See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

Kodak has unveiled the revolutionary KODAK PROSPER 7000 Turbo Press at its inkjet facility in Dayton, Ohio. Kodak's new inkjet web press uses KODAK Stream Inkjet Technology offering printing speeds of up to 410 mpm (1,345 fpm) or up to 5,523 A4/letter ppm, which is almost 35% faster than its nearest competitor. It enables commercial, publishing and newspaper printers to compete more effectively with offset and to shift more long run jobs from conventional printing processes to inkjet. Kodak is setting unprecedented standards in speed and productivity with its new full colour perfecting inkjet press.

Turbo productivity in a variety of applications

PROSPER 7000 Turbo not only impresses with its incredible printing speed, but also with its vast application and substrate versatility. It supports a maximum web width of 648 mm (25.5 inches) with a variable cutoff length up to 1,372 mm (54 in.) while printing on a wide range of coated and uncoated stocks, newsprint, specialty papers as well as recycled papers.

Offering three optimised print modes, the PROSPER 7000 Turbo Press meets the specific requirements of different applications. This allows printers to optimise their production process to always print at the best combination of speed and resolution. The Quality mode, which is roughly comparable to offset printing using a 200 lpi (80 L/cm) screen, is best for direct mailings, catalogs and magazines. The Performance mode (offset equivalent 133 lpi / 52 L/cm) is ideal for textbooks, fiction books and other medium ink coverage applications, and the Turbo mode (85-100 lpi / <40 L/cm) is ideal for newspaper printing with low ink coverage.

The PROSPER 7000 Turbo Press uses eco-friendly, water-based KODAK nanoparticulate pigment CMYK inks. The inks offer a wide colour gamut and, due to their proprietary ink formulations, support efficient drying even at peak press speeds. PROSPER 7000 Turbo features interstation drying using near infrared (NIR) technology. This drying solution enables the press to keep up with any of the print modes to ensure the highest quality output at the given speed.

To safeguard consistently high quality, even with the longest print runs, the new press features the KODAK Intelligent Print System. This patented solution automatically takes care of monitoring and optimisation of stitching, colour-to-colour and front-to-back registration.

“The game-changing speed of the PROSPER 7000 Turbo will help commercial, publishing and newspaper printers increase efficiency by shifting more long-run jobs from conventional printing processes to inkjet,” said Jim Continenza, Kodak’s Executive Chairman and Chief Executive Officer. “We believe digital technology will grow in importance as a complement to offset as ongoing supply chain issues continue to increase the cost of prepress. This new press reflects our continued commitment to investing in innovation that helps our customers succeed as the industry evolves.”

June 14 2022

ASLAN, developer and manufacturer of self-adhesive films, is expanding its portfolio of digital printing media with another specialty film: MonsterTack ASLAN DFP 05 is a white, glossy self-adhesive film that sticks securely even to the most difficult surfaces and under the toughest conditions.

Difficult substrates

The core element of MonsterTack ASLAN DFP 05 is the solvent gas and lubricating oil resistant adhesive formula. It is this that makes the film adhere to surfaces which would usually be so problematic. Examples of this are applications on plywood panels of box trailers, often equipped with a dirt-repellent surface, construction, agricultural and industrial machines subject to extreme dirt and mechanical stress, petrol pumps, powder-coated surfaces and low-energy substrates, ABS plastics, Moto-Cross vehicles and caravans/campers.

The characteristic

MonsterTack ASLAN DFP 05 perfectly supplements the UltraTack films DFP 06, 07 and 08, which are already established on the market. It is also suitable for bonding on rough surfaces inside and outside. Special benefits of note: It can be attached to flat or slightly curved surfaces from temperatures as low as -10° C – and it lasts up to 7 years outdoors. The polymer film can be printed with solvent, eco-solvent, latex and UV curable inks, as well as screen printing inks. Despite its extremely strong permanent adhesive, it can be removed from low-energy substrates and steel without leaving any residue. Additionally, the self-adhesive film is classified to salt spray test ISO 9227:2017.

Establishment in the market

Anja Falkenberg, marketing and sales director at ASLAN, is confident that the new digital printing film will quickly establish itself in the market: “We at ASLAN have been able to prove, time and again in the past, that we are able to meet, understand and solve the challenges in sign making and digital printing. We are proud that the MonsterTack ASLAN DFP 05 fills a gap in the world of self-adhesive films. This requires know-how and a lot of development work and it is what ASLAN has stood for more than 70 years. The result is a film that is extremely easy to process despite the high demands.”

p.p1 {margin: 0.0px 0.0px 0.0px 0.0px; font: 11.0px Arial; color: #000000} p.p2 {margin: 0.0px 0.0px 0.0px 0.0px; font: 11.0px Arial; color: #000000; min-height: 12.0px} p.p...

June 14 2022

PacPrint, running from 28th June to 1st July at the Melbourne Exhibition Centre, will see an important new release from Colour Graphic Services, David Crowther’s specialist colour quality certification, training and technology supply company.

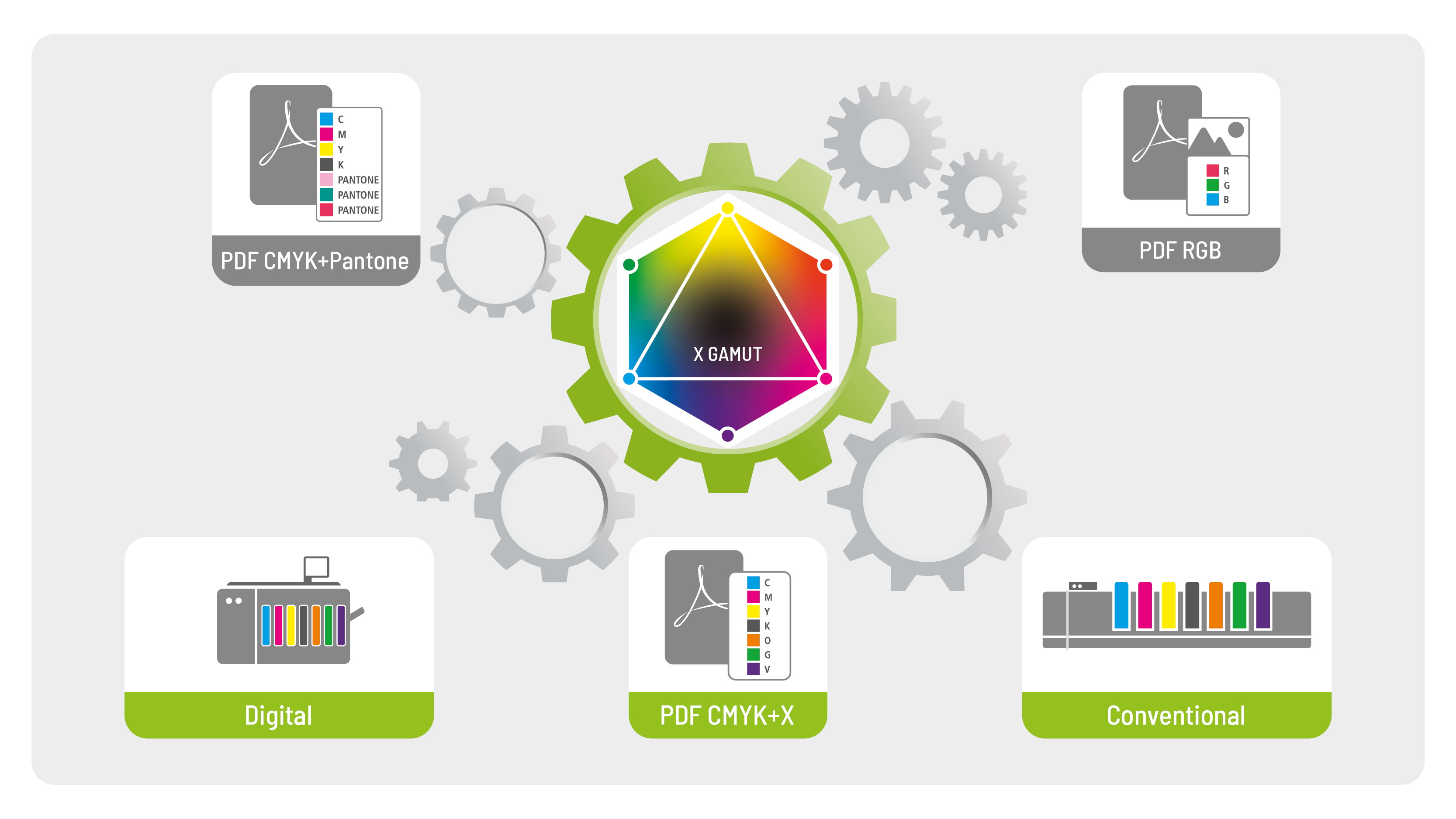

With the increasing demand for extended gamut colour reproduction across all disciplines – offset, digital, flexo, gravure and photography – the need for precise control of seven and eight colour ink sets becomes paramount. This is particularly true for labels and packaging, where colours such as orange, green and violet are added to the standard CMYK process colour combination. This is commonly referred to as ‘CMYK+X, or ‘extended gamut print.’As a result, Colour Graphic Services announces that it is now a local Australia-New Zealand dealer for CGS-ORIS.Established in 1985, CGS-ORIS (also known as CGS Publishing Technologies), is a global leader in colour management and was instrumental in enabling the change from expensive analogue-chemical proofing to low-cost digital using Epson wide format printers, which Crowther was also involved with in the early 2000s.

