See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

Meteor Inkjet Ltd, leading supplier of electronics, software, tools and services for industrial inkjet, together with Dyndrite, providers of the core accelerated computation engine used to create next-generation digital manufacturing hardware and software, expand their collaboration with the announcement of Meteoryte, a 3D software tool that simplifies the development and adoption of inkjet technology for additive manufacturing applications.

Industrial inkjet 3D system developers, particularly those just getting started, face hardware, software and materials challenges. In some cases, the software challenges can be resolved by adopting off-the-shelf, open-source tools, but when these tools lack sufficient features or can’t offer the required production-ready performance, Meteoryte presents an ideal solution. Built with the Dyndrite Application Developer Kit, Meteoryte offers additive manufacturing system builders a foundational set of tools for the initial stages of machine development. With an easy-to-use 3D geometry manipulation interface, Meteoryte features include:

May 24 2022

SA International (SAi), the leading provider of software solutions for the signmaking, digital printing, textile and CNC machining industries, has announced the launch of Flexi 22, a fully-updated and more powerful version of its highly-successful industry-acclaimed signmaking software. The new solution, the only all-in-one design, print and cut software for sign and print providers, is engineered to further increase productivity and workflow efficiencies for users and will be demonstrated live for the first time at FESPA Global Print Expo (Berlin, Germany, May 31st – June 3rd).

Building on the success of SAi’s flagship Flexi package, Flexi 22 meets the exacting production needs of sign and display users by incorporating proven sign-specific design tools, RIP software and print-and-cut software for direct vinyl cutting.

New and unique features

Additionally, the latest version of Flexi has been engineered to provide improved connectivity for users through the SAi Connect dashboard, a feature unique to the new software. Via one central interface, this allows users to easily manage their software licenses or subscriptions, download new versions or updates, as well as monitor and review production data reports. SAi Connect also resides in the user’s toolbar, enabling instant accessibility without taking up valuable real estate in the screen workspace.

Flexi 22 also streamlines the production workflow and delivers greater efficiency benefits by allowing more job modifications to be applied directly within Flexi Production Manager, thereby eliminating the need to back-track or redo. This includes the ability to create contour lines or develop and store orders with the original job files and settings, making reprint orders faster, easier and more profitable. In addition, Flexi 22 offers the capability to add jobs to nested groups, without the need to first ‘un-nest’ other jobs. Users simply add the new job to the queue, then drag and drop to the nested group.

Simplified design and production of DTF and DTG applications

Users of the new Flexi 22 also benefit from the capability to leverage profitable new application opportunities more easily. For example, Flexi 22’s Direct-to-Film and Direct-to-Garment features simplify the design and production process to provide an easier path for those seeking to add tee shirt and other textile printing applications to their service offering.

“Flexi 22 represents the most powerful version to date and comes fully loaded with specific productivity- and efficiency-enhancing tools that have been integrated following research into the additional tools needed by customers to address their precise needs,” explains Annette Plummer, VP Marketing, SAi.

“Unlike some software options on the market that comprise only the RIP, SAi Flexi combines an easy-to-use design interface with a powerful RIP to give users a complete, seamless package,” she adds. “With Flexi 22, we are confident that our sign and display customers will find everything they are looking for from a signmaking software.”

Available for purchase from June 22nd.

Leading finishing equipment manufacturer, A B Graphic International (ABG), has launched the next evolution of its highly popular Omega SRI label finishing system. Delivering high perform...

May 17 2022

Leading finishing equipment manufacturer, A B Graphic International (ABG), has launched the next evolution of its highly popular Omega SRI label finishing system. Delivering high performance slitting, rewinding and inspection, the updated model offers a range of new and adjustable options to meet future requirements.

With a larger unwind diameter at 830mm, and increased nip roller wraparound, waste is reduced and tension control improved, preventing slippage and interweaving of the web and providing unparalleled versatility. The upgraded features, which include a lower splice table, allow operators greater flexibility and increased ergonomic comfort, thereby improving productivity and efficiency. A market leader in innovative print finishing, the SRI3 is also the only machine in its class that doesn't rely on a third party inspection system. Providing 100% print inspection with ABG’s fleyeVision camera system, everything works perfectly together with seamless integration.

Other enhancements include an arm that enables a right handed operator to easily cut the reel, and a tape holder, which is built-in as per ABG’s Digicon range. Manual slitting can now be upgraded to autoslit, which was not possible on the previous SRI, and the rewind module can be taken out and replaced with a turret at a later stage.

Designed with retrofitting possibilities in mind and a modular setup to make future updates simple, the SRI3 can be fully configured to meet individual needs.

“At ABG, we strive to deliver premium service and the best experiences for our customers across the globe,” said Ralf Wirtz managing director of ABG GMBH. “And with over 30 years experience manufacturing slitter rewinders, this commitment to excellence is at the core of our evolutionary approach to the SRI’s unique design.”

For more information about ABG contact Australian and New Zealand distributors Currie Group www.curriegroup.com.au or watch www.youtu.be/7HBVg7cSbQE

Award brings further affirmation of sustainability efforts Epson has won this year’s DataMaster Lab GREEN Award in recognition of the environmental benefits afforded b...

