See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

Roland DG Australia, a leading manufacturer of wide format inkjet printers and printer cutters, today announced a fourth round of 2022 training dates for the company’s successful Roland Academy Online courses, including two sessions of the newly developed course for BN-20/20A customers.

As packaging companies around the world recognise the need to innovate to survive and thrive, Esko is launching its latest software release that empowers businesses to improve ways of working, eradicate waste and optimise operational processes.

“Innovation and change are inherent in any packaging business but driving and implementing that innovation is a challenge that can sometimes be difficult to achieve,” said Jan De Roeck, Esko Director of Marketing, Industry Relations and Strategy. “Many businesses, in the face of challenging market conditions, insecurity, and volatility, freeze investments in response. However, the opposite reaction is more appropriate. Investing in accelerating digital transformation maintains competitive advantage and efficiently deals with profitability pressures. We also know it is equally important that these innovations are integrated quickly and smoothly to ensure businesses achieve demonstrable improvements and a speedy return on investment.

“That’s why, as a reliable business partner, Esko is releasing its software version 22.07 bringing to market new technology developments that will advance the industry, whilst also equipping customers with the toolkit they need to realise the true potential of our technology.”

Esko Release 22.07 includes a host of new features, including:

• Inspection for digitally printed labels - a new complete print inspection solution for digitally printed labels

• AVT AutoSet for packaging – first of its kind automated print inspection settings for maximum efficiency and productivity

• Solvent Saver in Flexo Engine – delivers a solvent reduction of up to 20% in flexo production

• Cape Pack – the first solution to offer customers a cloud-based workflow for palletisation and logistics optimisation

• Automated Packshots – creates hyper-realistic packaging images that are perfectly rendered for your clients’ use with easy-to-use design and 3D tools

• ArtPro+ – upgrades include printing unit support and seamless repeat layout creation, as well as folding carton improvements and a new usage dashboard

• WebCenter – enhanced usability features to improve ease of use and maximise productivity and efficiency

• ArtiosCAD – new FEFCO parametric standards added to the library

“At Esko, our close relationship with customers and partners enables us to quickly respond to specific market trends. “With this latest software release we address today’s market needs and ensure our innovations significantly improve customer outcomes,” said Jan. “We are focused on helping businesses not only successfully adopt new technology, but also to make best use of it to deliver immediate results and meet the challenges they face today and tomorrow.”

Jan said the new Esko Release 22.07 will be launched at a live webinar event on Tuesday, 12th July. “We will demonstrate how Esko hardware and software solutions enable businesses, both large and small, to improve ways of working, identify and eradicate waste, and optimise processes with these latest innovations,” he said. “Crucially, we’ll also bring into focus the investments and tools we have developed to help customers make the best use of our technology and achieve long-lasting change.”

For more information about the new features in Esko Release 22.07 and the full range of Esko software solutions, visit the Esko Innovation Hub here.

July 12 2022

Italian manufacturer of converting and finishing technology Prati has cemented its partnership with Danish corona treatment specialist Vetaphone. The two companies are working on the DigiFast model for the HP 20000 and 25000 lines.

Since its inception in 1973 by Pietro Prati, the Italian manufacturer of converting and finishing technology, has always believed that quality breeds success. Today, almost 50 years later, the company is acknowledged worldwide as one of the leading manufacturers in the narrow and mid-web sectors of the market, with an annual output of more than 200 machines valued in excess of EUR 20m.

‘We first encountered Vetaphone when we were working on a special laminating line for one of the world’s largest manufacturers of tube laminates. It was 450mm wide and required a 4KW corona system for secure over-printing on a difficult substrate. We soon realised why Vetaphone was the most popular brand on the market – when you invent something, you have more experience than anyone else – and it matters,’ said ChiaraPrati, sales and marketing director at Prati.

Since then, the two companies have worked closely together on several special projects, and Vetaphone corona units have become the standard fit for Prati’s successful DigiFastOne and Digi Compact converting lines. Currently, the two companies are working on a special 630mm project in Spain that will handle linerless labels but needs the facility to spot-coat hotmelt adhesive.

‘We enjoy working with Vetaphone because our company philosophies align – we both like a challenge and using our expertise to find the best solution,’ added Prati.

Currently, Prati is working on a new DigiFast20000 model for the HP 20000 and 25000 lines. This 760mm-wide machine will need a 4KW corona system from Vetaphone, and global sales projections are ambitious.

‘We are delighted to be working closely with Prati on a number of exciting new products that will be hot prospects for the market,’ commented Giuseppe Rossi, Vetaphone’s sales manager for Italy. ‘I think both companies appreciate each other’s attention to detail and the investment made in R&D. This can only bode well for the future.’

Roland DG Australia, a leading manufacturer of wide format inkjet printers and printer cutters, announced today the launch of the VersaUV LEC2 S-Series Flatbed Printers, designed to maximise direct-to-object printing options to deliver unsurpassed graphic results.

FUJIFILM Business Innovation Asia Pacific Pte. Ltd. won the Buyers Lab (BLI) 2022 PRO Award from Keypoint Intell...

July 05 2022

FUJIFILM Business Innovation Asia Pacific Pte. Ltd. won the Buyers Lab (BLI) 2022 PRO Award from Keypoint Intelligence for Outstanding High-Volume CMYK+ Production Device, thanks to the Revoria PressTM PC1120’s specialty colours, mixed-media handling capabilities, efficient production workflow and an achievement of the highest 5 Star rating in colour gamut. Available for sale in the Asia Pacific region since its launch in July 2021.

With a high print speed of 120 pages per minute over a wide range of media types and paper weight as well as 2,400 dpi true/real output resolution, this production press was designed to maximise users’ business potential through infinite colour possibilities, out-of-the-box productivity, and limitless capabilities. Its single pass, six colour engine, offers unparalleled levels of CMYK+ expressions with an expanded gamut of colours and enhanced vibrancy. Workflow is also made seamless with AI technologies -- removing the hassle of pre-production enhancements such as 10-bit gradation correction and enabling smoother skin tones and colour vibrancy together with the Pink toner. The Revoria PressTM PC1120 harnesses the transformational power revolutionary productivity and performance to unlock the true value of CMYK+ printing.

