See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

SCREEN GP announces NIR Near Infrared Dryer for its 520HD Inkjet Web Delivers higher print speeds on coated litho stocks, expands lightweight paper capabilities, fine-tunes dryin...

October 21 2018

SCREEN GP announces NIR Near Infrared Dryer for its 520HD Inkjet Web

Delivers higher print speeds on coated litho stocks, expands lightweight paper capabilities, fine-tunes drying performance across all substrates used for commercial-grade digital inkjet print.

Sydney, October 16th 2018 - SCREEN’s flagship, high-volume production inkjet web press has made another leap toward becoming the preferred technology for printers looking for offset-quality on standard stocks, using inkjet technology.

Peter Scott, managing director of Screen GP Australia, says: “When we introduced the 520HD press a little over two years ago, the market was surprised by its offset-like image quality. It was the first time high speed inkjet demonstrated the capability for effectively printing jobs that approached offset quality. Development has been on-going since that time, with the SC inks being the most significant advancement.”

He continues: “Drying and curing is always an issue with high-volume inkjet, there’s a lot of water to get rid of and now, with the new Near Infrared (NIR) Dryer, we can achieve what no other digital inkjet press does. NIR technology dramatically advances productivity for work demanding high image quality and expands print applications for high speed inkjet across a broad landscape of products.”

The new SCREEN NIR Dryer technology, built into the existing press frame of the 520 HD, extends drying performance for both lightweight uncoated stocks and heavier weight, coated litho substrates. The result is an expanded range of applications and even higher productivity on difficult to dry substrates.

Drying on the 520HD is now 3-tiered: heat dissipation, hot air assist, and new infrared. This integrated solution achieves a drying balance along the entire paper path tuned specifically to the characteristics of the paper, reducing or eliminating the cockling often associated with traditional inkjet ink drying methods.

Intelligent drying

Operators create substrate profiles with embedded drying protocols at different print resolutions and ink limits. These profiles are managed seamlessly by Screen’s proprietary Equios front end software, providing intelligent drying balance for each specific stock helping achieve the highest quality, best speeds and desired ink coverages.

Scott adds: “All new Screen Truepress Jet 520HD machines may be optionally equipped at the factory with the NIR dryer. Screen branded 520HD units currently in the field can be upgraded with the new dryer at the machine site. It’s a major move forward in making production web inkjet a viable alternative to offset – with all of the benefits of no plates, short runs, variable data, offset stocks and streamlined digital workflow.”

www.screenaust.com.au

Avery Dennison Graphics Solutions has named four continental winning vehicle graphics installers in the “Wrap Like A King” Challenge. They are: ●

October 16 2018

Avery Dennison Graphics Solutions has named four continental winning vehicle graphics installers in the “Wrap Like A King” Challenge.

They are:

● North America - “Mission Flyer 2.0” by MetroWrapz of Hollywood, Florida

● Europe - “Barnfind 66” by Funkeefish of Tendring, Great Britain

● North Asia - “Tank Ray” by WrapStyle Korea of Gimpo-si, Kyeonggi-do, South Korea

● Australia and New Zealand - “Barn Find 24/7” by Fingerprint Signs of Launceston, Australia

The four Continent Wrap Kings showed their prowess with Avery Dennison® Supreme Wrapping™ Film, the Conform Chrome™ Series and MPI 1105™ Supercast Digital film. They will each receive a four-night stay in Las Vegas for the 2018 SEMA Show, where the “King of the Wrap World” will be announced. The US$3,200 prize pack for each continent winner also includes personalized Wrap Like a King swag, US$500 in gift vouchers, a Race Ramp product and a variety of promotional and marketing tools for the winner’s wrap shop.

Jeff Losch, Marketing Director, Avery Dennison Graphics Solutions said: “We’re one step away from a new global wrap king, and each of the remaining entries is a strong representation of what this challenge is all about. Our team cannot wait to see the winners in Las Vegas, because each one has accomplished something remarkable.”

Josh Nielsen of Fingerprint Signs, said: "Wrap Like A King has been a great experience and opportunity for my and the team at Fingerprint Signs. We didn’t expect to become the continental winner for ANZ but it has made us feel so much better about our work. I have always been inspired by the wrap work done all over the world which pushed me to follow my dream in becoming a wrap designer and installer. I never thought I would get this far with my work and it’s a great feeling to know that my work is not only enjoyed by the locals in Tasmania by now all over the world."

The 2018 Challenge judges include Justin Pate, co-owner of The Wrap Institute; Myles Kovacs, president and co-founder of DUB® Magazine; Jun Kinoshita, sales manager of Avery Dennison Graphics Solutions Japan; Mark Richardson, director of Elite Wraps and Vehicle Graphics; Alain Carcat, technical sales support for Avery Dennison Graphics Solutions Europe; Molly Waters, senior technical specialist for Avery Dennison Graphics Solutions North America; Peter Wright, technical marketing manager for Avery Dennison Graphics Solutions Asia Pacific; and Marco Kimme, founding member and chairman of the German Wrapping Association.

The eight professional judges evaluated the submissions based on the following criteria: visual transformation (difference between the before and after pictures submitted), quality and skill level of installation, overall public look and appeal and uniqueness of the design.

“Visual effects are impressive, but those that are executed with consistency across a wrap take it to another level,” said Molly Waters, senior technical specialist, Avery Dennison. “We were excited to compare awe-inspiring effects and textures from wraps in each continent, and at the end of the day, these four winners impressed us the most.”

The four Continent Wrap Kings will receive a four-night stay in Las Vegas for the 2018 SEMA Show, where the “King of the Wrap World” will be announced. The US$3,200 prize pack for each continent winner also includes personalized Wrap Like a King swag, US$500 in gift vouchers, a Race Ramp product and a variety of promotional and marketing tools for the winner’s wrap shop.

The 2018 King of the Wrap World grand prize winner will be announced on Wednesday, October 31 in Booth 12659 at the SEMA Show. The King of the Wrap World extended prize package is valued at almost US$5,000, with additional gift vouchers and exposure via the Avery Dennison website and web advertisements.

Please see the press release for the full announcement. I've attached the image of all 4 Continent winners for your reference.

More information about "Wrap Like A King" Challenge is available at http://wraplikeaking.averydennison.com/

HP INTRODUCES WIDE TABLETOP PRINT ENGINE FOR DIRECT-TO-PACKAGE PRINTING HP Inc. has announced a new wide tabletop print engine for OEMs to design on-demand specialty packaging solution...

October 16 2018

HP INTRODUCES WIDE TABLETOP PRINT ENGINE FOR DIRECT-TO-PACKAGE PRINTING

HP Inc. has announced a new wide tabletop print engine for OEMs to design on-demand specialty packaging solutions.

The HP OEM Fixed Imager 1000 by HP Specialty Printing Systems (SPS) enables convenient in-plant or print service provider printing on a wide range of applications including gift and shopping bags, personalised gift boxes, shipping packaging, cartons, and envelopes. The highly versatile HP F1-1000 print engine introduces a 297.18 mm (11.7 inch) wide print swath, offering a large image area for colour printing on variable lengths of media.

“This wider print engine can deliver more elaborate on-demand color packaging and commercial printing applications for short-run, personalized direct to package printing. Brand owners can differentiate their packaging, shopping bags, envelopes to make their products stand out with color and personal messages,” said Annette Friskopp, general manager, HP Specialty Printing Systems, HP Inc. “HP opens extensive opportunities for OEM partners with a range of inkjet printing capabilities to meet fast-paced market needs.”

