See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

August 16 2022

Esko, the global developer of integrated hardware and software solutions for the print, packaging, and label industries, has acquired imposition A.I. software company Tilia Labs, in a deal that delivers on the need of brand owners and converters to connect and integrate the entire value chain through upstream digitalisation.

Tilia Labs’ range of intelligent algorithms for sheet layout, estimation, and planning complement Esko’s existing software suite and the two companies will work together to develop next-generation integrated solutions.

“Converters are coming under increasing pressure to deliver more volume with shorter print runs to bring versatility to the market, while the adoption of digital printing continues to grow,” said Mattias Byström, Vice President and Group Executive Product Identification, Danaher Corporation. “This acquisition demonstrates our ongoing commitment to providing integrated software and hardware solutions that accelerate the go-to-market process for consumer-packaged goods.”

Mattias explained that the combined solutions within its software platform enable Esko to better serve its customers in the packaging, label, and wide format markets.

Mattias Byström concluded: “This acquisition also underlines our commitment to delivering the tools that serve to connect brands and converters upstream. For all our customers continuing their digital transformation journey, the integration of these next generation tools means businesses will be able to digitise, automate and connect more efficiently to drive significant workflow and operational advantages, as well as sustainability benefits.”

Gallus one poised to transform the industry by opening significant business diversification and growth opportunities for converters

- Gallus one poised to transform the industry by opening significant business diversification and growth opportunities for converters

- Company announces new Gallus Experience Centre designed to increase cross industry collaboration, innovation and success

- Joint development by HEIDELBERG and Gallus – integration into Prinect workflow

Gallus today announces the launch of its first fully digital label press, the Gallus One. Marking a ground-breaking new addition to the company’s conventional and hybrid portfolio of label presses, the Gallus One has been specifically designed to remove the Total Cost of Ownership (TCO) barrier for the adoption of reel-to-reel digital labels with the highest level of automation and cloud-based technologies. In doing so, it provides brands, for the first time, with access to cost effective and sustainable, high quality digital labels.

Engineered to spark a transformation across the industry, the Gallus One is built on the market leading Gallus Labelmaster press platform. As a 340-mm wide roll-to-roll UV inkjet digital inline labels press, Gallus One utilises a host of impressive features to achieve high levels of automation and press efficiency, with unrivalled UV inkjet print quality and stand-out print speeds of up to 70 metres per minute. With the new press available to pre-order, Gallus hopes to reinvent the way in which converters approach digital label printing – providing either a standalone digital offering, or a complimentary service within a traditional analogue operation.

“With the launch of the Gallus One, we are doing more than just bringing a new press to market – we’re providing a unique solution that has the capability to drive the next big opportunity in labels,” explains Dario Urbinati, Chief Sales & Service Director, Gallus Group. “With cloud capabilities in-built within Gallus One, you can not only enjoy remote set-up, but transparent performance monitoring and standardisation across your press portfolio and manufacturing sites. In conjunction with the sophisticated press design the Gallus One offers a complete reel-to-reel digital label solution, including all the software and hardware necessary to produce high quality, profitable digital labels. All this, with the highest level of automation available, and the most competitive TCO.”

“Offering all the familiarity benefits of a Labelmaster, Gallus One is a complete solution and not just a standalone print engine. Within the new Gallus One eco system, users have state of the art inkjet technology, a new Gallus One ink set, sophisticated workflow software and a new predictive press monitoring service to ensure minimum press downtime. All of these Gallus elements working in harmony, has enabled us to dramatically increase press efficiency and productivity, to unlock this new market opportunity.”

Joined development by HEIDELBERG and Gallus – integration into Prinect

Bringing together almost a century of experience in leading the narrow-web industry, together with the invaluable expertise and key resources of HEIDELBERG, Gallus has capitalised on the strengths of both businesses to develop Gallus One. For instance, HEIDELBERG’s ink testing laboratories were leveraged to develop digital inks specifically for the Gallus One’s Fuji Dimatix print heads - with a second lab utilised to optimise its waveform design, enabling better print performance. The Gallus One also integrates fully with the industry standard cloud-based workflow software, HEIDELBERG Prinect. Prinect allows production managers from start-up label businesses to large and mature label operations, to access insights and production data to ensure optimum production – and they can do that remotely across a secure network, from any smart device.

With its portfolio of cutting-edge technologies now extending across the conventional, hybrid and digital label markets, the launch of Gallus One enables the company to meet the needs of customers across each corner of the narrow web labels market.

Dr. Frank Schaum, CEO Gallus Group, concludes: “Gallus One is an important addition to our portfolio. It provides customers with a unique opportunity to pioneer a new and complimentary category of label service in the quest for significant business growth and differentiation.”

“But Gallus One isn’t the only exciting initiative we’re launching today. We are delighted to announce the creation of a new ‘Gallus Experience Center’ - currently being built in St. Gallen, Switzerland and expected to open late this year. As part of our vision for realising ‘the label industry of the future’, the new facility has been specifically designed to aid collaboration across the industry. Once open, we will invite customers, brands and suppliers from across the eco system to use the new facility to meet and share solutions, as well as develop new ideas to help solve key industry issues and create new opportunities.”