X GAMUT is a fully automated colour management software for extended gamut colour printing on digital and conventional presses. Spot and special colours can be accurately reproduced by using a standard fixed 7 or 8 colour ink set (CMYK+X). Often, orange, green, and violet are added to CMYK but other, such as Screen’s vibrant blue for its label presses, are possible.

One big advantage of CMYK+X one-pass printing is that there is no need for special colour ink mixes. This streamlines the production process considerably, since no press wash-up, changeover times or off-press mixing is necessary. This reduces ink inventory and waste from seldom-used tins of specially mixed inks. The nett result is that X Gamut helps to reduce costs for printers and clients alike – with clients able to claim greater environmental credentials and accurate, consistent special colours.

David Crowther comments: “At PacPrint and after, we will be focusing on Oris X Gamut, which brings numerous benefits to commercial, packaging and labels printers. With Oris X Gamut, spot/special colours can be accurately reproduced by using a standard colour ink set (CMYK+X), in seven or eight channels. The results are spectacular and we will be demonstrating this on our PacPrint stand F44 and welcome both digital and conventional printers to see and try for themselves.”

Why X Gamut?

Special colours are especially eye-catching and differentiate consumer appeal from plainer colours. However, until now, working with them requires effort and expense because of extra inventory, higher prices, frequent colour changes and subsequent wash-up and press downtime.

Oris X Gamut is not only ideally suited to reproduce spot and brand colours precisely, but also presents a perfect match of software features and intelligent workflow tools, enabling printers to leverage the full gamut of the press and ink set, so that images are printed brilliantly in all detail – without the need for special inks. This has also made X Gamut an important tool in the photographic/art printing industry where wide format printers always have extra colours to manage and workflows tend to be RGB.

Oris X Gamut’s key benefits are:

“We welcome all visitors to our small but powerful stand F44 at PacPrint,” says Crowther, “where we will also be showing colour measurement instruments from Techkon, Myiro and X-Rite, viewing booths from Just Normlicht, calibratable monitors from Eizo and demonstrating how Printflow CIP3 closed-loop colour and G7 & Mellow Colour ISO certification can ensure the right colours, first and every time.”

EFI announced that it has acquired Inèdit Software S.L., a developer of raster image processors (RIPs) and related software for digital industrial textile printing. The acquisition extends EFI’s strategy to accelerate digital transformation in industrial print through investments that advance the company’s presence and capabilities in Packaging & Corrugated, Display Graphics, Textile, and Building Materials/Décor applications. Inèdit will be integrated into the Reggiani textile business.

“Digital represents the biggest transformational opportunity we have ever seen in industrial printing,” said EFI CEO and Executive Chairman Jeff Jacobson. “We are committed to driving innovation and expanding our offerings through all economic cycles as we address our customers’ critical need to digitise and automate their workflows.”

Delivering powerful digital print workflows for textile

Based in Barcelona, Inèdit will help build on the market leadership of the EFI Reggiani portfolio of digital inkjet printing products for the industrial textile space.

“We are enthusiastic about the expanded business opportunities this acquisition creates by reinforcing EFI Reggiani’s strategic role as a trusted advisor for our customers,” said EFI Reggiani Senior Vice President and General Manager Adele Genoni. “Inèdit’s products and its world-class professional services organisation open the door to creating more-complete digital printing workflows that leverage best-in-class digital technologies. Our customers can continue to win new opportunities and grow by establishing higher-volume, higher-quality digital production services in ways that reduce the textile industry’s high carbon footprint.

“Inèdit’s extensive market coverage will be a key point of emphasis to fully leverage the strategic synergies arising from the combination of the EFI Reggiani and Inèdit businesses,” Genoni continued. “It is an acquisition that significantly strengthens our presence in key textile markets.”

Similar to EFI’s Fiery® digital front end and RIP technologies for the digital commercial and industrial printing markets, Inèdit’s neoStampa product is a worldwide leader and recognised benchmark solution for RIPs in digital textile printing. The Inèdit product portfolio features proven, highly advanced workflow solutions for textile profiling, calibration, design integration and much more. Inèdit’s RIP technology is employed across the worldwide textile industry and is a leading RIP used to drive EFI Reggiani digital printers and other digital industrial textile printer brands. As part of EFI Reggiani, Inèdit will continue to support products for a broad range of digital printers.

“Becoming part of the EFI Reggiani business empowers us to develop and deliver an even greater level of end-to-end textile integrated workflow solutions and Industry 4.0-driven automation enhancements that will further drive customers’ productivity, printing performance, profitability and sustainability in textile printing,” said Jose Antonio Caballero, Co-founder and Sales Manager of Inèdit. “Our team is excited to join a company that is a leading innovator in digital textile printing.”

Inèdit’s employees are joining EFI Reggiani but will continue to work from their current offices. Terms of the acquisition were not disclosed.

For more information about EFI’s advanced portfolio of innovative digital printing solutions, visit www.efi.com.

On stand G20, Epson will present applications printed on the ML-8000, the new standard in textile image qualityFor the first time in Australia at PacPrint 2022 on stand ...

June 14 2022

On stand G20, Epson will present applications printed on the ML-8000, the new standard in textile image quality

For the first time in Australia at PacPrint 2022 on stand G20, Epson Australia will present applications and samples on its new Monna Lisa ML-8000 direct-to-fabric textile printer - the new standard in textile image quality.

Monna Lisa ML-8000 textile printer

The ML-8000 is the new entry model in the Monna Lisa series with eight of the latest PrecisionCore printheads. The ML-8000 packs the power and performance of the latest world-class Epson inkjet printing and manufacturing technologies into a single package.

The Monna Lisa series combines performance and usability to meet the needs of the digital textile market for flexibility and sustainability. With its eight PrecisionCore printheads, the ML-8000 reaches typical print speed of 155 square metres per hour (600x600 dpi – 2 pass*1).

Monna Lisa ML-8000 textile printer

The ML-8000 is a next-generation digital textile printer with high print quality,

productivity, stable operation with minimal downtime, and allows easy operation for an affordable price, making it the ideal printer for companies looking to move into local, onshore digital printing and production.

Digital printing has become increasingly popular with fashion and textile designers as they strive meet the increased demands for short runs and fast fashion while under pressure from public criticism to ease environmental burdens. The ability to deliver digital designs for digital print on demand enables businesses to offer their customers a faster turnaround without having to rely on mass shipments of stock crossing continents, much of which result in higher waste streams due to analogue printing.

The Monna Lisa ML-8000 is symbolic of the all-round quality of Epson’s digital print technology, blended with the uncompromising standards of fashion inspired by Epson’s print partner Robustelli and its rich history of textile design and manufacturing in Italy’s Como province.

The ML-8000’s superior image quality is enabled by Epson’s high quality printheads. Epson’s exclusive Microweave and lookup table (LUT) technologies reduce banding and graininess and advanced new Multi-Layer Halftone Technology (MLHT), which randomises the halftone dot pattern on each layer, reduces image degradation caused by dot misalignment. Dynamic Alignment Stabiliser (DAS) technology also ensures stable print quality by controlling waveforms on each printhead chip for higher dot placement accuracy and more uniform dot density on each pass.

The ML-8000 also features symmetrical colour alignment for consistent colour overlap order during bidirectional low pass printing, and Accurate Belt Position Control (ABPC) technology automatically detects the belt feeding distance to ensure highly precise fabric feeding. The result is optimal quality and speed, with superb reproduction of colour gradations, fine details and complex geometric patterns.

Stable operation with unprecedented usability is realised with the advanced cleaning mechanisms and automated adjustment functions. A fluff blower system removes fluff from the fabric surface before it enters the printing area and an ink mist extraction system helps prevent ink mist from adhering to the nozzle surface.

Nozzle verification technology (NVT) detects missing dots that indicate nozzle clogging and adjusts ink delivery to maintain image quality and reduce printing errors. An easy-to-replace fabric wiper roll continuously wipes the printhead nozzles clean automatically, reducing daily manual maintenance work. High accuracy of printhead alignment technology allows the user to replace the head quickly.

Thanks to an automatic calibration function by an RGB camera, operators can carry out printhead replacement including adjustments in as little as 30 minutes.

Epson’s Remote Monitoring System (24/7 monitoring) enables a quick response to potential problems, reducing downtime and service calls.

Ease of use is enhanced by a 9-inch LCD touch panel that displays current printer status, operating instructions, and regular maintenance procedures, and by hot-swappable, dual 10-litre or 3-litre high-capacity ink cartridges that allow uninterrupted production.