Konica Minolta has received two prestigious Buyers Laboratory (BLI) awards, recognising excellent performance in Buyers Lab rigorous product field tests. Buyers Labor...

October 16 2018

Konica Minolta has received two prestigious Buyers Laboratory (BLI) awards, recognising excellent performance in Buyers Lab rigorous product field tests.

Buyers Laboratory is a division of Keypoint Intelligence. Its PRO awards are held annually. The 2019 PRO awards honoured Konica Minolta in two divisions: the Konica Minolta AccurioPress 6136 with Internal Image Controller was recognised as the most outstanding light/mid-volume production device; and the Konica Minolta AccurioPress C3080 Series with EFI 417 Controller was awarded outstanding light production colour device.

PRO awards go to the best performers in Buyers Lab’s production field tests, during which tens of thousands of pages are printed. Productivity is tested with both coated and uncoated media in a wide range of weights and sizes, using various finishing options to simulate a mix of job scenarios. Buyers Lab technicians also evaluate paper-handling capabilities, many facets of ease of use, and image quality.

David Sweetnam, director of EMEA/Asia Research & Lab Services, Keypoint Intelligence, said, “The Konica Minolta AccurioPress C3080 delivers a wide range of production print capabilities to growing CRD and commercial pay-for-print organisations. Chief among these advancements is the system’s unique ability to check and adjust front to back registration and colour consistency in real time without operator intervention, and without impacting productivity. And the flexibility an operator has to choose the frequency in which these self-checks and adjustments will be run ensures high-level, consistent quality, day in and day out.”

George Mikolay, associate director of Copiers/Production, Keypoint Intelligence, said, “The Konica Minolta AccurioPress 6136 series promises to be a true workhorse in both in-house CRDs and commercial pay-for-print establishments. AccurioPro Print Manager provides job management control by simply logging into the IP address of the embedded Konica Minolta controller. In addition, the system’s Scheduler allows for optimum resource planning, while class-leading media input and output capacities, and a wide range of in-line finishing tasks, allow for a diverse, high-volume workload with minimal downtime on a routine basis.”

Grant Thomas, product marketing manager, Konica Minolta, said, “To be recognised by an independent third party is significant for Konica Minolta in demonstrating its reliability, handling and capability to customers and prospects. Particularly, when approaching new customers, these types of awards hold great weight in supporting the feedback we already receive from our existing customers, on a global scale.”

Roland DG Australia Announces “Discover Roland, Explore Africa” Contest The prize winner of Roland DG’s global “Discover Roland, Explore Africa” con...

October 16 2018

Roland DG Australia Announces “Discover Roland, Explore Africa” Contest

The prize winner of Roland DG’s global “Discover Roland, Explore Africa” contest will hit the jackpot with an all-expenses paid, luxury African sight-seeing safari for two, including airfares, accommodation, meals and guided tours. The global contest, that will run between 10th October to 14th December 2018, is designed to encourage customers to get a hands-on product demonstration of Roland inkjet technology.

“Our best-selling eco-solvent, UV and dye sublimation inkjet printers and printer cutters are unequalled for their quality, performance and reliability,” Greg Stone, Roland DG Australia Product and Marketing Manager said. “We believe that it makes sense to offer the trip of a lifetime to those with Australia who are road testing the best products available on the market.”

To participate, entrants must live in Australia and do the following 3 steps: 1) Book a demo with Roland DG or with an authorised dealer via the contest website. 2) Following the demo, each entrant will be emailed a unique contest code. 3) Entrants finalise their entry via the website by entering their contest code, and writing a short 285 character (about 50 words) or less description on the contest entry form stating what they discovered about the Roland device. All entries will be judged based on creativity, passion and uniqueness, with one Grand Prize winner from all global entrants selected to receive the deluxe African safari for two. There will also be a local prize of $500.

Greg Stone said that the 11-day tour will include stays at three South African parks known for their wide variety of wildlife. “The winning couple will have an excellent opportunity to observe hundreds of birds and exotic animals in their habitat, including the “big five” of lions, leopards, African elephants, cape buffalo and both black and white rhinos.”

Among the 2019 tour highlights are stays in a variety of luxury accommodation, both night and daytime game drives with a ranger and tracker, and all meals, including a high tea. Airfares from several major cities are included.*

To learn more about the “Discover Roland, Explore Africa” contest, including eligible products, terms and conditions request a Roland product demonstration and enter, visit www.rolanddg.com.au/discover. For additional information on Roland DG and the complete Roland product line up, visit www.rolanddg.com.au.

Konica Minolta 2018 National Specialised Print Awards finalists announced from record 246 entries Konica Minolta has announced the finalists for its 2...

October 11 2018

Konica Minolta 2018 National Specialised Print Awards finalists announced from record 246 entries

Konica Minolta has announced the finalists for its 2018 National Specialised Print Awards (NSPA), which celebrate exceptional craftsmanship in digital printing with the help of a Konica Minolta digital press system. A record number of entries for this year’s awards makes them Konica Minolta’s most popular yet.

Following the awards’ success in 2016 and 2017, this year, Konica Minolta extended the awards categories to acknowledge a diverse range of digital print and imaging entries. The team has reviewed the highest number of entries to date, with 246 entries in one of five categories: Digital Flat Sheet; Digital Print Bound Books; Digital Brochures and Booklets; Digital Label Print; and Digital Embellishment.

The entries have now been considered by expert judges at a state level. Konica Minolta’s 2018 National Specialised Print Awards finalists for this year are:

Congratulations to the monthly prize draw winner of Graphic Art Mart’s “Work Hard, Play Hard” Trade Promotion. In September Graphic Art Mart announced the “Work...

October 08 2018

Congratulations to the monthly prize draw winner of Graphic Art Mart’s “Work Hard, Play Hard” Trade Promotion.

In September Graphic Art Mart announced the “Work Hard / Play Hard” Trade Promotion in conjunction with Avery Dennison and Mactac.

Entry into the competition is easy, customers simply spend $50.00 (exclusive of GST) or more on Avery Dennison or Mactac products in a single invoice to go into the draw.

There are some fantastic prizes on offer:

BALL AEROSOL PACKAGING LAUNCHES EYERIS® Aluminium aerosol customers traditionally have shied away from photo-realistic packaging designs because the graphics do not translate well ...

October 05 2018

BALL AEROSOL PACKAGING LAUNCHES EYERIS®

Aluminium aerosol customers traditionally have shied away from photo-realistic packaging designs because the graphics do not translate well to conventional offset printing. To overcome this limitation, Ball Aerosol Packaging is launching the highly anticipated Eyeris®, a proprietary high-definition printing technique.

For customers craving detailed graphics to bring products to life, Eyeris® printing is the solution to providing photo-realistic quality can designs without digital printing. This ground-breaking HD imagery spans 360 degrees of the can, creating premium product differentiation that engages consumers and elevates brands.

As the personal care industry continues moving toward more natural products, Eyeris® provides customers with the opportunity for the packaging to reflect this shift. Detailed life-like imagery, such as leaves, flowers and landscapes, can be printed on cans, allowing brands to stand out in today’s competitive retail market.

Jason Galley, Director of Global Innovation & Business Development for Ball Aerosol Packaging, comments: “We know the market is clamoring for inventive solutions to create standout packaging. There is such buzz in the industry for digital printing, and Eyeris® provides the perfect alternative to achieve similar results on aerosol cans. This unique technology will transform our customers’ ability to harness the increasing power of imagery and story-telling, truly representing the next generation of aluminum aerosol printing.”

