See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

Competition is open to all Australian registered print, signage and display business. We welcome applications on any self adhesive vinyl brand available in the Australian market.

Have you got the WOW factor installation? It can be floor, wall, window car, boat or even an airplane wrap installation. Its really up to your imagination!

Prize includes as a guests of Metamark, flights and 4 nights accommodation for two people and AUD$1000 spending money. Access hundreds of global exhibitors all under one roof, showcasing the very latest technological developments in machinery, software, consumables, and applications.

Discover the latest industry trends, insights to the market and where its headed, and tips & techniques to apply to your business. Network with likeminded professionals all eager to bring face-to-face business back and explore new relationships to

enhance your business offerings.

https://kwdoggettfinepaper.ac-page.com/metawrap-competition-2023

February 21 2023

Visual Impact, held this year in Sydney, is an annual event that caters to the visual graphics industries to showcase the best in digital printing and signage and host a wide range of workshops, seminars and demonstrations. At this year’s show Epson’s theme is, “Say Yes to Success” as the company demonstrates that the more solutions you offer your clients, the more work you can take on. Epson will also be showing companies how they can reduce their equipment footprint in smaller spaces and exhibiting the breadth and flexibility of their waste-reducing print products and solutions.

Epson Australia MD, Craig Heckenberg, said, “Due to the impact of Covid-19, businesses have opted to bring more print back to Australia. As a result, and to help businesses embrace this change, we have further expanded our print range to provide a solution for any requirement. Epson are also striving to further reduce wastage and water requirements. For example, we are placing more emphasis on inherently more efficient digital print processes for natural and synthetic fibres alike. You will see a range of these products and solutions on show and demonstrated at Visual Impact 2023 in Sydney.”

Epson SureColor T7760D

Kicking off proceedings is the Epson SureColor T7760D, which combines high-speed production and flexible media handling in an extremely compact footprint. It is designed for companies who want to produce large-format colour drawings and posters in moderate to high volume. This model is particularly suited to construction, retail and print-4-pay applications.

Epson SureColor S80660L

Then the Epson SureColor S80660L will be showing why it was designed to produce durable images with maximum impact and format flexibility, quickly, easily, and at minimum cost. The S80660L suits any operation with a medium to high production volume and a structured workflow. It is compatible with wide range of media and suits applications including high-value large format photo imaging, PANTONE® certified POS and signage, back-lit displays and window decorations, wallpapers, surface finishes and décor.

Epson’s SureColor R5000L

On to Epson’s new resin range and the SureColor R5000L, which not only offers a low running cost, but also brings accurate and repeatable colour to a platform optimised for rapid job turnaround. The SureColor R5000L is designed to produce signage, décor and promotional material. It uses aqueous (water-based) ink that is similar to latex but formulated for enhanced scratch resistance and a lower curing temperature. Enhanced print durability is matched with enhanced mechanical reliability and a reduced running cost.

Epson SureColor V7000

Leveraging Epson’s decades of colour and imaging expertise will be the Epson SureColor V7000 UV flatbed printer, which is powered by no less than eight PrecisionCore™ printheads and a new UltraChrome UV ink to deliver outstanding print quality and low cost of ownership on many types of media including paper, film, board, Corflute, vinyl, canvas, aluminium, timber and acrylic up to 80 mm thick.

Alongside these will be the Epson SureColor F6460 representing the company’s fourth generation 44" model and featuring enhanced image quality with faster performance and a simpler operation. The F6460 has been made to suit a wide range of production applications from customised fabric and garments to quality décor and merchandise, premium hard and soft signage. It can be ordered in either a 4c or 6c configuration and uses convenient 1.6L ink pouches. Prints are made on paper which is transferred (sublimated) via a heat press onto material with a polyester base or polyester pre-treatment.

Epson SureColor F6460

Epson will also be showing their latest solutions for direct-to-garment (DTG) and direct-to-film (DTF).

Joining the usual suspects from the Epson Australia team at the show this year will be Shuhei Sato – Epson Australia’s new Product Manager specialising in professional print solutions. Shuhei previously worked at Epson HQ in Japan and comes with a wealth of knowledge regarding global trends within the large format printing space.

PANTONE® is the property of Pantone LLC.

Epson has announced that, from the first half of the 2023 fiscal year beginning April 2023, it will launch sales of two new models of inkjet printheads that support solvent inks. The new I3200(8)-S1HD and S800-S1 are compatible with a wide variety of inks used for industrial applications. In addition to aqueous, UV-cured, and eco-solvent inks, they support oil-based, solvent, and other types of inks for digital printing applications in production printing.

-S1HD.jpg)

I3200(8)-S1HD

The I3200(8)-S1HD can handle up to eight colours of ink and deliver resolutions up to 1200 dpi, enabling the rendering of high-resolution images in a variety of situations.

S800-S1

The S800-S1 is equipped with only one chip. Its compact design helps to improve productivity in printing environments where space is limited.

These new products will expand Epson's offerings in the PrecisionCore printhead series and enable the company to support an even broader range of industrial and other digital printing environments, for applications such as marking/coding, signage, and printed electronics.

