See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

Lexmark Launches Enhanced Retail Print and Digital Signage Solution Lexmark, a global imaging solutions leader, today introduced a new version of Lexmark Print and Digital Signage, a u...

August 16 2018

Lexmark Launches Enhanced Retail Print and Digital Signage Solution

Lexmark, a global imaging solutions leader, today introduced a new version of Lexmark Print and Digital Signage, a unique and powerful solution that automates the store signage and labeling processes, allowing retailers to easily print and publish quality, on-demand signs, labels and tags, freeing store staff to interact with customers. The latest version features enhanced mobile capabilities that allow store associates to make signage without leaving the sales floor, so customers get the attention they need to make buying decisions.

"Generating engaging and accurate in-store signage is a challenge for retailers across the globe, as stores struggle with price changes, pricing integrity, template management and waste," said John Linton, director, Lexmark Retail Industry Solutions. "We developed the Lexmark Print and Digital Signage solution to automate the in-store signage process, helping retailers quickly and easily develop engaging, accurate and on-brand signage so store staff can be on the sales floor with customers."

The Lexmark Print and Digital Signage solution is a proven enterprise solution for printing and publishing shelf-edge signs, labels and tags used in retail stores. The Lexmark Publishing Platform, which evolved from AccessVia software, uses one system to print paper signs from laser printers in the store, produce volumes of press-ready output for high-speed printing at a central location, and print electronic shelf labels, allowing brand consistency across all signs and reducing IT costs.

Solution benefits include:

Mark Andy adds three new models to Performance Series line Mark Andy has introduced three new press models, P9E, P7E and P5E, to its Performance Series product line, as it seeks to mee...

August 16 2018

Mark Andy adds three new models to Performance Series line

Mark Andy has introduced three new press models, P9E, P7E and P5E, to its Performance Series product line, as it seeks to meet and support ever-evolving converter needs.

The P9E press is specifically designed for high-quality flexible packaging production. Available in web widths up to 26in (660mm), the flexo press is engineered as a production tool to print film, shrink sleeves, flexible packaging and foil lidding.

P9E is built standard with new servo-controlled impression adjustment, independent servo-driven anilox rolls and servo side adjust at print speeds up to 1,000ft/min. Ergonomic efficiency is at the forefront of the wider 22in and 26in web widths, which include plate cylinder loading support as well as an anilox and chamber drawer. Configured with Mark Andy AI, the Performance Series P9E offers advanced automation with automated registration and impression, job save, eight servo motors per station and a centralized control system. The enhancements reduce manual adjustments and associated downtime while meeting Industry 4.0 demands.

The Mark Andy AI package is intelligent and customized to unique business needs, curbing potential production bottlenecks.

Mark Andy identified increased demand for shrink and pouches, coupled with larger volumes of shorter run lengths, as making P9E a ‘profitable platform’ for short run flexible packaging production.

Jeff Cowan, business development director at Mark Andy, said: ‘Mark Andy has over 800 Performance Series installed worldwide. We continue to develop flexible printing solutions that allow our customers to evolve as their job mix changes. The Performance Series P9E is an extension of our commitment and solves the pain points narrow web converters are facing plus the growing demand for shrink.’

The Performance Series P7E has been engineered to allow converters to expand into new markets, targeting entry-level film and extended content applications. P5E is designed to increase converter profitability for the simplest to most complex label applications.

Cowan added: ‘The P5 and P7 have been best-selling models in the Performance Series line, based primarily on the versatility and productivity. The release of the P5E and P7E demonstrates updated servo architecture allowing for tighter registration and a complete redesign of the converting options all focused on providing a better operator experience.’

All three of the new presses deliver an updated ProLED system with air cooling and modular recirculation dryers, both offering sustainability benefits. The machines are equipped with Mark Andy Thread-It technology, which simplifies press webbing for operators and is claimed to be three times faster than traditional webbing methods. Additional press options include Digital Plus Screen, a digital inkjet replacement for rotary screen printing as well as QCDC-SR (Quick Change Die Cut Semi Rotary) adding advanced capability to flexo equipment that is also available on Mark Andy digital hybrid technology.