Epson GENESTA inks are available in Acid, Reactive, Disperse, and Pigment formulations in a degassed vacuum-pack. They are ECO PASSPORT certified to meet globally recognised standards for environmentally friendly textile printing. In addition, the Acid ink is bluesign® approved and the Reactive and Pigment inks are GOTS approved by ECOCERT.

ML-8000 Key Features:

- Printheads: eight Epson PrecisionCore printheads. The latest generation MicroTFP print chip combines quality, accuracy and speed.

- Productivity: typical print speed of 155 m2/hr (600x600 dpi – 2 pass*1)

- Maximum print speed: up to 250 m2/hr (300x600 dpi; 1 pass*2)

- Resolution: up to 1200 dpi.

- Width: 180 cm

- Ink colours: eight

- Ink types: Genesta Acid, Reactive, Disperse and Pigment. Genesta water-based inks allow precision and colour fastness in fabric prints. Genesta inks obtain the highest quality on any fabric type.

- Ink capacity: three or ten litres.

About F.lli Robustelli and For.Tex

The Monna Lisa project is the result of partnership between F.lli Robustelli for product engineering, For.Tex for inks development and Epson for Epson print technology.

Founded in Villa Guardia (Como, Italy) in the 1950s, F.lli Robustelli is a company100% owned by Epson Italia. They engineered the first digital textile printing machine on Epson print technology.

Established in Fino Mornasco, (Como, Italy), For.Tex is a company 100% owned by Epson Italia. For.Tex was chosen to develop the inks for Monna Lisa project and Genesta ink.

Summa and Valiani, join forces through a merger of their businesses. Summa acquires Valiani to strengthen its position as the leading manufacturer in print finishing equipment. The merged business will continue as before and will complement each other to offer customers an even broader range of cutting solutions.

Valiani, with its headquarters in Certaldo, Florence, Italy, is a developer and manufacturer of small to medium sized, highly reliable flatbed cutters with a worldwide distribution network. Moreover, Valiani has an extensive history in the picture framing industry and is a pioneer in converting this market to digital solutions: designing and cutting matboard and offering passepartout tools for bevel cuts. Their innovative approach has ensured the company to grow into other markets as well. The recent Omnia auto feed die cutting machine is a unique automated solution for the corrugated and folding carton market, whereas the brand new Integra offers an appealing finishing product for the Sign & Display market.

Nico Valiani, CEO and son of Franco, founder of the company, is enthusiastic: “In the recent years we have renewed our complete portfolio with a wider range of solutions. Now, this is starting to pay off with a significant growth. However, I know there is still a lot more potential. Therefore, my family and I are convinced that being part of the Summa group will accelerate our growth and give our customers much more possibilities. We are staying true to our values, being customer focused and offering high-quality solutions”. To put the money where the mouth is, the Valiani family is reinvesting in the Summa Group.

“Since the negotiations started, my appreciation for the Valiani company and its products has grown more and more”, said Geert Pierloot, Managing Director at Summa. “The organization with Lean manufacturing production lines in the Certaldo, ISO certified, plant is a true example for the industry. I look forward to working together with Nico and his team. In this merger, I see an absolute win-win as it combines the strengths of both companies. While we can help accelerating Valiani’s growth, our portfolio can be expanded with the solutions of Valiani and more markets can be served”.

“Our product ranges are extremely complementary”, adds Christof Van Driessche, Chief Commercial officer at Summa. “Although the most popular and attractively priced Summa F1612 flatbed table has a small and unique footprint, there are still a lot of customers looking at smaller, more affordable but reliable solutions. Therefore, the merger is an exciting step and meets Summa’s ambition to increase its presence in other markets and strengthen our position into the packaging market”.

Both companies will continue to operate under their current company names and with the actual management teams in place.

June 07 2022

The innovative display graphics and industrial textile solutions from Electronics For Imaging, Inc., at the FESPA Global Print Expo deliver remarkable efficiency, quality and sustainability to help customers drive profits and win new business. The new EFI Reggiani ecoTERRA pigment solution making its debut there is an advanced integrated solution for streamlined, greener textile printing.

“We are truly thrilled to provide our FESPA visitors a preview of an innovative pigment printing solution that delivers authentic textile printing results while cutting water and energy consumption,” said EFI Reggiani Senior Vice President and General Manager Adele Genoni. “This is another confirmation of our commitment to green innovation. The EFI Reggiani ecoTERRA solution contributes to making the textile industry more sustainable, reducing the environmental footprint to deliver an eco-friendlier direct-to-fabric printing experience.”

A new level of sustainable direct-to-fabric printing

The EFI Reggiani ecoTERRA is an all-in-one solution for water-based pigment printing that requires no ancillary equipment for pre- and post-treatment. Its patent-pending technology gives customers a distinct competitive advantage, dramatically cutting energy and water consumption in the overall process for a more sustainable direct-to-fabric printing experience.

Users will benefit from ecoTERRA’s ability to deliver excellent wet and dry fastness, remarkable sharpness in detail and extraordinarily high durability while also yielding longer printhead life with reduced maintenance costs.

The new ecoTERRA ink range features 7 colours – cyan, magenta, yellow, black, blue, red and green – for an expanded colour gamut. An enhanced polymerisation and finishing unit for the EFI Reggiani ecoTERRA also gives the fabric a softer hand feel, delivering performance that is in line with the most stringent textile industry requirements.

Always committed to deliver to the market new cutting-edge technologies, EFI Reggiani has world-class products offering boosted uptime and reliability, high performance throughput, and remarkable printing uniformity and accuracy – all while helping customers increase the sustainability of their textile manufacturing activities.

On stand G56, the SureColor V7000 will demonstrate how it combines superior image quality with enhanced production flexibility

For sign makers looking to produce UV output, Epson Australia will display its first-ever flatbed printer, the SureColor V7000, at PacPrint 2022 on stand G56.

SureColor V7000

The SureColor V7000 builds on the success of Epson’s award-winning SureColor S-Series range of signage printers, delivering flexible production with truly outstanding image quality and a reduced running cost.

Key features of the SC-V7000

The SC-V7000 has been designed to meet the needs of today’s signage businesses with flexible high-quality production and a reduced total cost of ownership (TCO). It will print on a wide range of substrates including paper, film, CorefluteTM, vinyl, canvas, aluminium and acrylic. It produces image quality to suit the most exacting applications including signage, POS/POP, premium packaging, décor, custom cabinetry and even fine art.

This robust and versatile printer incorporates eight Epson MicroPiezo printheads. Each head features 1,440 microfine nozzles with variable size dots as small as 4 pl. Working in conjunction with a new 10 colour Ultrachrome UV ink set, it will produce images with a very wide gamut and surprisingly fine gradation, sufficient to satisfy the most demanding customers. White and Varnish can even be applied as spot colours for enhanced detail and finish.

SureColor V7000

The SC-V7000 offers a 1.25 m x 2.5 m print area that supports media up to 80 mm thick and 50 kg/m2. It features a vacuum system with four independently adjustable zones for flexible operation. Integrated layout pins and a height sensor on the head carriage enable easy media setting while an ioniser ensures reliable and consistent output. The print heads are mounted in a staggered array that enables up to three layers to be applied in a single pass (White + Colour + Varnish) for fast and efficient production.

Epson has ensured that the SureColor V7000 is cost-effective to install and efficient to run. It is supplied complete with Epson Edge Print RIP software and Flatbed Controller software. It can be managed from the desktop using Epson Edge Dashboard and supports Epson’s new Cloud Solution PORT service. Installation is included in the purchase price and it ships with on-site CoverPlus that can be extended out to five years. Unlike many printers of its type, Epson even includes periodic maintenance.[1]

The SureColor V7000 is available for purchase via authorised Epson resellers in Australia and New Zealand now.

June 07 2022

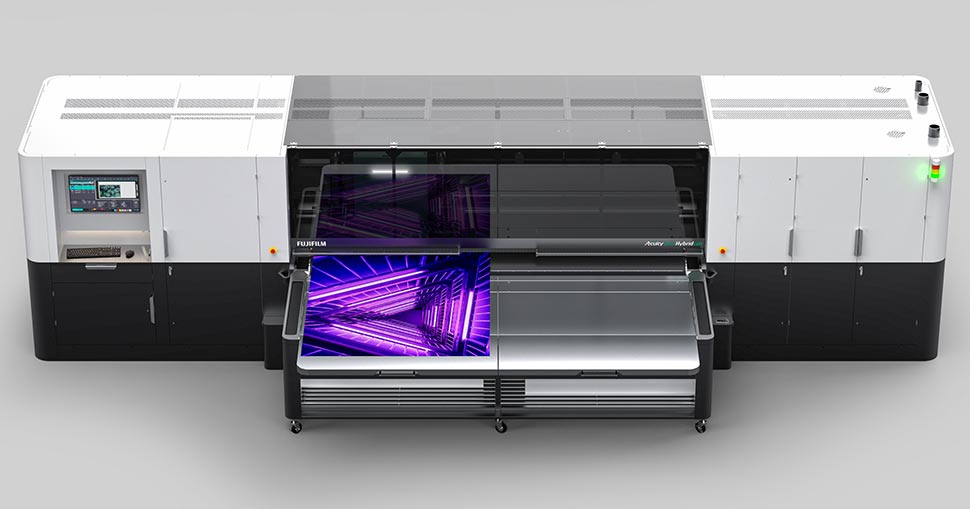

Fujifilm announces its entry into the high-end wide format hybrid market with the unveiling of the Acuity Ultra Hybrid LED at FESPA 2022. The machine, which will be commercially available from the autumn, is making its first public appearance on the Fujifilm stand (C30, Hall 2.2) at FESPA 2022.

