See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

ABG introduces new inline coating machine for HP Indigo 20000 AB Graphic International, a global manufacturer of print finishing equipment, has announced the ILC760, a new inline coati...

September 26 2018

ABG introduces new inline coating machine for HP Indigo 20000

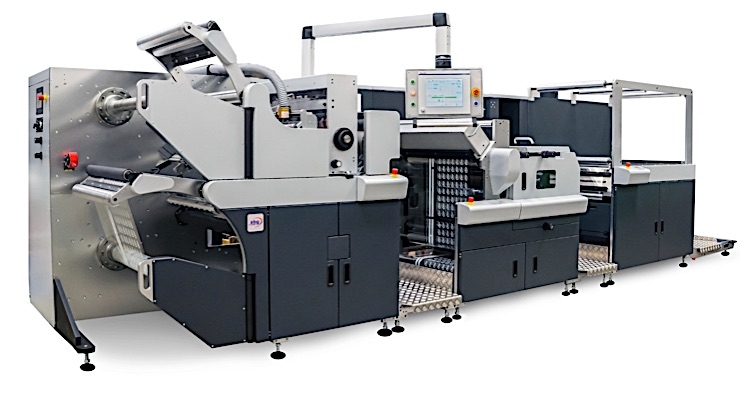

AB Graphic International, a global manufacturer of print finishing equipment, has announced the ILC760, a new inline coating solution for fully integrated inline coating on the HP Indigo 20000 digital press.

The ILC760 has made its debut at Labelexpo Americas at the HP booth, operating inline with the HP Indigo 20000, a top digital mid-web press for labels and packaging.

Supporting both water-based or UV coating, the ILC760 is a cost-effective, easy-to-operate, top coating solution with slitting-rewinding suitable for production of unsupported film applications such as sleeves, IML, wrap-around labels and various flexible packaging top-coated applications.

The 760mm wide ILC760 joins the Digicon 3000 in ABG’s growing finishing portfolio for mid-web digital production.

“The demand for digitally printed packaging is growing well beyond the pressure sensitive label market into areas such as sleeves, IML, and various flexible packaging applications,” says Tony Bell, ABG’s sales director. “ABG is pleased to continue collaborating with HP Indigo to redefine the boundaries of digital production by offering cost-effective innovations for simplified and efficient production.”

“ABG has a long standing strategic relationship with HP Indigo, and with this inline solution we are excited once again to bring a novel solution addressing the needs of the packaging industry,” says Yogev Barak, HP Indigo director of product development. “The new Digicon solution will help converters lower production costs and move towards more profitable digital printing solutions.”

Epson announces SurePress L-6534VW digital label press Epson has announced at Labelexpo the Epson SurePress L-6534VW digital label press. Joining the SurePress L-6034VW in the UV digit...

September 26 2018

Epson announces SurePress L-6534VW digital label press

Epson has announced at Labelexpo the Epson SurePress L-6534VW digital label press. Joining the SurePress L-6034VW in the UV digital label press line, the SurePress L-6534VW will offer three print speed modes from 49 feet per minute to 162 feet per minute (fpm). Epson will be demonstrating the new SurePress L-6534VW, as well as the SurePress L-6034VW and L-4533AW and workflow automation solutions with Wasatch RIP, at Labelexpo Americas in Chicago at Epson’s booth 5813.

“The SurePress L-6034VW set a higher standard for UV print quality,” said Mike Pruitt, product manager, Epson America, Inc. “Today we take our solution one step further by expanding the line to deliver faster print speeds compared to the previous generation; allowing prime label and packaging converters to fulfil demanding and varying portfolios more quickly – ultimately optimising productivity and efficiency.”

Designed for label converters investing in a digital label press for the first time or looking to expand production facilities with a reliable, easy-to-use press, the SurePress L-6534VW delivers three print speed modes to meet a range of converter needs:

Flexo Wash unveils new Laser Anilox Cleaner Flexo Wash is showcasing its latest offerings at Labelexpo Americas, which have been established in the industry for more than 25 years. Mor...

September 26 2018

Flexo Wash unveils new Laser Anilox Cleaner

Flexo Wash is showcasing its latest offerings at Labelexpo Americas, which have been established in the industry for more than 25 years. More than 3,000 converters and printers have chosen to use Flexo Wash anilox cleaners to improve their printing process.

The company has released its Flexo Wash Laser Anilox Cleaners. Converters and printers have been viewing the FW 2000 Laser Anilox Cleaner and discussing their printing process cleaning needs with Flexo Wash representatives during the show.

Ryan Potter, vice president of sales for Flexo Wash, attests that, “Our customers and prospects are excited to finally have an open and truly comparative conversation about the pros and cons of each technology. Flexo Wash provides the 'Flexobility' for converters and printers to choose which system works best for them.”

The industry now has access to two Flexo Wash cleaning technologies: the agile Liquid Cleaner and the emerging Laser Cleaner. Like the Liquid Cleaner, the Laser Cleaner gives an excellent cleaning result. “The FW 2000 and FW 3000 Laser Anilox Cleaners have the latest in laser technology. The FW 2000 Laser shown at Labelexpo Americas cleans an anilox roll or sleeve with a maximum cleaning length of 67” (1,700 mm)," states Anders Kongstad, technical director for Flexo Wash in Denmark. “The FW 2000 Laser can also be configured to clean multiple narrow web anilox rolls or sleeves in a single cycle.”

mprint showcases mlabel GEN3 UV inkjet hybrid mprint gmbh of Baiersbronn, Germany is displaying its new generation of hybrid UV inkjet presses, the mlabel GEN3 at Labelexpo Americas 20...

September 26 2018

mprint showcases mlabel GEN3 UV inkjet hybrid

mprint gmbh of Baiersbronn, Germany is displaying its new generation of hybrid UV inkjet presses, the mlabel GEN3 at Labelexpo Americas 2018. Aside from the obvious facelift from GEN2, the machine incorporates several technological advances and additional modules.