General Formulations, a leading manufacturer of Pressure Sensitive Films, is pleased to announce the launch of three NEW AutoMark Cast films; GF 830 AutoMark Cast with DRIFT Technology and two complimentary cast laminates, GF 831 AutoMark Cast Gloss UV Laminate and GF 840 AutoMark Cast Matte UV Laminate.

Joining the cast family with already popular GF 242 OptiMark Cast Optically Clear UV Laminate, is GF 830 AutoMark Cast with DRIFT Technology. This premium full-body gloss white wrap film is designed to meet the long-term demands of full or partial vehicle wraps as well as many other graphic applications. The DRIFT Technology and adhesive combination offer the right amount of adhesive tack and Micro Air Egress channels that make application quick, easy, and bubble-free.

GF 830 AutoMark Cast provides an excellent white point, delivering the perfect solution for high-quality printing across Eco-Solvent, Solvent, Latex, and UV print systems. For your preferred finish, UV protection, and added durability, pair GF 830 with GF 242 or the NEW GF 831 or GF 840 cast laminates.

Integrate is being held in Sydney from 17-19 August. It is Australia's leading platform dedicated to helping businesses harness the power of AV to transform customer experiences. It empo...

August 09 2022

Integrate is being held in Sydney from 17-19 August. It is Australia's leading platform dedicated to helping businesses harness the power of AV to transform customer experiences. It empowers the AV industry and technology professionals to share insights, source the latest in technology and collaborate to harness the potential of AV technologies. It is dedicated to bringing real world innovation directly to Asia Pacific AV buyers and driving the next revolution of AV and Digital Signage evolution.

As an Integrate supporting partner, ASGA has secured a 10% discount for its members to attend the optional Integrate & AVIXA Speaker Series being run in conjunction with the free expo.

“With digital signage playing a such a key role in signage today, we see this partnership as an opportunity to educate the sign industry on the latest products and trends in this space,” said ASGA President, Mick Harrold.

“Integrate visitors will be able to see the latest advances in LCD, LED and Projection as well the newest products on the market to help create immersive digital experiences. The optional Integrate & AVIXA Speaker Series that is being held in conjunction with the expo includes the topic ‘Digital Signage – Market Trends & Drivers & New Approaches to Integration’. With knowledge being key to having a competitive edge in the sign industry, this topic will be of interest to sign makers that currently offering or are seeking to offer, digital signage technology to their customers.”

Visit https://bit.ly/3BCeCPK for more details and to register to attend Integrate. ASGA members can obtain a 10% discount promo code to attend the speaker program by emailing admin@signs.org.au.

Epson returns to EduTech this year showcasing its popular range of education technology solutions, including ultra-short throw laser projectors and Heat-Free Technology printers, from 10 - ...

August 09 2022

Epson returns to EduTech this year showcasing its popular range of education technology solutions, including ultra-short throw laser projectors and Heat-Free Technology printers, from 10 - 11 August at the Melbourne Convention and Exhibition Centre (MCEC) on stand 222.

While conventional whiteboards and panels are limited to pre-determined height and width, projectors have no such constraints. At EduTech Epson will demonstrate how you can easily set the size of the interactive area to fit the available space in your classroom.

You will also discover the Epson Inkjet advantage on their stand by comparing the performance of inkjet and laser devices which will help you make a sustainable printing choice. With less energy use and fewer replacement parts,

Epson Heat-Free Technology increases productivity and reduces environmental impact without compromise.

Visitors to Epson’s stand will also be able to see exactly why ‘Size Matters’, particularly for education environments, by comparing different screen sizes and viewing angles on the stand.

EB-1485Fi

Featured in this space and powered by breakthrough laser technology, will be the interactive EB-1485Fi projector demonstrating how you can transform yesterday’s classroom into tomorrow’s collaborative learning space. It will compare a projected image onto 120-inch screen alongside a 75-inch panel for a true comparison.

WorkForce Pro WF-C579R printer

In the Heat-Free Technology area Epson will demonstrate its WorkForce Pro WF-C579R printer, bringing its signature inkjet technology, with low environmental impact, low intervention and high productivity, to workgroups wanting A4 mono and colour print capability. The multi-function WF-C579R colour printer offers significant Total Cost of Ownership (TCO) savings. The impressive ink yields of up to 50,000 pages for black and 20,000 pages for colour – amongst the highest in the segment – help to deliver this low TCO, while offering minimal user intervention.

August 09 2022

Herma has launched 152C, a new wraparound labeler signaling the new clean design, which will be soon extended to other machines. The new concept offers a wide range of benefits, from greater modular flexibility and ease of cleaning to enhanced sustainability.

Clean design marks a significant departure from the machine concept that is now being phased out visually and from a functional perspective. Thanks to sealed drill holes, a minimum of gaps and slots, and cladding with rounded corners, the hygiene-driven design of the updated machines offers a high degree of protection against contamination and facilitates cleaning and maintenance.

The machine frame uses elements from large-scale production that are shortened to the required lengths and thus conserve resources. Functional modules, such as the conveyor, labeling station and signal column, are attached exclusively to frame elements.

‘For our customers, this further enhances and accelerates machine availability because, thanks to their overarching compatibility, the functional modules are universal and can be pre-assembled from stock. When service requests arise, these modules can also be exchanged or retrofitted quickly. The machines are therefore highly future-proof and sustainable,’ said Erik Bächle, labeling machines development chief at Herma.