According to Keypoint Intelligence, the winning highlights of the Revoria PressTM PC1120 are the six colour stations with before-and-after CMYK capabilities that allow for wider range of inline creative options than other production devices on the market. The wide media handling capabilities of the production press ensures no slowdown on mixed-media workflows, resulting in more work to be handled inline as a single job submission. Furthermore, the device offers the largest CMYK colour gamut seen to date, which coupled with the range of specialty colours creates a very large colour palette. Last but not least, the Revoria Flow PC11’s customisable intuitive platform enables efficient management of the device and excellent remote management capabilities, making the device a truly outstanding production press.

“With print service providers (PSPs) looking to provide a wider range of output options to clients, whose aim is to ensure their printed pieces stand out from the crowd, the Fujifilm Revoria PressTM PC1120 really shines,” said David Sweetnam, Keypoint Intelligence’s Director of EMEA/Asia Research & Lab Services. “The extra imaging stations before and after the standard CMYK units, along with the diverse range of toner options, make the device stand out amongst others in this digital arena.”

“We are delighted to receive the recognition given to the Revoria PressTM PC1120. The award has established its position as one of the best digital production colour presses in the market for productivity, flexibility and workflow,” shared Scott Mackie, General Manager, Graphic Communication Services Business, FUJIFILM Business Innovation Asia Pacific Pte. Ltd. “This recognition has ratified our mission and commitment to never stop innovating to deliver customer value and create greater customers’ opportunity in the region. We are excited to show more of what we can do in the future.”

.jpeg)

On Friday 24th of June OMET opened the Innovation Park, a 1500 square metre permanent showroom in Molteno (LC), with a high-profile event and officially presented the new KFlex l...

July 05 2022

On Friday 24th of June OMET opened the Innovation Park, a 1500 square metre permanent showroom in Molteno (LC), with a high-profile event and officially presented the new KFlex line, a flexo printing machine with an ergonomic and flexible design, capable of being reconfigured at any time by the printer.

More than 150 industry players attended the official inauguration of the new OMET Innovation Park. In a spectacular frame, OMET CEO Antonio Bartesaghi welcomed the guests, presenting the OMET Group's exponential growth over the last 10 years, culminating in the relocation to the new headquarters in Molteno in 2021 and the realisation of the Innovation Park in 2022.

.jpeg)

The Innovation Park is a 1,500-square-meter space that OMET has set up with the aim of allowing printers, converters and suppliers to meet and collaborate, to host printing demonstrations and also to do trials of new materials on OMET machines. Everything is done with the will of improving not only the purchasing process, but above all the production process, strengthening a relationship of trust between sellers and buyers. In the exhibition area, in fact, there are reserved boxes and machinery from the Innovation Park's technology partners: Tesa, Simec Group, BST, GEW, Flexowash, Zeller+Gmelin, Simonazzi, Nazdar, Actega Ecoleaf and Rossini.

.jpeg)

Marco Calcagni, OMET Marketing & Sales Director, explained the further potential of the Innovation Park, such as the possibility for printers to use the OMET machines in the showroom to support their production, making not only samples but proper production lots that they are unable to produce at their sites.

.jpeg)

OMET's product range is undoubtedly the most comprehensive for converting and printing labels and flexible packaging with narrow- and medium-web machines, and is now enriched by a new printing line: the KFlex, officially unveiled during the opening of the Innovation Park on 24 June.

.jpeg)

The new machine, covered by a curtain in the first part of the event, was unveiled in a blaze of smoke and music before being beautifully presented point by point by OMET Sales Area Manager Andrea Angeli, who highlighted the machine's incredible flexibility. Tailor-made for the printer's needs, it has a design that allows total accessibility and easy maintenance, a new flexo printing unit with a contrasting UV lamp and, above all, an absolute innovation, the Switch System: the possibility of changing any of the machine's modules (printing units, pull-out die, digital print-bar, hotfoil, screen printing...) in a minute and in an extremely simple way. There are many other innovations presented on this line, which is, moreover, extremely scalable in its offer to meet the different needs of printers.

In the second part of the event, the participants were divided into groups for a tour of the Innovation Park, where OMET also showcased an iFlex and an XJet, plus there was also a stand by Ribes Tech, the OMET Group's start-up company that focuses on printed electronics, in particular smart labels, and offers integrated IoT solutions.

The Innovation Park is located just a few steps away from the new OMET Headquarters in Molteno. It was also possible for guests to visit the new headquarters, inaugurated in 2021 to allow further growth to the company's production reality, which extends over an area of more than 30 thousand square metres, more than 20 thousand of which are dedicated entirely to the production of label and flexible packaging printing machines. The OMET Headquarters represent the beginning of a path of change that aims to increase production capacity and make processes more efficient, indispensable factors for a breakthrough in terms of growth and innovation, which have always been the pillars of OMET's excellence.

For more information about OMET labels and packaging technology, speak to the Australian and New Zealand Distributor, Currie Group www.curriegroup.com.au

The Hexis Wrap Battle at Pacprint concluded with an epic final, after four days of competition. The skills on display show just how far the technical capabilities have improved amongst t...

