaging industries, connect technology leaders, newcomers and users and specifically focus on the top trends in the industry: the five Special Forums of drupa 2024 will open up new perspectives.

Being the biggest leading trade fair for print technologies, drupa is associated with innovations and novel approaches like no other. This is why again five Special Forums are planned for next year that will then turn into hot spots for new technologies, applications and ideas. The drupa cube, drupa next age (dna) as well as touchpoints packaging, textile and sustainability all pick up on global mega trends, future technologies with growth potential and best practices covering a comprehensive spectrum of themes.

The experts among our partners include DITF Deutsche Institute für Textil- und Faserforschung Denkendorf (German Institutes for Textile and Fibre Research), epda (European Brand and Packaging Design Association), ESMA (European Specialist Printing Manufacturers Association), The Marketing Cloud UK as well as VDMA (German Engineering Association).

“In times of continuous change, disruptive processes and the resulting new business models our Special Forums provide important guidance and are indispensable for the sector,” says Sabine Geldermann, Director drupa, Print Technologies Messe Düsseldorf, and underlines: “Jointly with our partners we bank on impressive industry expertise and on the topics defining the future for our target groups.”

drupa cube

The drupa cube stands for Thought Leadership and will also serve as the central stage for pioneering content in 2024. Keynotes, expert panels and workshops ensure knowledge transfer and interaction. The conceptual and strategic partner is the British agency The Marketing Cloud, which was already in charge of programme implementation at the previous editions.

drupa dna

The Special Forum drupa dna is the innovative technology driver for connecting industry newcomers, young talents, start-ups and well-established companies. dna offers scope for networking at eye level and gives a preview of tomorrow’s technologies setting the pace for the industry. Focal themes include, amongst others, Additive Manufacturing, Artificial Intelligence, Business Intelligence, New Materials, Platform Economy, Predictive Maintenance, Printed Electronics, Remote Services, New Business Models, and Process Design.

touchpoint packaging

touchpoint packaging (tpp) focuses on visionary packaging solutions and introduces brand owners to designers, material suppliers, print service providers and converters. The involvement of students and young talents such as NABA, Nuova Accademia di Belle Arti (New Academy of Fine Arts Milan) in partner projects with exhibitors promises to deliver smart packaging solutions for folding boxes, labels, flexible packaging and corrugated cardboard. Furthermore, important questions regarding such focal themes as sustainability or e-Commerce will be discussed. The participating companies will represent the complete process chain.

Responsible for the Special Forum is the European Brand and Packaging Design Association (epda), Europe’s leading association of brand and packaging design agencies. MINTEL Germany, an innovative enterprise in the area of consumer research will be the content partner of this project and is guaranteed to provide insights into consumer trends and their impact on the industry. The tpp enjoys the additional support of the EHI Retail Institute Cologne as a representative of retail.

touchpoint textile

The textile industry offers cross-industry technologies for many sectors –touchpoint textile brings these companies together providing a space for cross-sector cooperation, new projects as well as product and manufacturing ideas. In cooperation with industry partners DITF, Deutsche Institute für Textil- und Faserforschung Denkendorf, will set up a digital textile micro factory at drupa and, hence, a fully connected, integrated process chain ranging from the buyers’ requests and design through to large-format digital textile prints. Many exciting projects such as the efficient, personalised production of sportswear and outerwear from sustainable materials in one consistent digital workflow or a creative competition for young and upcoming designers feature on the agenda here. touchpoint textile is supported by renowned partners such as Assyst, Brother, d.gen, the Albstadt-Sigmaringen University, KURZ, Luxion (KeyShot), Mey, Mitwill, Multiplot, Vaude and Zünd.

Another partner responsible for the lecture programme at touchpoint textile is ESMA. Speakers from research, development, and industry will address questions related to print and finishing technologies, workflows, market developments or sustainability, to name but a few. The focus is also on trends and applications that tap into ever new potentials through the interplay between digital printing and textile print substrates.

touchpoint sustainability

touchpoint sustainability is THE “port of call” for learning more about the circular economy and sustainable print production. This Special Show comes care of the VDMA as a longstanding partner of drupa. Visitors can look forward to best-practice examples as well as innovative solutions associated with the sustainability theme: How can energy and resource consumption be reduced by using optimised techniques in manufacturing processes? How are materials and printing inks reduced to a minimum in new low-threshold areas? And how is finishing applied in an environment-friendly manner? For these and many other questions touchpoint sustainability will provide a central platform and stage for high-calibre knowledge transfer.