A further feature of the clean design concept is a lower centre of gravity, making labelling machines more stable, robust and suitable for the rigours of everyday operation. In addition, the clean design machines can be picked up by lift trucks more easily and securely.

‘For Herma, already an acknowledged pioneer of modular design in our industry, the development of a clean design principle represented a logical next step. It expresses our undertaking to customers as regards dependability, performance and innovation through a clear design vocabulary and well-conceived construction,’ added Bächle.

For the machine frame, the clean design envisages aluminium and stainless-steel variants.

‘No matter what our customers’ requirements relating to hygiene standards, there’s no need to accept any compromises when it comes to machine selection or performance,’ said Bächle.

Herma is now supplying the clean design machines in EU and US versions. Especially for multinational operators, this simplifies the standardisation of procurement and production processes across multiple facilities.

A newly developed online configurator will allow even complex labelling machines to be built on screen, including a visual presentation of individual functions in real time while talking to the customer. This tool enhances clarity and speeds up order processing.

August 09 2022

Jet Technologies is thrilled to be expanding into a new, substantially larger Victorian HQ. Almost 3 times larger than our existing site, the expanded site allows us to stock a wider range of products in Victoria, enabling us to better serve our Victorian clients.

Please note that there will be no despatches on Friday 19th of August from Melbourne due to the move.

Kindly update your records with our new address:

Jet Technologies Victoria

7 Yazaki Way, Carrum Downs VIC 3201

For any inquiries, please contact customer service on 02 8399 4999 or email us at orders@jet-ap.com

Landa Digital Printing today announces that it has opened a new European consumables manufacturing facility, based in Sittard, The Netherlands. Producing the revolutionary Landa Nanoink used to power Landa S10 and S10P Nanographic Printing Presses, the new site enables the company to double consumables production and support the rapid growth in demand for ink due to soaring customer print volumes.

By manufacturing in mainland Europe, the company has dramatically shortened its lead times for consumables and increased its production capacity. It has also reduced its environmental impact by reducing the shipment of raw materials and finished goods required to produce its products. Designed to improve its consumables supply chain, the new facility ensures market leading service to its portfolio of European customers and their international brands.

Gil Oron, CEO, Landa Digital Printing comments: “Our new Sittard site is geared towards sustainability, service reliability and business growth. It provides Landa customers with local supply, which in times of very challenging worldwide logistics and parts supplies, offers considerable reassurance. What’s more, with customer production volumes increasing daily, this also ensures prompt and reliable delivery too – crucial in increasing efficiency.”

The new Landa facility provides consumables for its revolutionary and unique portfolio of Nanographic Printing Presses, designed to address a huge gap in the market for cost effective short to medium run mainstream packaging and commercial jobs. Solutions include the Landa S10 Nanographic Printing Press - a B1 solution designed for mainstream packaging and converting industries - and the Landa S10P Nanographic Printing Press, which is ideal for two-sided B1 general commercial printing.

Gil Oron, concludes: “Our new European facility is another example of our long term commitment to the European market, and our ability to be the change-maker that the industry needs. Landa continues to revolutionise and digitise the mass production printing industry.”

www.landanano.com

August 02 2022

Ball & Doggett are pleased to announce they have reached agreement to acquire leading Sign, Display & Digital supplier Conect Enterprises with a completion date set for the 1st of September 2022.

As Australia’s largest distributor of printable materials and consumables this acquisition further solidifies Ball & Doggett’s already strong position as a leading supplier into the Signage market.

Conect Enterprises was established in 1985 and is privately owned by Tony & Pam Coniglio, who will stay with the business for a short transition period. Conect has offices and distribution sites in both NSW and Victoria.

This is an exciting next step in our diversification strategy and we welcome the Conect Team into the Ball & Doggett (JP) family. This partnership will serve to provide greater value for the combined customer and supplier base as well as our staff.

Conect will continue to trade independently for the time being to ensure a smooth transition for staff, customers and suppliers.

Tony Coniglio, owner of Conect, says ‘’this acquisition is good for our customers, suppliers and staff. Ball & Doggett have the resources and infrastructure to take the business forward. It is about leveraging our combined strengths to provide greater value and options to support our customers”.

For further information contact Tony Bertrand, National Marketing Manager Ball & Doggett 0409 206 235 or contact conect@ballanddoggett.com.au

Solimar Systems, Inc., the provider of leading workflow software solutions for print production and digital communications, has released version 9.2 of its dynamic output management suite, Solimar® Print Director™ Enterprise (SPDE).

SPDE plays a crucial role in the overall Solimar Chemistry™ platform, providing an onramp to PDF-centric workflows while offering robust data optimizations, conversions, job management, and device connectivity for non-PDF workflows. SPDE connects host computers to production print devices that normally do not directly interact, to provide a powerful enterprise output management system.

Enhanced with new capabilities to expand its application and ease of use, SPDE version 9.2 features an intuitive operator interface for improved overall job control, enhanced IPP security for compliance, and introduces new Job Definition Format (JDF) compatibility to better control finishing elements of the print process.

JDF Finishing Controls remove the need to convert PDF files into PostScript or other formats to further optimize the workflow. PDF finishing information in SPDE 9.2 is controlled by a rules-based system of JDF commands using conditional logic to map PDF file finishing commands to the required JDF format, saving processing and production time. Printers can now edit, maintain and add finishing commands throughout a PDF workflow, even when the source file is not PDF, thus supporting multiple industry standards.