July 05 2022

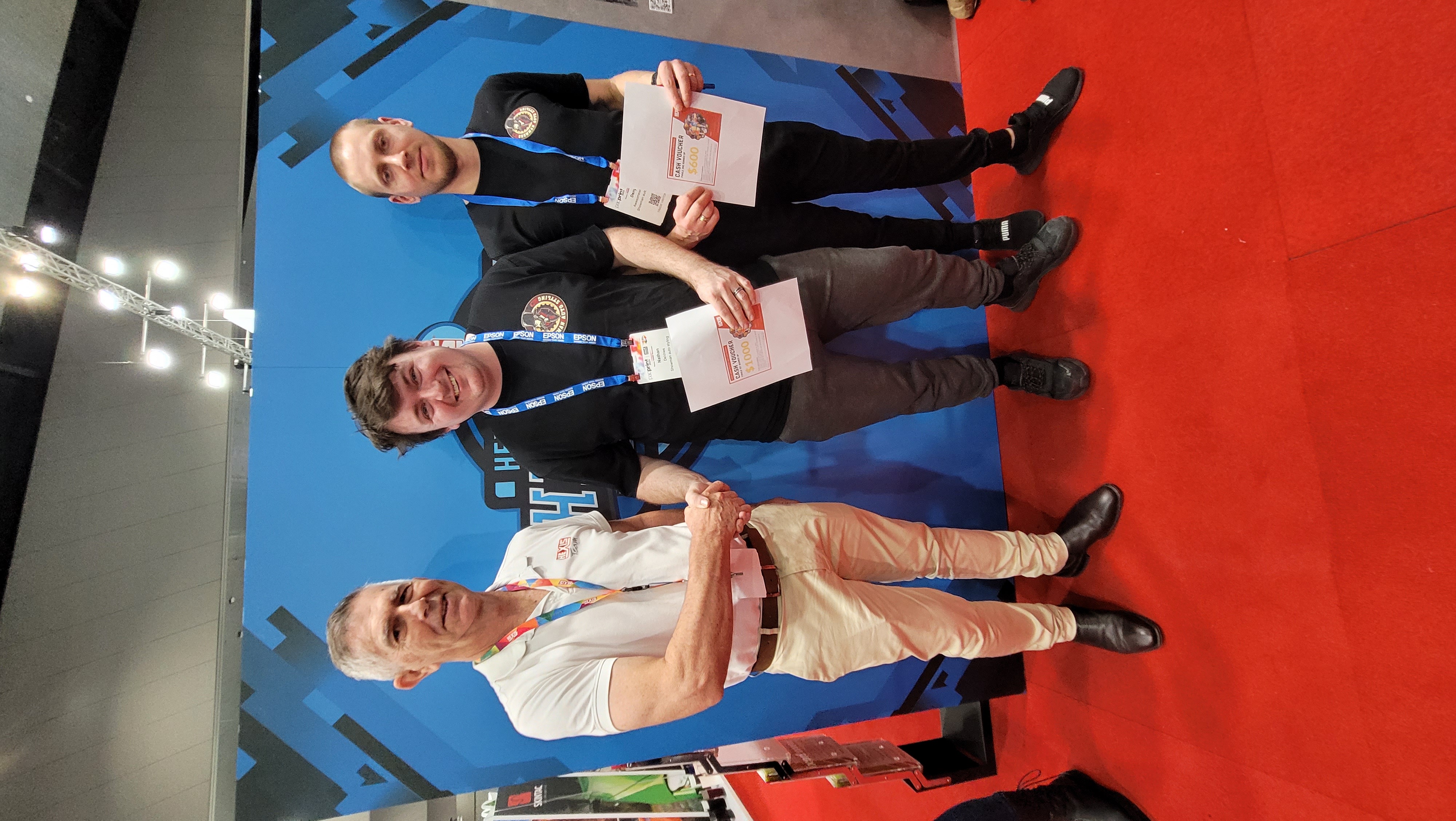

The Hexis Wrap Battle at Pacprint concluded with an epic final, after four days of competition. The skills on display show just how far the technical capabilities have improved amongst the next generation of vehicle applications specialists.

You can see some of the action here:

https://www.tiktok.com/@hexis_australia/video/7115346766853131521?is_copy_url=1&is_from_webapp=v1

Congratulations to the Hexis Australia team for putting on such a great event, and to all those who took part.

Finals Winners:

1st – Michael Palladino from Auto Artisan in Sydney (Won a trip for 2 to Cairns worth up to $6k)

2nd – Nathan Devries from Showman Auto Styling in Melbourne (Won $1000 Hexis Cash Voucher)

3rd – Denys Goncharov from Showman Auto Styling in Melbourne (Won $600 Hexis Cash Voucher)

4th – Sacha Rattray from Freestyle FX Signs in Tasmania (Won $400 Hexis Cash Voucher)

July 05 2022

Kongsberg Precision Cutting Systems (Kongsberg PCS) enjoyed record success at the recent FESPA Global Print Expo, achieving seven-figure sales of its digital cutting solutions across the four-day event.

“It was fantastic to meet so many of our distributor partners and customers face to face at this year’s event,” said Wim Brunsting, EMEA Sales Director for Kongsberg PCS. “We were thrilled to be returning to FESPA to showcase our latest innovations. As the number of deals agreed climbed into double figures, it became clear that demonstrating how the power, performance and versatility of our digital finishing solutions bring designs to life had really hit the mark.

“With our display at Messe Berlin featuring the C Series and our modular Kongsberg X24 table, we were able to highlight the benefits and performance our systems deliver in cutting, creasing and folding a variety of materials,” said Wim. “The result was a record number of sales agreed to supply digital cutting tables to customers across Europe and further afield.”

Wim said a new flagship Kongsberg C64, with full automation, will soon be installed with a French customer, while a second will be travelling further afield to its new home in Serbia. “We also sold a number of Kongsberg C and X tables to customers in Italy, Ireland and Norway, as well as to converters in Turkey, Israel and United Arab Emirates,” he said.

The Kongsberg PCS booth at this year’s FESPA also featured the MultiCam Apex 3R CNC router, one of the most versatile CNC Routers on the market. “Following our acquisition of MultiCam last year, it was great to be able to showcase the Apex, which sets the standard for routing capabilities with its perfect balance between performance and precision,” he said. “From our booth we were able to showcase how our complete range of digital finishing solutions enables sign and display businesses to streamline workflows and automate production to boost efficiency, while empowering designers and operators with the creative freedom to generate the ideas that will drive the future of their business.”

The Kongsberg team also demonstrated how a range of innovative tooling delivers new freedoms in design and creativity, like the VariAngle tool - a breakthrough innovation for the industry that enables cutting at any angle from 0o to 60o at up to 100m/min.

“As well as enjoying significant sales success, we were able to use our appearance at FESPA Global to demonstrate and explain the benefits our tooling range can deliver to businesses,” said Wim. “We now look forward to following up all the many leads and opportunities that we have developed form our attendance at the expo and adding to our continued sales success.”

Kongsberg President and CEO Stuart Fox was interviewed at FESPA, detailing the success of the company in its first year as a standalone business and discussing the company’s presence at FESPA. Watch the interview here: https://inkish.tv/inkish-video/fox

For more on the Kongsberg C series or the entire range of digital finishing solutions and tools from Kongsberg PCS, visit www.kongsbergsystems.com

July 05 2022

Onyx Graphics announced the global availability of ONYX 22, the company’s newest software version release of industry leading wide-format RIP and print workflow software that was showcased at FESPA Global in Berlin, Germany. ONYX 22 introduces a new drag-and-drop user experience for file management and Quick Set automation, smart job submission from design to print, artwork placement controls for flatbed and DTG printing, and easy-to-use tools for everyday automation.