Part of Fujifilm’s ‘Blueprint’ concept, the Acuity Ultra Hybrid LED is a 3.3m high-end printer that offers superb, high quality printing to both rigid and flexible substrates. Printing at speeds of up to 218 m²/hr (RTR), and delivering a print resolution of up to 1200 x 1200 dpi, the Acuity Ultra Hybrid LED is unique in being able to combine ultra-high quality and a competitive return on investment, for both rigid and flexible applications, all in one platform.

It is engineered with the operator in mind and designed with specialist inks to support the printing of exceptional near-photographic interior graphics and the high-speed printing of banners and PVC signage.

Along with media loading and unloading tables, the Acuity Ultra Hybrid LED also features a dimpled table surface to support all media types while allowing easy media positioning. A robust catch mechanism protects against accidental damage, and secure locking allows for media feed accuracy throughout every print run.

The GUI features the same exceptional design features found on the Acuity Ultra R2 and includes additional functionality to handle rigid media production – up to six sheets simultaneously.

An intelligent vacuum control system automatically turns on the correct vacuum zones needed for any print job based on the width of the media, and the vacuum motor power constantly adjusts to maintain optimal media hold down, regardless of media type and size, ensuring an accurate and high quality print finish.

For maximum flexibility when printing roll-to-roll, a bespoke designed airshaft allows dual roll functionality, so two media rolls of different diameters (each up to 36cm) can run at the same time.

Fujifilm has created an entirely new ink range, Uvijet UH, especially for the new machine, with six colours (CMYK, Lm, Lc) available as standard and white ink also available as an optional extra. The new ink has both Greenguard Gold and AgBB certification.

Uvijet UH has been carefully designed to adhere to a broad range of rigid and flexible substrates, while also matching the exceptionally high quality of the Uvijet GS and AU inks used in the Acuity Ultra R2. The machine and the ink have both been designed by Fujifilm and they work together to maximise quality while also minimising ink usage, helping to keep running costs down and boosting ROI.

Kevin Jenner, European Marketing Manager, Fujifilm Wide format Inkjet Systems says: “Our ‘new blueprint for wide format’, announced last year is our answer to industry demand for greater flexibility, ease-of-use and better ROI. Our all-new Fujifilm Acuity range, built to that new blueprint concept, has been designed to offer exceptional performance and unbeatable value, and the Acuity Ultra Hybrid LED is the latest evidence of Fujifilm’s commitment to the continued development of this range to meet changing market needs. Fujifilm has combined its expertise, built up over decades developing exceptional flatbed and roll-to-roll platforms, to design a new wide format hybrid platform that will set a new standard in price and performance and offer exceptional versatility and ROI.”

June 07 2022

At Fespa 2022 in Berlin, swissQprint dropped a surprise by unveiling a completely new model: the Kudu high-end flatbed printer, featuring an impressive combination of high productivity and first-class output quality.

Kudu high-end flatbed printer swissQprint

In a totally unexpected move, swissQprint unveiled a new printer model at Fespa 2022 in Berlin: Kudu is a 3.2×2 metre high-end UV LED printer that complements the existing flatbed range – Nyala, Impala and Oryx. Like the 4th generation of this trio, which swissQprint launched only six months ago, Kudu operates at a redefined standard of quality. It is also highly productive and offers ten colour channels (nine on the other models).

Top-rank output and quality

At its maximum productivity of 300 square metres per hour, the UV printer delivers convincingly high output quality. Carmen Eicher, Chief of Sales and Marketing Officer at swissQprint, explains: “Kudu incorporates the latest print head technology, with an addressable resolution of up to 1350 dpi.”

New mechanics and software

The flatbed printer stands on a newly designed mechanical foundation and operates using the latest linear drives. “This ensures precise droplet placement at such high speeds”, adds Carmen Eicher. Kudu features the Tip Switch vacuum, like the other flatbed and roll to roll printers from swissQprint. In the case of Kudu, it is divided into 260 zones, which gives the operator very simple and selective control of the vacuum. And speaking of control: Lory, the output software developed in-house by swissQprint, is the Kudu operator’s cockpit. The graphical user interface with its virtual flatbed is designed for intuitive and safe operation.

3.2 m roll to roll option and ten colour channels

Kudu, like all swissQprint flatbed printers, is expandable with a roll to roll option. It is the first swissQprint model to feature ten colour channels, which further increases application diversity. Users configure the channels according to their needs, and may adapt the configuration at any time later. The newly developed universal ink (Greenguard Gold certified) is available in CMYK, light cyan, light magenta, light black, white, effect varnish and primer as well as the spot colours orange and neon yellow and pink – a swissQprint exclusive.

Konica Minolta Australia has announced the retirement of Sue Threlfo, general manager, production and industrial print, after 33 years in the printing industry, effective at the conclusion of this year’s PacPrint.

The industry veteran, who has attended a record five drupas, has had an amazing career in the printing industry, spending the last five years with Konica Minolta leading the production and industrial print team through one of the most challenging periods in the industry. Despite this, the industry is seeing great signs of recovery with demand in label, light packaging, and wide format.

David Procter, chief operating officer, Konica Minolta Australia, said, “Sue has without doubt made a massive impact at Konica Minolta and more broadly in the industry. As a woman in leadership, I have no doubt she has contributed to equalising the gender bias and she should be proud of this achievement. We are grateful for her contribution and wish her all the best for the future.”

June 07 2022

swissQprint presents a new total solution for UV flatbed printing on glass, comprising the glass option and an adhesion-optimised ink set.

Individually printed glass elements are all the rage in interior design: for kitchen splashbacks, shower and room partitions, glass doors, lift cabin panelling, wall art, etc. For those already providing such services – and others with plans to do so – swissQprint has put together an interesting package: a mechanical solution for an efficient, clean process, supplemented by an ink set for optimum adhesion.

Glass option for an efficient and clean process

A pivoting alignment edge with five stepless adjustable horizontal stops ensures precise positioning of glass panels on the print bed. The latter is covered by special protective paper that is air-permeable. So the vacuum holds down the media but the paper retains ink printed in the bleed margin. The print bed stays clean, and with the roll to roll option the operator advances the paper at the touch of a button. This means short set-up times between jobs.

Inks that adhere without primer

The ink set optimised for glass printing includes process and light colours, as well as white and effect varnish. A bonding agent is unnecessary, which eliminates one process step. The varnish is used for finishing, for example to produce partial frosted glass or gloss effects.

With the new solution, both newcomers and existing swissQprint users can pick up on the trend and specialise in direct printing on glass. The glass option and inks are retrofittable to swissQprint LED printers. Thus, swissQprint once again delivers on its promise to continue offering users new perspectives. Without major new investment.

Further information: T +41 71 727 05 05 office@swissqprint.com www.swissqprint.com

Currie Group has been recently accredited as the first EFI Fiery® for Display Graphics Premier Partner in the re...

May 31 2022

Currie Group has been recently accredited as the first EFI Fiery® for Display Graphics Premier Partner in the region. Further strengthening the partnership between EFI and Currie Group, this program ultimately benefits the wide format customer base by way of additional support and expertise.

As a Fiery for Display Graphics Premier Partner, Currie Group are now listed on EFI’s website so customers can easily locate us. Just select our region to see us there. As part of the program, Currie Group were required to complete sales and technical training for the entire line-up of Fiery display graphics products.