The two new products will enable the implementation of inkjet printing technology in new fields, particularly in industrial printing applications. Epson will continue to develop original technology to contribute to the expansion of its customers' businesses and further accelerate inkjet innovation.

Product features

I3200(8)-S1HD

• Solvent compatibility

Compatibility with solvents with high solubility gives this printhead the ability to meet the requirements for printing things such as displays and photovoltaic cells.

• Prints with up to eight colours and easily equips printers for high-quality output

Up to eight different colours of ink can be used-and not just CMYK colour inks. Liquids of different types can also be jetted, enabling this printhead to flexibly adapt to industrial printing applications. It also delivers 1200 dpi high-definition image quality, making it ideal for high-speed single-pass as well as multi-pass printing.

S800-S1

• Compact design

The S800-S1 is compatible with the same inks as the I3200(8)-S1HD, but the single-chip design enables it to print where space is limited, as well as print in close proximity to substrates with a 3D surface.

For more information about PrecisionCore printheads, please visit:

• Micro Piezo inkjet technology

corporate.epson/en/technology/search-by-products/printer-inkjet/micro-piezo.html

• Micro Piezo printhead manufacturing technology

corporate.epson/en/technology/search-by-products/other/precision-core.html

February 21 2023

Australia’s last white paper manufacturer will permanently close with a suspected 200 workers to be made redundant.

After months of speculation about the company’s future, documents seen by the ABC show Opal Australia is set to withdraw from the graphic paper business.

A lack of timber supply is being blamed for the decision following a court verdict in November last year where the government-owned timber business VicForests lost a Supreme Court case for not amply protecting endangered wildlife, including two possum species.

As a result, the company was ordered to scale back its timber harvesting in parts of rural Victoria.

The mill previously produced up to 200,000 tonnes of white paper per year, with 300 reams of paper created a minute. At this point, the mill’s brown paper production is not affected.

Hunkeler’s popular Innovation days will return to Lucerne, Switzerland, from 27th February to 2 March 2nd and once again, SCREEN is a leading supporter.

Screen GP Australia Managing Director Peter Scott says: “I would normally be there myself but I can’t make it this time. It’s a pity because the Hunkeller Innovation days have proven to be highly valuable in demonstrating what can be accomplished using high-volume digital inkjet production and finishing.”

He continues: “What I can say is that Screen will be showing both the Truepress Jet520HD+ digital web press with newly launched SC+ ink for offset-quality of offset stocks and a first look at the Truepress PAC520P, developed for environmentally-friendly flexible paper packaging, using water-based pigmented inks that comply with appropriate food safety regulations.”

The development of the Truepress PAC520P is in response to the trend of reducing plastic material in packaging. It is a high-speed, water-based inkjet digital press for paper-based packaging substrates, with a much lower environmental impact than conventional printing processes. This is due to a drastic reduction in energy and material waste. Building on almost two decades of experience in inkjet printing, the Truepress PAC 520P uses newly developed proprietary water-based pigment inks that comply with appropriate food-safety regulations for sustainable flexible-packaging applications.

Winner of two technology awards – Intertech and the Japanese Society of Printing Science and Technology – the Truepress Jet520HD+ press with its newly launched ink, SC+ Ink, is a very reliable and productive commercial, transactional and publishing digital press. It will be configured with the Hunkeler Cut & Stuck system (CS8) at HID 2023.

Scott adds: “Our Truepress Jet520HD+ offers high printing quality on standard matt, silk and gloss offset papers at great productivity – with the added power of variable and short-run print-on-demand.”

New Partnerships

In addition to new products, Screen will demonstrate how it cooperates with 3rd parties, for the benefit of customers. One is with Solimar Systems, with the aim to streamline production flows, enabling greater automation and labour savings, while also reducing production losses and errors in the printing process. Solimar’s SOLitrack system provides excellent visualisation of each job’s progress and status of equipment, creating a seamless digital workflow with Screen’s highly reliable EQUIOS RIPing.

The second is with colour measurement and software solutions from MYIRO. All Truepress Jet 520HD printers will now come with MYIRO, a modern, automatic colour-calibration system that makes colour management much faster, easier, accurate, and reliable.

With almost 100 exhibiting companies, Hunkeler Innovation Days is held at Messe Lucerne exhibition facility, Switzerland from February 27th to March 2nd, 2023. Screen can be found in Hall 2, stand #P4

Are you ready to dive into a 360-degree marketing role? If your answer is yes, then we have the job for you!

Our Junior Marketing Coordinator position at Ricky is a fantastic opportunity to kick-start your career in marketing. This cross functional role will have you planning social media and writing long-form content, while assisting in the creation of brand campaigns and events alongside the Marketing and Brand Manager.

But who is Ricky? Ricky Richards is Australia’s leading specialised textiles and print media supplier. With 40 years of experience, exceptional customer satisfaction and a team that LOVES coming to work, the environment encourages long-term growth and development, all while having a good time.