May 17 2022

Award brings further affirmation of sustainability efforts

Epson has won this year’s DataMaster Lab GREEN Award in recognition of the environmental benefits afforded by its Heat-free PrecisionCore inkjet printers and MFPs and the sustainability measures employed as part of their development, production and distribution. DataMaster is an independent laboratory, expert in professional document imaging solutions.

DataMaster acknowledges that one of the primary environmental impacts of printing is energy use and has recognised the reduction that can be achieved by Epson’s Heat-free PrecisionCore inkjets. When compared to laser printers, this averages up to 83% less power consumed, which across a fleet can amount to a very significant saving.

That said, this award is not just about electrical consumption. Edward Bilson, Technical Director of DataMaster Lab said, "We take into account accreditations for manufacturing facilities, levels of noxious emissions – and the nature and lifetime of a machine’s consumables. When you consider the carbon footprint of a consumable item’s manufacture, transportation, distribution and its final resting place in a landfill site, you realise that all consumables need to be designed with the environment in mind and have the longest lifetime possible. The winners of DataMaster Lab’s GREEN Award have the least impact on our precious environment."

Since 2018 Epson has invested considerably into the development of their PrecisionCore printhead, and last year the company committed to investing 100 billion Yen into further developing sustainable technologies, decarbonisation and resource recycling. They also committed to becoming underground resource free by 2050.

HP is delighted to announce the launch of The Print Hub, an interactive platform specifically developed to support HP Latex users and help them get the best out of their printers.

The Print Hub offers personalised content covering all topics related to HP Latex, allowing users to explore a wide range of exclusive and specialist information dedicated to the HP Latex range of print technology.

Customers – both existing and potential – can explore insightful and informative content such as webinars, videos and expertly written articles, as well as access in-depth technical information about HP Latex printers and the applications they can be used for.

Visitors will enjoy a personalised experience when browsing content on The Print Hub based on their navigation history and asset clicks. The ‘Recommended for You’ feature suggests content that may be of interest to each individual visitor, while the ‘Continue Watching’ option allows users to pick up from their last visit.

Another stand-out feature on the interactive platform is the ‘Printer Selection Tool’, whereby users can select certain criteria to help them identify the most suitable printer for their business and proposed applications.

In addition, visitors will have the opportunity to sign up for live broadcasting experiences of certain events that are happening – such as the upcoming FESPA Global Print Expo in Berlin – allowing those who cannot attend in person to access key information from the comfort of their office.

“From its beginnings, when it was branded ‘Possibility City’ and used as a means to replace physical shows during the pandemic, the interactive site showed great promise. The HP Large Format team soon realised that the platform was fast becoming an essential – and 24/7 accessible – resource for customers wanting to research and explore content and learn about HP’s offerings in the Latex technology space,” says Isabella Jelinek, Large Format Marketing Manager UK&I at HP.

“Subsequently, we optimised and improved the platform’s functionality. We added more content to offer customers a rich, personalised experience, curated with exactly what they want to read, see and do – all in one place – and The Print Hub was born.”

Leading manufacturer, NUtec Digital Ink offers a unique proprietary bulk ink system engineered to ensure a continuous supply of ink to the Epson® DX4, DX5, DX6 and DX7 print heads used in wide-format digital inkjet presses.

NUbis is a bulk ink system from NUtec Digital Ink which enables more efficient printing with uninterrupted refilling, giving the functionality of a cartridge with the advantages of a bulk system. The system holds either 1000ml or 2000ml degassed pouches, which are easy to replace when empty, even during printing without disrupting the print session.

Replacing pouches can be done quickly and cleanly as the custom-designed needle connecter attaches easily to the nozzle of the pouch for a rapid, spill-free refilling process which reduces ink wastage. Empty pouches can be folded and disposed of in accordance with regional waste disposal measures, while the outer box is 100% recyclable.

“Installation of our NUbis bulk ink system is simplified with the supporting tools we provide including our Quick Install guide, detailed components list and step by step installation video available on our YouTube channel, “ says Darren Claassens, Head of Sales and Marketing at NUtec Digital Ink. “Additionally, our network of distributors and dealers are fully trained on the system and are able to assist with installation and technical support.”

Roland DG Corporation has launched the My TrueVIS campaign, a central webpage and social media campaign to share user testimonials about its TrueVIS large-format inkjet printers and printer cutters from around the world.

The TrueVIS series represents Roland DG's flagship models for producing sign and graphics with the extraordinary power to excite hearts and minds. The combination of unparalleled colour, durability and ease of use has appealed to large numbers of digital print business owners, with more than 24,000 units* shipped. On March 1st, the company launched its third generation of TrueVIS printer cutters, including the professional, high performance VG3-640 and 540 models and the value-packed SG3-540 and 300 models.

As part of the campaign, TrueVIS users everywhere are invited to enter the #MyTrueVIS competition by posting what they love about their TrueVIS with photos of their work and workplaces using the hashtag #MyTrueVIS. Australian users who mention Roland DG Australia (using the @ symbol) on Facebook and Instagram, will have the chance to win a full set of TR2 inks for their TrueVIS printer/printer cutter valued over $1500 inc GST**.

Tony Miller, President, Global Sales and Marketing Division, said, "We started this campaign to let people know about the benefits of TrueVIS, but it has revealed not only our customers’ thoughts about TrueVIS, but also many exciting success stories. For example, an American user sold her couch, put her TrueVIS printer in her living room and started a printing business. A British customer said that his sons will now be taking a bigger role due to TrueVIS furthering the growth of his business. A Brazilian woman said that TrueVIS has created new possibilities for her company and made her dreams come true.