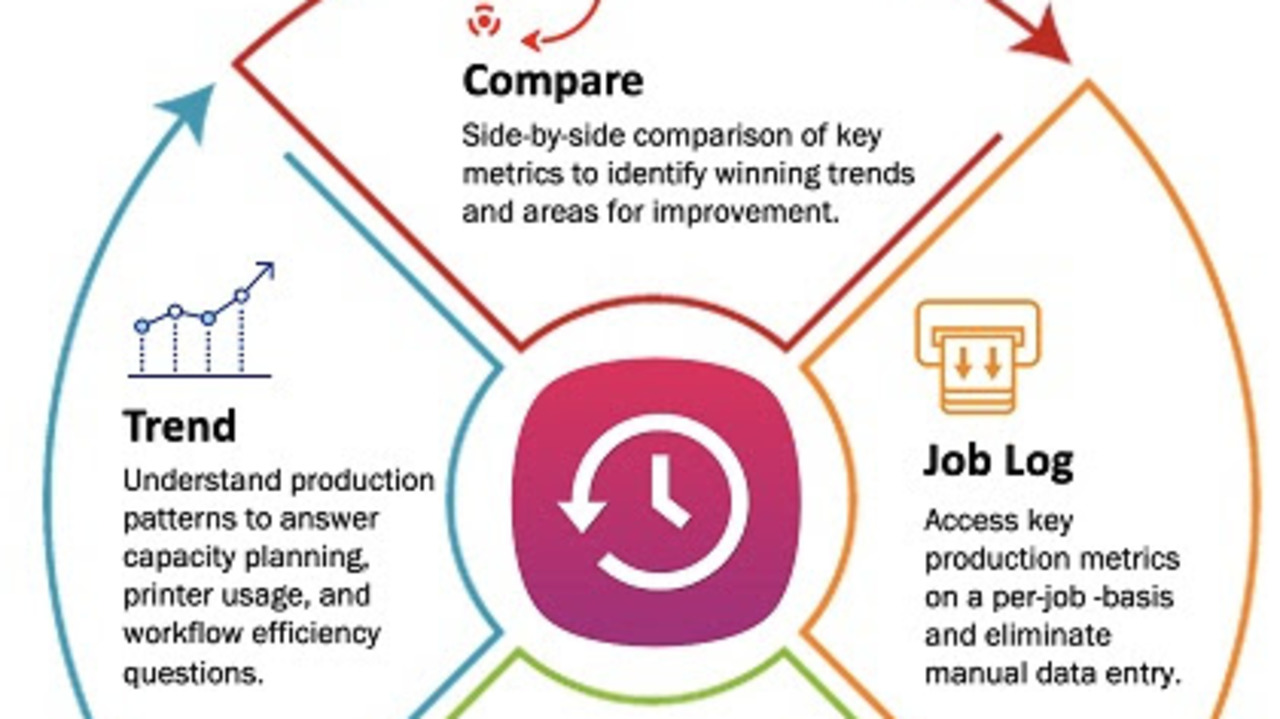

The portfolio has grown beyond the EFI Fiery XF and Fiery proServer itself. There is a complete suite of software solutions that will make customers more efficient, including Fiery JobFlowTM for prepress automation, Fiery Prep-ItTM for true shape nesting, and Fiery IQTM for display graphics that will help you better manage your fleet, even across multiple locations, by providing real-time operational data via the cloud.

Chris Schowalter, Global Sales Director - Fiery for Display Graphics said, “We are very proud to have Currie Group joining the Premier Partner program. They quickly met all our criteria achieving the highest-level accreditation for Fiery Display Graphics Products. They are a trusted partner and doing a great job supporting all our customers in the region. Now our partnership is even stronger, and we can together keep our customers happy and loyal.”

Paul Whitehead, Currie Group Business Unit Manager – Sign & Display said, “Currie Group is committed to becoming the leading supplier in both the Australian & New Zealand Sign & Display markets. EFI hardware was only the first step, and now we are excited to add the Fiery for Display Graphics software to our portfolio.

Becoming an accredited Fiery Display Graphics Premier Partner ensures we can support both our EFI customers to a greater level, whilst also providing a full suite of workflow support to customers that utilise printers from other manufacturers.”

Various components of the Fiery for Display Graphics software suite:

Fiery XF 7

Fiery XF7 is the easiest way to achieve superior colour results, gain maximum productivity and profit from business insights with EFI Fiery Command WorkStation digital print job management. It is a workflow solution that caters to different job types and makes it easy to automate repeat jobs and repetitive tasks.

Fiery Prep-It

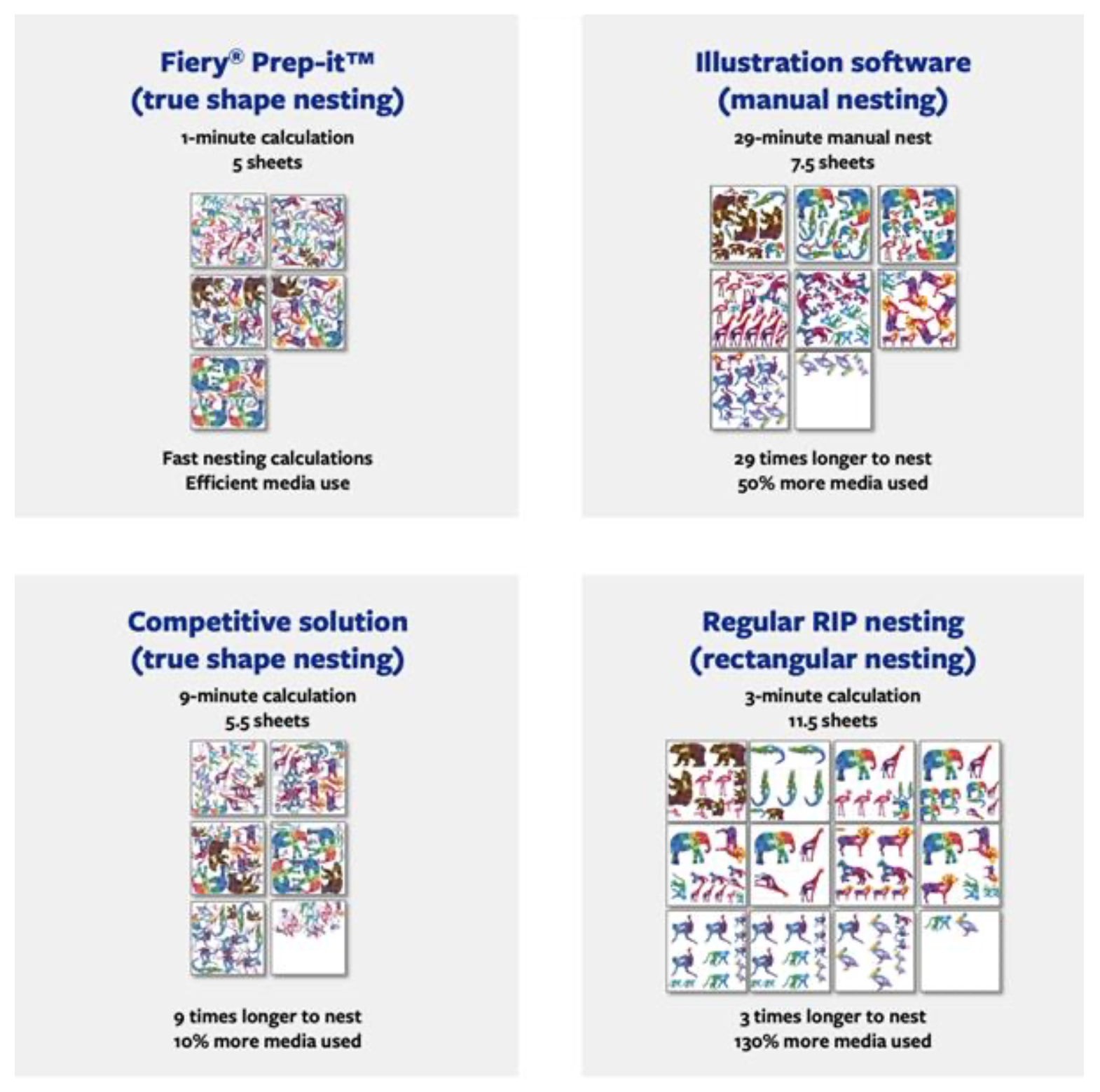

Fiery Prep-It is a print-for-cut preparation software. It’s an easy-to-use solution for the preparation, layout and automated production of print-for-cut jobs – which is likely most of the jobs our customers are producing! It can save them hours of prepress time and dramatically decrease media usage with efficient true shape nesting, as you can see from the graphic below.

Alternative means of true shape nesting either involve longer preparation times or excessive use of media or both, when compared to Fiery Prep-It.

Fiery JobFlow

Fiery JobFlow automates job preparation steps in prepress workflows to produce ready-to-print files. This easy-to-use print workflow automation software increases productivity and reduces costs. With its easy-to- build workflows, users can use it for automated image enhancement and automation, file submission and archiving, integration with other workflows for intelligent job routing and much more. The JobFlow mantra is “Don’t touch what you can automate.”

EFI IQ for Display Graphics

EFI IQ, a cloud-based application, provides the data analytics that help owners and managers make smart decisions. It can provide answers to questions such as:

How well is my shop running today?

How much ink did we consume in the last quarter?

Is there a disruption in my shop I need to know about?

How well are my printers being utilised?

By gaining real time access to the answers to these questions and more, owners and managers can quickly adapt to get things back on track, whether it needs additional operator training, better inventory management, scaling up production capacity, or any other action to ensure a smooth and profitable operation.