With Solimar’s continued focus on data security, the Secure IPP Print Server™ within SPDE 9.2 now features additional authentication support, further strengthening this crucial capability. Other enhancements include an expanded API for the submission of jobs, font upgrades, and job ticket conversions.

The award-winning ReadyPDF® optimization module has been enhanced in version 9.2 with new features to expand its applications and simplify its user interface. ReadyPDF now includes a new Preflight Mode that can detect certain PDF characteristics, such as image and text properties, and invoke necessary optimizations as needed. For example, if a user needs to flatten transparencies in a PDF, ReadyPDF can determine if there are transparency elements in the file. If no transparency elements are used, those jobs can bypass the flattening process, saving significant processing time.

ReadyPDF is available as a module within SPDE 9.2 and as a stand-alone subscription offering, ReadyPDF Prepress Server.

These additional capabilities underscore the flexibility and utility of SPDE for managing high-volume variable print. SPDE not only allows users to flexibly integrate various applications and printing systems, but to do so across a broad spectrum of data streams including AFP, IPDS, Xerox VIPP, PostScript, PCL, Xerox DJDE/Metacode, TIFF, and PDF. Moreover, SPDE is integrated with other components of the Solimar Chemistry™ platform to enable intelligent batching, job and piece-level tracking, postal optimization and other valuable capabilities."

Mary Ann Rowan, Chief Experience Officer at Solimar Systems, comments: “We're thrilled to bring these major upgrades to our global customers. Some early adopters have shared that they are now able to retain jobs in-house that were previously outsourced which improves their overall ROI.” Rowan continues, “SPDE 9.2, and all of our innovative products, are off-the-shelf configurable by end users and do not require coding or custom services. Solimar solutions are available through our extensive partner network enabling customers to choose the best solutions for their production environment. This makes Solimar the preferred partner for many global businesses.”

Learn more about this latest SPDE upgrade in this short presentation: https://vimeo.com/718097877?embedded=true&source=vimeo_logo&owner=50616180

August 02 2022

UV Unlimited allows you to print directly onto the UV transfer media and place a dishwasher-safe image to virtually any surface including glass, metal cups, rubber, wood, containers, plastics, sporting goods, industrial equipment, and more.

Xante Corporation is proud to introduce “UV Unlimited” the latest breakthrough in new UV print technology. UV Unlimited allows you to print directly onto the UV transfer media and place a dishwasher-safe image to virtually any surface including glass, metal cups, rubber, wood, containers, plastics, sporting goods, industrial equipment, and more.

Xante’s X-Series UV Inkjet Flatbed printers apply ink to a layer of clear glue transfer media. A second adhesive layer is then laminated to the printed sheet. Once the two sheets have bonded, the ink can then adhere to most any surface. It is the perfect solution. It is truly is UV unlimited.

Robert C. Ross, CEO and President of Xante, stated “UV Unlimited is clearly a breakthrough technology, vastly expanding the capabilities of UV printing. Paired with any of our X-series UV printers, UV Unlimited can create new, high-margin applications for our customers.”

The UV Unlimited Transfer System is now available for purchase and delivery. The system comes complete with everything needed to produce images that can be placed on nearly any surface. It includes a laminator that has been specifically calibrated to produce perfect transfer images, a starter pack of twenty A3 transfer media sheets, and one transfer media laminate roll. Additional transfer sheets and laminate rolls can be purchased as needed.

X-Rite Incorporated, Pantone LLC, and Sun Chemical announce a new Eco-Kraft corrugated board-dependent color library for PantoneLIVE, a cloud-based digital color standard ecosystem. The new library enables converters to set achievable expectations to produce Pantone color standards on corrugated board made from recycled materials.

Now available as part of the PantoneLIVE Production – Print and Packaging subscription, the Eco-Kraft library was built using a brown Kraft substrate with a substantially higher recycled content than in the previous libraries. The result is a base substrate color that is more chromatic. This new library captures the closest achievable match to the core Pantone Matching System colors that can be produced on Eco-Kraft substrate using water-based inks and flexographic printing.

“Consumers consider sustainability when making purchasing decisions and companies are responding by incorporating more recycled materials in their packaging,” said Chris Brooks, President, X-Rite. “With the addition of the Eco-Kraft library in PantoneLIVE, brands and their packaging suppliers can now see how a Pantone color will reproduce on recycled Eco-Kraft board and get recommendations on setting achievable and realistic color targets for this sustainable packaging substrate.”

“The market trend towards more sustainable substrates and inks opened a space for the creation of a new PantoneLIVE dependant library for the water-based market,” said Nicolas Betin, global sustainability business leader, Sun Chemical.

“We are glad to support X-Rite and Pantone in creating this new water-based library and we are ready at the local level with color management tools and processes to support customers matching these new color targets,” added Patrice Aurenty, global business leader for Color Management, Sun Chemical.

With over 84,000 Pantone color choices for the top packaging and printing applications, PantoneLIVE enables brand owners, designers, and printers to feel confident in selecting color standards that are achievable in production, resulting in improved speed to market and reduced press approvals, waste and rework.

PantoneLIVE is part of X-Rite’s digital color workflow and integrates with InkFormulation Software, ColorCert Suite, and X-Rite spectrophotometers such as the new eXact 2. With streamlined color communication, faster ink formulation, and improved quality control, brands, and printers can drive efficiencies and improve sustainability efforts.