“These are just a few of the stories we were impressed to hear from users working successfully in different environments in numerous countries. They remind us of the important role and responsibility that our products play in the personal lives of our users, not just in business,” Miller said.

“The purpose of our company is to provide more people with the joy of creation. These passionate and creative customers are a great source of pride for us and one of our most treasured strengths. They make us even more determined to continue to provide products and solutions that meet or exceed the expectations of our customers around the world,” Miller continued. "Through this campaign, we sincerely hope that more and more people will become aware of the value that TrueVIS offers and the stories of creativity, joy, and excitement that result from it."

Campaign page: www.rolanddg.com.au/products/printers/mytruevis

Agfa has announced the release of SolidTune, a breakthrough prepress software solution for offset packaging printing that excels by reducing ink consumption and allowing faster turnaround time for greater production efficiency, improved image quality.

SolidTune has been developed with the specific challenges of packaging production in mind, building on the success of the crucial elements of InkTune and PressTune, which are part of the highly regarded Agfa ECO3 program for sustainable innovation. The new technique applies a unique algorithm to the solids and text, after screening prior plate imaging. This process reduces the amount of ink needed for printing by an average of 3%.

SolidTune is available on license in Apogee and Amfortis prepress workflows and can be used with any screening technology, including Agfa SPIR@L.

New technology innovation for packaging

As the last stage of the rendering process, SolidTune applies a unique ink saving algorithm to the solid 1-bit pixels, before final output. Unlike other solutions, the software has been devised with unique edge protection, meaning the algorithm ensures the edges of the solids are preserved to keep the print clean and crisp. This helps to create a better printable 1-bit file for offset packaging printing, where spot colors are often printed as solids.

“The packaging market is growing, and the opportunity is growing for converters, meaning they are constantly searching for new technologies that can help them deliver even better print quality with strong colours, but at cost-efficient levels,” says Andy Grant, Agfa’s Global Head of Software.

“We are now ramping up our unique offering for the demanding packaging market by leveraging our deep expertise in offset printing to introduce innovative solutions, such as SolidTune, that will have a considerable impact on the bottom line for the converter and the long-term sustainability of the process.”

SolidTune: less ink, faster production

Delivering exceptional ink-saving benefits, this new approach naturally shortens the overall production times, as the thinner solid ink film enabled by SolidTune takes less time and energy to dry. And with faster drying, downstream processes such as finishing and die-cutting can take place sooner, allowing converters to respond to demands from brand owners for faster delivery and also to save on warehouse costs.

Furthermore, the implementation of SolidTune into the workflow improves ink distribution and reduces problems with ink offsetting from one impression to the next. There will also be less force on the substrate from the ink system, which prevents plucking (or picking) of fibers from the top paper layer; a problem that is known to cause reduced image quality and potential rejection of jobs.

“This clever tool, which is very user-friendly and simple to impose during the rendering process, provides quite significant improvements in print quality,” states Grant.

SolidTune can be combined with any screening but works optimally in combination with SPIR@L – Agfa’s revolutionary patented screening technology which was extended from commercial into packaging printing in 2021 – to achieve even bigger ink savings.

SolidTune & SPIR@L screening enlargement

Grant concludes, “SolidTune is another innovation that Agfa added to its ECO³ program to maximise ink reduction and value whilst still delivering the highest quality possible and putting converters at the leading edge of innovation.”

May 10 2022

In 1952 Mutoh initially produced measuring equipment such as disk-type slide rules for aerial navigation, callipers, and rotary protractors. Mutoh says these products reflected the technical capabilities required to engrave scales accurately and marked the beginning of the company’s spirit of supporting monozukuri (the act of making things).

In March 1952, MUTOH Memori Chokoku (MUTOH Scale Engraving) LTD was established. With this came new products like the drafter and pen plotter that printed product drawings. Over the years, Mutoh says it has continued to uphold the same spirit by supporting those in various aspects of monozukuri, especially when it comes to large-format printer products.

“Understanding the customer’s needs, providing security and trust, and the excitement of our future to reach new milestones and breakthroughs is our commitment to achieving our target of celebrating our 100th anniversary,” said Mutoh’s President Yasuhiko Isobe. “We are still in a difficult business environment due to the new coronavirus, soaring prices of materials due to the situation in Ukraine, difficulty in procurement, and turmoil in logistics, but all employees will continue to work to overcome these difficulties.”

With world headquarters in Japan, and its affiliates in the U.S., Europe, and Australia, Mutoh prides itself on being a source for wide and small-format printers and plotting cutters.

“Seventy years is quite a milestone for Mutoh,” says President of Mutoh America Brian Phipps. “It says a lot when a company can grow and adapt over the many decades and remain a leader in the markets they serve. I’m very proud to be part of this organisation and to celebrate this giant achievement with Mutoh."

Locally, Mutoh Australia Managing Director Russell Cavenagh says, "Monozukuri (the act of making things), and a commitment to quality are at the heart of Mutoh's design philosophy. Our customers benefit from this and I am proud to represent Mutoh in Australia and New Zealand."

The only all electric Automatic Screen-Printing Press in the world, made by Anatol, has arrived in Australia. Three excited customers are getting their Anatol Volt’s installed, undergoing training and watching their production rates skyrocket while their screen-printing processes become more efficient.