The base machine has a standard mechanical width of 13" (330mm) but does not have to be outfitted with a print engine of the full print width from the beginning. This will allow a technology implementer to start with a lower cost system and expand the print engine in the future, adding capacity without having to purchase a new machine.

Aside from being equipped with CMYK+W, the machine shown at Labelexpo incorporates the Digital Metal Liner module – a fully digital foil embellishing unit, allowing printers to not only generate metallic effects on labels and packaging in a single pass, but also to customize these effects with every print. This state-of-the-art module was developed in cooperation with KURZ Transfer Products using their Digital Metal UV Ink technology and presents a technological milestone in digital printing. Especially suited for wine and spirit labels, cosmetics and other high value label and packaging applications, the seamless integration of foil embellishments into the digital workflow will give brand owners more possibilities to enhance their products.

Recycling of the inks used for purging and flushing the printheads is engrained in mprint’s concept and has not only a big environmental impact but also reduces ink cost by increasing ink utilization to over 99%. In adherence to the philosophy of mprint to adapt the machines to customers' requirements, the machines can be equipped with a vast array of color options of the digital print engine – CMYK+W+OV+G plus/or spot colors or spot varnishes, etc. – aside from analog options like flexo print stations, etc.

Through the introduction of the mlabel GEN3 series, mprint has advanced its standard UV inkjet narrow web machine portfolio to cover print widths from 4.25” – 12.75” (108mm to 324 mm) and single to multi-color (seven or more) by giving the customer all possible choices in initial price and future machine expansion. Custom machines with print widths of 17" (432mm) and above are also available.

Phoseon introduces first passively cooled UV LED source Phoseon Technology has introduced FireEdge FE100, the first natural convection UV LED light source for industrial curing and wil...

September 26 2018

Phoseon introduces first passively cooled UV LED source

Phoseon Technology has introduced FireEdge FE100, the first natural convection UV LED light source for industrial curing and will show it at Labelexpo Americas 2018.

The FE100 UV LED curing lamp for digital inkjet pinning has no internal fan and is cooled passively through natural convection. A secondary application is edge curing during the manufacture of flat panel displays.

‘With its instant on/off and full intensity control, the FE100 enables precise finish control for digital inkjet pinning,’ said Ed Kiyoi, senior technical marketing engineer at Phoseon Technology. ‘And it’s extremely slim form factor makes it ideal for flat panel display edge curing.’

Using only ambient air for cooling, the FE100, which has an emitting window of 180x10 mm, eliminates the need for any external forced-air cooling system or chiller to remove heat from the UV source.

The FE100 joins the family of Phoseon FireEdge compact air-cooled UV LED light sources that minimize the distance required between inkjet heads, offer a simple, quick programmable logic controller (PLC) interface and provide high reliability and long life.

The FE100 will be available in the fourth quarter of 2018.

Xitron introduces Navigator Flexo Suite Xitron, an independent developer of RIP and workflow products for commercial, digital, flexo, and high-speed inkjet printing has introduced Navi...

September 26 2018

Xitron introduces Navigator Flexo Suite

Xitron, an independent developer of RIP and workflow products for commercial, digital, flexo, and high-speed inkjet printing has introduced Navigator Flexo Suite at Labelexpo. Comprised of several productivity tools designed specifically for flexo imaging, the modular workflow is fully compatible with any flexo CTP engine that accepts one-bit TIFF files, such as Amsky, Cron, Xeikon, and others.

Conceptualized in meetings with several flexo CTP vendors at last year’s Labelexpo in Brussels, the package was developed, tested, and sent to beta accounts around the world in the span of nine months. “We had a very specific list of requirements with which to work,” said Karen Crews, president of Xitron. “Besides our meetings with Flexo CTP manufacturers, we also worked with distributors and dealers before building the product roadmap. This gave us a short list of ‘must-have’s’ in terms of functionality. All of our CTP partners wanted a competitive price point, productivity beyond existing systems on the market, and the option of high fidelity screening for applications that require it,” she continued.

Navigator Flexo Suite starts with the ubiquitous Navigator RIP platform, of which more than 35,000 have been sold in commercial, in-plant, digital, screen printing, inkjet, and flexo markets around the world. Notably, Navigator Flexo Suite makes its debut being PDF 2.0 compliant right out of the box, as Xitron began shipping Navigator 12 on September 24th.

It’s coupled with the Client-Server properties of the Navigator workflow, which gives all prepress operators and artists independent submission, modification, pixel-level preview, and throughput control of jobs from their own workstations. This allows them to work independently and without interruption from anywhere on the network. Finally, all the color separated job plates are collected by Navigator Plate Controller, which helps the operator assemble the final flexo plate for output with as little material waste as possible.

The optional high-fidelity screening engine gives users the ability to specify FM to AM crossover points between highlights/shadows and mid-tones while also letting them determine minimum dot size through nine levels of sustainable “smart dots.” Users are able to customize the screening based on platesetter exposure accuracy and the print results of each individual press. Those customized setups are retained as screening templates for repeated use.

“From day one, our goal was to develop a product that could hit the market at a price point under $15,000 to stay in line with the decreasing cost of flexo CTP engines,” said Crews. “It was an intense development and testing cycle, but we brought it to the finish line without compromising the original requirements list.”

From the end user’s perspective, one thing that rated high on the list was annual maintenance costs; something they see as out of control in software and not always accounted for when considering a purchase. “We addressed the maintenance issue head on,” said Crews. Annual support for Navigator Flexo Suite is an affordable $1,495 per year, and that includes minor upgrades.”

Nineteenth Century Palace Restored Using Massivit 3D Printing All over the world, there are a wealth of iconic landmarks and listed buildings steeped in history. These structures...

September 25 2018

Nineteenth Century Palace Restored Using Massivit 3D Printing

All over the world, there are a wealth of iconic landmarks and listed buildings steeped in history. These structures often serve as monuments that recognize a region’s history. However, as the decades pass, many of these stunning buildings deteriorate, some naturally, others due to neglect, or simply a lack of investment.

