See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

The global leader in label and package printing equipment has partnered with Domino to further extend its Digital Series iQ product line.As the digital printing market conti...

October 31 2023

The global leader in label and package printing equipment has partnered with Domino to further extend its Digital Series iQ product line.

As the digital printing market continues to grow, Mark Andy has partnered with Domino to bring another solution to converters looking to expand their print portfolio.

DSiQ-R is a retrofit digital inkjet module designed to seamlessly integrate with Mark Andy Evolution and Performance Series press platforms to create a fully hybrid, single-pass production solution. The 600dpi engine, powered by Domino technology, can accommodate web widths up to 13.4 inch (340mm) and in production mode can run up to 230 fpm (70m/min), bringing higher productivity to versioning and multi-SKU jobs. The module is available with four (CMYK) or five (WW+CMYK) color modes, and mounts directly to the press, making high-end label enhancements including cold foil, lamination or diecutting a reality in single-pass production.

The DSiQ-R is equipped with iTech features including ActiFlow2, CleanCap2 and SetAlign, resulting in consistent density and quality across the printed web. Software integration is seamless, with the Digital Front End (DFE) included, and a single user interface makes job set-up and management intuitive. And all equipment is compatible with Mark Andy’s sMArt link technology, a cloud-based job management system that monitors real-time press data to optimize pressroom workflows from job to job and shift-to-shift, ensuring most efficient and effective print production.

For more information or to schedule a discussion with a specialist, contact Mark Andy. Mark Andy Marketing Team

When Dayne Nankervis, CEO of leading trade printer CMYKhub, surveys the new Horizon binding line at his company’s West Heidelberg premises, it’s not only with a sense of profession...

October 31 2023

When Dayne Nankervis, CEO of leading trade printer CMYKhub, surveys the new Horizon binding line at his company’s West Heidelberg premises, it’s not only with a sense of professional excitement at its potential but also the feeling that it is symbolic of a ‘full circle’ moment.

Dayne, his siblings and cousins, spent many childhood hours sorting and collating book sections in the bindery at Impact Printing, a pioneering Melbourne print shop owned and run by Dayne’s father, Garry, and Garry’s brothers Greg and Ray.

“In particular, when school yearbooks started to come in around October each year, it was all hands on deck,” Dayne recalls.

Fast forward to November 2022, and Dayne – together with family members and most of his executive team – found themselves once again in the bindery hand collating yearbooks, “and not doing it very efficiently,” he says wryly.

“When a job comes in over a Web2Print service like ours, it’s difficult to say no, but the truth is that we were not really geared up to do book work efficiently or profitably.

“Occasionally, we would turn down a job at quoting stage because it simply wasn’t feasible, or we’d outsource the finishing – but that added time and cost to the job. More often, we would say yes, then find ourselves on the factory floor at nights and on weekend to meet the commitment.”

It’s the kind of dilemma, ironically, that CMYKhub exists to solve.

“Print is a very diverse sector, but not every print business is equipped to produce every printed product,” Dayne points out. “That’s where CMYKhub comes in – we invest so our resellers can offer the widest possible range of solutions to their customers.”

This ethos had seen CMYKhub grow into a diverse operation which offers everything from business cards and flyers, to commercial digital and offset jobs, wide-format sign and display solutions, and most recently labels. As a trade supplier, all must be supplied to the highest standards, in the shortest deadlines and at the best possible price to allow print service providers to add their own margin.

“We are continually monitoring trends to identify new ways for our resellers to grow their markets,” Dayne says. “We have grown and diversified organically over the years in response to their evolving needs, and we’ll continue to invest to support their success.”

Earlier this year, CMYKhub introduced a now-growing range of label products. Now, their sights have turned to book production, driven by a significant resurgence in demand for conventional books.

“It may seem strange in the era of the iPad and Kindle, but while there are always ebbs and flows in the annual publishing cycle we are absolutely seeing an increase in demand, particularly for short run books,” Dayne says, attributing this to the growth of self-publishing and the trend for larger publishers to print local runs of even global best-sellers on demand.

“Consumers today better understand the inherent sustainability of paper products today and appreciate that the experience of reading a physical book has real benefits. There has also been a huge resurgence of book-like products including notepads and diaries during COVID – the pandemic reminded people that print has the ability to make a powerful physical connection with absent staff and customers,” he says. “We see no sign of demand slowing.”

While CMYKhub has always technically been able to produce digital or offset books, the margins – as with most print – were tight and what little profit there may have been was quickly eaten up by the need for manual processing.

“If there’s one thing I hate, it’s inefficiency,” Dayne says grimly. “Going down to the bindery to see people hand-collating frustrated me no end.”

Eventually, with the busy end-of-year school book season looming, the company decided it was time to ‘gear up, or get out’. That’s when supplier Currie Group came up with an option too good to refuse – a hybrid Horizon binding line straight out of the showroom in Japan.

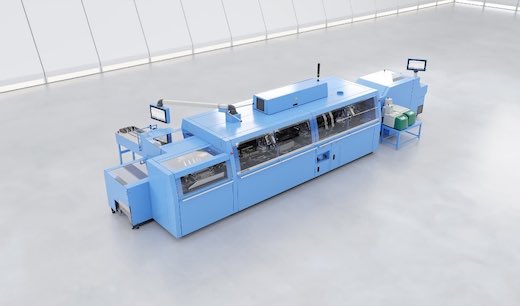

Installed in September by Currie Group engineers supported by Horizon technical specialists flown in from Japan, the new Horizon CABS4000 binding line comprises a 12-station gatherer which can handle A1 or A2 folded offset sections and a digital inserting station for pre-collated book blocks.

Once collated, sections are conveyed to a nine-clamp perfect binder which can handle both PUR and EVA glues, although CMYKhub opts for the stronger PUR finish as a default for customers. The binder can process books individually, or accumulate multiple products up to 60mm in height, before moving on to a HT-1000 variable three-knife trimming station.

Integrated weighing stations sit between sections to check for discrepancies in the collation, and a sophisticated optical inspection system with ‘auto-stop’ error detection ensures the right cover goes on the right book. In short, the system is designed to guarantee only ‘perfectly-bound books with perfectly-matched covers’ ever reach the in-built conveyor-stacker at the end of the line.

A high speed of 4000 units per hour makes this line a productive workhorse, however it’s the computer-aided binding (CAB) features which really make the difference for short-run book batches, with barcode-driven automated programming of all stations optimising set-up and job changeover times.

The new line is currently operating from a former storage area in one of the company’s West Heidelberg factories. Next year, it will be relocated with two offset presses to a brand-new factory currently under construction, forming a book production hub to service the company’s national customer base.

To ensure print capacity keeps pace with the new system, CMYKhub has lifted offset and digital production to 24 hours a day, six days a week. The intention is to streamline the system further by batch producing ‘like’ products.

“The Horizon is incredibly versatile, giving us the flexibility to choose the most efficient and profitable production method for each book project without being hampered by binding constraints,” Dayne points out.

“It will allow our resellers to support the growth of small brands and also look after larger customers by offering print-on-demand efficiencies. While the sweet spot will probably be runs between 2 – 4,000 copies, we anticipate being able to handle much shorter and much longer run lengths. Basically, we’d consider doing a single book if we can do it profitably and keep the price reasonable for our resellers.”