EFI Appoints Bill Muir as New CEO EFI announced that its Board of Directors has named William (Bill) D. Muir as its new Chief Executive Officer. Muir was most recently the Chief Operat...

October 05 2018

EFI Appoints Bill Muir as New CEO

EFI announced that its Board of Directors has named William (Bill) D. Muir as its new Chief Executive Officer. Muir was most recently the Chief Operating Officer of Jabil, a product solutions company. His appointment is effective October 15, 2018, when he will also join the Board of Directors.

Muir succeeds Guy Gecht, who informed the Board he intended to step down as CEO upon the appointment of his successor, as the Company announced on July 30, 2018. Gecht will remain a member of the Board of Directors and will be an advisor to the CEO.

“Bill is going to take EFI to the next level,” said Gecht. “At Jabil his experience and track record included scaling multi-billion dollar businesses, driving execution and setting the firm’s strategic direction. This background uniquely prepares him to be the next CEO of EFI. I look forward to watching him lead EFI and helping him in any way he chooses as the Company continues to lead the digital transformation of industries globally where colorful images matter.”

Gill Cogan, Chairman of EFI’s Board, noted, “In conducting a comprehensive search for the next CEO, the Board had the opportunity to speak with many highly skilled, strong leaders. Bill was our first choice, as his experience in managing a global manufacturing organization, track record in execution and leadership style most closely matched the characteristics we sought to successfully lead EFI in its next stage of growth, building on the legacy that Guy established over the last 20 years. I would like to once again convey the Board’s gratitude to Guy for his outstanding leadership, overseeing the transformation of EFI and driving the Company’s rapid growth to over $1 billion in annual revenues.”

“I am honored and humbled to join the EFI team,” said Muir. “I have developed a deep admiration for the culture of courageous innovation, technical leadership and customer care, and I look forward to leading our exceptional team as we work tirelessly to delight our customers and create shareholder value.”

Muir has spent the past 25 years helping innovative, leading brands bring exceptional products to the marketplace, including launching Jabil’s Blue Sky Innovation Center. He has a deep background in complex engineering and manufacturing honed over progressive leadership roles at Jabil, a $22 billion product solutions company with more than 100 facilities and 170,000 employees across the globe. Most recently, Bill served as Chief Operating Officer.

Before that, he served as CEO, Global Manufacturing Services, which at the time was a $14 billion division of the company, and as President of Jabil Asia, where under his leadership the business tripled in less than four years. Muir holds both a Bachelor’s degree in Industrial Engineering and a Master in Business Administration from the University of Florida.

Muir will join EFI’s third quarter earnings call, which is scheduled to take place after market close on October 29, 2018.

From their humble beginnings manufacturing watches, to now creating some of the most advanced print and display technology in the world, Epson has grown into a global leader by constantly in...

October 05 2018

From their humble beginnings manufacturing watches, to now creating some of the most advanced print and display technology in the world, Epson has grown into a global leader by constantly innovating and responding to the changing needs of their customers. Just how far the company has come, was highlighted by the launch of a range of new products at Epson’s ‘Innovation meets Evolution’ event in Sydney.

Epson Australia, Bruce Bealby, GM - Sales & Marketing, Consumer Division & Craig Heckenberg, GM Sales & Marketing, Business Division

Epson is a world leader in the field of print, sign and display technology. Their products are among the most popular for the business, professional and domestic markets. And it’s a position they will further solidify with a series of new printers developed to respond to the evolving needs of their customers.

Expanding their business portfolio, Epson Australia has launched four new WorkForce Pro printers for busy offices, bringing its signature inkjet technology, with low environmental impact, low intervention and high productivity, to workgroups wanting A4 mono and colour print capability. Two A4 mono devices – the multi-function WF-M5799 and single-function WF-M5299 – and two A4 colour devices – the WF-C579R and WF-C529R – deliver fast, reliable and high-yield A4 business printing with an extremely low total cost of ownership (TCO).

General Manager of the Business Division at Epson Australia, Craig Heckenberg, said, “These laser-beating inkjet printers save money, energy and time, and are packed full of business productivity and document management features. Designed specifically to reduce environmental impact, minimise intervention and streamline workflow, they keep cost-saving at the heart of what they do. The low intervention and environmental benefits make these devices ideal for specialist verticals too, such as education, healthcare, public administration and retail, to meet both their print and corporate social responsibility needs.”

The multi-function WF-M5799 and single-function WF-M5299 printers meet the demands of businesses where a robust mono printing solution is required with a compelling TCO for use in workgroups with a high print volume. Their impressive ink yield of up to 40,000 pages – the highest in the segment1 – helps to deliver this low TCO, while offering minimal user intervention. This not only boosts productivity, but its no-heat and no-warm-up printing process also supports extensive media flexibility that includes labels and envelopes.

These models use up to 87% less energy than comparable laser models2, helping to reduce environmental impact and lowering users’ energy bills. All this while still managing a zero second warm-up time and a first page out time of just 4.8 seconds, faster than comparable laser models2.

Offering the same business benefits for colour applications, the multi-function WF-C579R and single-function WF-C529R colour printers also offer potentially significant TCO savings. Their impressive ink yields of up to 50,000 pages for black, and 20,000 pages for each of the colours – amongst the highest in the segment3 – help to deliver this low TCO, while offering minimal user intervention.

Epson is renowned for exceptional colour print quality, and this now extends into these business models. Colour print resolution of up to 4800 x 1200 dpi is best-in-class4, but the specification provides little indication of what this really means

for a business. Eye-popping colour empowers sales and marketing material that can give it the winning edge in a competitive marketplace.

As with the mono devices, these models also use up to 87% less energy than comparable laser models4, helping to reduce environmental impact and lowering users’ energy bills.

For businesses and clients needing to print technical information, Epson has launched two new high-speed, easy-to-use large-format printers – the 24-inch SureColor T3160 and the 36-inch SureColor T5160, both are available as desktop or floor-standing models.

Marking Epson’s expansion of the T-Series product line to the low-to-mid-range CAD, AEC, GIS, POS poster and education markets, the wireless models feature a new clean and compact design coupled with the reliable printing performance inherent in Epson’s technical solutions.

Whether printing blueprints, line drawings, signage, or classroom posters, the SureColor T3160 and SureColor T5160 will assist professionals across a wider range of segments including architecture, engineering, CAD, GIS, education, corporate, home and small office users. The unique auto-switching functionality enables the printers to swap between large format roll paper and A4/A3 size paper, without users having to touch the printer, ideal for small companies that have multi-purpose print requirements in a limited workspace.

Epson Australia’s GM sales & marketing of their business division Craig Heckenberg said, “The SureColor T3160 and T5160 are designed specifically for the technical community including engineers, designers and architects who are looking for a fully functioned and compact printer that fits neatly in their office. These new printers also produce quality colour posters and displays, and they enable users to wirelessly produce accurate and vibrant prints from tablets and smartphones virtually anywhere.”

Leveraging Epson’s PrecisionCore MicroTFP printhead technology and Nozzle Verification technology to automatically detect and adjust nozzle condition, the new printers offer fast print speeds producing accurate A1 prints in 31 seconds for the SC-T5160 and 34 seconds for the SC-T3160, with precise detail and commercial-grade reliability. Featuring integrated wireless and Wi-Fi Direct connectivity, users can seamlessly print from tablets and smartphones or use the new 4.3-inch colour LCD touchscreen with simple and intuitive menu control and navigation. Next-generation high-capacity UltraChrome XD2 pigment inks deliver durable archival prints with brilliant colour and crisp lines on many paper types.