Key accountabilities include:

Skills & experience:

https://www.seek.com.au/job/60407862?type=standard#sol=29ab1ff91e22f91ce40f7181f146007ebab64d2e

February 14 2023

IVE Group Limited (ASX:IGL) (IVE) announced that AFI Branding (AFI) will rebrand to IVE following its acquisition in November 2021. As part of the rebrand, AFI will form part of a new market offering – Brand Activations.

IVE’s Brand Activations will bring together a full-service display, signage and activation offering to the retail, events and exhibition industries. Brand Activations sees IVE’s Retail Display, AFI and Active Display Group (ADG) combine to offer the most comprehensive onshore capabilities in Australia with extensive production facilities across NSW and VIC. The newly formed Brand Activations offers a full-service design team, large scale print production including wide format and fabric, hardware manufacturing and fabrication, alongside a national installation network. With an end-to-end service offering, it brings unparalleled on-shore production and cost efficiencies to the Australian market.

From idea to execution, Brand Activations will specialise in creating temporary, semi-permanent, permanent display solutions, and physical activations, for a client base of global and Australian brands.

IVE’s Production and Distribution CEO, Cliff Brigstocke said, “The acquisition of AFI and ADG is aligned with IVE’s growth strategy in the retail, events and exhibition space. Consolidating these complementary services into one offering provides a compelling value proposition, further strengthening IVE’s position as an industry leader in this space.”

AFI Branding was founded in 1992 and over its 30 years has grown to become Australia’s largest fabric printer. In November 2021, AFI was acquired by IVE Group and in December 2022 AFI moved sites to a state-of-the-art facility in Victoria’s Braeside, sitting alongside many of IVE’s other production and distribution services including print, premiums and merchandising and integrated logistics.

AFI’s Founder and Strategic Director, Glenn Watson said of the rebrand, “Becoming part of IVE Group last year has propelled AFI into its next chapter, opening up a host of opportunities for AFI and our clients. The rebrand and integration into IVE allows us to offer a broader range of products and a larger capacity to our clients, not to mention the wider expertise it brings through collaboration with IVE’s teams.”

For further information on IVE’s Brand Activations see https://www.ivegroup.com.au/our-services/production-distribution/brand-activations/

Topic: Channel Letter Bending – manufa...

February 14 2023

Topic: Channel Letter Bending – manufacture a sign in 30 minutes!

Date: Tuesday, 28 February 2.00pm AEDT

This webinar will showcase how channel letter bending machines can increase a sign business’s profitability by significantly reducing fabrication lead times. Attendees will learn how staff can be manufacturing signs with this technology with just two days of training. An overview of laser welding will also be covered in this not-to-be-missed webinar.

Peter Fitzpatrick of Lettertech Australia will provide the background on the technology, it’s capabilities and the training required. Mick Harrold of Visual Exposure and ASGA, will outline his experience in channel letter bending and how the technology has improved his business. Vernon Kingman of Kingman Strategies will moderate the webinar.

“This webinar will serve as a video resource where attendees can get some practical ideas on channel letter bending and help them to decide if it’s a good fit for their business”, said ASGA President, Mick Harrold.

“We want to bring manufacturing back to Australia. That’s what these machines and new technologies are allowing us to do. You can produce stuff at a cheaper cost base locally. The efficiency of fabricating a sign and the fact that a highly skilled fabricator is generally not needed for the process, makes the latest in channel letter bending technology very attractive for signmakers that are currently being squeezed by high material costs and staff shortages.”

ASGA members can register free. Non ASGA member cost is $33 inc GST.

For more details and to register, visit https://signs.org.au/events-and-news/current-events/

Epson has announced the expansion of the Epson Print Academy™ YouTube channel to include content for additional Epson Professional Imaging markets. Initially created for professional photographers, the expanded YouTube channel now includes videos featuring content for additional markets including promotional goods, signage & point of purchase, print production & commercial labs, t-shirts & garments, and CAD & technical.

“The Epson Print Academy YouTube Channel is designed to serve as a resource across the printing ecosystem, including our channel partners and customers,” said Dan (Dano) Steinhardt, marketing manager, Epson America, Inc. “The content is intended to assist and provide inspiration to our customers, and channel partners showcasing a variety of applications overviews, step-by-step tutorials and success stories with Epson Professional Imaging solutions.”

The Epson Print Academy YouTube channel features video content in both short overviews and step-by-step video formats. Ongoing video uploads will cover topics for SureColor® product lines and accessories including SureColor D-Series, SureColor P-Series, SureColor R-Series, SureColor S-Series, SureColor T-Series, and SureColor V-Series along with relevant printing techniques and events. The updated YouTube channel aims to be a central resource for the whole Epson Professional Imaging community.