Contact Currie Group for more information:

E: info@curriegroup.com.au

W: www.curriegroup.com.au

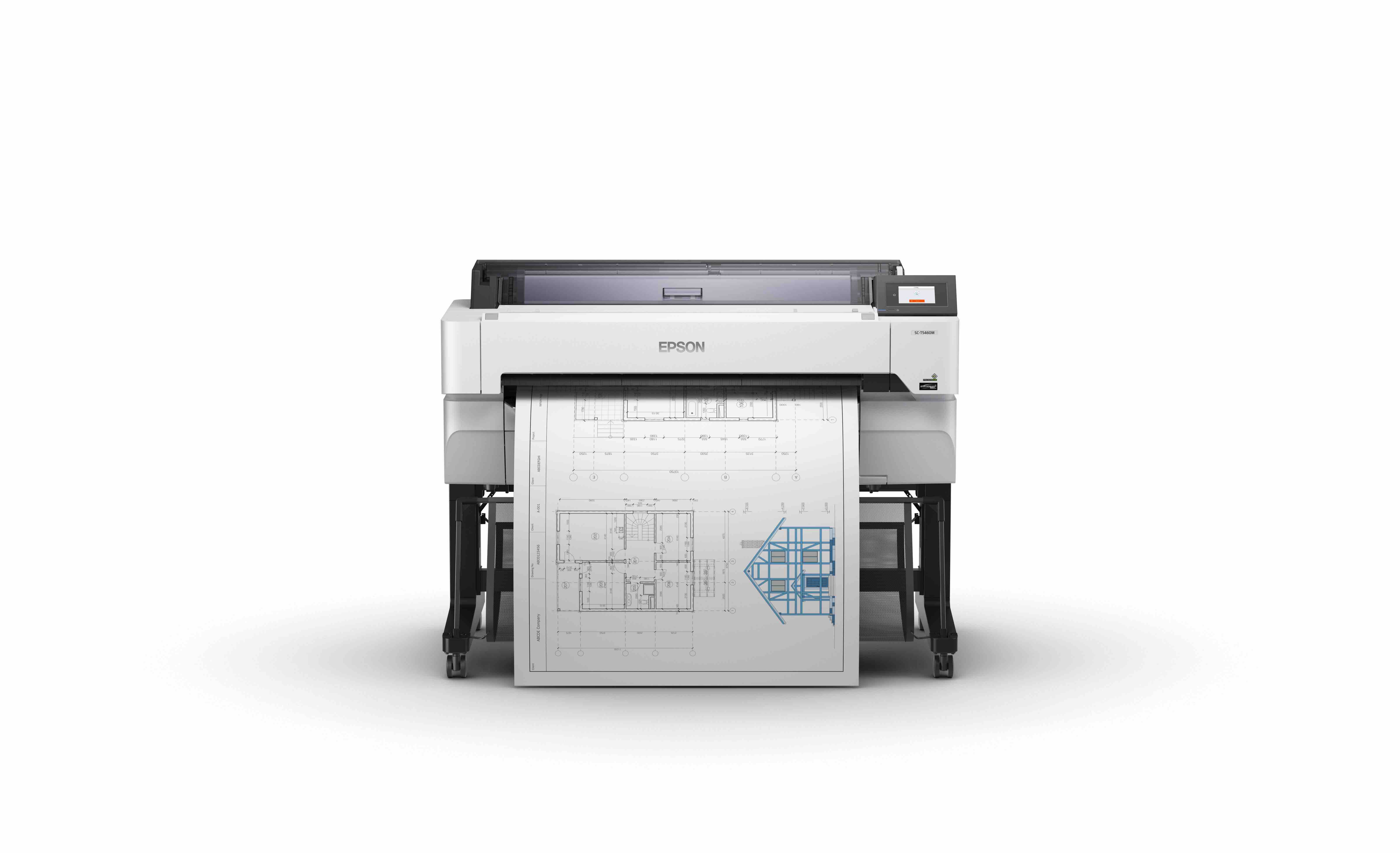

Epson will be debuting their new production-class, SureColor T7760D dual-roll technical printer for the first time, alongside their latest large-format and document printers, on stand G3...

May 31 2022

Epson will be debuting their new production-class, SureColor T7760D dual-roll technical printer for the first time, alongside their latest large-format and document printers, on stand G34 at Sydney Build 2022 - Australia's leading construction, architecture and infrastructure expo.

New SureColor T7760D dual-roll printer

The SureColor T7760D combines an extremely compact footprint with flexible media handling and a high print speed. It is designed for companies who want to produce large-format colour drawings and posters in moderate to high volume. The SureColor T7760D is particularly suited to construction, retail and print-4-pay applications. It uses 6 inks that come in large cost-effective cartridges with an additional red to enhance the colour gamut. Integrated high-speed hardware-based Postscript® enables fast and accurate image reproduction via drag-n-drop from the desktop or direct from a USB device. The SureColor T7760D features dual-roll support with the second roll also able to be used as an auto take up. There is also an integrated pull-out media bin and an optional flat sheet stacker.

The T7760D is targeted to be released in Australia in July, so visitors to Sydney Build will be the first to see this new generation production-class SureColor T-Series printer in the flesh.

Also on display will be the SureColor T5460M and the T3160M. Developed from the ground up, the SureColor T-Series models include Epson’s latest PrecisionCore printhead which provides outstanding image quality while enabling higher-speed performance than previous generation models. The SureColor T3160M compact industrial design provides a small footprint for space-constrained production environments.

SureColor T5460M

Attendees to the Epson stand at Sydney Build will also be able to see the Epson WorkForce Pro WF-C879R workgroup printer in action on the stand. The WF-C879R enables offices to benefit from increased productivity of a local distributed fleet that required minimal intervention, while providing predictable print costs.

WorkForce Pro WF-C879R

The WF-C879R uses up to 94 percent1 less power than comparable colour laser printers thanks to Epson’s Heat-Free Technology. It not only lowers electricity costs but also requires fewer supplies to reduce the environmental impact.The simple printing process and high page yield ink reduces downtime, making businesses more efficient and productive.

1Epson saves up to 94% energy used while printing comparing the Epson WorkForce Pro WF-C878RTC model with 64 competitive laser devices in the Australian 21 to 44ppm A3 colour MFD segment as at 1 July 2021.

Konica Minolta Australia has appointed Ted Garner to the role of chief strategy officer to help drive the business into the future.

At PacPrint2022, Mimaki will be showcasing its latest innovations alongside their tried and proven print technologies, debuting the JV330 Series and a range of new technologies to improv...

May 31 2022

At PacPrint2022, Mimaki will be showcasing its latest innovations alongside their tried and proven print technologies, debuting the JV330 Series and a range of new technologies to improve businesses’ print experience, as well as its well-known UCJV300 LED Print & Cut series.

“The JV330 Series features the new Mimaki Weaving Dot Technology (MWDT), which changes the order of ink droplet placement depending on the printing conditions,” says Brad Creighton, National Marketing Manager, explaining that this helps suppress unexpected occurrences of streaks or unevenness of printing caused by slight individual differences in the print head or subtle deviations in adjustment.

“The XY slitter and the Media Changer are two other, high-value functions that assist in saving work and labour. The XY slitter has an in-line function that cuts all sides of the media after printing, enabling automatic slit processing without the need of taking-out media. This will significantly shorten the post-process work and reduce the space required for the cutting work that used to be done manually.

“The Media Changer accommodates up to three rolls of media to be able to change by simply turning the handle with light force – this greatly reduces the time and effort required to change media, contributing to a more efficient work environment,” Creighton says. “The result is higher precision and consistency, with less manual interference required.”

In addition, Mimaki will be premiering new large and small format flatbed printers on the show floor. These new models pursue greater speed without sacrificing stability and accuracy, and use UV inks certified as GREENGUARD Gold due to their environmental friendliness.

“The new JFX600-2513 is the successor model to the JFX500-2131, Mimaki’s large format flatbed LED UV printer,” Creighton explains. “It’s a large-format flatbed LED UV inkjet printer with up to 330% faster print speed than JFX500, and is exceptionally versatile, with six colours available including light colours, a large table size and a vacuum table that supports media as thick as 60mm.”

.png)

The machine has also been designed with usability in mind, with support for MDL commands which make it easy for operators to achieve automation and labour savings on processes like work piece transfer, during printing.

Another showpiece sure to create interest is the new UJF-6042 MkII e, the successor to the smaller-format flatbed UJF-6042MkII printer.

“The new model has further improved image quality and machine stability, while maintaining the operability that was highly acclaimed in the current model,” Creighton explains.

“With a larger print size of 610mm x 420mm, this new model supports A2 size and 153mm height. In addition, the new printers provide improved usability to the operator by adding visual guidance on the 3.45inch full colour display.

“All UJF-MkII e Series printers feature new MFD2 processing for exceptional image quality as well as an improved, laser gap check sensor, which detects media placement to prevent printheads from making contact with the material during printing,” he adds. “It can even detect transparent materials for superior accuracy and highly controlled media detection.”

Mimaki will be running live demonstrations at stand C08 at PacPrint, which will co-locate with the Visual Impact sign and display expo and the Label & Packaging Expo, at the Melbourne Convention & Exhibition Centre from 28 June to 1 July this year. Go to www.pacprint.com.au for more information.

Electronics For Imaging, Inc., today announced the availability of its EFI IQ suite of cloud and mobile applications with supported EFI VUTEk, Wide Format, and Nozomi inkjet printers. With this advanced cloud service, EFI printer users can monitor production and printer utilisation, including exact device-level consumable tracking data, to reduce downtime, reduce costs and maximise the value of their EFI printer investments. New EFI wide- and superwide-format UV LED printers will include a one-year subscription to EFI IQ. EFI inkjet printer users can also purchase IQ subscriptions for other supported printers.