Italy is a prime example of this - the country is synonymous with historical buildings that dot the landscape. Construction companies are frequently approached to restore these magnificent remnants of history, something which is often far from straightforward due to cost restraints and the lengthy construction time it can take to complete such projects. Savvy palace-owners are overcoming these bottlenecks by enlisting the help of innovative companies like Sismaitalia.

Sismaitalia, a pioneer in visual communication, interior design and digital printing, was the first Italian business to adopt a Massivit 1800 3D printer. After initially acquiring the solution to provide customers with unique, interior design applications, the company subsequently recognised a gap in the restoration market that could be solved using rapid, large format 3D printing.

“With the capability to 3D print super-large objects, we can provide our customers with exact replicas within a fraction of the time and cost compared to traditional methods. This capability has seen us expand our service offering to existing customers as well as target new markets,” says Federica Tisato, Marketing & Communication Manager of Sismaitalia.

This is exemplified in a recent project, which saw Sismaitalia construct five life-size capitals for the grand Spada Palace in Ferrara.

Built in the 1800s, the palace was originally owned by the renowned Spada family and was subsequently inhabited by several other families before its current use as a hotel.

According to Tisato, the company was approached by the owners following a recommendation from a specialist restoration engineer. “The owners noticed that the crumbling façade of the capitals had become weathered over the years. As they are an essential element to the French balcony, the owners required them to be restored urgently,” she explains.

Traditional restoration methods involve prolonged turnaround times, mostly due to the manual labor required. Additionally, depending on the intricacy, costs can often soar. Seeking a more cost-effective solution, the owners considered a temporary polystyrene replacement until they discovered the multitude of benefits achievable with 3D printing.

With 3D printing, objects can be precisely replicated due to the technology’s digital nature. The five capitals were produced in two sizes, with one set measuring 480mm high x 430mm long x 215mm thick (19 x 17 x 8’’), and a larger set of three comprising pieces that measured 790mm high x 790mm long x 215m thick m (31 x 31 x 8’’). Using the Massivit 1800’s dual printhead, Sismaitalia could simultaneously produce a pair of capitals in just 20 hours.

Federica Tisato explains: “With the capability to produce each full-sized capital in one print, we could eliminate the lengthy turnaround times associated with traditional restoration methods. Beyond this, as the owners only required the 3D printed capitals for aesthetics, we could quickly produce the hollow structure and strengthen these with polyurethane foam to withstand the weight of the balcony. This ensured that manufacturing costs were kept to a minimum.”

Once filled, each capital was finished with plaster and painted the same color as the original counterparts to ensure an authentic look. “As an architect, 3D printing opens the door to greater design options. It enables me to realize large projects in short timeframes without compromising on the aesthetics,” says Alberto Apostoli, Architect at Studio Alberto Apostoli.

Tisato concludes: “From a business perspective, projects like these demonstrate the growing adoption of 3D printing in a vast gamut of markets. We anticipate that this capability will continue to open the door to new markets. In fact, to date, our Massivit 1800 has played an integral role in securing projects within the interior design and architectural sectors and we have a handful of additional restoration projects in the pipeline!”

www.massivit3d.com/about/

O-I : EXPRESSIONS TO TRANSFORM GLASS BOTTLE DESIGN A technological leap forward will create new marketing opportunities for brands through customisation and personalisation by sculptin...

September 24 2018

O-I : EXPRESSIONS TO TRANSFORM GLASS BOTTLE DESIGN

A technological leap forward will create new marketing opportunities for brands through customisation and personalisation by sculpting glass bottles into multi-dimensional works of art, enabled by digital printing.

O-I has launched O-I : EXPRESSIONS, an innovation developed for design agencies, packaging professionals and all food and beverage marketers who want to stand out and offer their consumers new reasons to love and choose their brands. O-I : EXPRESSIONS enables late-stage design, combining the integral benefits and heritage of glass with an agile, marketing-focused capability. The innovation allows O-I’s customers to build brand engagement, consumer satisfaction and loyalty as well as demonstrate premium value.

Enabled by digital printing, O-I : EXPRESSIONS will enable brands to create highly personalised and customised glass packaging at flexible volume, industrial speeds, and affordable value, with an unprecedented range of colour and design possibilities, compared to traditional decoration solutions.

With O-I : EXPRESSIONS, brands will be better equipped to respond to growing consumer demand for personalised and ‘made for me’ products. Brands will quickly and nimbly be able to develop packaging to support short campaigns, such as seasonal promotions or limited/special editions to mark major events. In addition, O-I : EXPRESSIONS is sustainable. It uses organic inks, not impacting the recyclability of glass, and it helps reduce waste through lower inventories.

A premium version of the service, O-I : EXPRESSIONS RELIEF, named after the sculptural technique, will also offer brands the opportunity to use customised tactile digitally printed effects, such as embossing and coloured embossing. This will enable brands to interact with consumers through the sense of touch through cost-efficient flexible volume runs. O-I : EXPRESSIONS RELIEF takes brands a step beyond what was previously thought possible in terms of customisation and premiumisation.

The O-I : EXPRESSIONS services are planned to be commercially available by mid-2019 in Europe and shortly after in the US. In the meantime, O-I is already available to initiate projects and discuss collaborations.

O-I : EXPRESSIONS offers extreme flexibility to marketers thanks to speed, small volume print runs, mass-personalisation, vibrant saturated colours in every Pantone hue, photo-quality. New product development cycles will be shortened giving customers the opportunity to make last-minute modifications, while the small volume runs will allow marketers to customise printing down to a single market, region, or even a single event.

For more information visit www.discoverexpressions.com

Books, Bills and Direct Mail Printing Now More Productive and Profitable with the Xerox Brenva HD Production Press With the demand for color inkjet pages expected to grow more than fiv...

September 20 2018

Books, Bills and Direct Mail Printing Now More Productive and Profitable with the Xerox Brenva HD Production Press

With the demand for color inkjet pages expected to grow more than five-fold through 20221, print providers need more productivity and flexibility from their inkjet devices to capture that growth. To respond to the demand, Xerox has increased output capacity for the Xerox Brenva HD Production Press by more than 50 percent, expanded stock choices and added a roll feed capability for continuous operation.