“Software has to be fast, reliable, and easy-to-use in today’s printing environment,” said Matt Crawford, Director of Product Marketing at Onyx Graphics. “The tools, technology, and controls for everyday automation in ONYX 22 are designed for the modern user, and continue our vision in providing superior software solutions to print businesses across the globe.”

ONYX 22 also introduces color tools for increased color output accuracy and an all-new ONYX Color Reference Library to easily match color for any printer. This dynamic reference library highlights in-and-out of gamut colors and can be printed or used in ONYX software to know what colors are possible on each device and media combination.

Highlights of ONYX 22 include:

• Drag-and-drop user experience for file handling

• Drag-and-drop Quick Set automation

• Smart job submission from design to print automation

• Job placement tools for enhanced nesting

• Auto-trim for flatbed and DTG printing

• Automated image cropping using Quick Sets

• Printer versioning and auto-backup

• D65 10-degree observer ICC profile build options for textile printing

• Snapshot color calibration for contone printers

• The latest Adobe PDF Print Engine APPE 5.7 for fine line rendering Onyx Graphics announces global availability of ONYX 22

Availability

ONYX 22, covering the entire product portfolio of ONYX solutions including ONYX Thrive print workflow software, all ONYX RIP products, and ONYX Go subscription RIP products, is globally available. It is automatically provided to ONYX Go subscribers through a soft download product update, available to all ONYX Advantage customers by requesting a key update, and to all other customers through a license purchase. Onyx Graphics is providing a special promotion to upgrade. Customers are encouraged to visit www.onyxgfx.com for more information.

| ||

June 28 2022

Starting from June 15, 2022, users will be able to update their RIP to access a range of new features designed to increase performance, output quality, and productivity.

French software creator Caldera has announced the release of the latest update of its award-winning RIP program, CalderaRIP Version 15.1. Starting from June 15, 2022, users will be able to update their RIP to access a range of new features designed to increase performance, output quality, and productivity.

Highlights of this new update include an improved nesting algorithm, CalderaJobs’ compatibility with Windows, and four exclusive features for CalderaCare subscribers. In addition, this update supports the cutters of French manufacturer VERSO, and more than 42 new Print & Cut drivers have been added to the V15.1 ISO.

Along with Version 15.1, the company is also releasing version 1.14 of CalderaDock, the toolbox to manage the license and installation of all Caldera solutions. With this new version, users can login to their WorkSpace account directly from CalderaDock to access their information. Production administrators will also appreciate the increased flexibility, security, and control during the installation process.

According to Arnaud Fabre, Head of Product at Caldera, “Giving our customers the tools to optimize their production costs and grow their printshop remains one of our top priorities.”

The new features and improvements included in Version 15.1 contribute to making it the most comprehensive, flexible, and powerful RIP solution on the market. CalderaJobs has been improved, making it the perfect tool for print operators whose role is to send ripped jobs to the printers, and for production managers who need to balance the workload or check the connectivity and statuses of the fleet. Users can drive and manage their fleet of printers from any of their workstations, including those running on Windows devices. For more flexibility, they can filter their RIP stations to focus on a subpart of the fleet. The nesting algorithm in Compose and Nest-O-Matik modules has also been improved to help operators reduce media waste.

Along with these enhancements to the RIP software, Version 15.1 comes with new exclusive features for CalderaCare subscribers, including the possibility to submit multi-page PDF files with different cut contours directly to CalderaRIP. Reducing the number of files to handle guarantees a more efficient workflow, with valuable time-savings and fewer manual errors. To speed up textile printing operations, the new "Use Printer S&R” option makes the ripping process faster when producing repeated patterns.

CalderaCare subscribers also benefit from two additional features to streamline their cutting operations. With Image Step&Repeat in VisualCut, CalderaRIP groups the shapes by images and builds optimized rows to streamline the cutting head path— which increases cutting speed and accuracy. In addition, both VisualCut & GrandCut come with a new option to streamline two-steps workflow such as sublimation and lamination requiring rolling and unrolling. In just one click, users can rotate jobs by 180° to save time and have their jobs ready for cutting right after printing, without additional manipulation.

Sébastien Hanssens, VP Marketing & Operations says, “Version 15.1 continues our 30-year long tradition of putting our customer’s needs at the heart of our innovations. Each new update aims to push their business forward and help them face the new challenges of the digital printing industry.”

Epson Australia will exhibit at PacPrint 22 with not only its biggest product offering ever, but also having cemented its position of Number 1* in terms of market share for Large Format’ and Direct to Shape printers across Australia and New Zealand for the last two years (2020-2021). Epson’s Number 1 position in these market areas is based on data from research specialists, IDC.

Taking with them the philosophies of “Be limitless” and “Expand your business possibilities” Epson is exhibiting a veritable armada of printing solutions, with many of the products that helped Epson achieve their Number 1 status also on their stand at PacPrint 2022.

In the Fabric area Epson will feature their large 76” SureColor F10060 aimed at soft signage and just-in-time manufacturing. The SC-F10060 achieves an outstanding gamut using just four inks. It combines advanced Epson Precision Dot Technology with UltraChrome DS HDk ink to achieve high image quality with intense and accurate colour. Alongside the SureColor F10060 will be the SureColor F6360 - 44” which suits a wide range of production applications including customised garments and fabrics, hard and soft signage, décor and merchandise.

Then there’s the Epson SureColor F9460H - 64” which represents the fourth generation of Epson’s proven 64” platform and combines Epson Precision Dot Technology, with advanced media management and UltraChrome DS HDk ink to enable outstanding image quality at high speed.

Finally in fabric will be the Epson SureColor F3000 – DTG which has scaled up to suit to needs of high-volume producers. The SC-F3000 combines advanced Epson UltraChrome® DG ink with Epson’s latest PrecisionCore™ head technology and an upgraded print engine. Staggered 2.6" print heads enable high-speed, single-pass, five-colour production.