For more information on PantoneLIVE, visit https://www.xrite.com/pantonelive-production

The outlook for this is profiled in a new detailed market data study – The Future of Inkjet Printing to 2027 – authored by Smithers print consultant Sean Smyth.

Supply chain and print buying changes, combined with technology advances mean digital print – and inkjet in particular – is now the most important print segment for innovation and market growth. The outlook for this is profiled in a new detailed market data study – The Future of Inkjet Printing to 2027 – authored by Smithers print consultant Sean Smyth.

In contrast to competing analogue processes, inkjet is forecast for strong future growth for a global market worth $86.8 billion in 2022. A compound annual growth rate (CAGR) of 8.2% for 2022-2027 will drive this value to $128.9 billion in 2027. While inkjet is well established in some lower-run applications, faster presses mean that it is becoming more cost-competitive for longer print runs, even as many customers have revised their print buying strategies. This is reflected in the volume of inkjet prints, which will rise from 1.0 trillion A4 print equivalents (2022) to 1.7 trillion (2027) – equivalent to a 10.0% CAGR for 2022-2027.

The greatest expansion will come in packaging applications with installations of the latest dedicated presses for corrugated, cartonboard and flexible substrates. Inkjet is also broadening its market with double-digit growth forecast across the same period in commercial print, books, catalogues, magazines and directories. As the technology suite for inkjet improves it is increasingly pushing electrophotography (toner) print out of several core markets.

Smithers’ comprehensive market data is combined with critical analysis of the technical developments that will shape and support the future evolution of inkjet printing:

These – along with complimentary market trends – are examined in-depth in the new Smithers study The Future of Inkjet Printing to 2027.

Its comprehensive market data forecasts are presented in over 250 data tables and figures, segmenting this dynamic sector by: End-use application (Books, Magazines, Newspapers, Directories, Catalogues, Advertising Print, Commercial Print, Photobooks, Transactional print, Security print, Graphics, Labels, Packaging, and eight functional/industrial print markets; Ink type (Solvent, Water-based, Radcure, Other); Eight geographic regions (North America, Latin America, Western Europe, Eastern Europe, Asia, Africa, Australasia, The Middle East) and 58 leading national markets worldwide.

The authoritative technical and market guide is available to purchase now

New Zealand Sign and Graphics distributor, Computaleta, have acqui...

July 26 2022

New Zealand Sign and Graphics distributor, Computaleta, have acquired a much larger building in Rosedale on the North Shore, Auckland, that will add another third capacity to their warehousing space in the city.

The new building, located at 9C Douglas Alexander Parade in Rosedale, will be operational from Monday, July 25.

Director, Arlette Farland (pictured right), says the additional space will enable them to better forward order and stock more products in light of the global supply chain issues.

“We’ve had a branch on the North Shore since 2003, and we are very grateful to those customers locally who support us. We must continue to invest in the area and in our stock to ensure consistency of supply to all our customers across Auckland. This larger building gives us the capacity to do so.”

Computaleta recently won HP’s Digital Partner of the Year Award, and the new purchase also executes its growth strategy for wide-format print hardware. It will eventually be home to a new flatbed showroom for HP and Summa.

“We want New Zealand sign and print companies to have access to the very best in sustainable technology, and this new purchase will be the Flatbed Home in Auckland for HP and Summa’s best printing and finishing equipment.”

The company also has a large warehouse and branch in Onehunga that they purchased in January 2021, as well as four other locations throughout New Zealand.

EFI Reggiani, the industrial textile printing business of printing technology company Electronics For Imaging, Inc. (EFI), has broken ground on a new textile campus to accommodate ongoing growth. The new 20,000-square-metre campus in Comun Nuovo, Bergamo, Italy, is expected to be completed midyear in 2023.

“EFI Reggiani has always worked diligently to take our offerings to the next level, thinking ahead and developing high-tech, high-quality and reliable textile solutions,” said EFI Reggiani Senior Vice President and General Manager Adele Genoni. “The new campus is an important step in our journey, and it is proof of EFI’s strong commitment to continued development of the textiles business unit. Not only will this provide us more space to continue our growth, but it will also be a welcoming and sustainable environment for our employees.”

The new facility was designed with environmental sustainability and employee well-being in mind. That focus includes plans to install 400 kilowatts of solar panels supplying 60% of the facility’s total energy requirements. Moreover, the building will benefit from superior thermal insulation that will ensure a reduction in heating and cooling costs. Numerous skylights in the facility will provide better natural lighting and a reduction in artificial lighting usage.

Green space on the campus was a priority in the design process, covering an estimated 20% of the total area. For a more welcoming work environment, the campus will also feature a canteen and gymnasium for employee use.

A 3,000-square-metre demo centre in the new facility will be nearly twice as large as the current EFI Reggiani demo centre in Grassobbio, Italy, offering a high-end, high-tech showcase for state-of-the-art EFI Reggiani printers, as well as Mezzera pre- and post-treatment and Jaeggli yarn treatment products. The demo centre will also feature EFI Reggiani’s recently acquired portfolio of Inèdit raster image processing (RIP) and workflow software solutions.