The Performance Series P7E and P5E are available now for order, with the official unveiling of the Performance Series P9E at Labelexpo Americas 2018.

New EFI Fiery DFE for Konica Minolta AccurioPress 6136 Series Delivers Best-in-Class Quality, Productivity and Workflow Integration Electronics For Imaging, Inc. (Nasdaq:EFII), and Kon...

August 16 2018

New EFI Fiery DFE for Konica Minolta AccurioPress 6136 Series Delivers Best-in-Class Quality, Productivity and Workflow Integration

Electronics For Imaging, Inc. (Nasdaq:EFII), and Konica Minolta Business Solutions U.S.A., Inc. announced a new EFI Fiery digital front end (DFE) designed to drive the AccurioPress 6136 series of monochrome digital presses from Konica Minolta.

Running on the latest EFI Fiery FS300 Pro software platform, the new EFI Fiery MIC-4160 external DFE is the first Fiery server for black-and-white print engines to launch on the new NX One server platform with Fiery QuickTouch. The new DFE is almost 50% faster than previous generations and is compatible with the innovative new Konica Minolta IQ-501 Intelligent Quality Optimizer for automated density control and accurate front-to-back registration. The latest Fiery Command WorkStation used with the DFE delivers a true unified job management interface for all Fiery Driven printers including cut-sheet, wide-format, superwide-format and high-speed inkjet devices.

“In-plants and commercial printing businesses need greater efficiencies to streamline their monochrome high-volume production operations and this new EFI Fiery DFE helps users get the most from their advanced AccurioPress 6136 investment,” said Kevin Kern, senior vice president, business intelligence services and product planning, Konica Minolta. “The DFE’s features help make users monochrome digital print workflows just as advanced as those found in high-end digital color print production.”

Free Fiery DFE training from EFI, found at the Learning@EFI site, will give AccurioPress 6136 series customers information to ensure they can use all the Fiery product features to the fullest extent possible.

New, bi-directional communication provides synchronized, real-time paper catalog updates that can be entered from either the press or the Fiery Command WorkStation interface, bringing operational flexibility to users, along with new paper tray assignment tools. Plus, the DFE’s Fiery QuickTouch display provides easy, automated backup and restore features. Optional EFI Fiery JobMaster software available with the DFE simplifies the process for creating manuals and other long documents with visual tools for tab insertion, scanning, image editing and media assignment.

End-to-end integration for greater efficiency

The new Fiery DFE also integrates into existing print production workflows through JDF implementation, which seamlessly connects with automated estimating, scheduling, job ticketing, accounting and other processes managed by EFI's suite of industry-leading MIS and web-to-print products, including EFI PrintSmith, Premium Pace and Enterprise Pace bundles for Konica Minolta.

In addition to built-in, industry-standard and certified JDF connectivity, Fiery API enables print service providers to rapidly develop live, bidirectional integration with their internally developed software or web services for their unique workflow automation needs. Fiery API is a REST (Representational State Transfer) application programming interface, allowing easy development regardless of application or software platforms including web browser, Windows, Mac, Linux, iOS, Android.

“We are pleased to continue our relationship with Konica Minolta in bringing this outstanding DFE to the AccurioPress 6136 series of monochrome printers,” said John Henze, vice president of Fiery marketing, EFI. “It not only gives users our latest production enhancements, it brings users all the efficiencies of our new NX One touchscreen display, giving users faster views of job status information and quick access to server management tools.”

The new Fiery DFEs run on Windows 10 and are available from Konica Minolta and authorised Konica Minolta resellers. For more information about EFI Fiery Driven products, visit www.efi.com

HP One Package Workflow Suite HP Inc. announced the HP One Package workflow suite for PageWide Industrial corrugated presses, the industry’s first ecosystem for digital corrugate...

August 09 2018

HP One Package Workflow Suite

HP Inc. announced the HP One Package workflow suite for PageWide Industrial corrugated presses, the industry’s first ecosystem for digital corrugated printing. HP One Package offers software and solutions from HP and partners to help converters maximize the flexibility of digital production.