Productivity Boost

With the new duplex speed kit, Brenva HD's output speed increases from 182 to up to 275 pages per minute, allowing print providers to take advantage of the inkjet value proposition, high quality and high output for key application areas.

"Print speed, workflow efficiency and production costs are among the top decision drivers for print providers considering inkjet," said Marco Boer, vice president, IT Strategies. "The Brenva HD speed upgrade means print providers can get more valuable jobs out the door faster, especially in key application growth areas such as transactional and direct mail."

Brenva HD's increased output also creates new ways to print more jobs faster. The new kit increases productivity by speeding up duplex (two-sided) printing, which is essential for books and manuals, as well as many transactional jobs. Depending on the sheet size used, print providers can now achieve up to 300 letter size impressions per minute with the Brenva HD.

Production Flexibility

Working with technology partner, Tecnau, Xerox now offers the Tecnau SheetFeederT BV roll feed system for up to nine hours of non-stop cut sheet paper feeding. Brenva HD is the first sheet-fed inkjet press to offer a roll feed option, enabling print shops to produce longer run jobs without frequent paper tray restocking.

The book, transactional and direct mail segments are all expected to have double digit compound annual growth rates in production inkjet pages by 20221. With Brenva HD's increased output and new roll feed capabilities, print providers can grow profitability by reducing run costs and increasing capacity.

More Applications, More Profit

To give print providers even more opportunities to produce new applications, Brenva HD can now print on heavier weight stocks up to 270 gsm. A wider range of applications such as postcards, ID cards, and other jobs that utilize thicker, heavier media can now be produced quickly and efficiently on the Brenva HD.

"We're continually looking for ways to drive new business efficiencies and opportunities for our customers, and our upgrades for Brenva HD were designed with those key elements in mind," said Ragni Mehta, vice president and general manager, Cut Sheet Business, Xerox. "Our customers can now focus on maximizing their business potential and growing revenue by taking on more print jobs, regardless of run length."

Availability

The Brenva HD speed kit will be available for order taking beginning September 17. The kit will be available for both new equipment and as an upgrade to existing machines.

HP technology behind 3.2 million unique water bottles in Europe Danone is now selling 3.2 million Aqua d’Or water bottles in one-of-a-kind packaging for the Danish mineral water ...

September 20 2018

HP technology behind 3.2 million unique water bottles in Europe

Danone is now selling 3.2 million Aqua d’Or water bottles in one-of-a-kind packaging for the Danish mineral water brand. Folienprint Rako, an All4Labels Group company, produced the water label campaign in two weeks using its HP Indigo 20000 Digital Press and HP’s SmartStream Mosaic and PrintOS print software.

The mineral water bottle labels for Aqua d’Or’s “Flow Your Way” campaign feature unique designs by Danish artist Emil Kozak expressing nature and individuality, in a collectables promotion for the Swedish and Danish market created to engage with millennials.

“Using HP digital printing, the labels tell the story of Aqua d'Or natural mineral water flowing for 300 years through the untouched Danish nature until reaching purity, using design elements of drops, waves and skies,” said Line Jorgensen, Brand Manager at Aqua D´Or. “The collaboration with HP digital printing and Danish artist Emil Kozak and HP made it possible to create these 3.2 million distinctive and creative labels.”

Eleven design patterns based on Aqua d’Or’s story elements were converted automatically into unique creations by HP Mosaic print software.

Aqua d’Or launched the special edition on August 30 at an event in the centre of Copenhagen, where the water bottles were exhibited in an art gallery. In a live printing experience for the 200 guests, posters of Emil Kozak’s designs were also printed by Damgaard-Jensen in Denmark.on HP Latex printers on site and signed by the artist.

“The Aqua d’Or campaign is a perfect example of how brands are using HP digital technology to become distinctive, while being creative and playful and generate excitement and buzz for the product among new customer groups, in this case millennials,” said Jose Gorbea, HP EMEA Brand Owner – Digital Print Solutions for Brands. “Flow Your Way showcases how HP´s technology can support the creation of multi-media campaigns, from 3.2 million unique labels to personalized in-store and outdoor advertisement, including transforming event spaces with HP Latex technology.”

The labels were printed on the 76 cm-wide HP Indigo 20000 Digital Press, delivering high-volume, wide-format label printing on a wide range of materials. HP SmartStream Mosaic is an algorithm which automatically generates a high number of unique graphic patterns from seed designs.

To create the 3.2 million ready-to-print PDFs, Folienprint used HP PrintOS composer, a cloud-based application using central high-performance servers, for super-fast creation of print files from variable data fed into VDP design templates.

“Thanks to the cloud-enabled PrintOS Composer application we were able to quickly turn around a very high volume of one of a kind print files on our HP Indigo 20000 and deliver a timely product for a key brand customer within two weeks,” said Michel Koch (Head of Pre Press Digital) of All4Labels.

PrintOS Composer creates compact PDF files for optimized fast processing on HP DFEs, making it up to 50 times faster compared to standard non-cloud tools. The ability to use PrintOS Composer on demand and with no hardware installation, simplified and expedited Folienprint production.

Mitsubishi Imaging (MPM) Inc. Introduces SWORDiJET 5.5 High Gloss Mitsubishi Imaging (MPM) Inc. announces the addition of the SWORDiJET 5.5 High Gloss to Mitsubishi Paper Mill’s ...

September 20 2018

Mitsubishi Imaging (MPM) Inc. Introduces SWORDiJET 5.5 High Gloss

Mitsubishi Imaging (MPM) Inc. announces the addition of the SWORDiJET 5.5 High Gloss to Mitsubishi Paper Mill’s (MPM) portfolio of high-speed production inkjet coated papers. “We are excited to bring to market one of the highest gloss levels available for high speed printing”, says Chris Hung, Vice President of Sales and Product Planning. “An 80% gloss level opens up a range of possibilities for Publishers”, he continues. Mitsubishi specifically engineered SWORD iJET 5.5 High Gloss to target the high-end Magazine, Catalog, Book and Scientific Journal market which are seeing growth from the benefits of personalized content and print on demand capabilities that are now possible with high speed production printing.