Since the launch of its first analogue printer, to its newest digital solutions, EFI Reggiani has at its core a heritage and expertise that have contributed to the transformation of the textile industry worldwide. With its total commitment to providing “Innovation in Green,” EFI Reggiani’s leadership is the result of extensive research targeted at improving productivity, quality and sustainability in its customers’ operations. Building on Reggiani’s 75+ year legacy, the company is focused on optimising the textile manufacturing process – and reducing energy use, water consumption and overall environmental impact – to ensure customers’ business growth and profitability.

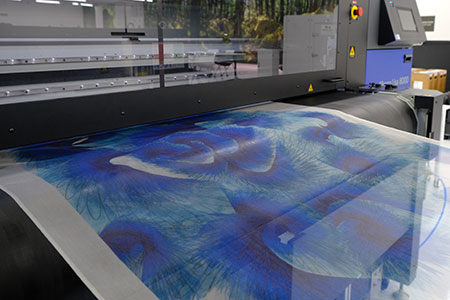

Over the years, EFI Reggiani’s product portfolio has continued to expand, ranging from rotary and flatbed printing machines, to scanning/multi-pass digital printers, to the world’s fastest digital textile printer – an award-winning EFI Reggiani BOLT single-pass inkjet printer that operates at 90 metres per minute. Additional leading-edge, best-in-class solutions in the portfolio include the world’s fastest scanning printer for textile, an EFI Reggiani HYPERmodel that can output up to 20 linear metres per minute at peak speed.

Known for high quality, flexibility and reliability, EFI Reggiani is also an innovator in ink – a recognised leader as one of the only companies to manufacture the full range of inks used in industrial textile manufacturing.

Epson provided support to fashion designer Yuima Nakazato for his collection shown at the 2022 Paris Haute Couture Collection on July 7, 2022. Epson supported the production of the fashions and stage design from June 3 to June 28.

Yuima Nakazato's fashion house has a vision that the evolution of clothing will create an even richer future. To fulfil its responsibility for the future, the fashion house has continued to carefully select the materials used and the sources from which they are procured. It has always sought to create clothing that is designed to be worn for a long time and then recycled.

Epson endorses the Yuima Nakazato vision and recently used digital textile printing technology to support the reproduction of the delicate textures and colours of hand-painted materials to the exacting requirements of the fashion house as well as producing the works with a reduced environmental impact. Yuima Nakazato's designs were faithfully reproduced on extremely thin (0.07 mm) silk organdy fabric that was used for some of the fashions using a Mona Lisa digital inkjet textile printer at the Solution Center in Epson's Fujimi Plant.

Digital textile printing does not require printing plates, so it is ideally suited for the rapid production of material in only the amount required. And, since these designs were printed using pigment ink, which requires fewer steps than a dye ink printing process, Yuima Nakazato was able to work on the designs for the fashion collection until shortly before the show. Inkjet textile printing has a far smaller environmental footprint than conventional textile printing because it uses only a tiny fraction of the amount of water.

In addition to supporting clothing production, Epson also supported the stage design by using its digital printing technology in the production of paper sculptures. These sculptures were important elements that helped to create the vision of the blue-themed collection. The entire stage was enshrouded in images of Earth that were hand-painted by Yuima Nakazato. These images were enlarged and printed over a total of 832 square meters of print paper using an SC-P20050 inkjet printer at the LFP Solution Center in Epson's Hirooka Office.

Armatures were used to support the printed paper to create three-dimensional objects d'art in the staging area. The armatures were made from used paper from within Epson that was processed using Epson's Dry Fibre Technology*. Epson collected the decorative pieces used for the collection after the show ended and plans to discuss their use in other applications with Yuima Nakazato.

Epson is committed to co-creating with partners to make a wide variety of its customers' creations possible, and through its initiatives to reduce environmental impacts, realise its vision of achieving sustainability and enriching communities.

- New generation film Supreme PPF Xtreme to safeguard vehicles’ painted surfaces

July 19 2022

- New generation film Supreme PPF Xtreme to safeguard vehicles’ painted surfaces

Avery Dennison Graphics Solutions today launched its next generation paint protection film, SupremeTM PPF Xtreme, aimed at empowering vehicle owners to safeguard their investment against the impact of extreme environmental conditions in Australia and New Zealand.

Built on the foundation of Avery Dennison’s top-of-the-range paint protection film, the new Supreme PPF Xtreme is a step forward in performance with an extended 10-year warranty across all zones, optimised installation performance, and enhanced self-healing and stain resistance.

“As materials science is in our DNA, the Avery Dennison team is driven to meet the constantly evolving needs of our customers through innovation,” said Chris Sherry, Senior Product Manager, Australia and New Zealand, Avery Dennison Graphics Solutions. “We are, therefore, proud to announce significant technological upgrades to our premium paint protection film, creating the new Supreme PPF Xtreme.”

“The new Supreme PPF Xtreme will help owners safeguard the painted surfaces of their vehicles against the impact of challenging road and environmental conditions across the ANZ region.”

The new Supreme PPF Xtreme, designed to answer vehicle owners’ need for a highly durable film for the extreme environment in the ANZ region, is a virtually invisible ultra gloss, non- yellowing, and self-healing polyurethane film that enhances a car’s appearance and preserves its resale value.

“Throughout our product development stage, we engaged with our installer community intending to deliver a film that not only protects against impacts from road debris, and environmental contamination, but also installs efficiently,” added Chris. “We want to ensure the best installation experience for our installers. We are confident that the new Supreme PPF Xtreme has the right balance of conformability and adhesive tack, giving installers of all levels faster and easier installation the first time.”