With the new line now in full flight producing the first of the 2023 School Yearbooks, Dayne says the company couldn’t be happier

“The addition of the Horizon binding line was very much a case of the right opportunity, at the right time, and from the right people,” says Dayne, who rates the company’s partnership with Currie Group as pivotal to their success.

“Like us, Currie Group are problem-solvers. Just as we try to support our customers success, they are always looking for ways to help us grow and diversify. Up until now, we’ve really been hampered in growing book printing, but the new Horizon from Currie Group has taken the brakes off…and given us our weekends back this summer.

“Books are back, and we are going full steam ahead!”

Muller Martini, a pioneer in print finishing solutions, is proud to unveil the Antaro perfect binder, available in two versions. This groundbreaking new binder platform redefines e...

October 31 2023

Muller Martini, a pioneer in print finishing solutions, is proud to unveil the Antaro perfect binder, available in two versions. This groundbreaking new binder platform redefines efficiency and versatility within a smaller footprint.

A Perfect Binder for Every NeedMuller Martini's Antaro binder is designed to meet the evolving demands of the print industry for both on-demand and conventional, offset applications:

· Antaro Digital: For digital finishing applications, the Antaro Digital stands in a class of its own, producing print-on-demand books at an unparalleled rate of up to 2,000 cycles per hour – an industry-leading achievement, while requiring minimal staffing.

· Antaro: For offset print applications, the Antaro delivers at an impressive rate of up to 4,000 cycles per hour. Its robust performance makes it the perfect choice for short-run offset production in small spaces.

Unparalleled Flexibility and Investment Protection

The Antaro platform brings flexibility and investment protection to the forefront. Its modular, expandable design caters to both digital nearline/inline production and conventional production environments:

· Antaro Digital: This version takes single book production to a new level, offering automation with manual feed or inline connection to the SigmaLine Compact digital book production system. With six clamps, it achieves an impressive output of 2,000 books per hour. Plus, its compact design delivers the same output with fewer than half the operators required by current single-book production solutions.

· Antaro: When combined with a gatherer and equipped with 12 clamps, the Antaro shines in offset runs, delivering an output of 4,000 cycles per hour.

Efficiency through Automation

Both Antaro models feature a continuously running swing clamp system, ensuring the smooth horizontal transport of book blocks through the machine. The Antaro Digital's unique clamp design enables the continuous production of brochures with varying block thicknesses of up to 20 mm, all at the highest performance level. These thickness variations are changed automatically, ensuring an unsurpassed productivity rate of up to 2,000 copies per hour for digitally printed products.

Exceptional Quality Guaranteed

The Antaro is equipped with two spine preparation stations, guaranteeing the highest quality book binding. The system utilizes EVA and PUR adhesives, backed by a glue monitoring system in the PUR nozzle for precise glue application. Replacing the gluing units is straightforward, enhancing maintenance efficiency.

The Antaro Digital features a newly designed drum coverfeeder coupled with a cover buffer wheel for reliable separation of covers and uninterrupted production through continuous feeding. Its barcode reader ensures a exact 100% match between book blocks and covers. The system's buffer wheel creates sufficient distance for barcode reading, enabling automatic responses in case of mismatches without interrupting the binding process. Together with the standard cover reject feature positioned in front of the scoring device, this system achieves a new level of productivity through waste reduction.

Unrivaled Versatility

The Antaro platform flawlessly combines trusted technology from Muller Martini with innovative features. It accommodates all conventional types of book blocks, including signature stacks, pre-glued or thread-sewn book blocks, as well as single-sheet stacks. Even without an inline connection, manual feeding is ergonomic and efficient. The platform surpasses other systems available today with its exceptional end-product delivery capabilities, spanning softcover brochures, hardcover book blocks, flex brochures, glued book blocks, and layflat brochures. Set to redefine the print finishing landscape, it offers unmatched efficiency, quality, and adaptability.

Scodix, the leading provider of digital print solutions for the graphic arts industry, is pleased to announce that Ricoh USA, Inc., a digital information services provider and majo...

October 31 2023

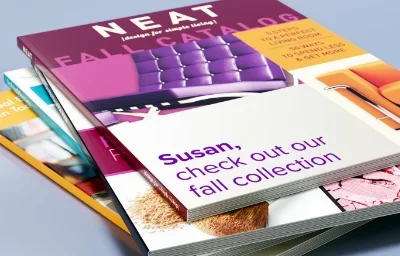

Scodix, the leading provider of digital print solutions for the graphic arts industry, is pleased to announce that Ricoh USA, Inc., a digital information services provider and major print industry player, has become a distributor for Scodix in the United States. This strategic partnership will strengthen and support Scodix in its goal of expanding market presence and providing economic and sustainable embellishment solutions to a larger network of print providers.

“This partnership is a deliberate step forward in providing maximum value to our customers, empowering them to increase the worth of their printed products,” says Gavin Jordan-Smith, Senior Vice President and General Manager, Head of Global Sales Strategy Division & RICOH Graphic Communications North America Sales, RICOH Graphic Communications. “Including Scodix embellishment solutions within our portfolio supports our competitive approach, delivering applications to the market that can catapult printers in their quest for competitive differentiation and heightened brand awareness.”

Scodix offers a variety of tools that enable brands to achieve a high level of luxury and customization in their print products and packaging. With an extensive range of top-tier embellishment options, including Smart High Definition (SHD) quality, and independently verified sustainability practices, Scodix has the capability to enhance the consumer experience, while also providing measurable economic and environmental benefits.

“Ricoh has a stellar reputation of understanding market needs in the graphic communications space, making them a perfect partner for Scodix,” said Mark Nixon, EVP Global Sales & Marketing at Scodix. “This collaboration allows us to work together to meet customer needs and create a portfolio that stands out with the goal of increasing profits through embellishment. Scodix has an easy go-to-market solution that supports the graphic arts community in providing printed products that effectively engage their audiences. With the wide range of embellishment effects achieved on a single Scodix press, we are able to offer businesses an opportunity for embellishment that was once considered too expensive. With Scodix, production costs and waste are minimized through the most sustainable methodology in the market.”

With an impressive 90%[1] of commercial printers anticipating that embellishment will play a vital role in their digital print growth strategies, Scodix' Ultra series of digital presses presents an opportunity for both in-plant and commercial print operations including book publishers, direct mail printers, prototypers, trade finishers, packaging, and folding carton printers.

The Scodix range of digital enhancement solutions seamlessly aligns with Ricoh's award-winning sheet-fed digital press portfolio. This ensures that adding Scodix to a Ricoh digital press delivers top-quality embellishments for high-end luxury prints designed to captivate attention, bolster commercial print profits, and rival both the economics and quality of conventional methods.

A global leader in pressure sensitive adhesive films, Avery Dennison Graphics Solutions, is partnering with Siser®, a leader in the world of personalisation and customisation through their premi...

October 24 2023

A global leader in pressure sensitive adhesive films, Avery Dennison Graphics Solutions, is partnering with Siser®, a leader in the world of personalisation and customisation through their premium heat-transfer products, to empower crafters across Australia and New Zealand with cutting-edge pressure-sensitive film products designed to expand crafting possibilities.