The next drupa will be held at the Düsseldorf Exhibition Centre from 28 May to 7 June 2024. Interested exhibitors can still apply for participation at all Special Forums and introduce their products and solutions to a high-quality target group.

For more information visit www.drupa.com.

FUJIFILM Business Innov...

February 28 2023

FUJIFILM Business Innovation Corp. will acquire*1 Australian IT services company MicroChannel Services Pty. Limited (hereafter, MicroChannel) and its affiliates. From March 1, MicroChannel will change its name to FUJIFILM MicroChannel Services Pty Ltd and Brett Matthews, current managing director of FUJIFILM Data Management Solutions Pty Ltd, will serve as the new CEO of the acquired companies.

Founded in 1995 and recipient of over 100 awards*2, MicroChannel is a leading business solutions and technology provider with customers across Australia, New Zealand, and Asia. MicroChannel is regarded by global technology leaders such as Microsoft, SAP and Sage as a top ERP and IT solutions provider in the region. MicroChannel specialises in small to mid-sized businesses and corporate divisions, and has offices in Sydney, Melbourne, Brisbane, Perth, Auckland, and Singapore.

“This is an exciting step on our path to growing our ERP systems and services as one of our core business offerings,” said Naoki Hama, president and CEO, FUJIFILM Business Innovation Corp. “MicroChannel has an outstanding team of committed and knowledgeable professionals. Their expertise aligns perfectly with our long-term ambition of providing customers with as much value as possible through a combination of solutions and services.

“We look forward to working with MicroChannel’s team and well-established customer base to leverage our combined expertise for all customers across the region and to further enhance digital transformations alongside our existing operations.”

“This acquisition marks a historic and exciting milestone for MicroChannel,” said Harach Lucas, Founder and Managing Director of MicroChannel, who will serve as Senior Executive Advisor for FUJIFILM MicroChannel Services Pty Ltd. “We are very excited to become part of a highly respected global organisation with a similar customer-centric culture and a rich history of providing innovative products and solutions.”

FUJIFILM Business Innovation began marketing and supporting the implementation of ERP systems with the creation of its subsidiary, FUJIFILM Digital Solutions Co., Ltd. in Tokyo, Japan, in January 2022. The acquisition of MicroChannel is an important step for FUJIFILM Business Innovation’s full-scale global expansion in this space.