The Supreme PPF Xtreme is available through our authorised Avery Dennison Graphic Solutions distributors in Australia and New Zealand. We invite automotive businesses and installers to be an Avery Dennison [Insider] to receive priority news and alerts from the company directly at

https://graphicsap.averydennison.com/en/home/news/subscribe.h

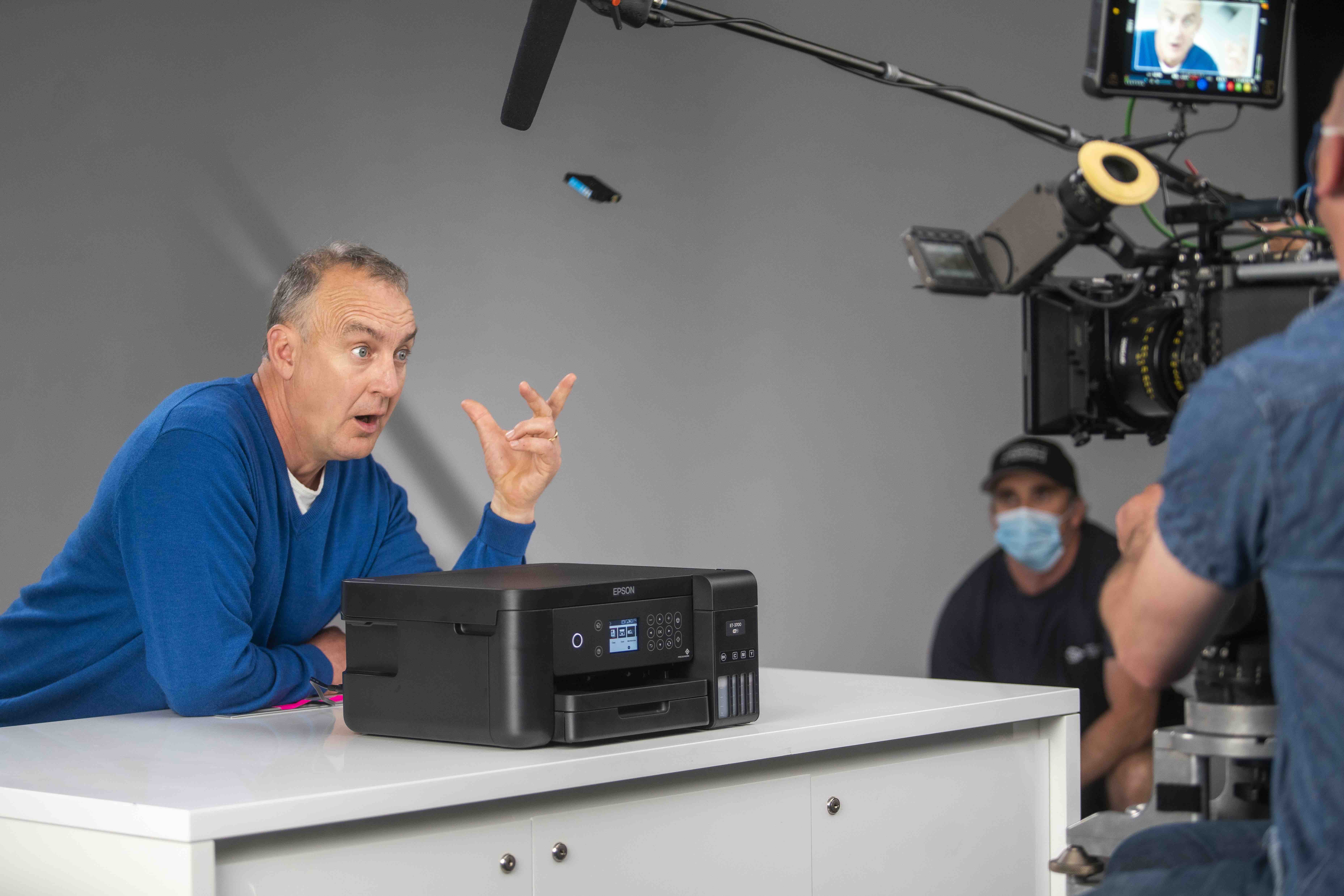

Epson has celebrated its global number 1 market share1 status in Continuous Ink Supply System printers – where Epson’s EcoTank models account for over 65%2 of all printers sold in the category in Australia alone – with its second TV, radio, VOD and digital campaign fronted by comedy legend Jimeoin in Australia and New Zealand.

The two-month campaign incorporates multiple channels including free-to-air and catch-up television, digital, radio and social media and sees Jimeoin front and centre promoting Epson’s EcoTank printers and how they are easy to use with their supersized ink tanks that come with enough ink in the box to print thousands of pages.

Cumulative global sales of Epson’s EcoTank high-capacity ink tank inkjet printers recently topped 67.9 million units3. Epson first launched EcoTank high-capacity ink tank inkjet printers in October 2010, in Indonesia. EcoTank’s popularity then grew consistently, and the range is now sold in over 170 countries and regions across the world.

As well as selling over 67.9 million units, by saving on plastic, which is the main component of ink cartridges, CO2 emissions are considerably lower than they would have been if all these units had been cartridge printers4.