Mitsubishi partnered with HP to license SWORDiJET 5.5 High Gloss with the HP ColorPro technology. “We’re proud to have worked with one of the most successful and trusted OEM’s in the High Speed Print market. The stringent print, color excellence and performance standards developed by HP ensure successful implementation. Together, we’re delighted to offer a seamless solution for high quality, efficient output for Printers and Publishers” says Mitsubishi Imaging (MPM), Inc. CEO and President Hide Tsukada.

HP and Mitsubishi are committed to the value of print and Production Inkjet technology. HP’s press advancements and technical support program combined with Mitsubishi Paper Mills coating technology offer high value opportunities for Print Service Providers (PSP) to expand existing business or create new markets to serve. PSP’s will see immediate cost savings in efficiencies, Mitsubishi’s coating technology maximizes press performance with increased speeds, reduced ink loading and unprecedented dry times. Additionally, high volume accounts can benefit from cost advantages in direct container paper shipments.

SWORDiJET 5.5 High Gloss is available in 90 gsm/24lb basis weight, with heavier grades to follow including a 7 and 9pt to serve Direct Mail applications. In addition to the Mitsubishi SWORDiJET 5.5 High Gloss, SWORDiJET 4.3 Gloss and Matte and Premier IJ Book and Form have also been licensed with HP ColorPro technology and will be available through established distribution partners. These grades are all produced at Mitsubishi Paper Mill’s fully integrated Hachinhoe Paper Mill in Japan. For additional information, please visit www.mitsubishiimaging.com/production-inkjet.html

Konica Minolta 2018 National Specialised Print Awards: judges announced, one week to go Konica Minolta has announced the judges for its 2018 National Specialised Print Awards. Th...

September 18 2018

Konica Minolta 2018 National Specialised Print Awards: judges announced, one week to go

Konica Minolta has announced the judges for its 2018 National Specialised Print Awards. The awards celebrate exceptional craftsmanship in digital printing with the help of a Konica Minolta digital press system.

The judges are:

· Anthony Parnemann, Manager – South East Asia, EFI

· Kellie Northwood, Executive Director, Two Sides Australia

· Darrell John, Technical Sales Specialist, Konica Minolta

· Kenneth Beck, Director, Carbon8.

Following the success of the awards in 2016 and 2017, the scope has been extended this year to include additional categories. Konica Minolta is looking for the best work produced in five categories: Digital Flat Sheet; Digital Print Bound Books; Digital Brochures and Booklets; Digital Label Print; and Digital Embellishment.

The expert judges will select the best of the best in the five categories as well as one overall winner. Finalists will be flown to Sydney to attend the Konica Minolta National Specialised Print Awards event on October 24, 2018, where the winner will be announced.

The overall winner will receive an exclusive trip to visit Konica Minolta’s headquarters in Tokyo, Japan, including a tour of its Customer Experience Centre and R&D facilities in 2018.

There is only one week remaining to submit entries, with entries closing at 5pm on Friday, September 21. To enter, please visit: www.konicaminolta.com.au/nspa

Konica Minolta Launches AccurioWide 160 and 200 Hybrid UV LED Wide Format Printers First-Ever Konica Minolta-Branded Wide Format Products Konica Minolta Business Solutions...

September 14 2018

Konica Minolta Launches AccurioWide 160 and 200 Hybrid UV LED Wide Format Printers

First-Ever Konica Minolta-Branded Wide Format Products

Konica Minolta Business Solutions U.S.A., Inc. (Konica Minolta) announced the commercial launch of the AccurioWide 160 and AccurioWide 200 wide format printers, both of which employ a hybrid technology platform that can print on most types of roll-to-roll, flexible roll and rigid media. The AccurioWide printers are positioned for commercial printers, franchise printers and sign shops that want to take their wide format production to the next level for efficiency and cost savings.

Powered by Konica Minolta KM1024i print head technology, both printers use UV ink technology that incorporates more color pigment per droplet, reducing ink consumption compared to other printers on the market. Outstanding print quality, with a large color gamut and outstanding color vibrancy, is achieved by printing up to 1440 x 720 dpi print resolutions. For print production savings, a combination of air-cooled ultraviolet light (UV) and LED curing lamps speed up ink drying times and, in most cases, the LEDs will last the life of the printer.

The AccurioWide 160 operates in various print speed modes, from draft to high quality, printing with four colors with white inks or six color inks only. The AccurioWide 200 has a larger print width, faster print speeds than the 160, and prints in six colors with white inks. Capable of printing to a wide range of media and substrates, the AccurioWide printers will allow for traditional sign and display applications like point of purchase banners, as well as niche applications including printing directly to aluminum di-bond metal or wood for specialty products.

In addition, the AccurioPro WideDirector, a complete and robust software workflow that drives AccurioWide printers, can handle the most difficult and complex print jobs. The all-in-one software has the capability of managing colors and pre-flight tools by automatically analyzing an incoming digital print job, making suggestions to improve image quality as needed. The software offers automated job layout with step & repeat, image nesting with printing to multiple printers and compatibility with print finishers. The AccurioPro WideDirector also features compatibility with Konica Minolta FD-9 scanning spectrophotometer and other third-party devices for color profiling and color management. In the near future, AccurioPro WideDirector will also provide support for the Konica Minolta FD-5 and FD-7 hand held spectrophotometers.

“The introduction of the AccurioWide 160 and 200 printers represents the first-ever Konica Minolta-branded wide format products released. They represent our continued achievements and expertise with Konica Minolta print head imaging technology and our color management tools to create incredible print value for our customers,” said Dino Pagliarello, vice president, Product Management & Planning at Konica Minolta. “For our North America launch, we are currently taking U.S. product orders for both printers, with launches in Canada and Mexico anticipated in the months ahead,” Pagliarello added.