With user-friendly operating software, the Volt can be operated by one printer, saving a salary or making your team more efficient as they perform other tasks. With the capacity to produce prints at rates of over 500 per hour, printers can take on bigger jobs without worry.

The Volt enables printers to maximise the quality of prints, minimises operating costs and increases production outputs.

Without the need for complicated pneumatic systems, the Volt offers years of reliable service with fewer maintenance requirements than traditional automatic screen-printing presses. With the lack of a compressor or pneumatics, the Volt provides printers with a quieter, more ergonomic working environment.

Having used the Volt for a few months, Sam Austrin-Miner from Ministry of Shirts is “absolutely delighted” with the press. He says: “The Volt has changed our life. Previously an 8-colour simulated process job on a manual would take around one minute per shirt; now, we are doing it in four seconds! It has given us the ability to reduce the minimum quantities we require for certain jobs, making it better for our customers.”

When asked what the key factor was in making their auto screen press decision, Sam advised: “Trusting the vendor supplying the equipment was the first priority, followed by the functionality of the machine and the price.”

Howard Debney from Leapfrog Machinery, the Australian agent for Anatol, says, “It is fantastic to see the Volt in action and better still to see the positive impact it is having on our customers. We look forward to helping more screen printers throughout Australia automate their printing with this innovative, high quality and robust machinery.”

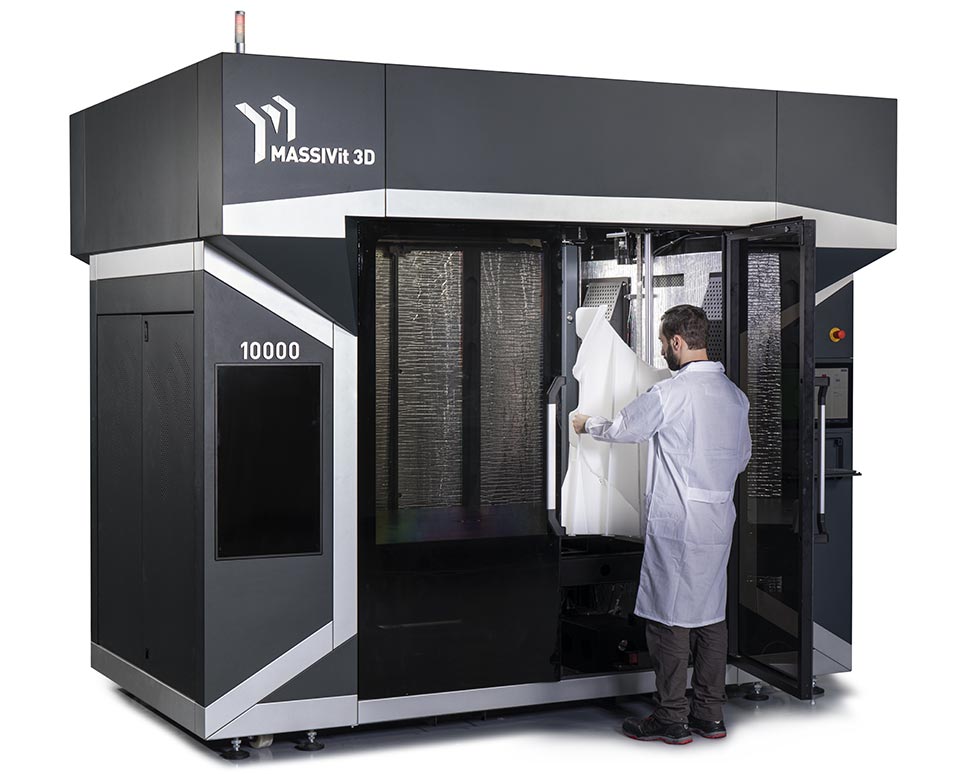

Massivit 3D Printing Technologies Ltd., a leading provider of large-scale 3D printing systems, has announced the launch of the Massivit 10000 additive manufacturing tooling system to be unveiled at the upcoming JEC World 2022 event in Paris from May 3-5.

Visitors to JEC World can reserve a live demonstration of the Massivit 10000 and see a range of moulds and parts at the Massivit 3D stand (Hall 5, M46).

The event will also provide an opportunity to secure limited-time pre-orders of the Massivit 10000. A press conference will be held at the Massivit 3D stand on Tuesday, May 3rd at 3 PM.

Designed to overcome recognised tooling bottlenecks in composites manufacturing, the Massivit 10000 automates and shortens conventional composites tooling processes that are slow, costly, wasteful, and heavily reliant on manual skilled labor.

The 10000 leverages the company’s new Cast-In-Motion technology that enables complex molds, masters, mandrels, and prototypes to be directly 3D printed. It provides geometry freedom for highly efficient designs as well as digital accuracy. The technology is designed to serve a range of industries including marine, rail, automotive, defence, and aerospace as well as sporting goods, bath ware, and furniture.

The Massivit 10000 additive tooling system was selected as winner of the prestigious ACE Award for Composites Excellence by the American Composites Manufacturers Association at the CAMX 2021 event in Dallas, TX. 17 pre-orders have been made to date – two of which include beta agreements with Israel-based company Kanfit (manufacturers of composite material parts for key players in the global aviation market) and US-based company Lyons (specialists in luxury bath ware). Massivit 3D will deliver Massivit 10000 systems to customers starting in H2, 2022.