Epson is famed for their ability to innovate, to see ways in which they can make things easier for their customers. One product in particular stole the show ... the FastFoto – the World's Fastest WiFi Photo Scanner.

You have to see the FastFoto to believe it. This device will scan a regular photos and documents within a second. It is an amazing timesaver. The device is Wi-Fi and is the world's fastest personal photo scanner, scanning thousands of photos – as fast as one photo per second at 300 dpi3 at up to 36 photos per batch.

The FF-680W scanner offers worry-free scanning for a variety of media types and sizes, including postcards, panoramic photos up to 36 inches and Polaroid photos as well as convenient photo restoration, editing and smart file organisation tools.

Families can scan, restore and organise collections of photos for quick and easy sharing, archiving and enlargements with the new FF-680W scanner and with the Easy Auto-Upload feature, the FastFoto scanner software makes it simple to share images to cloud services such as Dropbox® and Google Drive™.

General Manager - Sales & Marketing for Epson Australia’s Consumer Division Bruce Bealby said, “There was clearly a need for an ultra-fast and easy scanning solution that enabled people to digitise hard copy photos often stored in albums or boxes and vulnerable to many kinds of irreversible damage. The new FastFoto FF-680W not only saves these photos but also comes with a host of new features, making it easier to save and bring memories back to life using the latest digital technology."

Featuring Epson ScanSmart software, the FastFoto FF-680W scanner is also a powerful document scanner. Using the intuitive software users can easily scan, organise, email and store important contracts, receipts, documents and files. In addition, you can easily edit documents and save time with automatic file naming and use powerful productivity tools such as the built-in Nuance® OmniPage Optical Character Recognition (OCR) which enables users to create searchable PDFs, plus editable Word and Excel® files.

From digitising images to projecting them, Epson is the biggest name in projection equipment. In recent years, the company has looked at ways to immerse their projector technology within interiors, creating a system that is as technically advanced as it is subtle. The answer is the new LightScene EV-100 that is ideal for retail, galleries and museums with a low visual noise design that blends in beautifully to displays and exhibitions.

LightScene

Created to blend into the background with a sleek, conventional lighting design available in black or white, the 2,000-lumen WXGA EV-100 can work as either a projector or a spotlight without distracting viewers from the subject.

The LightScene EV-100’s unobtrusive design is ideal for curated visual environments such as retail showrooms, shop window displays, museum exhibits and art installations, where minimal visual clutter is key. It can be used to provide information, show video or moving patterns, and even projection map imagery onto small objects.

“The LightScene EV-100 is a completely new type of projector solution from Epson Australia and a great addition to our range of laser signage solutions,” said Craig Heckenberg. “The design is clearly stylish and visually unobtrusive, without compromising performance, versatility or reliability.”

Epson’s flexible laser technology gives the EV-100 a huge variety of mounting options – it can project from any angle, be floor-standing or attached to the ceiling, all without requiring specialist installation or set-up. It is also capable of projecting in portrait, and multiple units are capable of edge blending for larger displays.

The LightScene EV-100 is supplied with Epson Projector Content Manager Software, which allows single or multiple playlists to be easily loaded via SD Card and changed using remote control by employees, with no need for a computer. The software also allows you to add overlay effects including colour and shape filters to permit tinted and irregularly-shaped images, as well as creating and editing playlists, timetables and custom filters.

The new additions to Epson’s projector range didn’t stop there. They have upgraded their big guns, going bigger, better and brighter with three new projector solutions - their new 12,000 lumen native 4K 3LCD laser projector, the EB-L12000QNL, new compact EB-L20000UNL large venue projector and the EB-L600 series, a 5-6,000-lumen entry-level laser projector range.

Boasting up to 25,000 lumens of colour and white brightness, Epson’s laser projectors are powerful performers in demanding environments, including rental and staging events, lecture halls, and digital signage installations.

The new EB-L12000QNL and EB-L20000UNL models share the same robust, compact and lightweight chassis that makes them easy to integrate into existing infrastructure – a breakthrough at this level of brightness. The new projectors also feature support for HDR, 360-degree installation flexibility and a sealed light source and optical engine to protect from dust and smoke.

Epson’s L600 series is a range of 3LCD entry-level laser projectors that offer a number of useful features, as well as fit and forget reliability, presenting users with the ideal, low cost, solution for meeting rooms, teaching spaces and visitor attractions.

This series is designed to replace existing lamp based projectors in scenarios requiring 5,000-6,000 lumen solutions and feature a compact, contemporary design that is small and light. It also boasts advanced installation features such as HDBaseT, wide manual lens shift range and built-in wireless LAN Enterprise Security as added bonuses along with a class leading 5 year manufacturer’s warranty.

Epson also have some other really cool gear that they just launched, so stay tuned for more details.

Heidelberg Makes Digital Postpress Investment with Takeover of MBO Group Heidelberger Druckmaschinen AG (Heidelberg) is taking over the international MBO Group in a bid to further expa...

October 05 2018

Heidelberg Makes Digital Postpress Investment with Takeover of MBO Group

Heidelberger Druckmaschinen AG (Heidelberg) is taking over the international MBO Group in a bid to further expand its offerings in the growing market of postpress operations for digitally printed products. The move will also see the company gain access to new customers in the pharmaceutical industry and add mailing system offerings to its offset portfolio.

This decision highlights the company’s strategic focus on consistently aligning its portfolio and new business model with the growth segments of digital and packaging. Furthermore, Heidelberg aims to use this extended offering to tap into new customer groups for its entire product portfolio.

“The planned takeover of the MBO Group enables us to attain further sustainable and profitable growth by leveraging new technologies and customer segments,” said Rainer Hundsdörfer, CEO of Heidelberg. “By acquiring MBO’s digital portfolio, we are closing a gap for our customers and helping them achieve a smooth industrial process in the digital future. We also expect to see synergies in our own value added chain, which will bring about tangible benefits for customers, too.”

The acquired operations account for a sales volume of around €50 million and will see Heidelberg expand its postpress offerings. The acquisition involves, among other things, taking over the sites in Oppenweiler and Bielefeld, Germany, and the production site in Perifita, Portugal, which employ a total of approximately 450 staff. Besides the German sites, the efficiently structured site in Portugal opens up particularly interesting opportunities for the entire Heidelberg Group.

“Even when postpress operations are running efficiently, there is still huge potential for boosting productivity throughout the entire print shop,” claims Stephan Plenz, Member of the Management Board responsible for Digital Technology. “The takeover is another important step in offering our customers a comprehensive portfolio that generates value and covers everything from technology and consumables right through to service.”

Strong MBO Brand to Be Retained

The MBO brand is well-established on the market and its technology complements the Heidelberg product range well. Continuing to expand offerings together will optimize the portfolio and supply chain, while leveraging the MBO dealer and service network will also result in mutual benefits. Overall, the acquisition is set to create a better basis for unlocking shared potential for future-focused developments that are geared toward market demands.

The planned takeover of the MBO Group is another strategic step for Heidelberg as it seeks to secure its future by pursuing continuous innovation for the benefit of customers. The aim is to increase productivity and decrease costs by achieving maximum efficiency across all print shop processes. The Heidelberg Push to Stop concept and the company’s industrial digital print portfolio for the packaging market, which includes the Labelfire and Primefire product ranges, is driving forward digitalization. In this regard, integrated postpress solutions are playing an increasingly important role when it comes to optimizing the end-to-end process.

Subject to the agreement of the antitrust authorities, the takeover is due to be completed provisionally by the end of 2018.

Mactac Develops PUREapply Adhesive Mactac Performance Adhesives Group has announced the launch of PUREapply, a pressure sensitive adhesive designed to deliver a combination of high ini...