The next area on the stand is Signage where you will see Epson’s latest solvent models as well as their new resin range featuring the SureColor R5000L, which offers a low running cost and accurate and repeatable colour on a platform that enables rapid job turnaround.

You will also see the Epson SureColor V7000 - UV Flatbed. The SureColor V7000 is designed to produce durable images on a wide range of substrates, with superior colour and print quality. The SC-V7000 combines Epson precision imaging and print head technology with new UltraChrome UV ink. The printer supports flexible production with four separate print zones and support for media up to 80mm thick. This is a printer designed to provide durable and worry-free operation backed by a comprehensive service program that can be extended up to five years.

Also on display in signage will be the Epson SureColor S80660L - 64” CISS which is designed to produce durable images with maximum impact and format flexibility, quickly, easily and at minimum cost. Prints dry quickly to enable ad-hoc, same-day job turnaround, while the high-capacity media and ink supply systems enable efficient roll-to-roll production with remote status monitoring and reporting.

Then there’s the Epson SureColor S60660L - 64” CISS which also features Epson's latest PrecisionCore print head and UltraChrome Eco-Solvent ink technology. It produces images that are brighter and glossier than competitors with an outstanding colour gamut.

Epson is known as a leader in the commercial and professional photo printing space with models such as the SureColor P9560. That said, Epson are also a major player in small format photo printing and on the stand they will display in both key areas. This includes the new SureLab D1060 dry-film minilab which is designed for low-medium volume production. It can be operated as a standalone machine or in multiples for heightened production. It incorporates a high precision Epson Micro Piezo™ Thin Film Print™ (TFP) head that enables accurate and consistent output in resolutions up to 1440 x 720 dpi. Staying true to the SureLab series, the D1060 is compact, lightweight, and requires minimal operational space.

Epson has launched a huge range of models in the Technical & Poster segment over the last two years you will see a number of these at PacPrint along with the SureColor T7760D. This newly redesigned model combines high-speed production with flexible media handling in an extremely compact footprint and a clever new six-colour ink set.

Epson will also have the SureColor T5460M - 36” MFP on display. The SC-T5460M features Epson's latest PrecisionCore™ print head and aqueous UltraChrome® XD2 pigment ink. It will print an A1 image in as little as 22 seconds with output that dries almost instantly to be water and rub resistant. The SC-T5460M is Epson’s first wide format printer to include an integrated scanner. Developed for engineers and architects, it also provides the perfect solution for corporate, government, retail and education users.

If it’s colour and proofing you’re after then Epson’s unique SD-10 Spectrophotometer will also be demonstrated. The SD-10 is an ultra-compact high-precision spectrophotometer. Small in size but big in features, it is designed to be your constant print companion. It lets you determine the exact colour of a test item and compare it with another or with a known standard such as Pantone®. Most importantly the readings you take are accurate and consistent.