The AccurioWide 160 printer will be on display and demonstrated at the industry trade show, Print 18, McCormick Place South, Chicago, September 30 – October 2, at booth #1611; and at the Specialty Graphic Imaging Association (SGIA) Expo, Las Vegas Convention Center, at booth #3769. The AccurioWide 200 will also be on display for the first time and demonstrated at the SGIA Expo.

Océ Wins Best Stand with Tactile Custom Printing at Visual Impact The show preparation inside the Sydney Showground might have had the team from Océ Aus tralia working in...

September 13 2018

Océ Wins Best Stand with Tactile Custom Printing at Visual Impact

The show preparation inside the Sydney Showground might have had the team from Océ Aus tralia working into the night, but it’s been worth the effort, with the company taking out Best Stand at the Visual Impact exhibition and visitors flocking to stand D17 from the show’s opening this morning.

The stand is easy to spot, dominated by a custom-built tunnel, replicating the company’s popular mobile ‘pop-up- showroom. On the outside, it features a simple concrete look graphic, but on the inside it’s a vibrant, tactile print experience emblazoned with graffiti graphics – all custom-produced on the company’s Arizona and Colorado printers.

The revolutionary Océ Colorado 1640 64” roll-to-roll printer and new, Touchstone ‘2.5D’ printing on an Océ Arizona 2280, are the show drawcards for Océ in Sydney and visitor response is already proving that the combination is a winner.

“There’s one advantage to print that the online experience simply can’t replicate – and that’s the physical dimension which allows viewers to interact with a product not only visually, but with touch,” said Dale Hawkins, Senior Marketing Manager from Océ Australia, when we caught up with him on stand today.

“On one wall of the tunnel we have a Colorado media gallery with images printed on 12 different media, showcasing the versatility and quality this revolutionary printer. It’s quite extraordinary, even more so when you consider that it’s arguably the fastest roll-to-roll printer on the market, and it really demonstrates the different impacts you can achieve by using different media,” he says.

On another wall, as visitors will quickly work out, is printed on the Arizona, using Océ’s exciting new Touchstone workflow software, which opens the door to textured, dimensional print – or what Océ is calling ‘2.5D’ printing.”

“Touchstone itself is a set of extensions to the Adobe toolset which allow designers to build dimensional features into their print jobs, for output to Océ Arizona printers,” Hawkins explains.

“Not only do the results look good, with a range of exciting metallic and varnish effects and image quality which holds its precision regardless of the dimensional element, it feels amazing with areas that can be built up, creating an unique dimensional effect.”

The number of people running their hands over the wall at the show today bear testament to the novelty value, certainly, but Hawkins points out that for these VI visitors, Touchstone is an important tool which could enable them to leverage the demand for the added interest and tactile engagement that dimensional print provides, and create exciting new products which command a high margin.

“All these initiatives are part of our quest to help our customers build more flexible, more profitable businesses which put more money in their pockets,” Hawkins says, perhaps deliberately turning attention to another show stealer: A treasure hunt involving lost wallets hidden throughout the show, which finders can return to the Océ stand and redeem a $50 movie voucher after learning about the Colorado.

If that’s not enough to get you down to the Sydney Showground between now and Friday, Océ is also showcasing it’s FASTtrack Toolbox, a competitive finance offer which promises qualifying businesses no repayments for three months, an extra 20 litres of ink to get going, and a $7,500 credit for media

supplies from Ball & Dogget – as well as applications consultancy and ‘How To’ guide, and professional business and ROI assistance.

Visual Impact Sydney runs for the rest of this week at the Sydney Showground, Sydney Olympic Park. Doors open tomorrow from 10am until 6pm and on Friday from 10am until 4pm. With queues likely to lengthen as the week progresses, those intending to visit are encouraged to register online to ensure they make the most of their time at the show.

Alfex CNC is looking for two exceptional people to join their team. Positions include: Service Technician Brisbane, ...

September 12 2018

Alfex CNC is looking for two exceptional people to join their team.

Positions include:

Service Technician

Brisbane, Queensland

· EARN a Generous Salary Package | Negotiable Based On Experience

· Australia's Leading Supplier of Laser Engraving & Cutting Systems

· Exciting Opportunity To Showcase Your Skills in a Dynamic Role

· Take Home A Fully Maintained Service Vehicle, Laptop & Mobile Phone

· Join a Fun & Engaging Team & Service Clients Across Brisbane!

We are seeking a Service Technician to join us in Brisbane, QLD.

· Servicing, troubleshooting and maintenance for laser engraving and cutting systems

· Installing all types of machinery along with customer training

· Maintaining excellent communication with the suppliers and customers

· Building new relationships and creating new business

· Assist the sales teams and attend trade shows as required

To be successful in this role you will have:

· Previous experience as a field service technician

· A high level of mechanical aptitude

· A current QLD drivers licence

· Experience using graphics packages such as Coreldraw or Illustrator (beneficial)

· Excellent time management and customer service skills

· A high level of pride in your work

Marketing Coordinator

Broadmeadows, Victoria

· EARN a Generous Salary Package | Negotiable Based on Experience

· Join an Established & Reputable Technology Supplier in Melbourne, Victoria

· Flexible Role - 3 Days Per Week - Potential Opportunity to Work from Home

· Take the Next Step in Your Career in This Dynamic Role!

We are seeking a Part-Time Marketing Coordinator to join their head office in Broadmeadows, VIC with the potential to earn a generous salary package, negotiable based on experience. This role will be based over three days per week and once you are established, flexible work arrangements such as working from home can be discussed.

HP Pitches 3-D Metal Printer in Bid to Expand in Manufacturing HP Inc., the largest maker of personal computers, is making a big push into the manufacturing industry with its first pri...

September 12 2018

HP Pitches 3-D Metal Printer in Bid to Expand in Manufacturing

HP Inc., the largest maker of personal computers, is making a big push into the manufacturing industry with its first printer that can churn out 3-D metal parts.