HP One Package workflow streamlines submission and preparation of orders, allowing converters to take advantage of an array of digital value-added possibilities, including solutions for brands’ consumer engagement and piracy protection using variable data, imagery and unique ID serialization. One Package’s production management and automation software also enhances operational performance and optimizes the supply chain.

The suite supports a range of industry third-party workflow solutions, including MIS and pre-press, HP’s powerful print servers, color management tools, and PrintOS cloud-based management applications. HP One Package complements HP’s growing portfolio of corrugated digital presses, including the HP PageWide C500 press for post-print and HP PageWide T1190 for pre-print.

“HP is revolutionizing corrugated printing with digital flexibility, offering high-volume productivity, food-safe inks, and now a sophisticated and integrated workflow solution to drive corrugated jobs from order to fulfillment,” said Eric Wiesner, General Manager, PageWide Industrial division, HP Inc. “Whether converters adopt a strategy for digital pre-print or digital post-print, HP One Package provides an integrated set of solutions for end-to-end productivity.”

HP One Package allows converters to unlock the potential of digital print, while integrating HP digital presses into existing production and business workflows. In addition to HP’s own workflow components, HP selects and qualifies partners and integrates these products. HP One Package workflow suite includes:

HP workflow solutions

Kodak launches Global Flexo Innovation Awards 2018 Kodak is celebrating the 10th anniversary of its KODAK FLEXCEL NX System by launching the "Kodak Global Flexo Innovation Awards." The...

August 09 2018

Kodak launches Global Flexo Innovation Awards 2018

Kodak is celebrating the 10th anniversary of its KODAK FLEXCEL NX System by launching the "Kodak Global Flexo Innovation Awards." The Kodak Global Flexo Innovation Awards are a way of recognizing innovative, game-changing packaging, and emphasize creativity at its best.

According to Kodak, the continued adoption of FLEXCEL NX Plates worldwide underscores the industry’s demand for higher quality packaging with more cost effective and efficient production processes. Many Kodak customers are leveraging the capabilities of FLEXCEL NX Plates to drive growth through the conversion of gravure and offset work to flexo printing – delivering significant quality, cost and time-to-market benefits to their brand clients.

The Kodak awards will honor packaging that produces outstanding quality and convinces with innovation excellence in at least two of the following categories;

• Use of creative graphic design;

• Conversion from other print processes;

• Print production workflow efficiency;

• Commitment to sustainable print.

The competition invites entries from prepress providers, printers or brands from all over the world. It is open to any commercial packaging project printed with KODAK FLEXCEL NX Plates.

An independent panel of judges comprised of experts representing all players in the flexo and packaging value chain will assess the entries submitted. Chaired by renowned flexo expert Pier Luigi Sassanelli, the panel will also include Philippe Roulet, former Head of Packaging Material and Training at Nestlé, Sebastian Longo, Managing Director of Fotograbados Longo S.A. Argentina, Bernhard Stradner, Director Sales at Allstein GmbH, Chris Horton, former Senior Vice President of SGS, Ken McGuire, Research Fellow at Procter & Gamble and Jean-Paul Duquet, Director of Sustainability, Flexible Packaging Europe.

“The Global Flexo Innovation Awards are designed to honor companies who, through their commitment to excellence using FLEXCEL NX Plates, have played a significant part in the spectacular rise of flexographic printing over the last ten years,” says Chris Payne, President, Flexographic Division and Vice President of Kodak. “At the same time, the awards are a celebration of the journey we are on; they clearly demonstrate the FLEXCEL NX technology’s potential to help users gaining additional business opportunities by further improving efficiency, quality and sustainability to continue to fuel the industry transformation and raise the flexo standards.”

For full details on how to enter and a link to the entry form, visit www.transformationalflexo.com. Closing date for entries is October 16, 2018. The Global Flexo Innovation Awards will be presented to the winners in early 2019 at an exclusive gala hosted by Kodak and attended by key influencers from the international flexo community.

Printers Face Dilemma as Wallets Found Printers around the country are facing a dilemma, af ter a spate of unclaimed wallets have turned up at print businesses around the country...