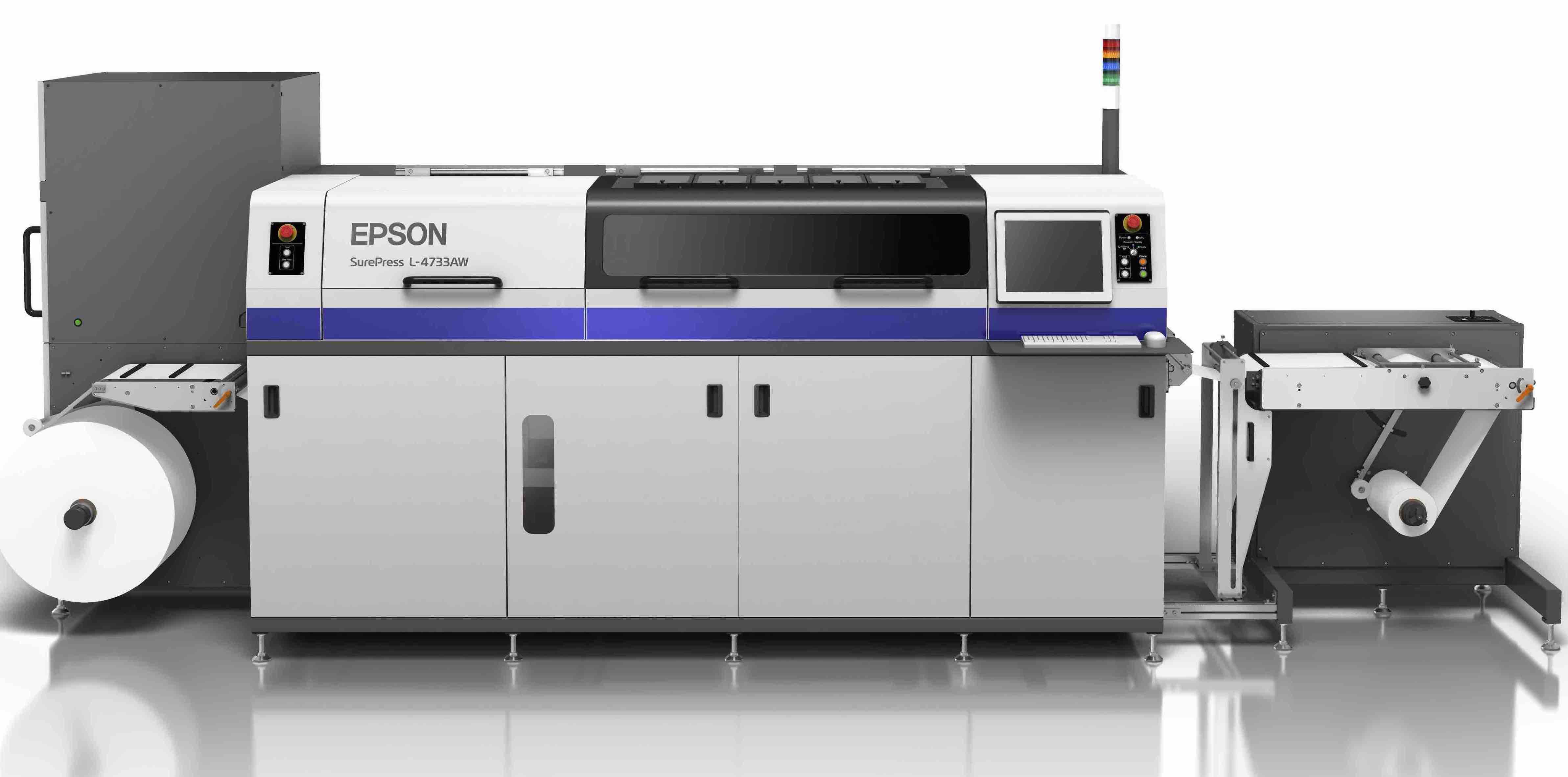

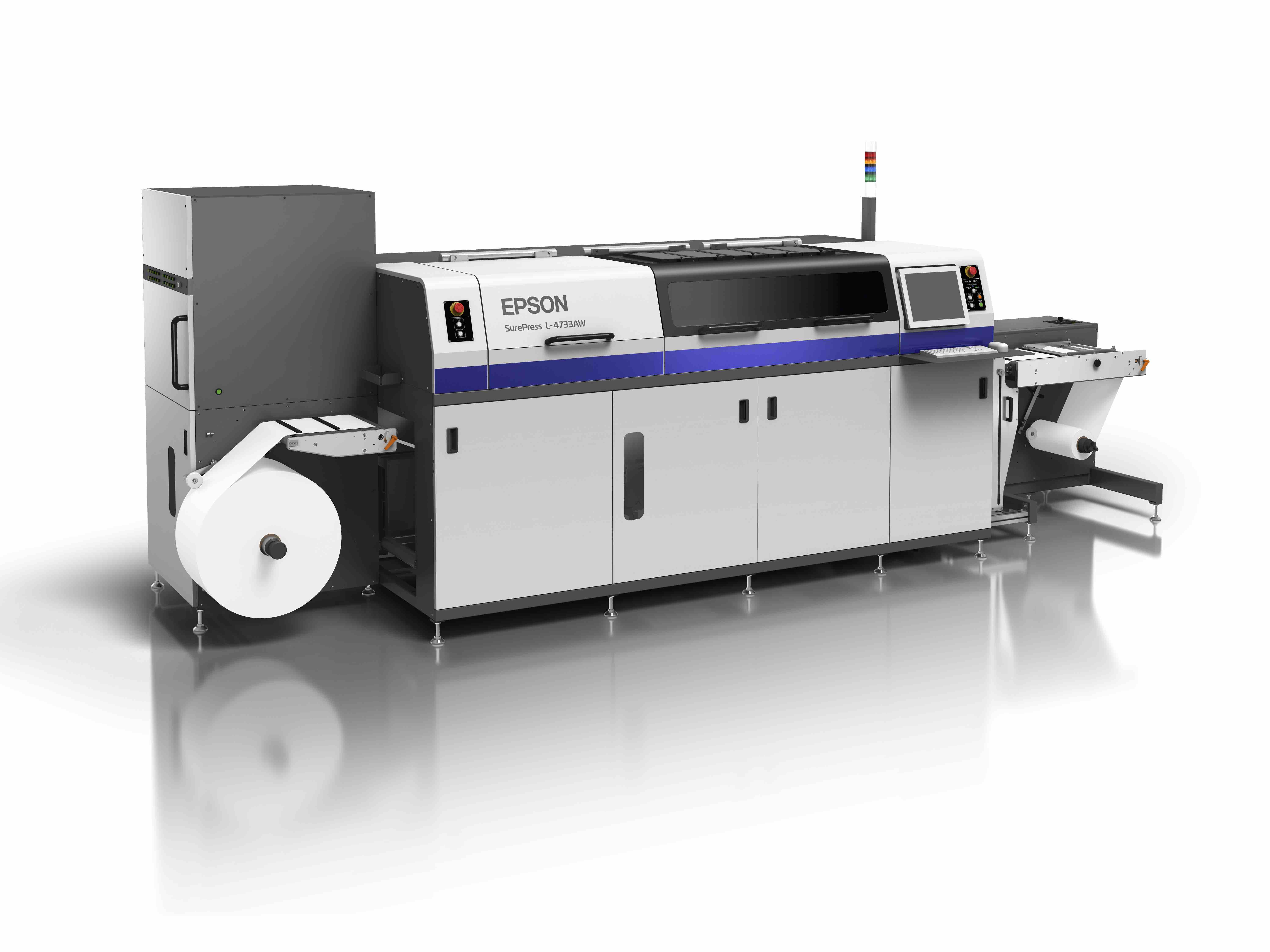

The industrial and commercial labels is where you will see Epson’s latest SurePress AQ ink industrial label press, the L-4733AW, as well as the ColorWorks CW-C4010, both on display for the first time in Australia.

The SurePress L-4733AW digital label press incorporates Epson’s acclaimed MicroPiezo® inkjet printhead and uses industrial grade Epson SurePress AQ ink. It is designed for converters who wish to produce general purpose and specialised labels in short and ultra-short print runs on mainly paper based stocks. It produces output on coated and uncoated substrates with a high colour gamut, high colour accuracy and outstanding print resolution and precision. Jobs are quick to set up and easy to complete with the absolute minimum in consumption, wastage and labour.

Bringing comprehensive connectivity and dynamic image quality together in a compact design, the ColorWorks C4010 label printer enables your business to harness the power of communication through colour. This versatile label printer features high-performance PrecisionCore® technology and is engineered for reliability. It delivers crisp, photo-quality colour labels on demand at up to 1200 dpi resolution.

Alongside is the Epson ColorWorks C6510A, the highly dependable 8” commercial inkjet label printer covering the full spectrum of label sizes for enhanced productivity and versatility.

The final area in this formidable library of printing offerings comes in the form of Epson’s Document Solutions and Business Printers that are designed to increase efficiencies and productivity while helping SMBs and SMEs to lower their impact on the environment. This important area will feature and demonstrate Epson’s WorkForce Pro WF-C579R network MFP, WF-C879RTC workgroup printer and the Epson WorkForce Enterprise WF-C20600.

June 28 2022

Earlier this year INX International Ink Co. expanded its information outreach to customers by introducing the Printer Space blog, which covers a wide range of printing-related topics. Taking another step to provide beneficial information, the INX Troubleshooting Guide App was recently updated with more solutions to common problems.