By using big refillable ink tanks, EcoTank printers can save you thousands of dollars compared to cartridge-based printers. Also, as EcoTank printers use Epson’s patented Heat-Free PrecisionCore™ printheads, they consume less energy too, especially compared to power-hungry laser printers. When, eventually, an EcoTank does run out of ink, refill bottles start from as low as just $14.99 each for thousands more pages worth of ink and continued hassle-free printing.

To mark the new campaign Jimeoin also gave a hilarious performance to all of Epson Australia and New Zealand’s staff at their recent “Kick Off” meeting at Commbank Stadium in Parramatta.

To learn more about EcoTank cartridge-free printers go to: www.epson.com.au/ecotank and www.epson.co.nz/ecotank

Epson aspires to achieve sustainability and enrich communities over the long term. Epson sees its inclusion in this index as objective evidence that its efforts to address environmental and social issues are recognised, and that it is seen as a sustainable company.

Epson is committed to co-creating sustainable and enriched communities by addressing solutions to environmental problems and other societal issues, as well as by providing surprise and delight that exceed customer expectations. This commitment is aligned with the sustainable development goals (SDGs) adopted by the United Nations.

Epson will contribute to the achievement of a better and more sustainable future as envisioned by the SDGs by using their efficient, compact, and precision technologies and digital technology to connect people, things, and information and by applying new ideas and methods to create fresh value.

The FTSE4Good Index Series was created by global index provider FTSE Russell and is designed to measure the performance of companies that demonstrate strong environmental, social and governance (ESG) practices. The FTSE4Good Index Series is widely used to create and evaluate sustainable investment funds and other financial products.

Transparent management and clearly defined ESG criteria make FTSE4Good indexes suitable tools to be used by a wide variety of market participants when creating or assessing sustainable investment products. FTSE4Good indexes can be used in four main ways:

• Financial products - as tools in the creation of index-tracking investments, financial instruments or fund products focused on sustainable investment.

• Research - to identify environmentally and socially sustainable companies.

• Reference - as a transparent and evolving global ESG standard against which companies can assess their progress and achievement.

• Benchmarking - as a benchmark index to track the performance of sustainable investment portfolios.

Epson’s CSR and SDGs

In the 2020 fiscal year, Epson identified four materialities (priority issues) that it should address in order to contribute to solutions to societal issues and progress toward its aspirational goal of achieving sustainability and enriching communities. Epson selected 12 key sustainability topics that it will act on to achieve the materialities.

After analysing the relationship between the 12 key sustainability topics and the 17 Sustainable Development Goals (SDGs) based on the 169 SDG targets, Epson found that the actions they are currently taking will contribute to all 17 of the SDGs (please click on the link below for more details).

Epson will help to achieve the SDGs by acting on the key sustainability topics, thereby achieving sustainability and enriching communities.

https://global.epson.com/SR/csr_initiative/sdgs.html

Meteor Inkjet Ltd, leading supplier of electronics, software, tools and services for industrial inkjet, has developed a new electronics platform to avoid reliance on key computer chips that are in worldwide short supply in 2022.

Meteor’s Print Controller Card (PCC) is used by hundreds of OEM customers around the world to synchronise image data sent by a PC to arrays of printheads including those by Epson, FUJIFILM Dimatix, Konica Minolta, Kyocera, Seiko Instruments, Toshiba TEC, Xaar and Xerox. The PCC was reliant upon an electronic component which is in critically short supply this year, potentially delaying more than £4 million (British pounds) of printhead drive electronics.

Anticipating these long-term supply issues, Meteor embarked upon a fast-track project to rearchitect the PCC. In quick response to the diminishing availability of alternative components, Meteor identified a suitable replacement chip that was freely available in high volume, taking the unusual step to acquire more than a year’s supply of the new chip before even starting development. The risk of this decision paid off, and Meteor’s new PCC2 print controller is now shipping in production quantities.

“Meteor’s products are trusted as the most reliable components with which to build an industrial inkjet printer,” said Jonathan Wilson, Meteor’s vice president of business development. “Our customer base, having grown over the last decade to make Meteor the largest datapath supplier in the industry, had to wait for us to find a solution to what continues to be the worst chip supply shortage ever. I am delighted that their patience is now being rewarded, and we will quickly clear the order backlog that developed over the last two quarters.”

During the PCC2 development, Meteor worked closely with a handful of companies including Dantex Digital, a leading digital press manufacturer and long-time Meteor customer. Richard Hall, Dantex R&D director, comments, “We have been pleased to participate as a beta site for Meteor’s PCC2 development. Supply chain issues, and particularly shortages of electronic components, have taken their toll and we are happy to work with collaborative partners that demonstrate resilience and customer focus.”

Clive Ayling, Meteor’s managing director, comments, “It is a source of immense pride for everyone at Meteor that this enormous task has been achieved. In particular, praise is due to our engineering team in Cambridge who pivoted their attention to this one project which has resulted in a robust,

backward-compatible replacement product for our customers in record time.”

The advanced chipset used in the PCC2 brings with it increased speed as well as the potential for future functionality enhancements. For now, Meteor’s customers and partners are relieved to have once again an abundant supply of print controllers. The industrial inkjet industry, which is accustomed to year-on-year growth in breadth of application and penetration into markets previously dominated by conventional printing or manufacturing, now has an essential component back in production.