The Epson Print Academy was first established in 2001 to help professional photographers better understand what was then the new world of digital photography and inkjet printing. Now, two decades later, the Epson Print Academy aims to be a resource for technical information and insight into advanced techniques for the many industries served by Epson’s Professional Imaging products. The Epson Print Academy YouTube channel can be found at www.epson.com/EpsonPrintAcademy

February 14 2023

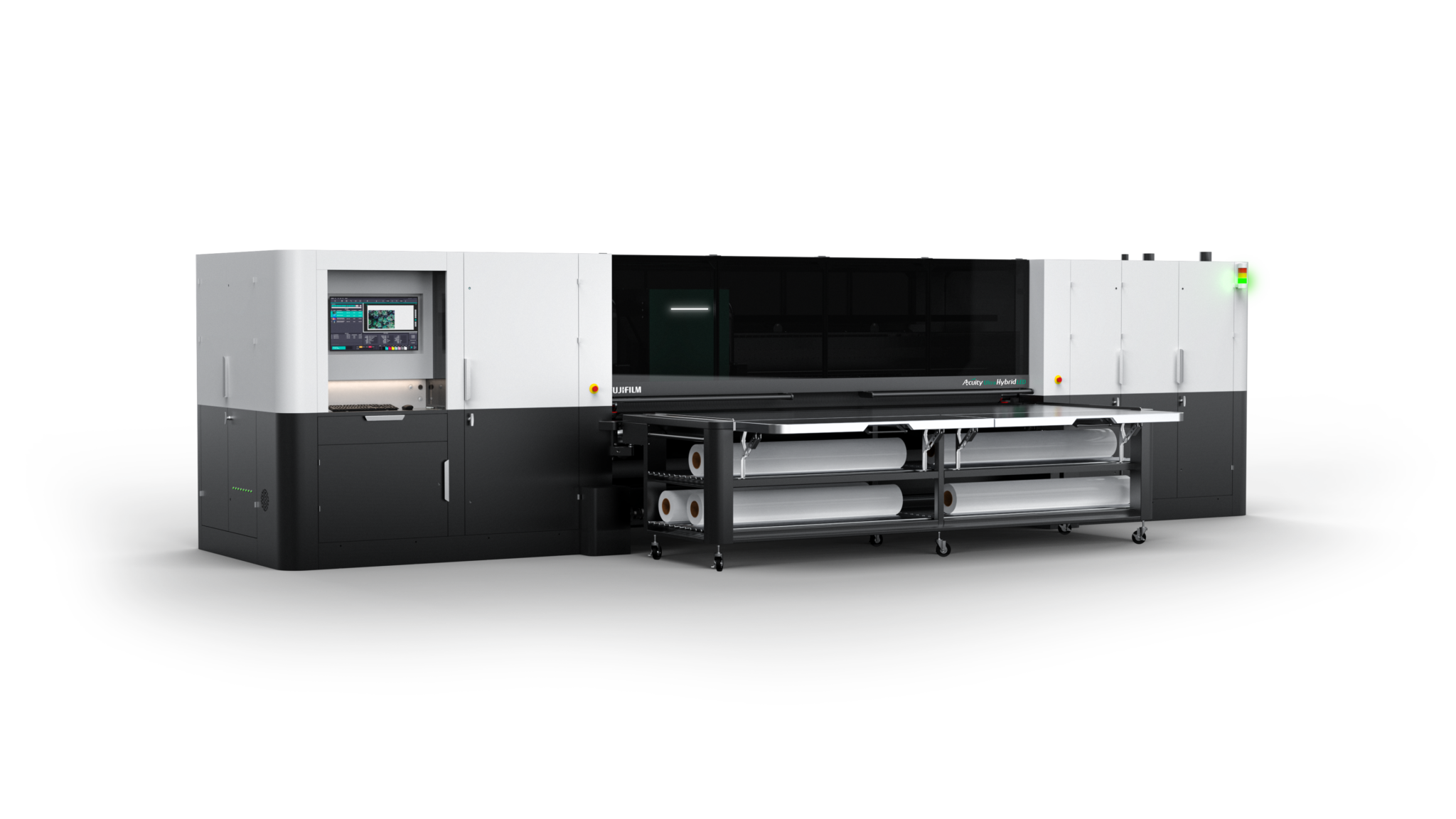

Fujifilm announces that the installation of the world’s first Acuity Ultra Hybrid LED got underway at Echo House in Surbiton, UK on Friday 27th January.

The highly-respected design and sustainable creative production company has a long and successful history of partnering with Fujifilm – having installed an Acuity Select flatbed press in 2014 and, more recently, the world’s first Acuity Ultra in 2018.

The Acuity Ultra Hybrid LED was Fujifilm’s big reveal at Fespa 2022 – the latest development in its ‘new blueprint for wide format’ concept that introduced an all-new Acuity range redesigned from the ground up for maximum ease of use and ROI.

A 3.3m high-end printer offering exceptional print quality and performance on both rigid and flexible substrates, the Acuity Ultra Hybrid LED prints at speeds of up to 218 m²/hr (RTR), and delivers a print resolution of up to 1200 x 1200 dpi. It is unique in being able to combine ultra-high quality and a competitive return on investment, for both rigid and flexible applications, all in one platform.