“The partnership between Avery Dennison and Siser is an exciting collaboration,” said Jordan Leach, Business Director, Graphics Solutions, Australia and New Zealand and ASEAN, Avery Dennison. “The combination of Siser’s consumer-focused expertise and our leadership in innovation and material science has created a new set of best-in-class products for the vibrant crafting community. We are proud to see Siser introduce these innovative, high-quality and industry-leading products to creative professionals and crafters across ANZ for the first time.”

This partnership is Avery Dennison's inaugural foray into the crafting industry. The Australia and New Zealand region is the first in Asia Pacific to offer the new Siser® by Avery Dennison brand, which leverages Avery Dennison’s technology leadership in pressure sensitive vinyl (PSV) and Siser's expertise in consumer crafting and heat-transfer vinyl. Crafters can harness its potential to create unique gifts and execute DIY projects suitable for indoor and outdoor environments.

Product lines under the Siser® by Avery Dennison brand include the remarkable EasyPSV® Starling™ range and the dazzling EasyPSV® Glitter collection. Crafted with precision, the EasyPSV® Starling™ range features 57 solid colours in both gloss and matte finishes, while the EasyPSV® Glitter range boasts 17 stunning glitter colours. These offerings give crafters and creative professionals an expansive pallet to manifest their artistic visions.

Some of the remarkable features that set EasyPSV® apart are its ease of use, versatility and durability. The range offers industry-leading ease of weeding1 and precise conversion on plotters. It will adhere strongly to a wide range of materials, as well as being dishwasher safe for up to 80 washes2. This sets an industry standard for resilience even in the face of frequent use.

Crafting professionals can learn where to procure these groundbreaking crafting solutions by visiting the following website: https://siseranz.com/

Three New Mesmerising Colours for Supreme Wrapping Film™ in Australia and New Zealand Avery Dennison Graphics Solutions introduced its 2023 Celestial Satins colour collection today, feat...

October 24 2023

Three New Mesmerising Colours for Supreme Wrapping Film™ in Australia and New Zealand

Avery Dennison Graphics Solutions introduced its 2023 Celestial Satins colour collection today, featuring three exciting new colour additions to the company’s Supreme Wrapping Film™ ColorFlow™ series, to the Australian and New Zealand market.

The three new colours, Satin Solar Dawn, Satin Moonstone and Satin Frozen Ocean, reveal a celestial light effect in these satin-finished films as a beautiful shifting spectrum of fluid colour. These iridescent shades transform a vehicle into a work of art as light moves around its contours with a mesmerising effect.

“The Celestial Satin range is an exceptional addition to our Supreme Wrapping Film colour change portfolio,” said Chris Sherry, Product Manager of Avery Dennison Graphics Solutions Australia and New Zealand. “These new captivating ColorFlow films are poised to inspire wrap designers to craft impactful visual effects that leave a lasting impression.”

The Avery Dennison Supreme Wrapping Film portfolio, renowned in the wrap installation community for its premium vehicle wraps, offers excellent conformability, durability, and performance. It has the innovative Easy Apply™ RS technology, which allows for rapid installation and easy repositioning, elimination of wrinkles or bubbles for a smooth finish, and damage-free wrap removal.

The three new Supreme Wrapping Film ColorFlow Celestial Satin colours are available for purchase via all Avery Dennison authorised distributors in Australia and New Zealand.

It was a warm welcome for the sign, graphics and vehicle wrapping professionals who attended the launch of the new Melbourne offices and showroom for Hexis Australia.

October 24 2023

It was a warm welcome for the sign, graphics and vehicle wrapping professionals who attended the launch of the new Melbourne offices and showroom for Hexis Australia.

Hexis global CEO Clément Mateu, Australian Managing Director, Ian Parsonson and the full Hexis Melbourne team welcomed guests to the new, 1300m2 facility in outer-suburban Keysborough.

Mateu spoke about Hexis commitment to its Corporate Social Responsibility (CSR) program and environmental leadership, as well as the achievements of their recycling program. Mateu also spoke passionately about their commitment to meet the challenges facing the plastics industry and the company’s responsible approach to product development and sustainability.

"For five years now, we have invested in our CSR policy,” says Mateu. “We are heavily focussed on our commitment to the environment. Because of this we have launched our PVC recycling program which first started in France. Today we recycle the kraft liner, the PE liner and PVC with adhesive.”

The new Melbourne centre comprises a spacious warehouse, office space for a growing team. There are currently three sales representatives, plus administrative staff. Hexis Australia has plans to build the team significantly next year and add a showroom area that will feature a colourful display of the latest Hexis innovations. These include Pure Zone® antimicrobial films, Bodyfence® self-healing vehicle body protection films, Skintac® series of films for digital imaging, the Hexis Textile range, and its Smartac and Supatac plotter films.

The spacious warehouse, now stocked with four full container loads of product, took the team weeks to unpack and organise. The company can now hold more than double its stock holding capacity in the south, providing faster and easier delivery particularly to customers in Southern NSW, Melbourne, Adelaide, and Perth.

In addition, Hexis Australia is planning a purpose-built training facility with capacity for three vehicles, which will be added to the end of the warehouse, to enable expansion of the company’s in-house training and certification program. Mateu says this is a strong focus for the group globally, with its team of ‘HEX’perts’ committed to ensuring customers can enjoy the full range of possibilities from the Hexis range of self-adhesive films.

“It has taken us a while to get to this stage, but our customers are already seeing the benefits of adding direct supply from Melbourne,” said Hexis Australia Managing Director, Ian Parsonson. “The additional facility enables reliable overnight supply to customers up and down the east coast and in Adelaide.”

Parsonson, who is normally based at the company’s other major supply centre in Yatala, Queensland, said the past couple of months had been busy setting up the new warehouse, relocating staff and unpacking four full containers of stock ready for distribution.

“What also sets Hexis apart also is our direct relationship with the manufacturer – if there is something a customer needs which we do not have in stock, we have a direct line to the factory in France and can generally get product here by air in five or six days.”

Mateu concurs, confirming their absolute commitment to Australia and expressing his confidence that the effective doubling of stock holdings here will enable more customers to benefit from the product range, driving a more regular delivery of stock from France.

Surveying the new warehouse, he says, “We have always had a strong commitment to the Australian market and work closely together with Ian and the team here. This is a great new facility and gives the team plenty to sell – we are looking forward to seeing what they can do, and to making sure from our part that we continue to supply plenty of product to restock these shelves regularly.”

So, now the doors are open in Melbourne, what about the future?

“We have quite a few things in the pipeline,” Parsonson says with a smile. “There will certainly be further growth of our footprint across Australia – and I promise the West has not been forgotten – but we must always make sure that we consolidate along the way and that we move ahead from a strong and stable position.”

With this impressive new Melbourne facility added to its Queensland operation, the innovative Hexis product range, and the strong support of Hexis in France, that position seems assured.

www.hexis-graphics.com/en/australia/

LogoJET, a global leader in direct-to-substrate printers for specialty items, is excited to announce the launch of its game-changing Strata Series at Print United 2023 in Atlanta, ...

October 24 2023

LogoJET, a global leader in direct-to-substrate printers for specialty items, is excited to announce the launch of its game-changing Strata Series at Print United 2023 in Atlanta, Georgia, taking place from October 18-20th. With 18-years of delivering top-of-the-line small format printers, LogoJET expands its product offering into the large format flatbed sector to meet its customers’ growing needs and reinforces its commitment to profitable, scalable solutions.