Massivit 3D’s Cast-In-Motion technology enables composites fabricators to shorten their tooling workflows from the traditional 19 steps down to 4 steps. It eliminates the need to produce an initial plug or master by directly printing and casting the mould using ultra-fast additive manufacturing combined with industrial-grade casting materials. This cutting edge process shortens tooling time by 80% and offers a myriad of business benefits including a reduction of manual labor, a 90% decrease in labor-associated costs, a reduction of associated inventory and transportation, and a significant decrease in waste of expensive materials.

The Massivit 10000 brings to market the first 3D printed isotropic mould for composites manufacturing. As opposed to existing thermoplastic additive tooling systems, the Massivit 10000 utilises high-performance thermoset-based materials to produce a single, uniform cast that results in a true isotropic mould. In addition, it provides moulders with casting materials that have highly predictable mechanical and thermal properties, a low Coefficient of Thermal Expansion, and a high Heat Deflection Temperature.

Massivit 3D’s CEO, Erez Zimerman, stated “We eagerly await this momentous occasion, marking a significant company milestone and injecting innovation into the composites manufacturing market. The composites tooling arena has long been held back by antiquated processes and technologies. It’s high time to facilitate digital transformation in this market and we are proud to bring the relevant knowhow, expertise, and innovation to the table for that purpose.”

The company’s second-generation technology, Cast-In-Motion, is based on its successful Gel Dispensing Printing technology that has provided a new league of high-speed, large-scale 3D printing to customers across more than 40 countries.

Due to high demand, a third round of Roland Academy Online training dates has been added for 2022, commencing May 17. Get in quick to secure your place!

We have also developed a new course for users of the VersaSTUDIO BN-20 and BN-20A, Session 6 – Getting Started with your BN-20/20A. The session covers printer set up right through to calibration, ink configuration, maintenance and how to best use the printer/s with different types of applications.

Upcoming Session Details

Tickets are still available to purchase online for the following sessions:

Session 1 – Basics

Date: Tuesday, May 17

Time: 10:00am AEDT

Duration: 120 mins

Price: $49 inc GST

Session 2 – Advanced Features: Cutting

Date: Tuesday, May 24

Time: 10:00am AEST

Duration: 120 mins

Price: $49 inc GST

Session 3 – Advanced Features: Understanding Colour

Date: Tuesday, May 31

Time: 10:00am AEST

Duration: 90 mins

Price: $39 inc GST

Session 4 – Advanced Features: Understanding Profiles

Date: Tuesday, June 7

Time: 10:00am AEST

Duration: 60 mins

Price: $29 inc GST

Session 5 – UV Features and Functions

Date: Tuesday, June 14

Time: 10:00am AEST

Duration: 120 mins

Price: $49 inc GST

New! Session 6 - Getting Started with your BN-20/20A

Date: Tuesday, June 21

Time: 10:00am AEST

Duration: 120 mins

Price: $49 inc GST

Recent Feedback from Attendees

Delivered online by expert Roland DG trainers in a small group setting, the 1 to 2-hour sessions continue to receive great feedback from attendees.

Corinna McNally from Trophy Mart said the "trainer was very clear and organised. Presentation and instructions were very easy to follow. Will definitely recommend and even do these again as refreshers", while Larna Sparrow from Little Sparrow Designs commented "I learnt more about my machine and its settings in VersaWorks in 15 minutes than I have learnt in the 2 weeks that I have had it."

Book Your Place Today!

Places are strictly limited to 8 people per class so get in quick to secure your spot and avoid disappointment.

For further information, including course detail, dates and booking links, click the link below, or contact Roland DG on 02 9975 0000.

May 03 2022

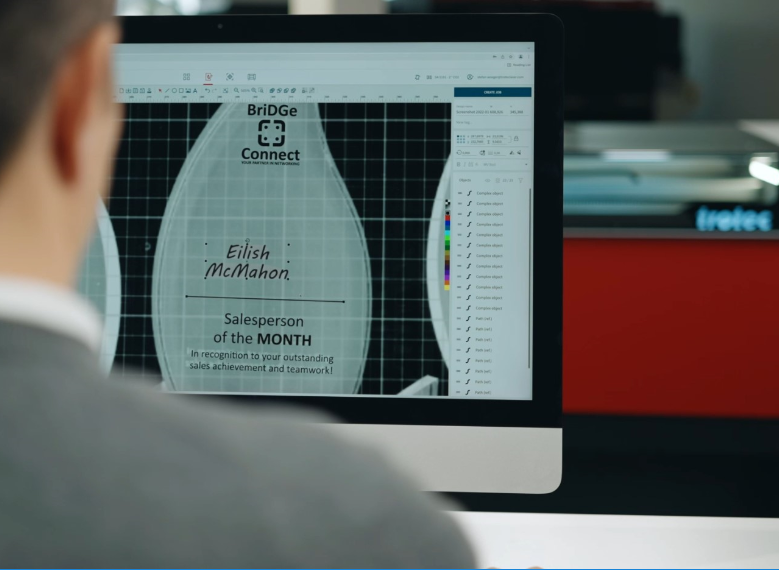

The most intelligent laser engraver just got smarter with Trotec’s new Vision Design & Position vision positioning camera. The new 12 megapixel patent-pending lid camera further speeds workflow by delivering a live image of the work area to the operating PC in real time.