The machine features a range of intelligent design features to ensure unrivalled ease-of-use and excellent overall performance and Fujifilm has also created an entirely new ink range, Uvijet UH, especially for the new machine, with six colours (CMYK, Lm, Lc) available as standard and white ink also available as an optional extra. The new ink range has both Greenguard Gold and AgBB certification.

Peter Onyskiw, Director of Operations at Echo House, comments: “We’ve built a collaborative and trusting relationship with Fujifilm over the many years we’ve worked with them – that’s what led us to be the first company in the world to install a 5m Acuity Ultra back in 2018. That machine is still going strong – though we did have to move it to a new spot to make room for the new one! We’re excited to be first again. We work in a rapidly innovative and highly creative sector, serving some of the largest companies in the world, with brands who set extremely high expectations for us. The Acuity Ultra Hybrid LED combines exceptional quality with greater flexibility through its hybrid capability – giving us even more creative potential to continue to meet, and exceed, our customers’ expectations. The technological efficiencies, flexibility and reliability further extend our sustainable credentials to boot.”

David Burton, Director, Fujifilm Wide Format Inkjet Systems says: “We’ve had a long and successful partnership with Echo House over many years – they’re never afraid to be first – so they were a natural fit to be the first to trial the latest press in our all-new Acuity range.

“We’re delighted to be starting a new chapter in our journey with them – and we look forward to working with them as they look to harness the considerable potential of this hybrid press to target new business opportunities.”

February 14 2023

FUJIFILM Imaging Colorants, Ltd., has announced global commercial availability of an expanded range of colours to its series of high performance RxD pigment dispersions for water-based inkjet ink formulation. Fujifilm now offers dispersions in Orange PO71, Green PG7, and Violet PV23 pigments. The new inkjet pigment dispersions are now available world-wide through Fujifilm’s Ink Solutions Group.

OGV colours are typically used to formulate ink sets that extend the gamut of a print system beyond the colour space achievable with CMYK, which is particularly important for achieving higher vibrancy, colour accuracy and matching brand spot colours in packaging, textile and commercial print applications.

Grant Murney, product manager of RxD inkjet pigment dispersions, says “In developing the new RxD Orange, Green and Violet dispersions we’ve carefully selected the best polymers and processing conditions to ensure optimum stability and print performance for our customers, in line with the standard CMYK products already in the RxD product range.”

RxD pigment dispersions are used in Fujifilm’s aqueous ink developments for OEMs and are available to other ink formulators.

Fujifilm’s RxD dispersions are highly stable and suitable for ink formulation across a wide range of applications. They are engineered with Fujifilm’s proprietary reactive dispersant technology which uses a cross-linked polymer to create a secure cage around the pigment. This provides a stable dispersion that is compatible with a wide range of components used in inkjet ink formulation, enabling the design of stable ink formulations that meet demanding performance requirements. The high-quality pigments used in RxD dispersions comply with Swiss Ordinance SR817.023.21, making indirect food contact compliant applications accessible.

Last year, Fujifilm announced a further expansion within a $47 million investment in its global RxD inkjet dispersion manufacturing capabilities, part of its commitment to meet the growing demand for new applications with aqueous inkjet inks and supporting its global customer base.

About three months before its kick-off on 16 May, the PRINT & DIGITAL CONVENTION 2023 is on a very positive course for success: the bookings received so far already exceed the previous year’s levels. Numerous international industry players will be represented again making the Düsseldorf congress trade show the trendsetting platform for multi-channel and dialogue marketing. The Ticketshop is open as of now.

They will demonstrate how print becomes an experience, how haptics sparkle and what tomorrow’s digital and online strategies will look like: the exhibitors and speakers of the PRINT & DIGITAL CONVENTION 2023 will offer countless opportunities to discover trends and be inspired. Renowned enterprises such as Konica Minolta, Canon, Xerox, RISO, and KURZ will be “on board” as exhibitors and introduce to participants their solutions and applications for a modern and sustainable media production.

“It is a great success that we have already achieved an increase of 5% in exhibitor registrations compared to the previous event at this point in time,” explains Rüdiger Maaß, Managing Director of Fachverband Medienproduktion e.V., f:mp. (Media Production Association). “What makes us especially happy is that we have currently canvassed 20% first-time exhibitors.”

One of these new exhibitors is Zaikio, a development studio that emerged from software company Crispy Mountain and Heidelberger Druckmaschinen AG. Commenting on this, Thomas Ahlrichs, advisor at Zaikio, says: “The format of the PRINT & DIGITAL CONVENTION convinces me: the atmosphere is familiar and allows in-depth exchange at eye level. I meet old acquaintances here and learn about new things. This makes the PDC a brilliant interface for the industry. We do have a bit of a weak spot for open interfaces…”

After all, the PRINT & DIGITAL CONVENTION is not only a congress trade show but also a hands-on experience and content-focused event. A concept that has also convinced Kim Niemeyer, Marketing & Communication, Ing. Fritz Schroeder GmbH & Co. KG: “The PRINT & DIGITAL CONVENTION demonstrates time and again and in many ways that the world of print is alive and diverse. The exhibitors bring print to life. We are happy to be a part of this, flagging up the opportunities offered by print processing and finishing and provided by this mix of technology, knowledge transfer and networking.”