The newly available cloud service for superwide-format production is making its debut at the May 31-June 03 FESPA Global Print Expo in Berlin.

User-friendly with better business intelligence

According to an early user of the cloud service’s new inkjet offering – Dave Brewer, chief technology officer of Foothill Ranch, California-based Image Options – “EFI IQ is a user-friendly tool that gives me better business intelligence to make better decisions.”

By monitoring their printer fleets in real time, EFI IQ users can reduce consumable spend, save on labor costs, improve margins, and more.

“Print business leaders often want and benefit from having more-complete knowledge of their plant operations,” said John Henze, vice president of sales and marketing, EFI Fiery. “With EFI IQ, they can have their finger on the pulse of the business. This advanced cloud offering gives print business leaders a detailed, accurate understanding of production operations, which is key to knowing how a company can best meet its customers’ needs at any given point in time.”

Prepare for productivity with powerful cloud tools

The decision to adopt EFI IQ comes down to several key questions owners and managers should ask themselves about business performance, including:

Can you accurately measure ink usage? Ink is one of the most expensive consumables and knowing exactly how much ink is consumed in a given time period, on specific media types and on individual jobs, can help you plan and price jobs more effectively.

Is your team able to get real-time production blocking alerts? Production downtime can quickly accumulate if an operator is away working on another task when a stoppage happens on a printer. With IQ, users can set alerts customised to notify individuals who need to be informed of production blocking events. IQ also provides a detailed report on usage, uptime, downtime, etc., delivering verified information managers can use to improve overall productivity.

Are you able to compare performance metrics between printers and shifts? Many production managers don’t have access to the level of data that allows them to make these comparisons. Or, they have to constantly ask operators and other sources for details to find indicators for possible improvements. With EFI IQ, this information is at managers’ fingertips; they can compare performance in real time or customize reports that enable streamlined analysis of historical performance and trends.

Are you able to check production status from anywhere, at any time? Accessing information when away from the production floor often involves contacting a manager or operator who then must stop what he or she is doing to report back. With EFI Go, a remote management intelligence application in the EFI IQ suite, users can check overall production performance, jobs in progress, and many other indicators from any mobile device.

The IQ suite is the only management solution to have a direct connection to EFI printer data, and it gives business leaders powerful tools to handle their day-to-day production and administrative challenges. Plus, the suite’s EFI Go component helps to ensure that managers receive urgent updates wherever they are. At early user site Studio DAR in Bielsko-Bia?a, Poland, notifications from the mobile application allow managers and operators to keep the company’s EFI Pro 32r+ roll-to-roll printer running as much as possible.

“The EFI Go application,” said Studio DAR Owner Bartosz Przybyla, “displays important warnings, monitors material quantity, or lack thereof, and informs us when the material on a roll is about to run out, which is very useful with long webs.”

With the data insights and notifications EFI Go and the entire EFI IQ suite provide, “print business owners gain the Industry 4.0 advantage they need for more streamlined, efficient and profitable print business management,” said Todd Zimmerman, vice president and general manager of Display Graphics, EFI Inkjet. “The integrations we developed between EFI IQ and our VUTEk and Wide Format inkjet printers elevate what our customers can achieve in operational efficiency and business strategy.”

Electronics For Imaging, Inc., today announced the availability of its EFI IQ suite of cloud and mobile applications with supported EFI VUTEk, Wide Format, and Nozomi inkjet printers. With this advanced cloud service, EFI printer users can monitor production and printer utilization, including exact device-level consumable tracking data, to reduce downtime, reduce costs and maximize the value of their EFI printer investments. New EFI wide- and superwide-format UV LED printers will include a one-year subscription to EFI IQ. EFI inkjet printer users can also purchase IQ subscriptions for other supported printers.

The newly available cloud service for superwide-format production is making its debut at the May 31-June 03 FESPA Global Print Expo in Berlin.

User-friendly with better business intelligence

According to an early user of the cloud service’s new inkjet offering – Dave Brewer, chief technology officer of Foothill Ranch, California-based Image Options – “EFI IQ is a user-friendly tool that gives me better business intelligence to make better decisions.”

By monitoring their printer fleets in real time, EFI IQ users can reduce consumable spend, save on labor costs, improve margins, and more.

“Print business leaders often want and benefit from having more-complete knowledge of their plant operations,” said John Henze, vice president of sales and marketing, EFI Fiery. “With EFI IQ, they can have their finger on the pulse of the business. This advanced cloud offering gives print business leaders a detailed, accurate understanding of production operations, which is key to knowing how a company can best meet its customers’ needs at any given point in time.”

Prepare for productivity with powerful cloud tools

The decision to adopt EFI IQ comes down to several key questions owners and managers should ask themselves about business performance, including:

Can you accurately measure ink usage? Ink is one of the most expensive consumables and knowing exactly how much ink is consumed in a given time period, on specific media types and on individual jobs, can help you plan and price jobs more effectively.

Is your team able to get real-time production blocking alerts? Production downtime can quickly accumulate if an operator is away working on another task when a stoppage happens on a printer. With IQ, users can set alerts customized to notify individuals who need to be informed of production blocking events. IQ also provides a detailed report on usage, uptime, downtime, etc., delivering verified information managers can use to improve overall productivity.

Are you able to compare performance metrics between printers and shifts? Many production managers don’t have access to the level of data that allows them to make these comparisons. Or, they have to constantly ask operators and other sources for details to find indicators for possible improvements. With EFI IQ, this information is at managers’ fingertips; they can compare performance in real time or customize reports that enable streamlined analysis of historical performance and trends.

Are you able to check production status from anywhere, at any time? Accessing information when away from the production floor often involves contacting a manager or operator who then must stop what he or she is doing to report back. With EFI Go, a remote management intelligence application in the EFI IQ suite, users can check overall production performance, jobs in progress, and many other indicators from any mobile device.

The IQ suite is the only management solution to have a direct connection to EFI printer data, and it gives business leaders powerful tools to handle their day-to-day production and administrative challenges. Plus, the suite’s EFI Go component helps to ensure that managers receive urgent updates wherever they are. At early user site Studio DAR in Bielsko-Bia?a, Poland, notifications from the mobile application allow managers and operators to keep the company’s EFI Pro 32r+ roll-to-roll printer running as much as possible.

“The EFI Go application,” said Studio DAR Owner Bartosz Przybyla, “displays important warnings, monitors material quantity, or lack thereof, and informs us when the material on a roll is about to run out, which is very useful with long webs.”

With the data insights and notifications EFI Go and the entire EFI IQ suite provide, “print business owners gain the Industry 4.0 advantage they need for more streamlined, efficient and profitable print business management,” said Todd Zimmerman, vice president and general manager of Display Graphics, EFI Inkjet. “The integrations we developed between EFI IQ and our VUTEk and Wide Format inkjet printers elevate what our customers can achieve in operational efficiency and business strategy.”

Epson, who is today celebrating its 80th year in business, has opened the new Epson Museum Suwa at its corporate Head Office in Suwa, Nagano, in Japan. The two-part museum, which consists of a renovated Monozukuri Museum and a new Memorial Hall, gives visitors a chance to learn about Epson’s history and products from the past. Memorial Hall is housed in what was the original administrative building, construction of which was completed in October 1945 and this recently renovated historic building is open to the public from today.

Epson Museum Suwa, Memorial Hall

Epson’s predecessor, Daiwa Kogyo, Ltd., was founded in May 1942. Over the ensuing eight decades, the company evolved while passing on its DNA as an innovator and manufacturer. Refining the micromachining and precision processing technologies Epson developed for watches and deploying them in other areas are what fueled the company’s growth.

Construction of the administrative office for Factory 1 of Daiwa Kogyo was completed in 1945 (the picture was taken in 1949)

The company have renovated the original administrative building from the founding era and reopened it as Memorial Hall to allow visitors to step back in time to experience the history and stories of products from a bygone era.

Exhibits in Memorial Hall cover the period to the 1970s, the time during which the building was actually used. From the technology and skills that go into mechanical watches, to the world’s first quartz watch, to the compact EP-101 digital printer from which the Epson brand name is derived, visitors will be given a retrospective look at the efficient, compact, and precision technologies that Epson has developed since its founding.

Visitors to Epson Museum Suwa can tour both the Monozukuri Museum and Memorial Hall.

Epson has also launched an 80th anniversary website to trace the company’s philosophy and history since its founding. To visit the website go to: https://80th.epson.com/en

Epson has ticked off eight decades by ceaselessly pursuing creativity and challenge. The company is committed to solving societal issues by working to achieve sustainability and enrich communities.