A full colour and detailed image of the laser bed and workpiece is displayed within Trotec’s proprietary Ruby® software, allowing the laser operator to position the artwork file exactly where they’d like it to be cut or engraved, and to see a visual representation of how it will look before the job is started. This new feature eliminates the need for manual positioning of the laser pointer and saving graphic position data to the software, making laser job setup faster and easier than ever.

Virtual graphic design and job positioning in Ruby

The cleverly integrated camera on the lid of the laser delivers a live image of the work area to the Ruby laser software in a matter of seconds. It does not matter whether the lid of the laser is closed or open. The graphic is then placed on the workpiece in Ruby at the same scale. In this way, text can be set, a graphic can be designed or an existing job can be aligned directly on the workpiece, e.g. on a gift item or a cell phone, live in Ruby.

This patent-pending feature helps the laser user ensure that the job to be processed is where you want it to be the first time, even if it is a 3D object. There is no longer any need for time-consuming measuring of workpieces , residual materials and objects.

Increase productivity. Save costs

The user no longer has to switch between laser engraver and software or take the cumbersome route via graphics software with printer driver. The job to be executed can be changed directly on the live image in Ruby.

April 26 2022

Taking a Significant Step in its Digital Printing Business with Special Focus on Growth in the Packaging Market

The Agfa-Gevaert Group announced today that it will acquire Inca Digital Printers, subject to meeting and obtaining customary conditions and approvals. The acquisition strengthens Agfa’s position in high speed digital printing and brings an additional focus on packaging printing markets.

“The Inca acquisition is a major step in Agfa’s transformation. Digital printing is a profitable growth engine for the Group with a tremendous potential that will be further accelerated by the addition of Inca,” said Pascal Juéry, President and CEO of the Agfa-Gevaert Group.

Inca Digital Printers is a Cambridge UK based leading developer and manufacturer of advanced high speed printing and production technologies for sign and display applications as well as for the rapidly growing digital printing market for packaging. Inca is an ideal partner for Agfa, bringing a complementary portfolio of printing solutions of the highest standard and a strong technological platform to launch robust single pass printing presses for the packaging market.

The acquisition encompasses the portfolio of existing high speed multi pass printers, including a strong service organisation; a newly designed line of single pass printers for several packaging applications as well as a joint development of a customised in-line Print Engine in collaboration with leading corrugator manufacturer BHS Corrugated.

Stephen Tunnicliffe-Wilson, CEO/CTO of Inca Digital Printers Ltd.: “The acquisition by Agfa allows us to combine our technological knowhow and will enable us to become a leading digital packaging press manufacturer worldwide. Our new parent has shown long term commitment to the digital printing market and we are extremely proud and look forward to becoming part of the Agfa family.”

Vincent Wille, President of Agfa’s Digital Print & Chemicals division, comments: “The combination of Inca Digital’s manufacturing knowhow and Agfa’s technical expertise, worldwide presence and excellent service networks will allow us to bring unparalleled printing solutions to our customers and to adapt seamlessly to their needs in this rapidly evolving space. This investment leverages and strengthens our position in the high-end and high speed wide format market as a whole and specifically in the promising packaging segment.”

.png)

Australian Sign & Graphics Association (ASGA) has scheduled a free webinar on training and education on May 12, 2.00pm AEST. The webinar will be run as a panel discussion and Q&A ...

April 26 2022

Australian Sign & Graphics Association (ASGA) has scheduled a free webinar on training and education on May 12, 2.00pm AEST.

The webinar will be run as a panel discussion and Q&A and moderated by Vernon Kingman of Kingman Strategies.

The panel will consist of a team of dedicated industry professionals that are currently working towards achieving outcomes in this space: Damian Nielsen, ASGA Education Committee Chair; Ben Eaton, Visual Connections Education Committee Chair, and John Watters, AusSIP (ASGA Industry Education Liaison Managers).

“Industry feedback clearly highlights the need for more training options and a means of addressing staff shortages. Together with input from the Visual Connections Education Sub-Committee and AusSIP, the ASGA are implementing and continually investigating initiatives to address these issues,” said ASGA Education Chair, Damian Nielsen.

“This webinar is aimed at communicating to industry what the current training options and future opportunities are and what work is currently being done to attract the next generation of sign industry professionals. We’re also interested in input from industry, so we welcome feedback from attendees during the webinar or any time after.”

Registration is available online at: https://signs.org.au/Events-and-News/Current-Events .

This milestone highlights Durst Group's transformation from a press manufacturer to a solutions provider (“Pixel to Output”) in the digital printing industry.

Durst Group, manufacturer of advanced digital printing and production technologies, announces the 500th customer installation of Durst Workflow Software. This milestone highlights Durst Group's transformation from a press manufacturer to a solutions provider (“Pixel to Output”) in the digital printing industry. Founded in 2019, the Durst Software & Solutions Division now has more than 60 employees and has developed Durst Workflow, the most comprehensive software solution in the market that is also open to third-party providers, and successfully integrated it into its customers' production.

Michael Deflorian, Business Unit Manager, Durst Software & Solutions, explains: “We are proud that more than 500 customers from different sectors rely on our workflow solution. With the help of their feedback, we try to improve our products every day to offer the best software ecosystem for the digital printing industry."