With their innovative solutions and applications Konica Minolta are also a perfect fit for the diverse range of topics covered by this congress trade show. Confirming this, Mirko Pelzer, Offering Manager Germany & Austria at Konica Minolta Business Solutions Deutschland GmbH, says: “As a longstanding partner of the PRINT & DIGITAL CONVENTION we look forward to once again helping to shape one of the most relevant meetings of the graphics industry in 2023. In tune with the motto ‘Use your Opportunities’ we will present GLAMPRINT showing how customers can fully leverage their creative potential to turn print into a unique experience that delivers its impact on all levels.

What also makes the PRINT & DIGITAL CONVENTION so special is the presentation of innovative technologies by way of highlight projects, which not only feature individual machines or tools but practice-oriented total solutions. One of these highlight projects involves LEONHARD KURZ Stiftung & Co. KG, a global leader in thin-film technology. Elke Andersch, Marketing Manager Packaging and Print at KURZ, emphasises: “The holistic congress concept of the PRINT & DIGITAL CONVENTION allows finishing specialists KURZ to introduce to visitors a plethora of their comprehensive solutions for both analogue and digital finishing. As part of the planned highlight project, KURZ - jointly with its subsidiary SCRIBOS - will demonstrate a combination of finishing and functional security features by means of an impressive practical example. And, needless to say, KURZ will also score points in terms of sustainability here.”

Also awaiting participants here will be an extensive and high-calibre lecture agenda on both trade show days alongside exciting exhibits and in-depth expert advice at the exhibitors’ stands themselves. In addition to three parallel lecture slots focusing on the topical themes “Value Added Printing”, “Marketing Automation & Programmatic Printing” and “Sustainable Media Production” there will also be inspiring panel presentations at the “Forum Stadthalle” within the exhibition area.

The PRINT & DIGITAL CONVENTION will be held in Düsseldorf from 16 to 17 May 2023 and organised by the Fachverband Medienproduktion f:mp. (Media Production Association) in cooperation with Messe Düsseldorf and drupa. Tickets and further information are available at: https://www.printdigitalconvention.de/en

February 14 2023

Roland DG Australia, a leading manufacturer of wide format inkjet printers and printer cutters, today announced the first round of 2023 dates for its successful Roland Academy Online Training courses.

Launched in 2020, Roland DG’s Academy Online Training courses aim to help customers increase their efficiency and productivity from the comfort of their home or office. The courses are delivered online in 1 to 2-hour sessions by expert Roland DG trainers to small groups of attendees to encourage participation and interaction. "Our online training sessions are a great way for us to support our customers no matter where they are located" said Greg Stone, Product and Marketing Manager at Roland DG Australia. "We continue to receive positive feedback from attendees, many of whom have attended multiple sessions. The overwhelming response is that they come away with a greater understanding of their machine and its capabilities." Alana from AJ Embroidery and Apparel attended Session 6 – Getting the Most Out of your BN-20/20A at the end of last year and said: "Great starter tool for me. It answered all of the questions I was wanting to ask without asking them. Trainer was encouraging, patient and willing to go in depth until your question was answered to your understanding." Kerry Baker from Just Ribbons and Rosettes attended Session 1 - Basics and Session 2 – Advanced Features: Cutting and commented: "Highly recommend these training sessions no matter what level of user you are. Always something to learn and share with everyone." Topics covered across the six individual courses include VersaWorks basics, advanced cutting, understanding colour and profiles, a dedicated session covering some of the features and functions of UV printing and a course specifically for VersaSTUDIO BN-20 and BN-20A customers. Initial 2023 Roland Academy Online course dates are outlined below: Session 1 – Basics Date: Tuesday, March 7 Time: 10:00am AEDT Duration: 120 mins Price: $49 inc GST Session 2 – Advanced Features: Cutting Date: Tuesday, March 14 Time: 10:00am AEDT Duration: 120 mins Price $49 inc GST Session 3 – Advanced Features: Understanding Colour Date: Tuesday, March 21 Time: 10:00am AEDT Duration: 90 mins Price: $39 inc GST Session 4 – Advanced Features: Understanding Profiles Date: Tuesday, March 28 Time: 10:00am AEDT Duration: 60 mins Price: $29 inc GST Session 5 – UV Features and Functions Date: Tuesday, April 4 Time: 10:00am AEDT Duration: 120 mins Price: $49 inc GST Session 6 – Getting the Most Out of your BN-20/20A Date: Tuesday, April 11 Time: 10:00am AEDT Duration: 120 mins Price: $49 inc GST Further dates will be added in the coming months, based on demand. Places are strictly limited to 8 people per class, so make sure you get in quick to secure your place. For further information, including course and booking detail, click here or contact Roland DG on 02 9975 0000. |

January 31 2023

Brand Management Group (BMG), the brand licensee for KODAK Wide-format Media, is proud to announce that a portfolio of KODAK photo and fine art papers is now FSC-certified. The Forest Stewardship Council (FSC) is an international non-profit organization that promotes environmentally sound, socially aware, and successful management of the world’s forests. Media that carries the prestigious FSC-certified label are certified to be sourced from responsibly managed forests that ensure trees are replanted and that wildlife, local communities, and the environment are protected.