Breaking New Ground with the Strata Series

The Strata Series features two groundbreaking flatbed printers: Luna, with a print area of 3.2 feet by 5.9 feet, and Terra, boasting a generous print area of 4.9 feet by 8.2 feet. These additions represent industrial engineering excellence, built to provide consistent, high-quality prints across a diverse range of substrates.

The move into large format printing isn’t just an expansion—it’s a revolution that aligns perfectly with LogoJET’s mission to empower their customers with profitable solutions that scale, and backed with LogoJET’s 3-Year Warranty and 5-Star Support.

Susan Cox, CEO of LogoJET, shared her enthusiasm: “As we mark our 18th year in the business, LogoJET is thrilled to unveil the Strata Series, a transformative line of medium and large format flatbed printers designed to elevate what is possible in signage and specialty printing. Expanding into large format has been a pivotal decision that aligns with our mission to provide our customers with scalable, profitable solutions. The Luna and Terra represent the future of LogoJET—innovative, customer-focused, and limitless. We can’t wait to introduce them at Print United 2023.”

logojet.com

Vanguard Digital Printing Systems, a Durst Group Company, introduces the Vanguard VK3220T-HS ultra-high production UV-LED flatbed.This printer offers a larger bed...

October 24 2023

Vanguard Digital Printing Systems, a Durst Group Company, introduces the Vanguard VK3220T-HS ultra-high production UV-LED flatbed.

This printer offers a larger bed size, up to three rows of industrial printheads for maximum productivity, an electromagnetic carriage drive system as well as field-upgradeability. It offers up to 1800 dpi print resolution and speeds up to 3,875 sf/h.

The VK3220T-HS redefines the meaning of productivity on a 3.2 x 2 meter (126” x 80”) UV-LED flatbed. With up to three Rows of printheads, print speeds can reach over 3,800 square feet per hour.

Utilising 4 picoliter drop size Kyocera printheads and a high-speed magnetic drive, there’s no compromise on speed to achieve remarkable quality. With the ability to add channels for additional speed or application potential after installation, the VK3220T-HS can grow alongside business possibilities.

Jim Peterson, COO and founding partner, Vanguard Digital North America, said, “The VK3220T-HS is the culmination of years of technological advancements and our response to the demands of the market. We are dedicated to delivering the best printers available, and through our innovation and commitment to our customers, we have created the new benchmark for speed and quality, with a focus on productivity and efficiency. The VK3220T-HS symbolises the start of a new chapter for Vanguard Digital, and we are so proud to share it with the North American market.”

The VK3220T-HS can print on nearly any substrate up to 4 inches thick and is driven by an electromagnetic drive. Other features include auto height detection, one-touch pin registration, front-to-back and back-to-front printing, water-cooled LED curing technology, and ionization bars.

Accelerates Digital Transformation for Print Service Providers Seeking New Ways to Engage CustomersRICOH Pro Z75 Digital Press offers businesses a clear path from...

October 24 2023

Accelerates Digital Transformation for Print Service Providers Seeking New Ways to Engage Customers

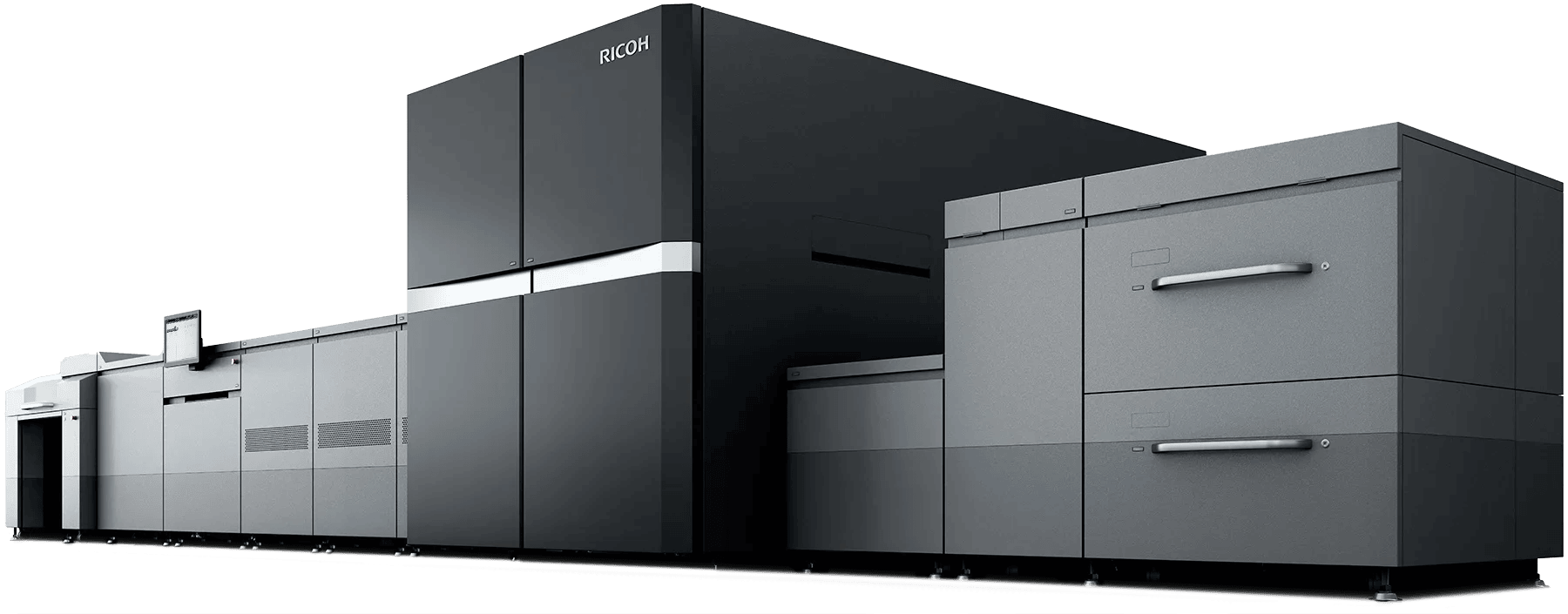

RICOH Pro Z75 Digital Press offers businesses a clear path from offset to digital with global availability after driving efficiency, adding production flexibility, and expanding application opportunities for beta customer.

Ricoh announced the global debut of the RICOH Pro Z75 Digital Press, the first B2 perfecting (auto-duplexing) sheetfed inkjet platform using aqueous ink, accelerating the shift from offset to digital with higher print quality, faster turnaround times and fewer demands on staff following successful in-market testing. The press will be officially available for public orders in North America as of November 15, 2023, with orders for immediate placement expected based on strong interest across international markets.

In June 2022, Heeter Printing – a Pittsburgh area full-service secure marketing provider for highly demanding industries like insurance, retail, and gaming – teamed up with Ricoh to serve as the official beta site for the iF DESIGN AWARD winning B2 sheetfed inkjet press platform.

“There’s a significant gap in the industry today when it comes to the size of jobs that are most efficient to run on offset, continuous feed inkjet and cutsheet digital production platforms,” said Kirk Schlecker, President, Heeter Printing. “The RICOH Pro Z75 is like a multitool for our operation. It gives us flexibility in how we produce customer jobs by bridging that gap, with the productivity to take on work from our traditional 40” offset, inkjet web and cutsheet toner devices. It combines the image quality, efficiency, print size, substrate flexibility and economics that allow us to say ‘yes’ to more jobs, and ultimately deliver a better customer experience for our clients. With the support Ricoh provides and their commitment to stand behind their products, the RICOH Pro Z75 makes a compelling case for any print service provider looking to achieve what they once could have only imagined.”