October 05 2018

Mactac Develops PUREapply Adhesive

Mactac Performance Adhesives Group has announced the launch of PUREapply, a pressure sensitive adhesive designed to deliver a combination of high initial adhesion with clean initial removability.

Ideal for semi-rigid or rigid container substrates like high-density polyethylene (HDPE), polypropylene and glass, it forms a strong bond when applied, yet at the same time, provides clean removability.

“PUREapply was designed to help customers cleanly and easily remove labels that may have been misapplied initially to quickly replace old labels with new labels,” says Kim Hensley, marketing manager, Mactac Performance Adhesives. “It is uniquely formulated to provide extended open time for clean removal, allowing the product container to be re-labeled while continuing to offer excellent tack for long-lasting shelf appeal.”

PUREapply performs well on low-surface energy substrates and is suitable for cold, damp labeling applications. It can be used across a broad range of applications, including beverage, cosmetics, toiletries, household goods and food packaging labeling.

PUREapply exhibits:

High-Tack

Excellent Initial Removability

Ultimate Adhesion

Exceptional Clarity

Roland DG Wins Two SGIA 2018 “Product of the Year” Awards Roland DG Corporation, a leading manufacturer of wide format inkjet printers and 3D devices worldwide, has announc...

October 05 2018

Roland DG Wins Two SGIA 2018 “Product of the Year” Awards

Roland DG Corporation, a leading manufacturer of wide format inkjet printers and 3D devices worldwide, has announced that two of its products – the Roland DG VersaUV LEC-540 printer cutter and ECO-UV ink – have won coveted 2018 Specialty Graphic Imaging Association (SGIA) “Product of the Year” Awards. Roland DG’s VersaUV LEC-540 received top honors within the “Roll-to-Roll UV Printer” category, while the company’s ECO-UV ink was recognised as the best product in the “Digital Inks – UV” category. This year’s competition featured a record-setting 255 submissions, with winners selected in 68 different product categories.

“As a pioneer of UV print and cut, Roland DG has played an integral role in introducing and advancing this important technology, enabling users to take their design and print production capabilities to the highest possible levels,” said Roland DGA, Roland DG’s US-based sales and marketing subsidiary, President Andrew Oransky. “We’re thrilled that the SGIA judging panel saw fit to give our UV printer cutters and inks the recognition they deserve.”

The 54-inch VersaUV LEC-540 printer cutter is ideal for producing everything from vibrant signs, labels, decals and specialty graphics to realistic packaging prototypes on actual press substrates. With its integrated cutting capabilities, the LEC-540 scores and contour cuts in one seamless workflow, maximising efficiency, productivity and convenience.

Also winning a 2018 SGIA Product of the Year Award was Roland DG’s ECO-UV ink, which comes in CMYK, Gloss and White and is specially formulated to bring out the best in the company’s VersaUV LEC, LEF and LEJ series printers. In addition to imaging beautifully, these premium inks cure instantly and are extremely flexible, producing graphics that can stretch around curved surfaces and edges without cracking. Gloss and White ECO-UV inks enable users to incorporate stunning dimensional and textural effects into prints, adding appeal and value.

To learn more about Roland DG’s award-winning VersaUV LEC-540 wide format printer cutter and ECO-UV inks, or the complete Roland DG product line, visit: http://go.rolanddg.com/e/66942/-lec-series-uv-printer-cutters/dkq9ss/461035013

Sato launches intelligent touchscreen label printer Sato, a global provider of auto-ID solutions that empower workforces and streamline operations, has launched the FX3-LX, a cloud-con...

October 05 2018

Sato launches intelligent touchscreen label printer

Sato, a global provider of auto-ID solutions that empower workforces and streamline operations, has launched the FX3-LX, a cloud-connected touchscreen label printer that can be operated without the need of a PC. It has been engineered with the needs of restaurants, retail, healthcare, manufacturing and logistics workplaces in mind.

Research shows that legacy hardware and outdated technology can have a major impact on worker productivity and competitiveness by impeding a collaborative workforce. Also, companies that are highly connected are far more likely to report a favorable market position than those with poor connectivity (57% versus 27%).

To address these concerns and more, Sato has designed the 3" FX3-LX label printer to be highly intuitive and customizable for increasingly tech-savvy businesses that expect a consumer-level user experience. With support for the Sato Application Enabled Printing (AEP) enterprise label printing platform, the printer enables apps specialized for various work environments that can be accessed intuitively as you would with a smart device.

The durable, portable device has a small footprint, allowing users to print labels anywhere they are required around the workplace.With its multi-lingual display and 7" TFT full-color touchscreen and ability to load original training videos, it gives operators on-demand insight into operational procedures to render training virtually unnecessary.

FX3-LX also supports the cloud-based maintenance service, SOS (SATO Online Services), allowing identification of issues before they cause downtime, visualization of printer status and asset management. This add-on service helps ensure stable operations and peace of mind for the user.

“We’re delighted to introduce our cutting-edge FX3-LX to the market,” says Sato Holdings chief product planning officer Noriyasu Yamada. “As the user experience boundaries of personal and workplace tech become ever more blurred, we’ve created a next generation label printer that is user-friendly from the first use and offers operators a high degree of autonomy via easy database updates. We aim to further increase customer value with new IoT solutions to boost productivity.”

Yamada continues, “With the FX3-LX, we’ve worked hard to understand how we can empower workforces and streamline the operations of end users. The result is a universal device with simple cross-sector integration to improve Total Cost of Ownership (TCO) for Sato customers.”

The FX3-LX was recognized with the Red Dot Design Award 2017 for its minimalist design and practicality.

Xeikon announces newest X-800 DFE Xeikon has announced the newest version of its X-800 digital front-end (DFE). It is designed to deliver maximum automation to enable the most powerful...

October 05 2018

Xeikon announces newest X-800 DFE

Xeikon has announced the newest version of its X-800 digital front-end (DFE). It is designed to deliver maximum automation to enable the most powerful workflow on the market.

The X-800 6.0 combines consistent print with enhanced productivity to enable digital printers to process their print jobs, no matter how complex, in the fastest, most flexible and secure way. It is upgradable to all press-models from the Panther UV inkjet presses – the PX3000 and PX2000 to the Xeikon 3000 series to the Cheetah series for labels and the Xeikon 8000 and 9000 series for the graphic arts markets.

The product enables print service providers to reduce job preparation time, automate converting and serve new businesses that can only be enabled through digital print, such as variable data.

“We are constantly innovating our press portfolio and, as a result our, software solutions that support them, so our customers can maximize their production possibilities,” comments Filip Weymans, vice president of marketing at Xeikon. “The Xeikon X-800 6.0 DFE builds on our highly successful and established dedicated Xeikon press software platform that works with open standards and delivers scalable functionality.”

Weymans continues, “It will allow all our customers to add value no matter their specialty area. From label and packaging converters to operations with high-volume data throughput requirements, the latest version will help them streamline their workflow, reduce job preparation time for even the most complex work and become more responsive and efficient.

“Our X-800 DFE is designed from a digital printing perspective to outperform any other DFE in the market when it comes to the level of automation possible. X-800 6.0 strongly focuses on enhancing operational capabilities, one of which is automated impositioning," Weymans explains. “Streamlining this process can easily help operations save hundreds of prepress and job preparation hours per year. This alone delivers a clear and measurable value.”

To demonstrate the possible business gains for individual operations Xeikon has launched a new initiative called “Workflow Challenge”. Customers can request an online review by simply mailing info@xeikon.com comparing the X-800 6.0 to other workflows.