August 09 2018

Printers Face Dilemma as Wallets Found

Printers around the country are facing a dilemma, af ter a spate of unclaimed wallets

have turned up at print businesses around the country this week.

While the idea of stumbling across a wallet full of valuables is one of those ‘windfall’ opportunities

most of us dream of, the reality is somewhat more complex, with the finder often torn between keeping

the loot or trying to get the treasure back into the right hands.

Happily for the finders in this instance, the explanation – and the course of action – was made clear,

with the wallets turning out to be a clever marketing initiative for Océ Australia, who used the gimmick

to promote its Océ Colorado 1640 roll-to-roll printer, the first to use its patented UVgel technology.

As well as outlining the ways a Colorado printer could help ‘put more money in [their] hip pockets’, the

wallets contain goodies like complementary vouchers worth $2000, to be used on ink or media when

purchasing their new Colorado 1640, and even free movie tickets – all redeemable, of course, by

returning the wallet to an Océ Business Development Manager and attending a machine demo.

“In a competitive market, we’re always looking for ways to achieve cut-through, and there’s no better

way to illustrate the benefits of print than by using print in a creative way,” says Dale Hawkins, who

conceived the campaign for Océ Australia.

“We hope the original approach will create a bit of a buzz, maybe inspire a few people to think outside

the box for their next print campaign and, of course, get the message across about the breakthrough

productivity, automation, economy and versatility of the new Océ Colorado printers.”

Should a wallet turn up at your place of business, Hawkins says, all the details of how to claim your

rewards will be inside – and, you’ll even get to keep your new wallet.

And for those who don’t come across one? “No problems,” Hawkins confided. “If it sounds interesting

to you, visit www.oce.com.au/wallet or give your Océ Australia rep a call and we’ll tell you how you can

claim your reward anyway!”

Afinia Label unveils mid-run digital label printer Afinia Label, a manufacturer and distributor of industrial color label printing and finishing equipment, has announced the release of...

August 07 2018

Afinia Label unveils mid-run digital label printer

Afinia Label, a manufacturer and distributor of industrial color label printing and finishing equipment, has announced the release of the L701 Industrial Color Label Printer. The L701 is the newest addition to Afinia’s family of products. The L701 offers the speed and performance of Memjet in a new, smaller and more affordable configuration geared toward installations requiring multiple printers across several production lines or locations.

This full-color printer can print directly to inkjet-printable, diecut labels and tag stock. The L701 supports printing roll-to-roll, roll-to-cut – with the option of printing and presenting the label – and can accept fanfold stock for applications where space is at a premium. The L701’s five (CMYKK) 150ml capacity ink cartridges offer convenience and economy over smaller systems on the market, and can produce labels in full-color, with photo-quality, at print speeds up to 40 feet (~12 meters) per minute.

According to Afinia, the L701 has a lower price point, making it a more affordable option where multiple printers are required, and has the smallest footprint available of any production class color label printer currently available. “With the addition of the L701, Afinia offers the most comprehensive line of color label printers available today,” says Mike Atkins, National Sales Manager for Afinia Label. “The L701 has incredible print quality and speed, and it fits a perfect price point between the low volume, economy priced color label printers, and the high volume, production-level printers on the market. This combination of speed and economy will enable manufactures across many industries to implement full color label printing across multiple production lines.”

Nathan Daniel, EMEA Sales Manager for Afinia Label, is excited about how the L701’s purchase price will open the door to a new group of users. He says. “The low price point of the L701 allows those who, in the past, may not have been able to stretch their budgets to a higher yield printer, to take advantage of the many benefits gained by this print technology.”

The L701 is currently available through Afinia Label’s worldwide network of dealers. “We believe the L701 at this price point and size will enable companies to move away from buying printed labels. This will allow purchasers and packaging engineers the flexibility to more efficiently manage their label inventory without sacrificing the look of their brand,” concludes Atkins.

Amcor Limited, Bemis Company Combine in $6.8 Billion All-Stock Transaction Combined revenues are US$13 billion; Amcor shareholders to own 71%; Bemis shareholders to own 29% of comb...