The RICOH Pro Z75 delivers the advantages of a sheetfed platform with the low running costs and high productivity of inkjet. It offers print speeds of up to 4,500 sheets per hour (SPH) in straight printing or 2,250 SPH in duplex / perfecting printing. Stainless steel piezo print heads bring 1,200 dpi native resolution at all speeds with 4 Colour (CMYK) pigment-based inks, while the proprietary drying system greatly reduces cockling and waviness ensuring high-quality results ready for immediate finishing. The RICOH Pro Z75 also expands substrate flexibility, handling uncoated, inkjet treated and offset coated media up to 400 gsm (24pt) with a max sheet size of 23 x 29-inches.

“As shorter runs and increasing demand for data-driven communications push print service providers to adapt their production strategies, we are helping them leverage the latest hardware, software and data to become indispensable to their end customers with the RICOH Pro Z75 as a powerful example of that commitment in action," said Gavin Jordan-Smith, Senior Vice President and General Manager, Head of Global Sales Strategy Division & RICOH Graphic Communications North America Sales, RICOH Graphic Communications. “The result is a new level of performance that enables easier, faster and more profitable production of applications like direct mail, postcards, marketing materials and other commercial print work.”

Beyond the high print speeds and automatic duplexing capabilities, the press incorporates significant automation solutions and an intuitive control panel to reduce the need for operator intervention and improve shift efficiency. A heavy-duty, offset-like build quality and advanced, durable printheads are designed to maximize press uptime and availability. Attention to detail from the air-assisted sheet feeding that minimises feed and paper transport issues, to a configurable high-capacity stacker that delivers accurate, flush paper stacking, streamlines the entire job process.

Designed for print businesses managing high volumes of jobs that require reliable uptime and significant throughput capacity, the new production inkjet platform is backed by Ricoh’s global organisation that is committed to customer success. Customers will have access to Ricoh’s best-in-class proprietary workflow automation solutions, such as RICOH TotalFlow™ Producer, RICOH TotalFlow BatchBuilder™ and RICOH Supervisor™, plus consulting services and full-service marketing solutions such as MarcomCentral®, to maximise return-on-investment and business value.

For more information about the RICOH Pro Z75 or to get in touch with a Ricoh sales representative visit https://takealookatricohproduction.com/production-inkjet/sheet-fed-inkjet/ricoh-pro-z75/.

Epson has announced that it is sponsoring Onigiri Action 2023 as an official partner. Onigiri Action 2023, which will run throughout October and November, is an initiative of TABLE FOR TWO (TFT)...

October 17 2023

Epson has announced that it is sponsoring Onigiri Action 2023 as an official partner. Onigiri Action 2023, which will run throughout October and November, is an initiative of TABLE FOR TWO (TFT), a non-profit organisation dedicated to fighting world hunger.

According to estimates by several United Nations agencies, as many as 783 million people globally faced hunger in 2022. Hunger remains significantly above pre-COVID pandemic levels, with over 122 million more people facing hunger now than in 2019*.

Epson aspires to achieve sustainability and enrich communities through social programs in areas such as environment, society, and economics. The company is also working to redistribute stable economic value and correct gender, regional, and other disparities.

Epson endorses Onigiri Action's commitment to social cooperation and balancingsocial responsibility and economic viability and is proud to be a new sponsor of this social initiative aimed at addressing the growing problem of global hunger.

Under the Onigiri Action scheme, each photo of onigiri, a Japanese rice ball, posted to the campaign website or on social media (Instagram, X [formerly Twitter] and Facebook) with the hashtag #OnigiriAction helps provide five school meals to children in need in Africa and Asia through TFT.

Visit the Onigiri Action campaign site here: https://onigiri-action.com/en/

Currie Group Offers Sign & Display…By AppointmentWhat if you could see end-to-end solutions for sign and display, catch up on the very latest tec...

October 17 2023

Currie Group Offers Sign & Display…By Appointment

What if you could see end-to-end solutions for sign and display, catch up on the very latest technical insights from the market leaders in large-format, and chat to a team of experts about your specific business requirements? That’s exactly what’s on offer in Sydney next month at the Currie Group Sign & Display…By Appointment event.

For Sydneysiders, the event will be the first opportunity to see Currie Group’s sign and display solutions in person, and it will also be the first outing of the company’s newly-expanded range of large-format print solutions since it announced its new channel partnership with Canon Production Printing Australia on the market-leading Arizona and Colorado printer ranges.

Paul Whitehead, Business Unit Manager – Sign & Display for Currie Group, is clearly delighted to finally have the opportunity to showcase the company’s sign & display range in the Harbour city, saying it’s well overdue.

“We actually launched the EFI partnership in Melbourne two years ago, and included that range on our stand at PacPrint Melbourne in 2022, but with supply chain issues over the past few years it has been challenging to secure machines for a showroom display in Sydney,” Whitehead explains.

“Those printers which could be landed in Australia were inevitably already earmarked for print businesses who were keen to have them installed. The customer comes first…but it meant our showroom missed out.”

Now that things are settling down on the shipping front, Whitehead says it’s exciting to be able to commit to having both an EFI and one of the latest Canon Colorado M-Series printers in the Sydney showroom for at least six months.

“We’re very excited to be able to bring these products to Sydney…and we are going to make the most of it, kicking off with this customer event,” he says.

The three-day Sign & Display…By Appointment event will run from Tuesday 14 to Thursday 16 November inclusive and will, as its name suggests, provide print businesses with the opportunity to make personal appointments to hear about the latest developments across the ranges and see both print engines live in action. There will also be the opportunity to discuss their business’ unique requirements with the Currie Group team, not only in the sign & display space but also across commercial print, labels and packaging.

Whitehead, together with Ashley Playford-Browne who recently joined the Currie Group team in Sydney, will lead with presentations on the company’s entire sign & display portfolio – now arguably the most extensive in the production wide-format space in the Australian market - and the 12-month outlook for the sector. They will be backed by the full Sydney service and support team, who will also be on hand to discuss technical and practical aspects of investment.

“Of course, as well as these presentations, the appointments will also feature live demonstrations of two flagship machines – the EFI Pro 30h hybrid flatbed/roll-fed LED printer, which was launched at PacPrint just over a year ago and is being demonstrated for the very first time in New South Wales, and a brand new, top-of-the-range Canon Colorado M-Series 1.6m roll-to-roll printer,” Whitehead announces.

“We will also be carrying a full suite of samples and prints from the entire EFI and Canon ranges, so customers can not only access personalised advice on the available options, but get a tangible feel for what is best for their business … and of course, ask any questions.”

As well as showcasing the new channel partnership with Canon Production Printing Australia, the event will also demonstrate Currie Group’s wider connections, with a number of leading names participating to enable demonstrations of true, end-to-end production.

“We operate in a very tactile, applications-focused industry, so seeing these technologies in action – and being able to see, touch and feel what is possible by using various printer models – is absolutely critical to help businesses make sound investment decisions,” Whitehead acknowledges.