February 28 2023

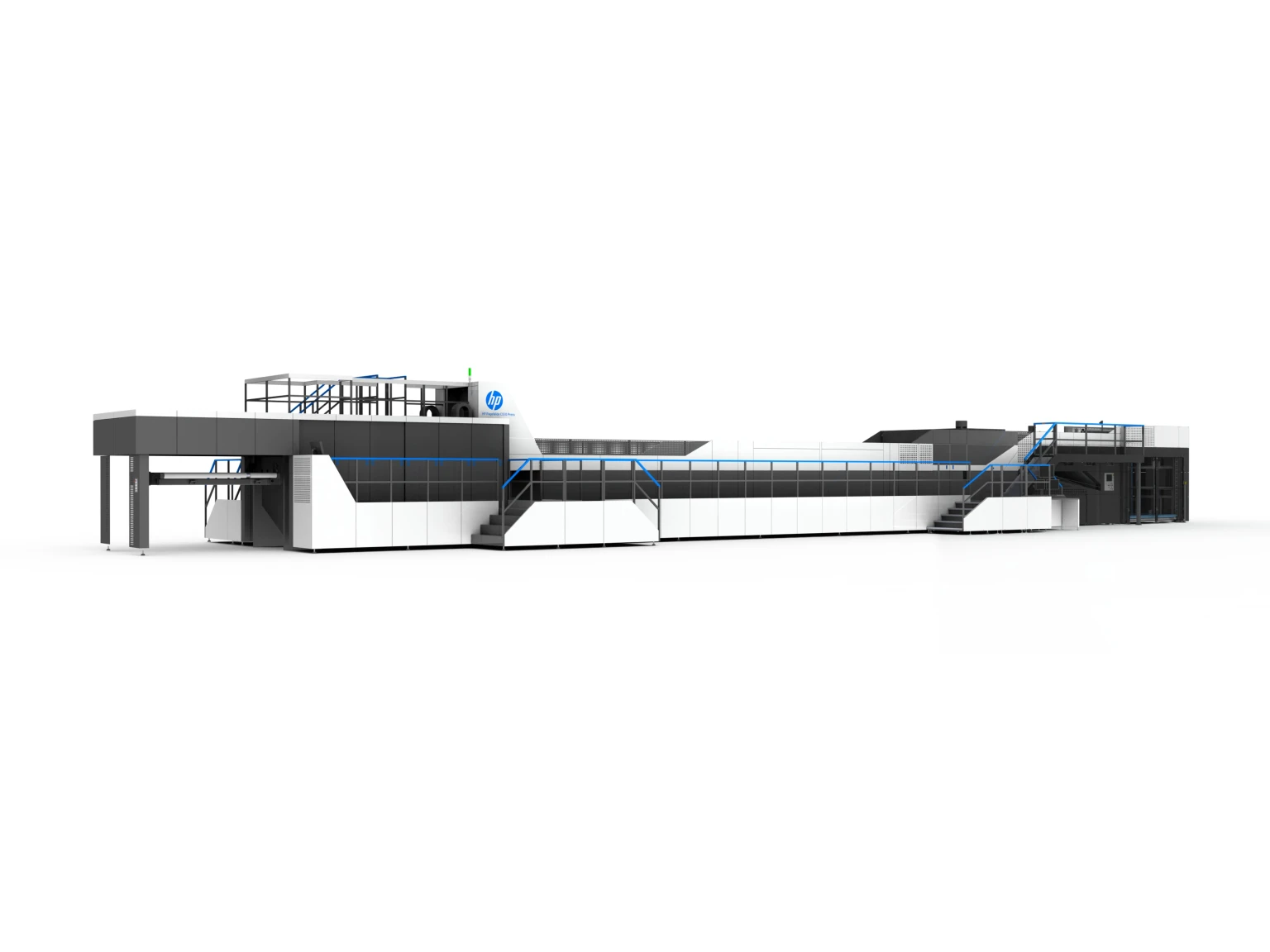

HP launches its newest high-speed, post-print digital corrugated press, the HP PageWide C550 Press. This advanced single-pass platform is designed to help converters optimise manufacturing costs and improve operational efficiency for the production of corrugated packaging.

Based on the award-winning, field-proven technology of the C500 press, the C550 offers enhanced productivity and value to the industrial packaging industry. It uses HP's Thermal Inkjet technology and true water-based inks to deliver consistent offset print quality at fast production speeds, while also supporting packaging converters' circular economy goals .

With a speed of 90 linear meters per minute (295 linear feet per minute), the C550 press is capable of producing high-quality Flexo and Litho boxes at a constant speed, without slowing. It will also help converters to optimise inventories, reduce obsolescence, and accelerate turnaround times through digital printing technology.

By enabling improved economics, greater production versatility and more sustainable packaging solutions, the C550 press presents a significant opportunity for business growth for converters facing increasing supply chain pressure. It allows them to say 'yes' to jobs that require flexibility, which can only be achieved with digital production.

David Tomer, General Manager of HP Post-print corrugated solutions, said, "HP is continuing its investment in the packaging market to create new opportunities for packaging converters and brands to benefit from the analog to digital transformation. We are very excited to deliver the C550 press to the corrugated industry. It is built on the field-proven success of the C500 press and allows converters to economically produce Flexo and Litho boxes at high speeds without slowing down the press. We are constantly working on innovative solutions that not only improve post-print stability and productivity for converters, but also meet the quality and flexibility demands of brands for packaging."

Available for installation later this year, the new press runs at a constant speed of 90 lm/min (295 lft/min), delivering outstanding print quality. The press supports increased plant capacity and helps reduce manufacturing costs for corrugated packaging production .

Corrugated packaging specialist, Saica Group, has ordered the C550 for their operations in Viana, Spain. The company is committed to digital transformation and using innovative technologies to respond to the growing demand for shorter and customised runs. The press is set to be installed later this year and will support increased plant capacity for corrugated packaging production.