Adds Weymans, “Simply seeing the impact a software solution has on other similar operations does not always make it easy to understand how it will help your business’s performance. With our Workflow Challenge, a much more direct comparison can be made helping define specific goals that will achieve tangible results. We will highlight how job automation reduces job preparation, enables variable data management and supports web to print with laser diecutting.”

Böttcher & Brissett: From Good, to Great Leading Names Combine Forces in Australia Two leading industry names, Böttcher Australia and Brissett Rollers, have ...

October 02 2018

Böttcher & Brissett: From Good, to Great

Leading Names Combine Forces in Australia

Two leading industry names, Böttcher Australia and Brissett Rollers, have today announced the merger of their two operations in Australia and New Zealand, creating a strong new force in the Australasian print market.

Mitch Mulligan, Managing Director of Böttcher Australia, and Terry Brissett, Managing Director of Brissett Rollers, announced today that the local arm of the global Böttcher Group will acquire the plant, goodwill and equipment of the local family-owned business and integrate the two operations under the one roof before the end of the year.

The acquisition, like so many before it, has been driven mainly by market consolidation and contraction. By combining their resources, the two men say local customers can continue to enjoy the best from both companies, with a seamless transition and continuity of supply.

While any investment in Australian manufacturing is positive, this move is particularly good news for the companies’ customers, as it brings together Böttcher’s market leading products and expertise and Brissett’s unmatched local manufacturing and market knowledge.

“We genuinely believe this is a ‘win-win’ for the industry, securing the future of a trusted local roller manufacturing business and offering our customers an expanded value proposition – the improved lead times, flexibility and continuity of supply which local manufacture ensures, combined with the competitive edge that Böttcher’s world leading technology, compounds and processes provide,” Mulligan says.

Indeed, the combined credentials of the two companies are impressive. Böttcher is a 293-year-old family-owned business which is renowned globally for its quality printing rollers, blankets and pressroom chemistry. Brissett is the largest manufacturer of printing rollers in Australasia, having served the market here with distinction for 60 years.

“While our backgrounds differ, we share much in common and have been ‘friendly competitors’ for years,” says Brissett. “Both Böttcher and Brissett are family owned companies who believe strongly in partnering with our customers and building relationships on the basis of quality products, reliable service, honesty and loyalty.

“We’ve both successfully navigated enormous change, from hot metal days to the high-speed, digitally-controlled and highly automated offset operations we see today, so we understand that the ability to evolve is vital in such a rapidly changing industry. Our merger with Böttcher is just the latest step in that process for us.”

Mulligan agrees, saying it’s the Böttcher philosophy to ‘retain the good things from tradition, and create the new from our own strength’. In line with this, Böttcher plans not only to keep the core of Brissett’s manufacturing team, but is also gaining what Mulligan describes as ‘the centre of knowledge’ – current owner Terry Brissett and his son, Craig.

“While securing the future of a local manufacturer is important to us, it’s even more pleasing to be able to retain the invaluable expertise, knowledge and relationships which Terry and Craig Brissett enjoy with so many print businesses in Australia and New Zealand,” he says.

“Brissett has a proud heritage and an enviable reputation for quality, service and expertise in this part of the world. Terry’s contribution to the industry, in particular, has been outstanding. We are absolutely delighted to be able to bring both he and Craig into the Böttcher Australia fold.”

Already, the team at Brissett’s Tempe plant and Böttcher’s headquarters in Castle Hill are preparing for relocation, which will commence in the second half of October. Official handover date is 1 November, 2018.

After a ‘settling in’ period in the fourth quarter, the two manufacturing teams and processes will be fully integrated into a combined operation on a new site at Smithfield, where the entire business will be converted across to Böttcher’s world-leading manufacturing methods and compounds.

“Over the next few weeks, Glenn Brissett and I will be visiting customers around the country to explain the changes and the extended value we can deliver in more detail,” Mulligan says.

“We’re looking forward to maintaining and growing our relationships with our customers across Australia and New Zealand, and are genuinely excited about the future.”

Gallus and Heidelberg unveil Smartfire digital label press In April 2018, Gallus and Heidelberg announced the completion of their full integration in North America. To highlight their ...

October 02 2018

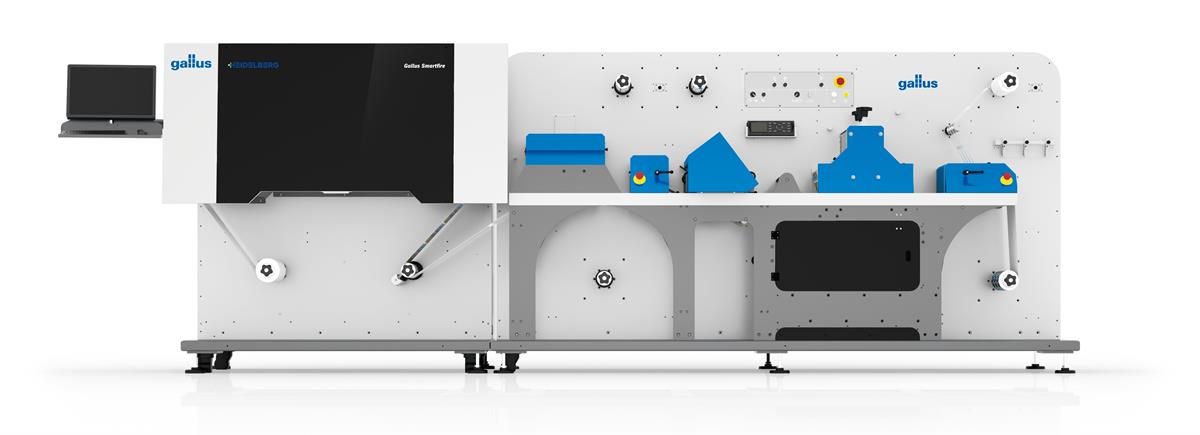

Gallus and Heidelberg unveil Smartfire digital label press

In April 2018, Gallus and Heidelberg announced the completion of their full integration in North America. To highlight their commitment to the label industry and to show the combined strength of both companies with their aligned product portfolios, Gallus and Heidelberg are exhibiting together in Booth 6150 at Labelexpo Americas 2018.

At the show, Gallus’s new Smartfire digital label printing system is being unveiled to the North American market, and Heidelberg’s Omnifire 250 4D inkjet digital printer is available for demonstration. Respective market leaders in narrow-web and sheetfed offset printing, Gallus and Heidelberg now offer a complete print shop solution for label printers with reliable equipment, parts, service and consumables support – all from a single source.

Gallus’s vast portfolio includes the Labelmaster, the most cost-effective system in the industry. From the economical basic model to the fully equipped version, the Labelmaster is redefining conventional flexographic label printing; its modular design enables customers to configure the press to the needs of their business. On the digital side, Gallus’s Labelfire, an advanced hybrid inkjet system that was developed with Heidelberg and Fujifilm, is setting the standard for UV inkjet image quality with the lowest cost of production in its class. For high quality conventional flexo label production, customers can also rely on the Gallus ECS 340 for cost-effective label production and Gallus RCS 340, an extensively automated system for high-output label production.

On the offset side, Heidelberg has, for years, been a supplier to the label industry – most notably with their flagship press, the Speedmaster XL 106 with 41” sheet size, ability to print 18,000 sheets per hour, and optional UV, LE UV, and LED curing systems, which enable it to print on a variety of substrates, including synthetics. Customers can now also turn to Heidelberg’s Primefire 106, the first commercially available industrial inkjet digital printing system in the 70 x 100 (40”) format. Printed labels can be finished with the Heidelberg portfolio, which includes POLAR cutters and a variety of die cutters from Masterwork.