The following KODAK Wide-format Media have received this certification; find them here: kodak-fsc-certified-papers.

The Forest Stewardship Council (FSC) is an international non-profit organization that promotes environmentally sound, socially aware, and economically successful management of the world's forests. FSC®-certified papers carry a label that certifies they are sourced from responsibly managed forests that ensure trees are replanted and that wildlife, local communities, and the environment are not harmed.

ASGA have announced full details of their Annual Genera...

January 31 2023

ASGA have announced full details of their Annual General Meeting which will be followed by a Special General Meeting on Friday, 17 February 2023. Both will be hybrid meetings.

Meeting Venue: The Duxton Hotel, 1 St Georges Terrace, Perth, WA and online via Microsoft Teams

Time: 12.30pm – 2.20pm (Perth time)

Guest Speakers will include: ASGA’s Legal and IR Advisor, Warwick Ryan from Hicksons Lawyers, and WH&S and Risk Advisor, Glenn Hain from G Hain Risk Pty Ltd.

Warwick will provide a review of 2022 and outline upcoming legislative changes. Glenn will provide an update on WH&S regulations. Glenn will be available after the meeting if members have any specific questions on WH&S, ACM, building permits and licenses.

At the conclusion of the AGM, the ASGA will be holding a Special General Meeting to vote on adopting a new constitution consolidating a number of changes. Voting on the new constitution can be made in person, online or via a proxy form.

A dinner will be held on Friday 17th February 2023 at the Sen5es Restaurant & Wine Bar, Perth commencing at 6.30pm. Members are encouraged to attend to network with other industry personnel and meet ASGA Directors, advisors and staff.

Prior to the AGM, members can nominate for election to join the Regional Sub-Committee, as a Sub-Committee Member or Chairperson. Nomination forms needs to be received by the ASGA by Thursday 9th of February.

Members that require additional information regarding the AGM, Special General Meeting, networking dinner or nominating for election to join the Regional Sub-Committee, or have not yet received an email with full details, can contact the Returning Officer, Kym Oakley, by emailing admin@signs.org.au.

Epson has partnered with renowned Japanese fashion designer Yuima Nakazato and his eponymous YUIMA NAKAZATO brand at Paris Haute Couture Fashion Week Spring - Summer 2023 to unveil creations that are both stunning and sustainable. In addition to utilizing Epson's digital textile printing to reproduce his unique and creative worldview, YUIMA NAKAZATO realized some of its creations with the help of a new, more sustainable and potentially industry-transforming textile production process.

Epson's dry fiber technology, which is already used commercially to recycle office paper and which requires virtually no water, has been adapted to produce printable non-woven fabric from used garments. The new fabric production process was revealed in Paris as part of a three-year collaboration between Epson and YUIMA NAKAZATO and was used in the creation of items for the first time during the latter's runway show at the Palais de Tokyo on January 25, 2023.

The collaboration between Epson and YUIMA NAKAZATO builds on the success of the company's printing support for his couture and evolves the level of his creations to enable the low-impact production of high-quality custom garments. Both Epson and YUIMA NAKAZATO are keen to raise awareness of the water and material waste associated with excess production. The Paris Show illustrates how switching to digital textile printing using more environmentally friendly pigment inks offers the fashion industry a more sustainable and less wasteful means of textile printing.

The fabric taken to create the latest YUIMA NAKAZATO fashion line was derived from material from used garments sourced from Africa, the destination for many discarded garments from elsewhere in the world. Nakazato visited Kenya where he collected around 150 kg of waste garment material destined for the "clothes mountain" of discarded textiles he encountered there. Epson then applied its dry fiber process to produce over 50 metres of new re-fiberised non-woven fabric, some of which was used for printing with pigment inks with Epson's Monna Lisa digital printing technology.

Hitoshi Igarashi from Epson's Printing Solutions Division explains the importance of the technology: "Although in its early stages, Epson believes its dry fiber technology combined with pigment ink digital printing could offer the fashion industry a much more sustainable future, significantly reducing water use while allowing designers the freedom to fully express their creativity.

"Epson's Environmental Vision is committed to contributing to a circular economy, and this development could be one step towards achieving this. Dry fiber technology applied to the fashion industry offers the possibility of producing material for new clothes that have been recycled from used garments."

In a trial of distributed printing for venue decoration, Epson inkjet printers in Japan and France with remote support from Epson engineers were used to create decorations in the venue space. Both Epson and YUIMA NAKAZATO intend to continue exploring the possibilities for contributing to a more sustainable fashion industry.

Digital textile printing using pigment inks offers a far more sustainable approach to the fabric production process. compared with traditional analog methods. In addition to pigment inks requiring significantly less water, the digital process requires far fewer stages and is less complex. Unlike analog it requires no plate production, washing or storage, results in little disposal of used inks, and allows on-demand production that contributes to less waste.