August 07 2018

Amcor Limited, Bemis Company Combine in $6.8 Billion All-Stock Transaction

Combined revenues are US$13 billion; Amcor shareholders to own 71%; Bemis shareholders to own 29% of combined company.

Amcor Limited and Bemis Company, Inc. announced that their respective Boards of Directors have unanimously approved a definitive agreement under which Amcor will acquire Bemis in an all-stock combination. Combining these two complementary companies will create the global leader in consumer packaging.

The transaction will be effected at a fixed exchange ratio of 5.1 Amcor shares for each Bemis share, resulting in Amcor and Bemis shareholders owning approximately 71% and 29% of the combined company, respectively. This is equivalent to a transaction price of US$57.75 per Bemis share based on Amcor’s closing share price of A$15.28(4) on Aug. 3, 2018 and represents a premium of 25% to Bemis’ closing price of US$46.31 per share as of Aug. 2, 2018.

The sales of the combined company were $13 billion, EBIDTA was $2.2 million, and will have increased economies of scale and resources through Amcor’s leading positions in Europe, Asia and Latin America, and Bemis’ leading positions in North America and Brazil. Annual cash flow, after capital expenditure and before dividends, will be in excess of US$1 billion.

“The strategic rationale for this combination and the financial benefits are highly compelling for both Amcor and Bemis shareholders,” Amcor CEO Ron Delia said. “We are convinced this is the right deal at the right time for both companies, and with the right structure for both sets of shareholders to participate in a unique value creation opportunity. Amcor identified flexible packaging in the Americas as a key growth priority and this transaction delivers a step change in that region.

“There are an increasing number of opportunities arising for a leading packaging company to capitalize on shifting consumer needs, an evolving customer landscape and the need to provide responsible packaging solutions that protect the environment,” Delia added.

“The combination of Bemis and Amcor is transformational, bringing together two highly complementary organizations to create a global leader in consumer packaging,” William F. Austen, Bemis’ president and CEO, said.

“Our employees will benefit as part of a larger and more global organization focused on a commitment to customer service, integrity and supporting strong teams,” Austin noted. “In addition, the combination will enable us to offer global, regional and local customers the most compelling value proposition in the industry through a broader product portfolio, increased product differentiation and enhanced operating capabilities, while leveraging Bemis’ extensive US manufacturing base and strengths in material science and innovation. Our shareholders will receive a significant premium in this transaction, reflecting the value we’ve built as an organization, as well as the opportunity to continue to participate in the upside potential of a more diversified combined company with greater scale and resources. We look forward to working together with Amcor to ensure a seamless integration.”

“Amcor and Bemis have many things in common starting with proud histories that date back more than 150 years,” Delia concluded. “Both companies are grounded in strong values, a shared commitment to innovation and value-added consumer packaging, and have talented management teams. We have always had a great deal of respect for Bemis and we are thrilled that its team in Wisconsin and around the world will be joining Amcor. Many people at Amcor today have joined us through acquisitions, including many of our leadership team, and we would expect Bemis to be well represented in Amcor at all levels of the organization.”

Upon completion of the transaction, New Amcor’s Board is expected to comprise 11 members, eight of whom are current Amcor directors, and three of whom are current Bemis directors. Amcor’s current chairman, Graeme Liebelt and current CEO Ron Delia, will continue in those roles after the transaction and Delia will continue to serve as the only executive director on the Board.

New Amcor will continue to maintain a critical presence in Wisconsin and other key Bemis locations. The combined company also expects to leverage Bemis’ plant network and innovation center while continuing to invest in the US.

Closing of the transaction is conditional upon the receipt of regulatory approvals, approval by both Amcor and Bemis shareholders, and satisfaction of other customary conditions. Subject to the satisfaction of the conditions to closing, the transaction is targeted to close in the first quarter of calendar year 2019.

A SECOND LIFE FOR PIZZA PACKAGING Under the scope of the World Cup, DS Smith’s display and packaging units worked in close collaboration with Pizza Hut in Portugal, to provide a ...

August 07 2018

A SECOND LIFE FOR PIZZA PACKAGING

Under the scope of the World Cup, DS Smith’s display and packaging units worked in close collaboration with Pizza Hut in Portugal, to provide a second life to pizza packages during this period.