All Gallus-Heidelberg customers benefit from the specialist industry expertise of both companies along with Heidelberg’s established service network and extensive parts availability.

Gallus Smartfire

“The Smartfire focuses on new target groups who are looking for a low risk, easy entry into digital label printing,” explains Michael Ring, Head of Digital Solutions at Gallus. “Incorporating Memjet technology allows us to offer an inkjet printing press that produces labels with a quality of 1600×1600 dpi – while establishing a new, low investment price point in the market.”

The Memjet water-based inks and print heads mean that labels produced by the Smartfire are eco-friendly, with a minimal ecological footprint. Virtually “plug and play,” the Smartfire uses an ordinary power outlet, needs no exhaust equipment, is extremely compact, and does not emit VOCs (Volatile Organic Compounds), which makes it the perfect press for any work environment.

“The name says it all, the Smartfire is absolutely easy to operate via a self-explanatory touch panel,” says Ring. With this digital press, limited prepress skills are needed to create professional CMYK 4-color inkjet labels. Addressing the shortfall of other offerings in this space, a finishing unit is integrated into the press, where labels are laminated and cut, which means the Smartfire delivers finished die cut labels in one pass, ready for shipping.

Heidelberg Omnifire – Inkjet Personalization in the Fourth Dimension

Also available for demonstration in Booth 6150 at Labelexpo Americas will be the Omnifire 250 – Heidelberg’s “4D Printer,” which combines advanced Inkjet technology with high-precision robotics. The Omnifire 250 can personalize and customize most three-dimensional products. From a wine bottle to tumbler and beyond, the Omnifire gives customers the ability to change products over within seconds — providing shorter delivery times with on-demand printing.

“We think that the Omnifire is a great fit for the label market,” said Steven Calov, Product Manager of Omnifire for Heidelberg USA. “Most label printers are already creating customized labels for a variety of consumer products – with the Omnifire, they can take this same thinking and print a customized image direct to the object in many cases.”

INX International launches new inks From a new electron beam low migration ink solution and a preview of the NW340 UV digital label printer, to an overflow of various tag and label ink...

October 02 2018

INX International launches new inks

From a new electron beam low migration ink solution and a preview of the NW340 UV digital label printer, to an overflow of various tag and label ink and coating solutions, eco-friendly INXhrc inks, and a small batch ink dispenser that ideally suits the tag and label market, the INX booth has plenty of options for consideration.

“The Labelexpo crowd is always looking for a product with that something extra so they can separate themselves from the competition. I think it best describes the products we are exhibiting this year,” says Jim Lambert, INX International’s vice president of digital sales – Ink and Hardware. “We have an ink solution for nearly every occasion and Prodigy EBGA, the new low migration ink we are introducing, was just named SGIA’s 2018 Product of the Year for its category. I’m also excited about previewing the NW340 printer at our hometown show.”

The single-pass NW340 printer is a UV digital label press that gives label converters, packaging, in-house and commercial printers the opportunity to seamlessly transition to digital inkjet technology. The complete solution includes high quality inks and expandable modules to help printers meet the increasing demand for high quality, short-run digital printing.

The NW340 represents third generation label technology that Lambert says is an important and natural progression.

“It seems like only yesterday when we previewed the NW140 printer at Labelexpo,” remarks Lambert about its 2010 pre-launch debut. “A few years later we followed with the NW210. Both of those printers offered resolutions of 360-by-360 dpi and produced labels at speeds up to 80 fpm. The main difference was the printing width of 140mm and later, 210mm.

“The NW340 is a whole different ballgame. We’ve elevated the resolution to 1200-by-600 or 1200-by-1200 dpi, improved the width range to 340mm, and have increased the speed up to 300 fpm to satisfy market demand. Printers want faster equipment and higher resolution so they can more favorably compete with offset presses. This machine does that and more.”

Prodigy EBGA is the new EB low migration solution from the popular line of industrial and packaging application inks. SGIA’s 2018 Product of the Year for Digital Inks - Industrial and Packaging -, the premium inkjet ink cures by electron beam using Uteco’s GAIA printer. It is the first inkjet machine offering electron beam technology, eliminating the need for photoinitiators, the company says.

EBGA inks provide strong adhesion to a range of traditional label material and film, with high chemical and scratch resistance. Available in CMYK, they can create custom spot color in addition to orange, green and violet.

A complete assortment of AquaTech water-based tag and label inks and coating solutions, including the new AquaTech ION-X series, are on display. Known for their strong performance and excellent print stability, these inks are formulated to provide premium strength for today’s higher line anilox rolls and excellent cure rates at high press speeds. Whether it is AquaTech or a solution for sheetfed or web offset, flexographic, UV hybrid, HUV and LED or electron beam printing, INX has those inks and coatings at Labelexpo Americas.

INXhrc water-based inks have replaced over two million pounds annually of petro-chemically derived resins, waxes and additives. The eco-friendly, fast drying ink offers clean, renewable and sustainable ingredients that are free of allergens, nanomaterials, flurochemicals, fanal pigments, heavy metals, latex and PTFE. When used in tandem with INXPlus dispersions, INXhrc provides for the strongest finished inks available with excellent resolubility and transfer properties and other benefits.

The HMJ-200 small batch ink dispenser offers many advantages, especially for the tag and label market. It provides a single point dispense into jugs with small openings, and a quick adjust scale base accommodates multiple dispense containers from jugs to pails. The HMJ-200 is also fast, dispensing four ingredients in a one-gallon jug in 90 seconds. Available for water-based or UV curable inks, the small footprint machine has an automated valve cleaning system.

Mark Andy debuts new Performance Series presses Mark Andy demonstrated at Labelexpo its newly-released press models, the P9E, P7E and P5E, which have been added to the award-winn...

October 02 2018

Mark Andy debuts new Performance Series presses

Mark Andy demonstrated at Labelexpo its newly-released press models, the P9E, P7E and P5E, which have been added to the award-winning Performance Series product line. The Performance Series platform, according to Mark Andy, redefines workflow productivity through its simple design, efficient waste savings and fast changeovers.

The new Performance Series P9E press is specifically designed for high-quality flexible packaging production. Available in web widths up to 26 inch (660 mm), the flexo press is engineered as the ideal solution to print film, shrink sleeves, flexible packaging and foil lidding.

Performance Series P9E is built standard with new servo-controlled impression adjustment, independent servo-driven anilox rolls and servo side adjust at print speeds up to 1,000 fpm. Ergonomic efficiency is at the forefront of the wider 22 and 26 inch web widths, which include plate cylinder loading support as well as an anilox and chamber drawer. Configured with Mark Andy AI, the Performance Series P9E offers advanced automation with automated registration and impression, job save, 8 servo motors per station and a centralized control system. The enhancements reduce manual adjustments and associated downtime while meeting Industry 4.0 demands. The Mark Andy AI package is intelligent and customized to unique business needs, curbing potential production bottlenecks.

Given the increased demand for shrink and pouches coupled with larger volumes of shorter run lengths, the P9E is a profitable platform for short run flexible packaging. Key to its success is the flexibility it offers converters, with a rail system providing endless opportunity through decoration versatility.

“Mark Andy has over 800 Performance Series installed worldwide. We continue to develop flexible printing solutions that allow our customers to evolve as their job mix changes. The Performance Series P9E is an extension of our commitment and solves the pain points narrow web converters are facing plus the growing demand for shrink,” said Jeff Cowan, director – business Development, Mark Andy.