New information for users of water-based Flexo inks makes it the tenth guide to be available where customers can quickly find answers when they encounter printing issues. The library already consists of separate guides for Sheetfed, Web Offset/Heatset, EB Litho, UV Flexo, UV Litho, UV Hybrid, UV Metal Decorating, and both 2-piece and 3-piece metal decorating.

The app identifies problems and symptoms, provides recommended solutions, and now offers nine different languages for the three metal decorating guides with the addition of Czech. Besides English, it is also available in French, German, Italian, Portuguese, Polish and two Spanish versions – Latin America (Español) and Castilian.

“This latest update with the Troubleshooting Guide App is indicative of our commitment to help improve the flow of information to our customers,” said Renee Schouten, INX’s Vice President of Marketing. She pointed out that when it was first introduced in 2014, one of the main goals of the app was to limit the amount of downtime for printers.

“Our ink experts continue to keep the dialogue fresh because change is constant in our industry. There is great value in knowing about new products and capabilities, the most recent regulatory changes, and best practices and techniques to keep you at the forefront of print and package innovation. And like our free online INX University courses, we’ve added another language to this app.”

Learn more about the Troubleshooting Guide app by clicking here.

Konica Minolta Australia has announced the launch of the new SD-435/450 inline booklet makers with Plockmatic Group, extending the companies’ partnership and bringing a cost-effective solution for heavy production finishing to commercial print environments.

The inline versions of the SD-435/450 will be exclusively sold by Konica Minolta throughout 2022. Plockmatic Group’s inline platform introduces architecture that delivers new features for the first time in the low- to mid-sized volume market segments, across Konica Minolta’s AccurioPress colour production machines.

The new system architecture will let customers produce high-quality booklets from A6 to A4 landscape. It has all the key processes needed to produce corner and edge staple, folding, spine forming, and full bleed trimming, combined in one, easy-to-use system.

Johan Mikaelsson, VP business unit inline & group technical support, Plockmatic Group, said, “Plockmatic Group is delighted to extend our successful partnership with Konica Minolta with an exclusive agreement that benefits the customers of both companies. Customers recognise that the finishing of any document has never been more important. The SD-435/450 series uses the latest patented Plockmatic technologies to deliver top-quality output in a wide range of print applications. These can be customised for document finishers and will help them grow business in their territories.”

Tatjana Ferguson, product marketing manager, Konica Minolta Australia, said, “The SD-435/450 series is powerful and versatile to meet the changing demands of customers in the commercial print sector, delivering true value. Key features such as long sheet capability, corner and edge stapling, square folding, and bleed trim functionality. And, the ability to produce A4 landscape booklets is becoming increasingly important for customers.”

Other key features include:

p.p1 {margin: 0.0px 0.0px 12.0px 0.0px; font: 12.0px Arial; color: #000000} p.p3 {margin: 0.0px 0.0px 12.0px 0.0px; font: 12.0px Arial; color: #000000; background-color: #ff...

June 28 2022

Solimar Systems, Inc., provider of leading workflow software solutions for print production and digital communications, has unveiled the latest version of its award-winning Rubika® document re-engineering solution. Rubika 4.4 introduces an enhanced user experience and more workflow efficiencies at its core, enabling customers to streamline implementations and achieve significant savings within their businesses.

Rubika is renowned for adding value to existing documents with a modular suite of post-composition document re-engineering capabilities that maximize postal discounts, add barcodes for insertion control, modify finishing, automate device load balancing, and enable white paper workflows. Rubika is part of Solimar’s Chemistry™ platform, integrated with other workflow and data optimizing, document enhancing and job tracking solutions.

Among the many benefits of Rubika 4.4 is an enhanced graphical user interface (GUI) to boost the ease of commonly used tasks with fewer clicks, while hiding more advanced options until needed. These updates increase user productivity, reduce training times, and improve overall customer satisfaction.

"Rubika's popularity is largely driven by the substantial revenue opportunities and operational cost savings it enables. Our client testimonials speak to the value of its capabilities. The features in version 4.4 demonstrate our commitment to expanding the ways that Rubika underpins the successes of our clients." states Mary Ann Rowan, Chief Experience Officer.

Some of the new Rubika features include:

Rowan concludes, “Solimar Systems strives to solve difficult problems for our customers by delivering powerful, economical, and configurable off-the-shelf software. We are very proud that Rubika has transformed the way that highly variable and personalized communications are produced. We encourage Rubika users to take advantage of the many benefits of version 4.4.”

Quickly learn about these advancements in Rubika 4.4 by watching our on-demand new release video:

Australian Sign & Graphics Association (ASGA) is encouraging all business owners and staff based in NSW that have been working in the sign industry for at least two years but are not yet...

June 21 2022

Australian Sign & Graphics Association (ASGA) is encouraging all business owners and staff based in NSW that have been working in the sign industry for at least two years but are not yet formally qualified, to consider a fee free Certificate III qualification under TAFE NSW’s Trade Pathways Program.

This training is subsidized by the NSW Government. The enrolment window has recently been pushed back to 31 August and the completion date for the course to 30 June 2023. As there are no guarantees that the program will be available after this time, the ASGA is urging those considering the opportunity to act now.

“We know a lot of the workforce in signage around Australia may not have technical qualifications. What the ASGA is working towards across Australia is to work with the training organisations to have RPL for registered Certificate III courses. TAFE NSW’s Trade Pathways Program is a start and we are hopeful of a positive take-up of this initiative as it will guide us for what we can do for the rest of the nation,” said Damian Nielsen, ASGA Education Sub-Committee Chair.

“If you have been in the industry for a period of time and you have the skills, you can then be assessed on those, and at the end of the day you are going to walk out with a Cert III. What does that mean for you? If you own a business, you can employ other apprentices. If you work in the industry, you’ll have a qualification which goes on your resume which makes you more employable.

“What an increase in Cert III qualified workers means for the sign industry as a whole is a lift in standards of work practice, a higher number of qualified workers and greater recognition of signage as a skilled trade, all of which are of benefit to all that operate within the industry.”

For more information and eligibility criteria, visit https://www.tafensw.edu.au/trade-pathways .

On stand G20, the SurePress L-4733AW will demonstrate how it delivers improved automation functionality

Epson Australia is continuing its legacy of providing world-class white ink prime label printing with the introduction of the SurePress® L-4733AW water-based resin ink digital label press, delivering improved automation. This new addition to the SurePress line offers higher levels of print quality, consistency, flexibility and value for label converters, specialty printers and vertical manufacturers.