HP is unveiling the Metal Jet printer, and some early customers, at a manufacturing trade show in Chicago on Monday. Engineering firm GKN Plc is using the printers in its factories to produce parts for companies including Volkswagen AG, one of the biggest automakers. GKN makes more than 3 billion components a year and expects to print millions of production-grade HP Metal Jet parts for customers as early as next year, HP said in a statement.

“We are in the midst of a digital industrial revolution that is transforming the $12 trillion manufacturing industry,” HP Chief Executive Officer Dion Weisler said. “HP has helped lead this transformation by pioneering the 3-D mass production of plastic parts and we are now doubling down with HP Metal Jet.”

Since its split from Hewlett Packard Enterprise Co., HP has redoubled efforts to expand beyond its core PC and paper printer businesses. 3-D printing is a big part of this plan. The new steel-printing machine could open up new opportunities in the automotive, industrial and medical-equipment fields. Metal parts manufacturer Parmatech Corp. has also signed on as a partner.

Printers that make three-dimensional metal objects already exist, but HP said Metal Jet can produce a lot more parts at "significantly" lower cost than existing machines.

Technology like HP Metal Jet lets manufacturers produce parts without first having to build the factory tools that are traditionally needed, according to Martin Goede, head of technology planning and development for the Volkswagen brand. “By reducing the cycle time for the production of parts, we can realize a higher volume of mass production very quickly.”

Stephen Nigro, HP’s president of 3-D printing, was more cautious than his boss Weisler, saying it will be at least five to 10 years before the unit generated a material share of HP’s sales, which topped $50 billion last year.

The reason for the caution is that even at early-adopter Volkswagen, use of the printer will be reserved for specialty parts on certain models, and not for the highest-selling vehicles. Volkswagen will start out with cosmetic pieces, having partner GKN use the printers to make customized car key rings and nameplates that drivers can put on their trunk lid or door. For its next generation of cars, Volkswagen plans to use printed mirror mounts and gearshift knobs, and continues to evaluate other use-cases for HP’s machines.

“The sweet spot of 3-D printing technologies is not in giant numbers in vehicles like the Golf,” said Sven Crull, Volkswagen’s head of design for new manufacturing technologies. “There’s a better use case in more specialty parts for vehicles with volume of 50,000 to half a million.”

That underscores the challenge of making the Metal Jet printer ubiquitous: At very high volume, other manufacturing methods are more economical. Still, Nigro said it’s one of HP’s best shots to bolster its future.

“We needed to come up with a disruptive or winning technology,” he said. “We need to have a vision that’s not just compelling today, but in the future.”

W&H furthers development of inkjet press for flexible packaging Windmöller & Hölscher (W&H), a specialist in machinery and systems for the manufacturing and conve...

September 12 2018

W&H furthers development of inkjet press for flexible packaging

Windmöller & Hölscher (W&H), a specialist in machinery and systems for the manufacturing and converting of flexible packaging, has developed an inkjet press concept that will allow the technology to be effectively used in this market.

W&H CEO Dr Jürgen Vutz explained: ‘We see a need in the flexible packaging market to use digital printing in addition to the established processes. This is driven by the need for faster time-to-market and very short order lengths.

‘However, the application of flexible packaging has very special requirements, for example regarding the adhesion of the ink to the film. As specialists in this market, we bring expert knowledge to offer answers to these challenges. First, by continuously advancing the established processes such as flexo and gravure printing. Second, by opening up the possibilities of digital printing for flexible packaging.’

W&H noted that while digital printing is already firmly established in the label and commercial printing sector, flexible packaging continues to be a challenge. An economical and stable digital printing process has yet to be developed, it noted.

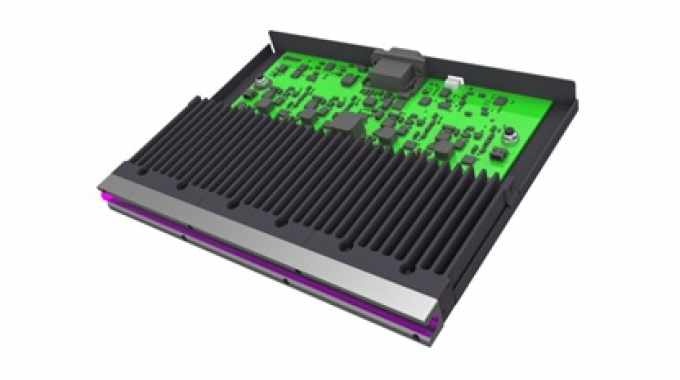

To this end, W&H has now begun onboarding partners for its single-pass option, with Xaar providing the piezo inkjet technology upon which the W&H inkjet press is built This will see Xaar 5601 printheads used after successful performance tests. Xaar 5601 printheads use Xaar's new thin film piezo silicon MEMS technology, and offer very high resolution with over 5600 nozzles capable of jetting up to eight litres of fluid per hour. New innovations such as AcuDrp Technology allow complete control over greyscale drop ejection for perfect image quality. In addition, the Xaar 5601 incorporates TF Technology to maximise production up time, print quality and lifetime.

Hermann Veismann, general manager of the printing and finishing business unit at at W&H, commented: ‘We are delighted to be developing our latest system using the Xaar 5601. We saw an opportunity for digital printing in flexible packaging, driven by the need for faster time-to-market and very short order lengths, and aim to overcome the traditional difficulties in this area using our expert knowledge and outstanding new technology.’

Doug Edwards, Xaar CEO, stated: ‘This announcement is a significant milestone for Xaar. Windmöller & Hölscher is a major player in the flexible packaging machinery market and is renowned for placing innovation at the heart of its new product developments. I’m delighted that the Xaar 5601 has been selected for this new development on the basis of the printhead’s high performance.’

W&H has been conducting research in the field of digital printing for several years.

Sven Michael, head of the digital team at W&H, added: ‘We first collected practical requirements, evaluated technologies and tested new approaches. This has resulted in a machine concept that stands out from all existing approaches and provides our customers with added value. We are now implementing this with suitable partners. The new digital machine concept from W&H is characterized by higher quality and higher speeds.’