HP has recently collaborated with HYBRID Software on prepress workflow for packaging to easily transition artwork from litho and flexo formats. HYBRID PackZ provides a unique blend of automated actions and dedicated prepress tools. The professional PDF editor makes designs ready for any print process, by enriching them with priming and finishing separation, handling ink sets and object-based screening, as well as applying trapping and generating dynamic marks and panels. HYBRID PackZ will enable C550 converters to prepare files efficiently, and reduce errors, making prepress easier and more productive .

HP will be presenting at the CCE International 2023 in Messe München, Munich, Germany, March 14-16, in booth #2528, and will be delivering an introductory presentation about the new C550 Press on March 14th in the exhibition Hall.

Australian ...

February 28 2023

Australian Sign & Graphics Association (ASGA) held its 2023 AGM and a Special General Meeting last week in Perth. Eight West Australian members took advantage of the meeting being held in their state. Apart from the opportunity to network with others and meet the Directors in person, they also had access to Glenn Hain in person after the AGM, where they were able to question him on a range of sign regulatory issues. Others from around the country attended the hybrid AGM online.

During the AGM the 2023 Executive Committee and regional state committees were confirmed, with Lisa Michalanney voted in as the new South Australian Chair, while other committee members remain unchanged from 2022: Mick Harrold (President, Victoria Chair), Damian Nielsen (Vice President, Queensland Chair), Marc Martello (Treasurer, New South Wales Chair) and Wade French (Western Australia Chair).

The AGM included a review of 2022 and upcoming plans for 2023 across the finance, membership, marketing and communications areas, and presentations were given by ASGA Advisors, Warwick Ryan and Glenn Hain on employment law and building code changes.

During his 2022 review presentation, Harrold commented that while the activities of the past year had resulted in a net loss for the year, the activities were necessary to provide the association with good foundations moving forward.

“2022 was about continuing to build foundations to enable the ASGA to move forward and effect change,” said Harrold.

“ASGA is gaining momentum, with a lot of the back end items are now done.”

Harrold thanked ASGA sponsors and outgoing South Australian Chair Julie Rochester for their contributions, noting that the ASGA was in a better position for Julie being involved.

A Special General Meeting followed the AGM where changes to ASGA’s constitution was passed by members.

“Updating ASGA’s constitution was one of the back end items that was important for us to address,” Harrold said as he addressed those in attendance at the Special General Meeting.

“This will now be in line with other model constitutions. We cleaned up ambiguous clauses and increased the range of membership classes, both important for management of the association for current and future Directors.”

The new constitution will now be registered with NSW Fair Work. For more details contact admin@signs.org.au.

swissQprint flatbed and roll to roll printers are highly energy efficient as certified according to ISO standard 20690. Economical in power consumption, the printers thus con...

February 28 2023

swissQprint flatbed and roll to roll printers are highly energy efficient as certified according to ISO standard 20690. Economical in power consumption, the printers thus conserve resources.

The swissQprint range of printers, has undergone tests as specified by the ISO 20690 standard – and earned excellent grades. Fogra experts certify the printers’ Kudu, Nyala and Karibu "top in class” energy efficiency".

The large format printers consume little electricity in relation to their productivity, which bears positively on operating costs and the environmental balance. The average consumption is 2,2 kWh. swissQprint is the only manufacturer who can provide this certification.

The Swiss UV LED large format printers consume an average of 2.2 kilowatt-hours of electricity, exactly the same as an average kettle.

Another comparison: A two-hour video streaming session on a 65-inch 4K TV requires about the same amount of power, calculated from the data centre to the end device.

February 28 2023

Tecnau, a leading company with a complete product portfolio dedicated to paper handling, monitoring, processing and finishing for the digital printing industry, announces the opening of a new division. Tecnau Automation & Packaging will deliver end-to-end solutions in the fields of industrial automation and smart packaging.

The company has a proven record in engineering, manufacturing and servicing customized solutions to support customer demand for automation aiming to simplify and streamline whole production processes, reduce touch points and errors, as well as increase efficiency and throughput.

Industrial automation: responding to industry trends

With the opening of the new division, Tecnau is responding to a recent impetus toward more complex solutions in industrial automation, integrating a broad spectrum of hardware, software, robotics and Internet of Things (IoT). These trends are present in several markets, including the digital print industry, where Tecnau is a leading supplier with highly-automated finishing solutions, as well as in packaging, where Tecnau has developed its latest automated solutions.