Durst Workflow is the high-end solution for fully automated management of prepress and production tasks. Originally developed to provide the highest print quality for Durst printing systems, it is now also available for third-party printing systems. The complete browser-based solution has a user-friendly interface that allows the entire PDF workflow to be fully automated. Durst Workflow integrates seamlessly with the customer's existing software environment, enabling a higher level of automation than comparable stand-alone products. Thanks to preconfigured corrections, data preparation is faster and more efficient, and the integrated, powerful color engine guarantees exact color accuracy right from the start. With Durst Workflow, it is possible to print more while using less ink, thanks to predefined color saving profiles that can be applied with just one click.

Serge Clauss, Product Manager, Durst Software & Solutions, explains: "We develop software solutions that help our customers make their prepress and production processes more predictable and productive. Reaching 500 users with our Durst Workflow solution is a clear statement that we are meeting our customers' expectations."

The Epson International Pano Awards are back and bigger than ever in their thirteenth year. Epson Australia has helped continue to grow these awards into the world’s largest competition...

April 26 2022

The Epson International Pano Awards are back and bigger than ever in their thirteenth year. Epson Australia has helped continue to grow these awards into the world’s largest competition devoted to the craft and art of panoramic photography and now, Epson and The Pano Awards have launched this year’s call for entries.

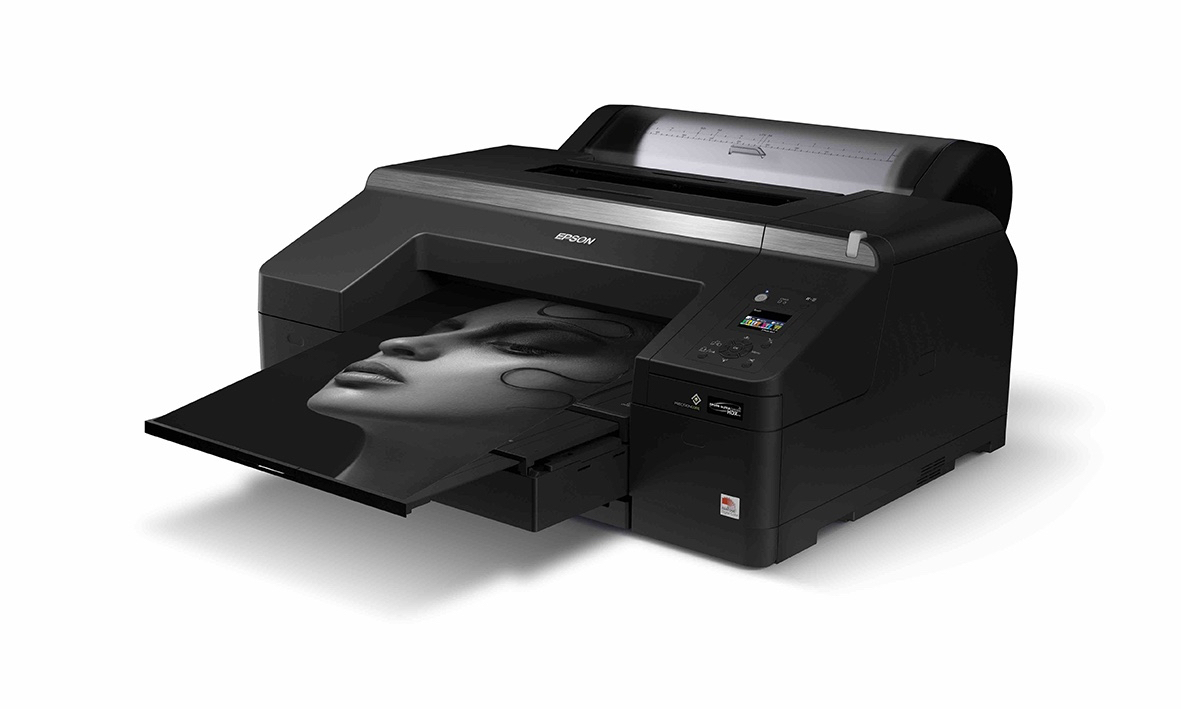

The Pano Awards’ Curator, David Evans, explained, “It’s always a very exciting time when we call for entries to win a US$40,000 prize pool that includes $14,000 in cash and an array of prizes including an Epson SureColor P7070 printer, an Epson SureColor P5070 printer and an Epson EB-1795F ultra-slim projector as you can feel the creative ripples go through the industry. With that said, I’m delighted to officially announce that professional and amateur photographers around the world are now invited to enter the 13th Epson International Pano Awards and that early-bird entries are open until Monday 27 June 2022.”

The 2021 Pano Awards surpassed expectations in light of the many challenges the world faced, seeing 5,378 images submitted from 1,245 photographers in 97 countries and these numbers are expected to be exceeded again this year.

Epson GM marketing Bruce Bealby said, “The Pano Awards truly stand alone in terms of their reach and support within the industry. This is the thirteenth year Epson has been proud to support these amazing awards and the wonderfully talented photographers who embrace them. It’s no secret that Epson has a long, rich and successful history in the photographic industry with photographers of all levels. As a company images and imagery are at our heart and we are very committed to the photographic industry. As always, we are very much looking forward to seeing the entries and how they come to life, seen as the artist intended, when printed out on Epson’s dedicated photo printers.”