“Our experience, certainly, is that those who are able to experience technologies in person are able to more clearly see the potential for their business and invariably integrate their new equipment very successfully, often becoming long term customers.

“We are delighted to finally be able to present these outstanding solutions to businesses in Sydney and surrounds, and to be hosting our very first open house event since we announced our exciting new partnership with Canon Production Printing. It’s an incredibly exciting time for us, and for our customers, who now have access to solutions for every sign & display application, all in one place.”

While the new kit will be on display in the Sydney showroom for some months, there’s no question that the ‘by appointment’ event is the best opportunity for those serious about sign & display success to get the jump on the market.

There are four timeslots available on each of the three days, so you’ll have to move quickly to book. If you are interested in a live demonstration and a personal audience with sign & display experts and the wider Currie Group team, book as soon as possible via the dedicated booking link.CLICK HERE to book now!

For two days visitors can attend demonstrations on Mutoh’s Japanese made printers and learn how to print braille, promotional products, create their own jigs with the Mutoh 2.5D fe...

October 17 2023

For two days visitors can attend demonstrations on Mutoh’s Japanese made printers and learn how to print braille, promotional products, create their own jigs with the Mutoh 2.5D feature, on Mutoh’s award winning XpertJet 661UF UV printer.

Additionally, printing and cutting workflows will be demonstrated on Mutoh’s ‘space saving’, but 1370mm (54”) wide, XpertJet 1341SR Pro.

Canon announces a technology preview of the Canon LabelStream LS2000, a new 40m/min inkjet label press, at Canon Expo in Yokohama, Japan (19th – 20th October 2023). Designed for in...

October 17 2023

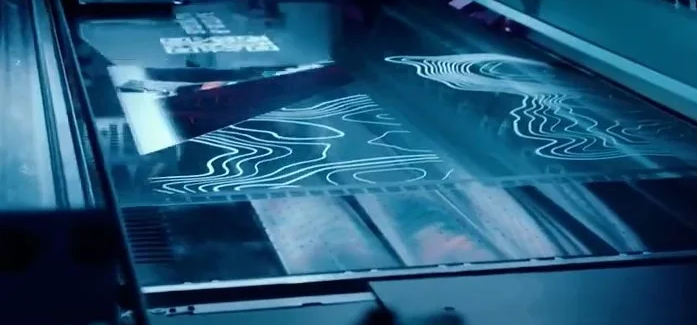

Canon announces a technology preview of the Canon LabelStream LS2000, a new 40m/min inkjet label press, at Canon Expo in Yokohama, Japan (19th – 20th October 2023). Designed for industrial-scale label printing, the LabelStream LS2000 is based on a new blend of innovative and proven Canon technologies. As Canon’s first water-based inkjet label press, the LabelStream LS2000 prints CMYK plus white on self-adhesive substrates including paper and film with a new ink set designed to comply with food safety standards. The LS2000 makes Canon’s LabelStream digital label press series accessible to a broader range of label converters serving industries including food and beverages, personal care, household goods and electronics, and the manufacturing of bespoke or customised products.

Built on water-based inkjet technology, the LabelStream LS2000 is the ideal solution for label converters looking for a reliable, productive, and flexible digital press that fulfils the demand for shorter runs of diverse, self-adhesive labels, produced against tighter deadlines. This demand results, amongst others, from the need to respond quickly to a growing array of different products, packaging innovations, and the challenges of an ever-changing supply chain. In Europe, visitors to drupa 2024 will be amongst the first to witness the output diversity of the LabelStream LS2000 on the Canon stand (Hall 8A, Stand B41).

Reliable, high-quality, label production with new printhead technologyThe LabelStream LS2000 is a five-colour (CMYK plus white) inkjet label press that prints at up to 40m/min with a maximum printing width of 340mm. The press features a new 2400 x 1200 dpi printhead with an ink circulation mechanism that keeps the ink moving along a precise flow path to the tips of all the nozzles, minimizing nozzle failure due to clogging and helping to extend the life of the printhead. For reliable and stable production, printhead maintenance and quality control are automated, as is colour measurement and adjustment, while the digital front end offers tight workflow integration for outstanding ease of use and operational efficiency.

Application flexibility with innovative ink technology designed for food safety compliance.The new inks in the LabelStream LS2000 are high-density, water-based polymer inks that have been developed specifically for the new printhead by Canon. Containing highly saturated pigments and producing a wide colour gamut, the inks form a very thin layer on the substrate that drastically reduces the scattering of light, resulting in superb colour reproduction. White ink comes as standard and allows for printing on transparent film and other media – it also produces high-opacity white, which can be used as an undercoat for other inks for vivid and clear colour printing. Suitable for a wide range of applications, the LabelStream LS2000 inks have also been designed to comply with several food safety standards.

Fast label production on a wide range of substratesLabels used on the exterior of food packaging and other everyday items, from personal care to household products, are often required to be produced in small batches and with fast delivery times due to shorter product lifecycles – and with printing speeds of up to 40m/min, the LabelStream LS2000 is equipped to deliver. The new label press will be able to flexibly handle substrates from coated to synthetic paper and film, including lower-heat-resistant film, opening up possibilities for diverse label applications. The thin ink layer of the print is almost imperceptible to the touch, which allows printed substrates – including textured media, chosen for a certain design – to maintain their original look and feel.

Jennifer Kolloczek, EMEA Planning, Marketing & Innovation Senior Director, Production Print at Canon Europe, comments, “While demand for labels continues to grow, converters are facing challenges, such as the increasing trend of shorter runs and the production of high-quality labels on demand, which continue to drive the adoption of digital printing technology. As our first water-based inkjet label press, the LabelStream LS2000 will offer converters the reliable productivity and speed needed to meet their customers’ demands and, thanks to its versatility and expected food safety compliance, will allow them to diversify their offering.”

The LabelStream LS2000 will become available in the EMEA region in early 2025. Additional product details will be provided in due course.

The new exhibition area offers customers and visitors close-up view of SCREEN’s innovative inkjet printing technology for label, commercial and packaging markets. Local MD Peter Sc...

October 17 2023

The new exhibition area offers customers and visitors close-up view of SCREEN’s innovative inkjet printing technology for label, commercial and packaging markets. Local MD Peter Scott visited the centre during Labelexpo, describing it as 'amazing.'

SCREEN Europe unveiled its new Inkjet Innovation Center (IIC) in Aalsmeer, the Netherlands, with a ‘Grand Opening’ exhibit late last month. For the first time, the leading manufacturer of inkjet digital printing equipment showcases all its series of innovative presses for label, packaging, commercial and CtP printing in one room. More than 100 customers, sales agents, partners and local community representatives attended the celebratory event at Screen Europe’s new headquarters.

SCREEN Grand opening of the IIC/HQ Sept 2023

“Establishing the IIC reflects our confidence in the status of the printing industry and Screen’s position as a leading player in the market for inkjet digital printing equipment,” said Mr. Eiji Kakiuchi, chairman Screen Holdings. He adds: “We overgrew our previous building due to our solid and steady growth in existing inkjet and CTP markets and also needed more space for the next wave of industrial inkjet digital innovations for both existing markets, such as label and commercial, as well as new markets such as flexible packaging.”