“Over the last few years Tecnau has responded to an increased demand to act as a comprehensive solution provider, combining existing products which are typically supplied as stand-alone items, into a single connected process” stated Stefano De Marco, chief executive officer at Tecnau. “Tecnau has the experience and flexibility to integrate systems not only from a mechanical/hardware perspective but also from a software standpoint, with a single point of operation, a seamless control and diagnostic capabilities. In addition, Tecnau has the experience to design and produce missing modules, thus adapting to customer needs for a tailored solution fitting each customer requirement.”

Smart packaging: automation is even more important in the packaging phase

Companies have been focused on improving the efficiency of the last phases of the process, specifically packaging, for multiple reasons: turnaround times and SLAs have become more and more tight; the packaging phase is currently a bottle neck or a critical point for many company’s operations; online business and multi-channel sales are requiring companies to reconsider the way they pack their products and to define more secure, ecological and cost effective packaging. Such focus goes across industries, from traditional manufacturing to e-commerce, where accommodating high volumes and minimizing time to market are particularly important.

Scalable packaging solutions

Packaging can involve multiple processes such as material loading, wrapping, banding, boxing, document printing and insertion, labelling, and palletizing - all these processes are supported by Tecnau Automation & Packaging. “There are several companies offering well-fitting technical solutions in each segment of the process, but most fall short of delivering an end-to-end solution which fits a specific customer application”, continues Stefano De Marco. “By choosing a partnership model which leverages on the best of each process solution, plus adding what is missing with our own know-how and experience, we are able to deliver well-fitting, scalable solutions to our customers”.

The goal of the new division is to provide significant advantages to existing and future customers that will benefit from a cross-industry expertise capable of offering a one-stop-shop for complex and tailored projects. The Tecnau knowledge and capability to function as a system integrator will result in higher-quality products that can better serve specific customer's needs in shorter times. Innovative, automated, streamlined solutions are augmented by tracking and other advanced smart process features.

Cross industry benefits for Tecnau customers

The demand for automation to reduce touch points and errors, as well as to increase efficiency and throughput is evident across the digital print finishing marketplace. With Tecnau Automation & Packaging the company will develop further its expertise in this field with the ability to propose a wider range of solutions to its current and long term customer base.

Ashley Playford-Browne has joined Currie Group as Business Development Manager for Sign & Display products in NSW and Queensland, adding to the strength of the company’s already impressive Sign & Display team.

The industry veteran, who started his career as a qualified prepress operator, has worked across technologies from prepress, to offset, digital, direct mail, textiles and wide-format, moving from operational roles in recent years to sales and senior management roles with a number of leading supply companies.

Currie Group moved into the sign and display market in 2021 when it became a channel partner for EFI, marketing its roll-to-roll, flatbed, and hybrid inkjet printers to the Australian market. It’s become a strong performer for the company, and the addition of Playford-Browne’s expertise and experience is set to drive that success even further.

“I’m certainly excited to be joining such a great team, in a company which delivers such a broad offering to the print and graphics sector,” Playford-Browne says.

“Sign and display are a rich and varied market which encompasses a wide range of businesses, from dedicated signage professionals, to print service providers who want the opportunity to grow their business into new and complementary markets, to innovative businesses across areas as diverse as fashion, industrial products and promotional items.

“My background has given me an understanding of this diverse landscape and how to help businesses capitalise on the mix of opportunities. The chance to work with a multi-disciplinary team to offer customised solutions for businesses is very exciting.

“Just as important for me is Currie Group’s outstanding reputation for customer support. They have a professional and well-run service operation with a huge network of technicians and engineers across the country, supported by significant in-house infrastructure. I know it gives customers confidence, and it demonstrates to me just how highly they prioritise customer experience.”

Paul Whitehead, Business Unit Manager – Sign & Display for Currie Group, says the appointment demonstrates the company’s commitment to this vertical, and to customers in NSW and Queensland.

“Ashley brings vast expertise and an outstanding knowledge of all facets of print production to his new role, as well as many years of experience on the wide-format and digital inkjet sector,” Whitehead says. “We are delighted to have him on the team and look forward to introducing him to customers in those regions over the coming weeks.”