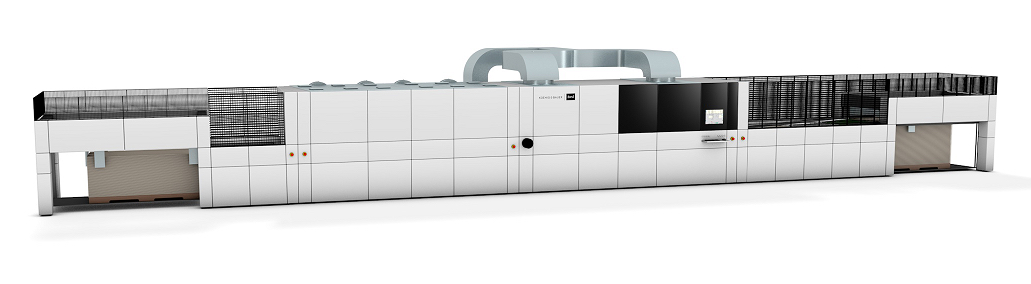

Koenig & Bauer Durst has used its latest SPC Open House to announce a new addition to its product portfolio with the unveiling of the Delta SPC 130 FlexLine Eco+ industrial production press for run lengths from one to millions of square metres. The entry-level, compact model will offer corrugated converters a new route into digital packaging or will enhance their current capabilities.

The Delta SPC 130 FlexLine Eco+ press, using water-based, food-safe, sustainable inks, will offer an impressive price performance ratio for converters with media sizes up to 1.3 metres by 2.8 metres. This new press will be fully upgradeable to the Delta SPC FlexLine Automatic press. Sales start now. Based on its established, market-proven Delta SPC 130 FlexLine Automatic press, the new machine will be addressing converters with volumes of between 4 million and 8 million square metres a year. It also includes a compact drying system.

With more than 60 guests at the SPC Open House at the Durst Innovation Center East in Lienz, Austria, in May, Koenig & Bauer Durst also announced the introduction of Dynamic Nozzle Management (DNM). This tool will significantly reduce the printhead maintenance across its Delta SPC 130 product portfolio, which will be another boost for customers’ productivity.

DNM will become part of the standard package for the Delta SPC 130 portfolio, including the new Eco+ model, and will further reduce the maintenance cycles of the Koenig & Bauer Durst’s industry acclaimed, long-lasting printheads. The tool identifies nozzle clogging and can then be programmed to manage the level of ink being jetted from the head. It ensures that high-quality production is always maintained.

Matthias Krautgasser, Koenig & Bauer Durst’s Delta SPC 130 Product Manager, said: “We have already implemented our automated non-contact cleaning system – DNM will further increase uptime and productivity of our Delta SPC 130 product lineup. DNM is another tool in our parcel of advanced technologies which will give our customers even more confidence in these challenging times. The DNM will be fitted to all new products, including the Delta SPC 130 FlexLine Eco+ model that will be available from next year. It can also be upgraded to existing customer machines.

“Many of the corrugated converters we are in discussion with have run lengths of between 4-8 million sq/m per year, so the new Koenig & Bauer Durst Delta SPC 130 Eco+ will be perfect for them, with the capability to upgrade to the SPC 130 FlexLine Automatic press later.”

Robert Stabler, Managing Director, Koenig & Bauer Durst, said: “Raw material shortages, cost pressures and mitigation strategies continue to be high on the agenda for customers. Coupled with brand owners demanding that new production methods are reliable, compliant and cost effective, we are confident that our complete product portfolio, including the new Eco+ press from Koenig & Bauer Durst, will meet the rapidly changing requirements. It was clear from discussions at our SPC Open House that converters increasingly need to have the capabilities and competencies to mass customize without any compromise on quality, and all at an effective total cost of ownership, which we provide.”

The event highlights the power of digital production to transform an industry transitioning from the challenges of waste and overproduction to sustainable, efficient production.

Kornit Digital (“Kornit”), a worldwide market leader in sustainable, on-demand digital fashionx and textile production, is today disrupting the fashion status quo during Kornit Fashion Week London, May 15-17 at the historic Freemasons’ Hall. The event highlights the power of digital production to transform an industry transitioning from the challenges of waste and overproduction to sustainable, efficient production.

Kornit Fashion Week London kicked off on Sunday, May 15 at 8pm UK with a stunning opening gala featuring designs by world renowned Manish Arora – produced on demand and sustainably with Kornit technology, supplemented by a virtual reality presentation that illuminates his creative process for attendees before connecting it to the physical realisation of those inspirations. The following days offer spectacular runway shows combined with keynote and panel sessions by high-profile fashion industry experts addressing critical industry topics. The Kornit press event will take place on Monday, May 16 at 1pm UK at the Freemasons’ Hall.

“Attendees who experience Manish Arora’s virtual reality presentation drawing a direct route from his imagination to runway collection at our opening night gala will understand how we’re transforming what fashionX can and will be,” said Ronen Samuel, Chief Executive Officer at Kornit Digital. “Kornit is enabling the connection between the virtual world and brilliant, finished apparel, unleashing creativity in new and fascinating ways. This program offers a glimpse into a completely new experience, from the moment of inspiration to the moment a cherished garment arrives, satisfying and invigorating every creator, brand, producer, and consumer throughout the fashion value chain.”

Samuel continued, “According to a new report by McKinsey & Co., the new face of this industry is digital and on-demand – with investments in technology expected to double by 2030. Kornit embraces this potential with our leadership – from inspiration to the consumer’s door, powered by technology. We’re excited to explore these trends at Kornit Fashion Week, demonstrating the brilliance, diversity, and values of visionaries leading this transformation.”

The runway program by seasoned producer Motty Reif incorporates 12 outstanding designer collections created in days using Kornit’s on-demand production – each challenging the limits of creativity, color, and imagination. Attendees will explore the new ways Kornit is driving sustainability and efficiency in a fashionX industry eager to overcome challenges of overproduction (30 percent) and water waste (95 percent).

The collections at Kornit Fashion Week London could not be created without Kornit’s digital production technology – accelerating creativity and unleashing the potential for unprecedented design freedom. In addition to the numerous fashion collections on display, another renowned designer, Preen by Thornton Bregazzi, will debut their “Breakfast in Bed” collection of home décor applications, also created using Kornit on-demand capabilities. To see the amazing list of designers and their fashion statements, please follow #KornitFashionWeek on LinkedIn, Twitter, and Instagram, and Kornit’s press kit with full designer bios.

Keynote Sessions

According to McKinsey, three-quarters of fashion companies surveyed see shipping disruptions as the greatest threat to flexibility and speed. Seventy-one per cent say they are looking to increase nearshoring by 2025 — bringing manufacturing sites closer to their consumer market — and 24 per cent are planning to reshore manufacturing to the same country of operation as the brand. The rich keynote and panel discussions explore exactly these critical industry issues such as the shift towards nearshore production, developing responsive, conscientious operations balancing responsibility and profitability, and achieving agility to meet changing customer demands. The robust lineup of keynote speaker sessions include:

Ex-Chief Supply Chain Officer at PVH, Bill McRaith, “Are You and Your Partners Agile and Ready to Meet Changing Consumer Demands in a Sustainable Way?” This keynote analyses evolving challenges of supply chain economics, managing inventory, curbing overproduction, and the value of bringing production back home.

Commercial ESG & Sustainability Director at ASOS, Simon Platts, “The True Cost of Traditional Fashion Practice – and Our Alternative.” This session analyses the true cost of traditional fashion practices and explores the demand-and-supply production models that can rapidly respond to consumer needs while boosting speed-to-market and reducing risk.

Designer and Social Entrepreneur, Patrick Grant, “Are You Comfortable in Your Clothes?” In this session, Patrick will share his views on how the industry got to where it is today – and where it needs to go in the future.

Media and Technology Entrepreneur, Bobby Simms, “The Business of Fashion in the Era of Web3.” This session focuses on how NFTs, the Metaverse, and Crypto are changing the fabric of fashion.

“In the fashion world, success demands a great deal of agility – developing a global production structure and manufacturing footprint that strikes the right balance between cost and an ability to respond quickly to ever-changing consumer demands is critical,” said Bill McRaith, Ex-Chief Supply Chain Officer at PVH, a company with an acclaimed house of brands including Tommy Hilfiger and Calvin Klein. “Many of the rules that made the fashion industry successful over the last 30 years just don’t apply anymore. Companies must take a fresh look at their internal processes, value chains, inventory models, and the appropriate balance between producing product offshore and onshore. We’ll learn how to thrive during this transformation at Kornit Fashion Week London.”

“Kornit is flipping the script to supply by demand rather than produce for inventory,” concludes Samuel. “We are confident that fashion will change forever with a digital-first mindset, liberating brands and fashion producers from the waste quagmire, clearing a path to generations of boundless self-expression, unlimited creativity, and sustainable consumption. Those joining us in London will see and understand that complete new creation journey, fully realised by Kornit and our partners in fashion and tech innovation.”

VIP attendees are also invited to demo tours at the Kornit/Fashion-Enter Fashtech Innovation Center to observe the digital, sustainable, on-demand production experience – from inception to delivery of a finished garment, in real time. During these sessions, participants will join live demos of digital production of designs in action – acting as a catalyst for nearshore production and bringing fashion and textile manufacturing back to the UK.

To learn more about how Kornit Digital is boldly transforming the world of fashion and textiles, visit www.kornit.com.