Chiyoda President Hiroyoshi Sato (L) and SCREEN GA President Yukiyoshi Tanaka confirm the PAC 830F deal.

In the 2,000m² showroom and demonstration center, visitors can explore Screen's inkjet digital printing solutions across three distinct product lines: Truepress JET for Commercial Printing and Direct Mail, Truepress LABEL for label printing, and the new Truepress PAC range for Flexible Packaging. The new IIC also showcases Screen's well-established CtP product range.

“In addition to showcasing our expanding range of digital printers, the Inkjet Innovation Center will serve as a hub for innovations in digital printing. Collaborating closely with our software and finishing partners, our aim is to provide customers with end-to-end printing solutions, offering a glimpse into the future of the printing industry,” said Osamu Yamagata, President Screen Europe.

Screen Europe was honoured to host distinguished guests, including Mr. AJ Kakiuchi, Chairman of Screen Holdings, Mr. Yukiyoshi Tanaka, President Screen Graphic Solutions, and Mr. Takanori Kakita, Advisor of Screen Graphic Solutions.

Also present was the esteemed Mayor of Aalsmeer, Mr. Gido Oude Kotte, for a momentous ribbon-cutting ceremony at the official Grand Opening event. Japanese drummers marked the occasion with a thrilling performance of traditional Taiko drums.

First PAC 830F flexible packaging press installed

The Screen Truepress PAC 830F, now entering the market

In other Screen news, Screen Japan and Chiyoda Gravure Printing have reached an agreement that will see them work together to drive the use of digital printing for flexible packaging materials. The initiative will use Screen's Truepress PAC 830F, a new water-based digital inkjet system that is capable of full-scale production of small to medium lot jobs, first announced in developement in 2020.

Countries worldwide have increasingly moved to create a sustainable society and the packaging industry has also seen a growing need for more environmentally - conscious production methods and greater responsibility in its supply chain. At the same time, maturing consumer preferences have also created a trend toward diversified small lot production using flexible packaging.

Pouches for pooches? Typical flexible packaging work printed inkjet on the PAC 830F - Pet food pouches

Solving the short-run issue

While gravure, and some Flexo printing has been the standard across the industry until recently, this method is best suited to large print runs. When it is used for small to medium lot work, a number of problems arise, including low productivity, significant strain on operators and considerable losses due to the discarding of unused products. Naturally, these issues have led affected companies to search for potential solutions.

Against this backdrop, Chiyoda and Screen GA have recently worked together to install the Truepress PAC 830F at Chiyoda’s facility. Screen has specifically developed this water-based digital inkjet press to enable full-scale mass production of small to medium lot jobs. Both companies have agreed to jointly drive the increased use of digital printing for flexible packaging, with the shared aims of expanding target applications for the Truepress PAC 830F as a production system, constructing an improved digital workflow, and identifying and resolving various issues that occur in small to medium lot production processes.

The two companies intend to pursue this initiative based on Chiyoda’s corporate philosophy of: “Trust, continuous growth and human resource development” as well as the Screen Group’s corporate purpose of “Innovation for a Sustainable World.” In addition to making a social contribution, they hope to upgrade the working environment at production sites for flexible packaging and deliver print quality that will make the world an evermore colorful place. The two companies cooperate closely in order to achieve the necessary technological innovations.

It is expected that a PAC 830F will be installed in the new IIC in The Netherlands, and may be exhibited at drupa 2024, late May-June in Düsseldorf, Germany.

Sales in Australia will be through Screen’s label press partner Jet Technologies

www.jet-ap.com

ENDS

Roland DG Corporation, a leading manufacturer of wide-format inkjet printers and printer/cutters worldwide, today announced that the TR2 Orange and Green inks used in the TrueVIS VG3/VG2/VF2 wide-f...

October 17 2023

Roland DG Corporation, a leading manufacturer of wide-format inkjet printers and printer/cutters worldwide, today announced that the TR2 Orange and Green inks used in the TrueVIS VG3/VG2/VF2 wide-format eco-solvent printer models are now compliant with the 3M™ MCS™ Warranty program. This is in addition to the previously announced CMYKLcLmLk.

The 3M™ MCS™ Warranty provides full, non-prorated protection for the intended life of each graphic, including fading, cracking, peeling and other aspects of graphic performance. The weathering technology and rigorous testing of ink and printer combinations that 3M stands behind with this warranty assures customers that the quality of their images will be maintained for the life of the graphic.

TR2 inks in CMYKLcLmLk were previously compliant with the 3M™ MCS™ Warranty Program, and now the Orange and Green inks are certified under the same program. Tony Miller, President of Roland DG’s Global Sales and Marketing Division said, “The combination of the TrueVIS series, which delivers rich printing expression with the power to excite hearts and minds, and 3M's highly durable graphic media and laminating films, enables the production of high-quality sign graphics that offer a long-term warranty with greater peace of mind than ever before. I believe that the TrueVIS series will help take our customers’ business success to the next level.”

To learn more about the Roland DG TrueVIS brand, please visit https://www.rolanddg.com.au/products/printers/truevis-brand-family

Fiery, LLC, the largest independent provider of digital front ends (DFEs), today announced the latest rele...

October 10 2023

Fiery, LLC, the largest independent provider of digital front ends (DFEs), today announced the latest release of the award-winning Digital Factory RIP software, making it easier than ever to create personalized, customized, and other specialty production products with perfect color accuracy through custom print modes and color profiles. Driving virtually all direct to film (DTF), direct to garment (DTG), sublimation, UV, toner transfer, and wide format print and cut devices, Digital Factory v11.1 features a more intuitive user interface, redesigned layouts, enhanced workflow automation, and true shape nesting. The new capabilities streamline print operations, save hours in production time, and increase profitability by reducing costly material waste.

“Customers expect quality, accuracy, and speed when it comes to direct to film and specialty print applications, and no other software RIP combines color accuracy with device support like Digital Factory,” said John Henze, Vice President, Sales and Marketing, Fiery. “Collaborating with our extensive customer base, we developed a next-generation interface with the user in mind. With this latest update to Digital Factory, businesses of all sizes canquickly find the right tools and dial in the perfect settings to achieve efficient, high-volume production with the highest possible quality.”

“Digital Factory v11 was already a favorite, but with the launch of v11.1, it has taken a giant leap forward,” said Tony Lee, Sales Director, All American Print Supply Co. “There’s simply no match out there for its excellence. The improvements are astounding – it’s now even better, cleaner, more intuitive, and easier to use than ever before. Digital Factory v11.1 sets a new standard for digital solutions, and it’s a joy to see how it continues to evolve and exceed expectations.”

Digital Factory offers powerful production management tools and color profiles to achieve stunning color reproduction and accuracy on the widest variety of substrates. New capabilities in Digital Factory v11.1 include:

Improved Usability, Organization & Layout. A new interface offers clear navigation and user-friendly controls, reducing the learning curve, streamlining job setup, and increasing productivity while minimizing production errors. For example, Queue Groups can now be created with a single icon click with drag and drop features, allowing both Queues or Group tabs to be quickly reordered for improved organization and layout.

Reduced Material Use: Digital Factory now provides true shape nesting, allowing more efficient use of spaces or gaps when nesting print and cut designs. This reduces material usage and supports sustainability efforts.

Quickly Identify Job Lists: New icons, settings menu, and image scaling make it easier for operators to quickly see production feedback and what has been processed.