Vutz concluded: ‘High availability and usability in daily use are our top priorities. Our goal is to go to market with a functioning and mature digital printing machine that delivers on the promises of digital printing for flexible packaging as well.’

Screen’s Peter Scott to attend Labelexpo Americas Screen GP Australia Managing Director Peter Scott will be present on the company’s booth 6432 at Labelexpo Americas, Chica...

September 10 2018

Screen’s Peter Scott to attend Labelexpo Americas

Screen GP Australia Managing Director Peter Scott will be present on the company’s booth 6432 at Labelexpo Americas, Chicago from 25-27 September. Also at Labelexpo will be David Reece of Screen’s label press dealer Jet Technologies.

“I have been encouraged by the number of Australians and New Zealanders who say they are attending Labelexpo Americas,” says Scott. “The venue – the Donald E Stephens Convention Centre (formerly Rosemont) is very close to O’Hare International airport, so very convenient to access. Downtown Chicago is just 16 miles south. There are five halls covering approximately 70,000 square metres with over 400 exhibitors – anyone who is anyone in the label industry. Screen is in Hall F.”

The Labelexpo series of exhibitions have been hugely successful since the first one in London, 1980 and now cover Europe, Americas, Asia, India, SE Asia and Latin America, under the ownership of Tarsus Group Inc, a FTSE-listed $200 million UK company.

“General printing trade fairs have suffered and shrunk, or even disappeared as with the case of Ipex, but Labelling is still a healthy growth sector. Labelling relates directly to population growth and consumption of branded goods, foodstuffs and beverages, so it is unlikely to suffer the contraction in general commercial printing,” observes Scott.

“At Labelexpo Americas, Screen with feature working demonstrations of two Truepress Jet L350UV Plus Presses - one with standard Ink and one with Low Migration ink targeted at food packaging. Both will be with CMYK + White + Orange + Chiller Roller and can run at up to sixty linear metres per minute. Finishing will be on a SMAG converter. We will also show our PlateRite FX870 CtP for filmless production of flexographic and letterpress plates – this CtP device has already enjoyed several local installations through our dealer Jet Technologies.”

Screen is also partnering with other companies on its booth: OneVision, SMAG, Eizo Monitors, UPM Raflatac, Avery Dennison, Wasau Coatings and Spinnaker.

Scott invites all ANZ visitors to drop by the Screen stand: “David and I will be there the whole three days and we warmly welcome all visitors from our region.”

Xeikon announces new entry-level solution for digital label production Xeikon today announced an entry-level label printing and converting solution, offered at a price point that bring...

September 07 2018

Xeikon announces new entry-level solution for digital label production

Xeikon today announced an entry-level label printing and converting solution, offered at a price point that brings the lucrative label market squarely within reach for label converters of all sizes.

The Label Discovery solution consists of a Xeikon 3030, an entry-level web-fed digital label press and the new entryDcoat, a digital converting line that can be used inline or offline with the Xeikon 3030. The new solution will be featured at the company's booth at Labelexpo Americas, September 25-27, Rosemont, Illinois.

"Although digital label printing has become a fast-growing mainstream business, some companies are still reluctant to invest in the technology - either due to the cost or lack of a truly professional-quality entry-level solution," said David Wilkins, Xeikon's Vice President of Sales for the North American market. "The lower cost of the Xeikon Label Discovery solution enables these companies to embrace digital technology and capture a business potential that previously required a steep investment - the crucial business of producing short-run labels.

"The Label Discovery solution is a turnkey label production system that provides everything needed to offer an expanded range of services to their customers and to experience the benefits digital production can bring to their businesses. In addition to enabling an affordable entry into this lucrative market, the Label Discovery solution is a platform that can be field upgraded in terms of productivity as the business grows, ensuring long-term viability of the investment."

The Xeikon 3030 digital label press is a dry toner solution ideal for producing labels for a broad range of applications using standard flexo materials. This avoids the need to use specially-treated substrates, and eliminates the associated warehousing costs. Its five-color printing features CMYK and white or even a special spot or gamut-extending color. Changing toner colors on the system is relatively easy, a clear benefit of dry toner compared to other printing technologies. In addition, dry toner is recognized as the best technology for food labels in terms of food safety due to its non-toxic nature. Xeikon dry toner has also received FDA certification for both indirect and direct food contact with dry food, which is unique in the digital landscape.

The entryDCoat is a compact converting unit which consists of a varnish, die-cut and rewind station. To limit startup and tooling costs, the die-cut unit uses semi-rotary die-cutting technology. This ensures the lowest cost converting without loss of productivity while still delivering the well-known quality of conventional die-cutting. With semi-rotary die-cutting, costs can be reduced by as much as 50% with no need to acquire special tools and no setup time as required with conventional die-cutting.

Agfa Graphics to Acquire the Prepress Business of Ipagsa Agfa Graphics announced it intends to acquire the prepress business of the privately-owned Spanish printing plate supplier Ipag...

September 06 2018

Agfa Graphics to Acquire the Prepress Business of Ipagsa

Agfa Graphics announced it intends to acquire the prepress business of the privately-owned Spanish printing plate supplier Ipagsa Industrial S.L.

The transaction excludes the printing plate manufacturing activities in Barcelona, Spain. The printing plate volumes to be acquired will be partly integrated in Agfa's global manufacturing network and partly procured from third party suppliers. It is expected that in 2019, this acquisition will contribute up to 30 million Euro to Agfa Graphic’s top line with a double digit EBITDA.

''This acquisition is another step in our strategy for profitable growth. Next to a significant increase of our prepress top line, the acquisition will also help Agfa achieving its EBITDA target of 10% in average over the next few years. Ipagsa’s experienced team will continue to operate under its own brand as a separate entity, managed by its current owner, Lorenzo Ferrari,'' says Stefaan Vanhooren, President of Agfa Graphics.

“We are excited to become part of a strong player in the prepress industry. Through Ipagsa, Agfa Graphics will be able to better address the price sensitive regions and segments of the global printing market, making a clear distinction with the premium segment served by the Agfa Graphics organization,” says Lorenzo Ferrari, CEO of Ipagsa.