SurePress L-4733AW

The SurePress L-4733AW builds on the success of its predecessor, the L-4533AW, one of the leading selling digital inkjet label presses on the market today, to offer advanced automation and unattended printing features, higher productivity with improved print speed on film and support for printing on a wider range of substrates. Additionally, an optional inline spectrometer is available.

SurePress L-4733AW

Label converters and specialty printers are looking for solutions that are simple and cost-effective to operate and maintain, and can deliver on stable, predictable production. Epson enhanced its industrial SurePress line-up by adding new capabilities to the L-4733AW which can help businesses save on upfront costs and maintenance. These advancements come without the compromise of simple operation and maintenance, production or print quality.

The SurePress L-4733AW delivers on automation and ease of use. Virtually automatic, requiring no manual cleaning of the printhead surface, the L-4733AW is primed for unattended printing. With the optional SureSpectro AS-4000 inline spectrometer for real-time automated measurements to speed profiling and ensure consistent output for multi-plant networks, the L-4733AW delivers accurate spot colours and gradients required for brand-quality colour prime labels and packaging.

The L-4733AW supports a range of substrates, including off-the-shelf flexo materials, without the need to surface prime. Its inks meet the latest safety standards and regulations, such as REACH, and deliver high-quality images, making it a versatile press ideal for converters focusing on food and beverage and health and beauty labels.

Epson’s SurePress digital label press systems are engineered with Epson components including ink, printheads, LED pinning and curing and use an Epson Industrial Robotic Controller to manage the press rather than a PC, further enhancing reliability and stability.

The SurePress L-4733AW is available for purchase via authorised Epson resellers in Australia and New Zealand now.

New Fiery print servers boost graphic communications to new heights with familiar and unified ...

June 21 2022

New Fiery print servers boost graphic communications to new heights with familiar and unified user-interface for users of Revoria Press PC1120 and the Revoria Press E1.

FUJIFILM Business Innovation Corp. and Electronics For Imaging (EFI) announce the launch of new EFITM Fiery® print servers and workflow software for FUJIFILM Business Innovation’s two Revoria production printer models, the Revoria Press PC1120 and the Revoria Press E1 series. Sales of the new Fiery print servers for these printer models, EFI Fiery PC11 and EFI Fiery E11 respectively, will begin from June in the Asia-Pacific regionNote 1 and selected countries in the European region.

FUJIFILM Business Innovation is a leader in world-class graphic communications, providing cutting- edge technologies to innovative print providers with its Revoria Press series. EFI, as the worldwide leader in digital color print server and print workflow technology, is uniquely positioned to deliver best-in-class technology to meet today’s challenges of shorter runs, faster turnaround time, increased security standards, and the need to streamline workflow for efficient operation to reduce cost. Together, the two companies will meet the diverse challenges of today’s print professionals.

Catering to the various needs for high-speed, superior quality printing with ease of use, the new Fiery print servers bring innovation to an extensive line-up of Revoria Press series for use in office, commercial, in-plant and package printing environments.

EFI Fiery PC11 drives the Revoria Press PC1120, a production color printer for the high-end professional printing market, by providing greater advantages and enhancements to create professional quality prints.

EFI Fiery E11 powers the Revoria Press E1 Series, a monochrome production printer for on- demand printing both for professional and office use, with improved usability and seamless integration across Windows and macOS business environments.

Both Fiery print servers are equipped with Fiery Command WorkStation® to bring a familiar and easy- to-use unified interface to customers.

“Customers rely on market-leading Fiery technology to deliver exceptional quality digital prints while increasing their production efficiency and profits,” said Toby Weiss, Chief Operating Officer, Fiery Business at EFI. “EFI is excited to partner with FUJIFILM Business Innovation Corporation and broaden the reach of Fiery technology and solutions.”

"We are incredibly excited about the new business partnership with EFI which ensures FUJIFILM Business Innovation continues to evolve within an ever-changing print industry, keeping us at the forefront of technology," said Hiro Kida, Corporate Vice President and Executive General Manager, Graphic Communication Business Group at FUJIFILM Business Innovation Corp. "The collaboration with EFI, and the combination of our Revoria Presses with Fiery technology, are a digital enabler for many customers with whom a Fiery workflow will accelerate their growth. We also see this as an exciting opportunity that will enable us to deliver our technology to several new markets outside of Asia-Pacific as well.”

Konica Minolta Australia has appointed Andrew Cocker to the role of general manager, production and industrial print, effective July 1, 2022.

Andrew will be responsible for continuing to drive the production and industrial print business in Australia, helping customers in print, label, and packaging to evolve and thrive in a recovering market. He will continue to focus on accelerating high-growth in these areas of print, driven by the growing demand for short-run and increased onshore manufacturing.

Andrew has more than 24 years of experience in the digital document and workflow industry, supplying hardware, software, and service enterprise solutions. He was previously sales manager – production and industrial print at Konica Minolta Australia. Prior to this, he has held management and leadership roles in operations and production sales within the industry.

Yohei Konaka, managing director, Konica Minolta Australia, said, “Andrew brings extensive industry experience along with an innovative, creative, and organised operational style with strong leadership skills. Konica Minolta is renowned for its outstanding service and support and Andrew’s skillset ensures that this will continue well into the future. We congratulate him on this new role and have no doubt he will be successful in leading the team.”

Andrew Cocker said, “I look forward working with the team, sharing my experiences in commercial print rooms and high-volume production environments to help our customers diversify, save time, and reduce costs to empower the growth of their business. Konica Minolta has a diverse product offering, unique market approach, and a great culture, which is what attracted me to the business in the first place. We offer many complementary industrial and production solutions that are relevant across a broad range of industries including government, education, corporate, franchises, and commercial print operations. After spending a year getting to know the team and the customers, I feel ready to lead them into the next phase of the production and industrial print era.”

About Konica Minolta Australia

Konica Minolta Business Solutions Australia Pty Ltd is a market-leading provider of trusted technology solutions for enterprise, government, small business, education, and manufacturing.

Konica Minolta Australia helps Australian organisations keep pace with the needs of the changing workplace to start leveraging the technology of tomorrow today.