“This new release takes the powerful tools and features customers love and makes it easier than ever to operate. Designers and printers have the power to create at their fingertips and produce vibrant DTF or DTG prints that set them apart from the competition,” continued Henze.

fiery.com

Digital printing remains a lucrative growth market in the printing industry worldwide. It now accounts for some 20 percent of the global print production volume (P...

October 10 2023

Digital printing remains a lucrative growth market in the printing industry worldwide. It now accounts for some 20 percent of the global print production volume (PPV) and is growing at an annual rate of around 3 percent.

The latest Versafire generation from Heidelberg offers systematically enhanced digital presses for the commercial sector. The company is thus taking the integration of offset and digital printing to the next level and further strengthening its market position in the digital segment.

“Our integrated solutions are a must for anyone who is looking to combine offset and digital printing and use them efficiently in tandem. That’s because Heidelberg has comprehensive process and application knowledge relating to both these printing methods, which makes us unique in the industry,” said Heidelberg CEO Dr. Ludwin Monz.

Virtually all offset print shops focusing on the commercial sector are already using a digital press. Heidelberg has therefore equipped the new Versafire LV and Versafire LP digital printing systems with an enhanced Prinect Digital Frontend (DFE). In conjunction with a new user interface, this software ensures a flexible, standardized, highly productive, and intuitive combination of offset and digital printing technology.

The new generation incorporates integration know-how and experience based on the installation of several thousand Versafire digital printing systems for customers located worldwide.

“With the latest Versafire generation, customers are investing in a further improved over-all performance and enhanced competitiveness,” says Frank Schaum, head of the print solutions segment at Heidelberg.

Here is a brief summary of further benefits of the digital printing solutions from Heidelberg:

• Versafire LP: This is the ideal solution for the cost-effective production of larger volumes and/or lots of short runs. With up to a million clicks each month, it is one of the market’s most productive toner-based digital presses in the A3 format and gives digital print pro-duction a far more industrial thrust.

• Versafire LV: The possibility of a fifth inking unit and thus a choice of seven spot colors makes this the flexible solution for wide-ranging applications in short-run printing. Thanks to its impressive level of automation and upgrade options, the Versafire LV offers excellent flexibility and investment security.

• Prinect Digital Frontend: This software solution was developed in-house by Heidelberg. The second generation that has now been unveiled is the centerpiece of the new Versafire systems and supports the standardization of print shop production.

• Ecosystem: Heidelberg digital printing customers have access to an extensive ecosys-tem that includes consumables, digital services, software, cloud-based solutions, training, consulting, inventory management, and logistics and thus benefit from significant added value with just a single contact partner.

• Expansion of digital printing portfolio: In recent years, Heidelberg has established it-self on the market as a high-performance supplier of digital printing solutions by steadily expanding its digital printing portfolio with the Versafire systems for the commercial sec-tor and the Labelfire and Gallus One digital inkjet systems from the company’s Swiss sub-sidiary Gallus for the labels market.

HP Inc has announced a new 36-inch DesignJet portfolio that simplifies the printing needs of AEC (architec...

October 10 2023

HP Inc has announced a new 36-inch DesignJet portfolio that simplifies the printing needs of AEC (architecture, engineering & construction) professionals who increasingly work in a hybrid environment - needing a high-quality printing experience, whenever and wherever they are. The devices will also enable copy shops to better meet the requirements of AEC customers.

With 54% of AEC firms deploying a hybrid work policy, flexible working models are here to stay. This new approach has changed workflows, requiring aspects of the job, including large format printing, to be enabled in a hybrid environment. Because of this, users need intuitive print technology that meets their technical needs, whether that is printing A3-A1 CAD drawings or architectural boards, all without compromising on security.

“More than ever, AEC pros, or the copy shops that serve them, need easy-to-use tools that help them be more productive and deliver high-quality work - whether they are in the office, at home or somewhere remote,” said Daniel Martinez, General Manager, Large Format Business, HP. “With our new HP DesignJet lineup - alongside software such as HP Click and the HP app - users can print, monitor jobs and check device status from virtually anywhere, as well as collaborate on documents with colleagues.”

Sustainable and Secure

With the new 36-inch DesignJet portfolio, HP helps customers to go beyond and run their businesses while achieving their sustainability goals. Thanks to HP’s Forest First initiative, with every page a user prints with the HP DesignJet T850/T950, Smart Tank T858/T908 MFP or XL 3800, HP collaborates with non-profit organizations , to ensure forests are restored.

The HP DesignJet T850/T950 are both made from at least from 35% recycled plastic, use carboard-based cartridges, and, along with the DesignJet Smart Tank T858/T908 MFP, can be scheduled to power on and off automatically to preserve energy consumption. Meanwhile, the T858/T908 MFP and the HP DesignJet XL 3800 are comprised of at least 33% recycled content.HP has also prioritized cyber-security, with HP Wolf Security protection built into the HP DesignJet T850/T950 and XL 3800. HP Wolf Security provides comprehensive endpoint protection and resiliency that starts at the hardware level and extends across cloud-based software and services – safeguarding an organization’s PCs, printers and people from cyber predators.

With additional Enterprise-level Wolf security features, the HP DesignJet XL 3800 is also the world’s most secure large format printer, based on third-party analysis of security features available on the market.

Solutions for all AEC Requirements

The new HP DesignJet lineup – consisting of three product families - provides several options and features to cater for all AEC user needs, including:

HP DesignJet T850/T950:

HP DesignJet Smart Tank T858/T908 MFP

HP DesignJet XL 3800

SCREEN Graphic Solutions Co., Ltd. announces its cooperation with KYOCERA Document Solutions Inc. in the development of the Truepress JET S320, an A3...

October 10 2023

SCREEN Graphic Solutions Co., Ltd. announces its cooperation with KYOCERA Document Solutions Inc. in the development of the Truepress JET S320, an A3 sheetfed digital inkjet printer. The Truepress JET S320 prototype will make its debut at PRINTING United Expo October 18–20, 2023, in Atlanta, Georgia.

In recent years, especially in the commercial printing and publishing markets, there has been a shift toward businesses utilising digital printing technology. This change is driven by a broader societal shift toward businesses that leverage digital data. In contrast to the traditional production of broadcast-style advertisements and prediction-based mass production, there is now a demand for data-driven targeting and personalized advertising materials. This shift has resulted in a move toward production that involves printing only the necessary quantity at the required time, often with targeted messaging.

SCREEN GA has provided a line of high-speed, continuous-feed inkjet digital presses, the Truepress JET 520 series, in response to these needs. These digital inkjet presses have been widely embraced for various printing applications such as transactions, direct mail, catalogs, brochures, publications, and more. Now a global leader in this market, SCREEN GA has been commercialising an A3 sheetfed inkjet digital printing machine by leveraging the technical expertise in A3 production printers held by KYOCERA Document Solutions Inc., along with SCREEN GA’s Truepress ink SC/SC+ technology for ink compatibility with standard coated papers. This proprietary ink prints on commercially available coated papers without the requirement of coating or priming.

With the introduction of this product, SCREEN GA is expanding various solutions, including the enhancement of workflow solutions integrated with our EQUIOS workflow system, hybrid printing in conjunction with CTP and offset printing, and increased productivity through the combined use of the Truepress JET 520 series.