The Performance Series press line also welcomes the P7E and P5E models. Engineered with precision, the Performance Series P7E allows converters to expand into new markets, targeting entry level film and extended content applications.The P5E is designed to increase converter profitability for the simplest to most complex label applications.

Cowan added, “The P5 and P7 have been best selling models in the Performance Series line, based primarily on the versatility and productivity. The release of the P5E and P7E demonstrates updated servo architecture allowing for tighter registration and a complete redesign of the converting options all focused on providing a better operator experience.“

The three new presses deliver an updated ProLED system with air cooling and modular recirculation dryers, both offering sustainability benefits. The machines are equipped with Mark Andy Thread-It technology, which simplifies press webbing for operators and is three times faster than traditional webbing methods. Additional press options include Digital Plus Screen, a digital inkjet replacement for rotary screen printing as well as QCDC-SR (Quick Change Die Cut Semi Rotary) adding advanced capability to flexo equipment that is also available on Mark Andy digital hybrid technology.

P9E, P7E and P5E models are offered alongside the well-known P3 and P4 press models, designed for the everyday converter’s book of pressure sensitive prime label business.

“Partnering with Mark Andy is more than just future-proof equipment. It’s a Total Solutions Partnership. We stand by our customers every step of the way, offering best-in-class service, endless opportunity of press upgrades, and the technical support to ensure proper use of the right supplies for various applications. It all works together nicely to maximize our customers profitability,” Cowan said.

METEOR INKJET FIRST TO OFFER ELECTRONICS & SOFTWARE TO DRIVE NEW SG600 PRINTHEADS FROM FUJIFILM DIMATIX Meteor Inkjet, the leading independent supplier of electronics and software ...

October 02 2018

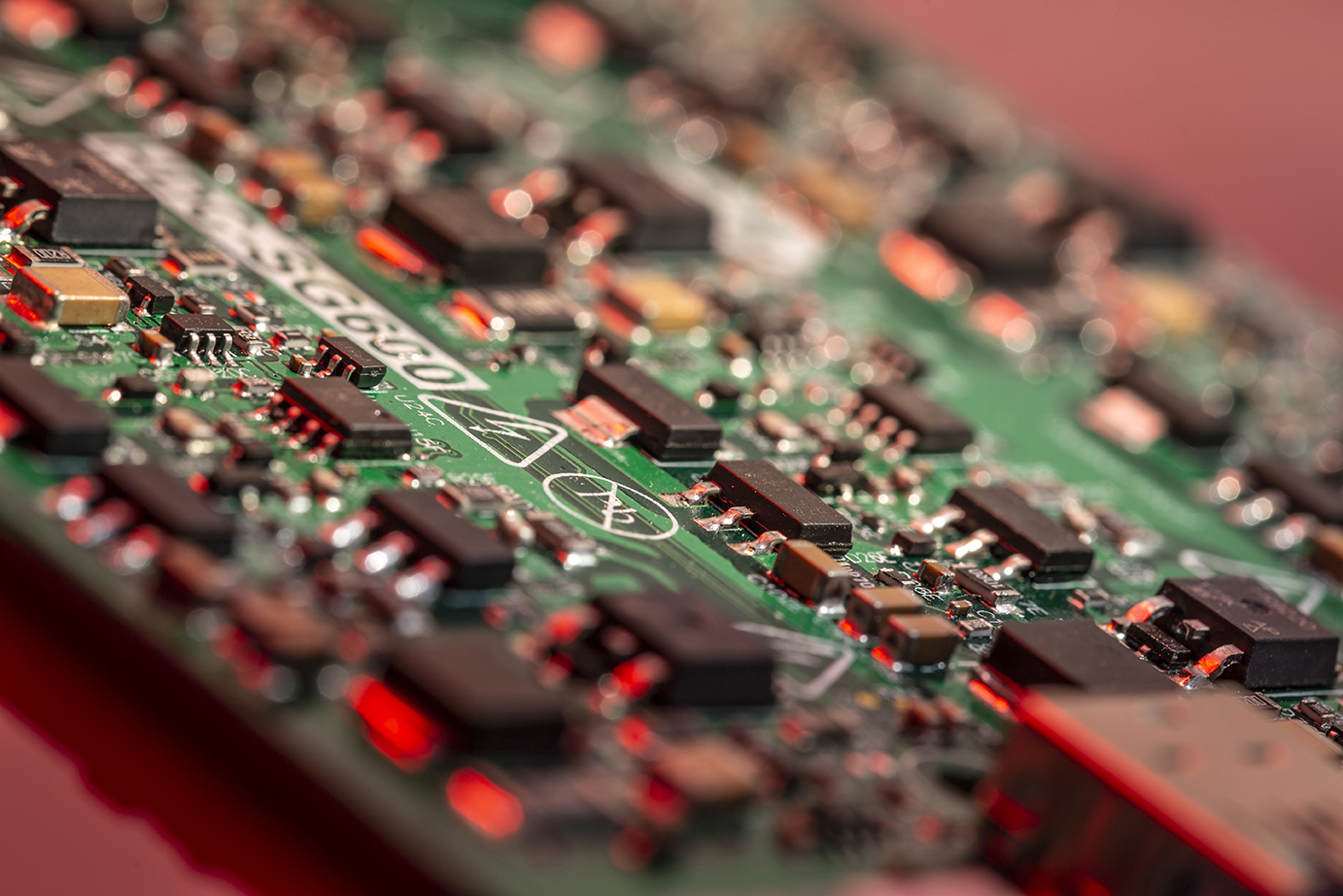

METEOR INKJET FIRST TO OFFER ELECTRONICS & SOFTWARE TO DRIVE NEW SG600 PRINTHEADS FROM FUJIFILM DIMATIX

Meteor Inkjet, the leading independent supplier of electronics and software to drive industrial inkjet printheads, further expands its product portfolio with the addition of the HDC-SG600 Head Driver Card, Printhead Evaluation Kit and Waveform Development Kit for FUJIFILM Dimatix SG600 printheads.

Formally launched today by FUJIFILM Dimatix, the SG600 recirculating printhead is suitable for textiles, corrugated packaging, ceramics, and many other industrial print applications. The SG600 is in the same printhead family as the highly successful SG1024 but takes the native resolution up to 600dpi. This allows printer OEMs to offer much higher ink deposition or finer detailed imaging at desired print speeds.

Each Meteor HDC-SG600 Head Driver Card (HDC) drives one SG600 printhead supported through a Meteor PCC-E GbitE Print Controller Card (PCC) which can accommodate up to eight HDCs. Multiple PCCs can be linked seamlessly to drive up to 2024 printheads. Used in conjunction with the electronics, Meteor’s powerful software supports a wide range of applications and allows print system builders the flexibility to design as much or as little of the Digital Front End as they choose.

In addition to electronics and software for the SG600, Meteor also offers a Printhead Evaluation Kit and a Waveform Development Kit to ease print system design and significantly speed time to market. Multi-head, multi-ink configurations can be evaluated and integrated using electronics and software that can then be transferred straight to manufacturing.

Clive Ayling, Meteor’s Managing Director comments, “We have a long history of collaboration with FUJIFILM Dimatix, having launched our first Meteor-branded drive electronics for Dimatix printheads in 2006. We are proud to be the first supplier to offer production-ready electronics, software and evaluation equipment for the new SG600 printhead and we look forward to providing customers an easy to integrate, scalable solution with the assurance of long-term, reliable supply for both development and production requirements.”