The new, special edition pizza boxes (medium, large and extra-large), had a built-in puzzle/ball, allowing those who bought two pizzas to construct a ball with the two detachable covers from these new boxes. Based on the fact that these pizza boxes could do more than just deliver pizzas, DS Smith developed this solution, which allowed Pizza Hut to communicate a brand message and stand out in an active and differentiating way within this specific time frame.

This special edition of new boxes provided customers with an experience which was both fun and educational, engaging them on an emotional level. In addition to the fun that a puzzle provides, bringing friends and family together, the concept also aimed to offer a moment of relaxation while assembling the puzzle, especially after such a stressful situation as a football match!

The solution provided by DS Smith combined innovation and sustainability. The packaging specialists at DS Smith worked in partnership with Pizza Hut to extract the maximum benefit from its 100% recyclable cardboard packaging, giving it a new purpose and functionality, and avoiding its disposal immediately after its primary use was fulfilled.

AstroNova launches new digital colour desktop printer AstroNova GmbH, the European headquarters for AstroNova, Inc., has introduced a powerful digital color desktop printer, the QuickL...

August 07 2018

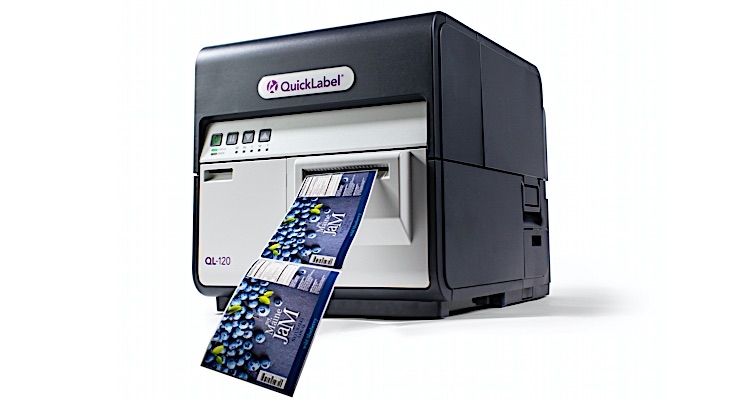

AstroNova launches new digital colour desktop printer

AstroNova GmbH, the European headquarters for AstroNova, Inc., has introduced a powerful digital color desktop printer, the QuickLabel Kiaro! QL‑120 high-quality label printer. The product marks the company's expansion into the area of product identification. The Kiaro! QL‑120 is built on the company's color label printer, the Kiaro!.

The versatile QL‑120 surpasses the Kiaro! with a faster print speed, new features and ease of use.

Its fast printing speed of up to 300 mm/s makes the QL‑120 the fastest desktop color label printer in the QuickLabel series by AstroNova Product Identification. Its 1200 dpi resolution ensures that even the smallest font sizes and images are printed sharply. The printer's water-based ink and color range allow printing on a wide variety of materials.

Even with water-based ink, QuickLabel's QL‑120 offers greater durability, as well as resistance to water, oil, and solvents. Thanks to its resistance to various fluids, the QL‑120 is ideal for the food, chemical, cosmetic and E-liquid industries.

Its electric cutting feature for post-printing label-web cutting and its ability to print individual labels with zero label loss make the QL‑120 an economical and intelligent colour desktop printer for high-quality labels. The QL-120's simple integration into label dispensing systems and networks and its automatic periodic cleaning feature, which requires no separation of the label web, delivers smart label printing and integration into automated production.

Avery Dennison and L'Oréal collaborate to eliminate label waste Avery Dennison Corporation and L'Oréal Australia, in conjunction with Australia's leading waste management...

August 07 2018

Avery Dennison and L'Oréal collaborate to eliminate label waste

Avery Dennison Corporation and L'Oréal Australia, in conjunction with Australia's leading waste management company, Wasteflex, are collaborating on a recycling program to deliver zero waste to landfills.