2 Epson's Monna Lisa digital Direct-to-Fabric printers use less water compared with analog methods. Pigment inks are more eco-friendly and Epson GENESTA pigment inks are GOTS approved by ECOCERT.

Esko is launching a new software solution to help growing brands and small businesse...

January 31 2023

Esko is launching a new software solution to help growing brands and small businesses bring quality products to market in a consistent, fast, and sustainable way. Mox is the new cloud-based tool that has been specifically developed to help small-to-medium sized consumer brands (SMB) meet the challenges of today’s omnichannel market, to work more efficiently, and to deliver right-first-time packaging and marketing content on time.

“Combining project management with digital proofing and DAM in one simple solution enables small teams and growing businesses to increase their speed and simplify their go-to-market processes,” explained Adrian Fernandez, general manager of Mox. “This rapidly reduces approval time for impactful product packaging and content, enabling teams to develop and deliver artwork and content to get new SKUs to market quickly, efficiently and in compliance with all regulation requirements.”

Adrian added that Mox was created by Esko, the global provider of software and hardware solutions that accelerate the go-to-market process of packaged goods. “With Mox, we are leveraging the many years of Esko’s experience with top consumer product companies and their ecosystems,” he said. “We have been able to use that to develop a new best-practice software tailored to the needs and budget of growing consumer brands, helping them increase productivity, reduce costs, and save time in their packaging and content creation process.

“We developed Mox as a collaborative, scalable solution for marketers, packaging and project managers, creatives, and all internal and external stakeholders who participate in creating and distributing product packaging and content,” he said. “Many businesses and brand teams are still relying on emails with file attachments, spreadsheets and shared drives for workflow management and collaboration. In today’s omnichannel environment, this is simply no longer fit for purpose. It’s easy to lose track of digital assets and team’s input, especially for approvals, feedback, and version histories,” he said. “If the final content is incorrect, or the wrong version is used at the wrong stage of the go-to-market process, brand reputation is at risk.

“Mox delivers real-time project and task visibility, improves collaboration, and helps accelerate speed to market. It provides the tools you need to take control and scale your brand,” said Adrian. “With Mox, small businesses and growing brand teams can now get to market faster, overcoming the challenges of demand for ever-changing SKUs in a fast-paced, omnichannel market - and all while safeguarding their brand consistency.”

Mox delivers a host of benefits to businesses, including:

• Collaboration - Bring internal and external contributors together with the right information to create and review before product launch

• Review & Approve - Get feedback in real-time, make revisions, and obtain approval before content distribution, with automated notifications

• Workflow Templates - Configure and build standardized templates to use consistently every time

• Track & Audit - Fully understand your content process, including when, how, and who approved it

• Advanced Proofing Capabilities – View content for proofing with deep zoom, visual comparisons, ink type and density, and font usage for most popular file formats

• Digital Asset Management – Tag and organize content, leveraging metadata with 100 GB of storage per user

• Permissions & Roles - Manage who has access to projects and assets, including fast external sharing

“Mox serves to connect teams, content, and consumers at SMB brands like never before,” said Adrian. “With Mox, businesses can create content that actually connects their brand to their consumers, helping teams to build brands that people love.”

Want to see for yourself? Try a free 30-day trial of Mox by clicking here

To explore the benefits of Mox for your business, click here and complete the simple form to be put in touch with a Mox expert.

January 31 2023

Leading ink developer, NUtec Digital Ink has achieved GREENGUARD Gold accreditation for select products within its Amethyst UV-curable roll-to-roll and rigid ink ranges, certifying them for use in schools and healthcare facilities.

GREENGUARD certified products have been rigorously tested and proven to meet some of the world’s most demanding chemical emissions standards intended to reduce indoor air pollution and the risk of chemical exposure, leading to healthier interior environments. The GREENGUARD Gold certification standard is the highest level achievable for health-based chemical emissions criteria, requiring lower total volatile organic compounds (VOC) emission levels, ensuring that products are acceptable for use in sensitive environments.

NUtec Digital Ink is proud to announce that its Amethyst A20-RTR UV-curable inks for roll-to-roll printing and its Amethyst A20-RIG UV-curable inks for rigid media have recently been tested by UL Solutions, a global leader in applied safety science, and have been approved for GREENGUARD Gold status.

“Being listed on UL Solutions’ SPOT website, one of the largest sustainable product databases globally, means NUtec Digital Ink GREENGUARD Gold certified products may now be specified with confidence for use on furniture, walls, floors, building materials and interior décor items used in educational institutions and hospitals,” says Darren Claassens, head of sales and marketing at NUtec Digital Ink.

Roland DG Corporation, a leading manufacturer of wide format inkjet printers and printer cutters, announced today the worldwide launch of six new models in the best-selling TrueVIS Series of large format inkjet printers and printer-cutters: the AP-640 Resin Printer, the LG-640/540/300 high productivity UV printer cutters, and the versatile, cost effective MG-640/300 UV printer cutters.