Epson SureColor P7070

The Epson SureColor-P7070 is a 24" (610mm) large format printer and the SureColor P5070 is a 17" (432mm) large format printer both of which are designed for premium photo, fine art, proofing and packaging design. They support a wide range of standard and specialist media in roll and sheet formats and feature a PrecisionCore® Thin Film (TFP) head with Variable Sized Droplet Technology™ that enables the output of images in high resolution with superior fidelity and tonal gradation.

Both printers use Epson’s latest UltraChrome® HDX all-pigment aqueous ink for accurate colour with an enhanced gamut, Dmax and image durability. The printers also use a 10 colour ink configuration with two levels of black, a choice of a third black or alternative Violet ink for outstanding colour and black and white prints with up to 99% PANTONE® coverage.

Its ultra-slim design, radiant widescreen performance and easy wireless connectivity make the Epson EB-1795F the ultimate choice in portable projectors. It delivers value, convenience and performance and easily delivers brilliant content from any widescreen notebook with native 1080p (1920 x 1080) resolution. Couple that with 3200 lumens colour and white light output and the results are truly amazing.

David Evans concluded, “At The Pano Awards we have much to be grateful for. Firstly, the incredible photographers and their rare talent that make the awards such a success. Then Epson, their continued support and their amazing photo and fine art printers which set the standard for image reproduction across the spectrum. We thank our amazing photographic community for getting behind the awards and equally thank Epson for being such an amazing sponsor with their wonderful support.”

The judging panel for The 2022 Pano Awards includes some of the world's top photographers and industry professionals – Erin Babnik, Dudley Edmondson, Adam Williams, Isabella Tabacchi, Bill Bailey, Chris Collacott, Aaron Spence, Justin Majeczky, Andreas Paehge, Jason Denning, Thomas Erh, Tim Shields and Juan Pablo de Miguel.

Early bird entries for The Pano awards are open now. To enter go to: https://thepanoawards.com/enter-2022-awards/

General Formulations, a leading manufacturer of Pressure Sensitive Films, announced today the launch of GF 765 Rainbow Holographic Film. GF 765 adds a whole new dimension of colour to graphics. It is 6-mil thick, for easy handling, and the permanent adhesive makes it great for decals, retail displays, packaging, or whatever you can dream up! It is compatible with solvent, latex, and UV curable inks.

“We are extremely excited about the launch of GF 765 Rainbow Holographic Film,” states Matt Edwards, Digital Print Media Product Manager, General Formulations. “GF 765 is a fantastic product for our visual market. We can’t wait to see how it is creatively used in different applications and graphics.”

April 19 2022

Many leading print businesses are making it a top priority to diversify their large-format print offering as customers increasingly demand unique ideas, eco-friendly output, more creative solutions and new content.

One recent study from Report Linker said the value of the global wide-format print market will rise to $4.0bn by 2027. The only way to take advantage of this and secure new business is to innovate and pivot your offerings to meet demand, while also delivering reliable and efficient services.

In a new, free-to-download article, HP analyses how print businesses can grow and evolve with large-format print. By offering more competitive services that will shape the future and better serve existing customers, they can transform their operations enabling them to enter new markets, develop new solutions, find fresh revenue opportunities, and scale up their print offerings into the future.

Whether this is by adapting to meet rising demand in the interior décor market, or capitalising on the growth in the printed packaging and labels sector, there are plenty of opportunities for expansion.

Additionally, the sharp rise in web-based content has led more customers online and this shift towards ecommerce could also open up multiple opportunities for print service providers.

Whatever industry transformation means to you, now is the time to explore your options.

April 19 2022

Richard Roth has been appointed to the role of General Manager EMEA for Esko, the global developer of integrated software and hardware solutions that digitize, automate and connect the go-to-market process of consumer goods.

The move follows Eddy Fadel taking the position of Global Commercial General Manager - where he will oversee global sales, services, marketing and product management - after three successful years serving as EMEA General Manager.

“I am very happy to welcome Richard to the Esko family,” said Eddy Fadel. “We will certainly benefit from his broad experience in Danaher’s Product Identification Division. His experience at X-Rite Pantone leading innovation in color management and his commercial leadership in Videojet’s packaging and print business will be a great asset, both for Esko and for our customers.

“Since our integration of AVT inspection systems and our strengthened connections to X-Rite’s R&D and commercial teams, the Esko portfolio has extended beyond prepress and is rapidly becoming the packaging backbone for our customers,” he said. “With his breadth and depth in both packaging technology and business, I am convinced Richard is the right leader to help our commercial team in EMEA support our customers in their digital transformations.”

Richard has worked in the Danaher Product Identification platform for almost a decade, most recently leading X-Rite’s R&D and Product Management having joined as Vice President in 2017. In his new role, Richard will be responsible for the management of the commercial, support and financial performance of the Esko business across Europe, the Middle East and Africa, operating from the company’s offices in Gent, Belgium.

“This is a hugely exciting time for the business,” said Richard. “I am delighted to now take on the role of General Manager, building on Eddy’s work in successfully bringing teams closer together to better serve our customers. Following the market uncertainty and volatility that we have all experienced, our business has a clear focus on delivering innovations that support our customers along their digital transformation journey.

“I am proud to now be leading the team and look forward to working with them to achieve our common goal of helping our customers around the world overcome the many challenges they face today, and will face tomorrow,” he said.

For further information, please visit www.esko.com