Avery Dennison's liner recycling program, dubbed the first of its kind by the company in the South Asia Pacific and Sub-Saharan region, supports the company's sustainability goal to help customers reduce waste from its products. This liner recycling program will help brands divert glassine paper liner (waste from label application process) from landfills into recycled products. Through this program, L'Oréal Australia will divert over six tons of glassine paper liner in Australia into recycled paper for use in the recycled paper industry.

"As a materials science innovator committed to making a meaningful difference, we see sustainability as both a responsibility and an opportunity to lead. With our liner recycling program, brands now have a solution that will enable them to reduce the environmental impact from discarded label liner waste," says Anil K. Sharma, vice president and general manager, Label and Graphic Materials, South Asia Pacific and Sub-Saharan Africa, Avery Dennison. "We are delighted to partner with L'Oréal Australia and Wasteflex on this sustainability journey."

"The savings from this program have been significant, but the biggest benefit for L'Oréal Australia is being able to meet our zero waste to landfill through the services and expertise of Wasteflex and Avery Dennison," says David O'Leary, national logistics manager, L'Oréal Australia.

"Wasteflex is proud to be part of the Avery Dennison liner recycling program," says Matt Tamplin, chief executive officer, Wasteflex. "Through this program, we can offer the industry an exciting new solution that is easy to implement and will improve sustainability and commercial outcomes for business."

"As the pioneer of the pressure sensitive label industry, Avery Dennison has always focused on helping customers and brand owners achieve their goals by delivering label materials that can elevate brands, improve productivity and help products become more sustainable," says Marcel Cote, strategic marketing director, Avery Dennison. "With the launch of our Avery Dennison Liner Recycling Service, we can offer a sustainable solution to divert glassine paper liner from landfills and into recycled paper products."

Avery Dennison introduces accent film to add chrome touches to vehicles Avery Dennison, the global materials science and manufacturing company, today introduces a new accent film desig...

August 07 2018

Avery Dennison introduces accent film to add chrome touches to vehicles

Avery Dennison, the global materials science and manufacturing company, today introduces a new accent film designed to add special effects and a sporty touch to vehicles.

The Avery Dennison® Conform Chrome Series is a premium quality specialty film designed for use in vehicle and graphics markets where high end chrome accents are desired. The three striking colours of Violet, Rose Gold and Matte Silver will add special effects and a sporty touch to vehicles in Australia and New Zealand markets.

“Car enthusiasts and vehicle owners who want to bring their designs to the next level with sharp, eye-popping chrome accents and details will appreciate our Conform Chrome Series,” said Jordan Leach, business manager, Avery Dennison Graphic Solutions in Australia and New Zealand. “The film has been carefully tested for outstanding durability and outdoor performance to satisfy car owners who are looking for a premium look combined with strong protection.”

The Avery Dennison Conform Chrome Series is designed for application to solid surfaces like automobiles, buses, and trains and applied over existing graphic films such as the Avery Dennison® Supreme WrappingTM Film or the Avery Dennison® MPITM 1105 Wrapping Films to create a striking impact with its sharp, eye-popping accents and details.

The Avery Dennison Conform Chrome Series film has the patented Avery Dennison® Easy Apply RS™ feature allows for faster positioning, bubble free application, and long-term removability after the intended period of use.

For more details of the Avery Dennison® Conform Chrome Series, please visit graphicsap.averydennison.com.

Avery Dennison shortlisted for Label Industry Global Awards Shortlisted as one of three finalists, Avery Dennison received the nomination for its recent introduction of a Sustainabilit...

August 07 2018

Avery Dennison shortlisted for Label Industry Global Awards

Shortlisted as one of three finalists, Avery Dennison received the nomination for its recent introduction of a Sustainability Procurement Program, a collaborative evaluation platform providing sustainability ratings and performance improvement tools for the company’s global supply chain.

The program rates suppliers in four key areas of activity: environmental, fair business, supply chain, and labor practice. The program’s overall objective is to engage suppliers in a continuous improvement process related to sustainability.

To operate this Sustainability Procurement Program, Avery Dennison partnered with EcoVadis, a leading sustainability performance rating solutions provider. The platform delivers simple and reliable scorecards to monitor supplier best practices. A total of 21 internationally recognized sustainability criteria are reviewed and separated into four criteria themes: environment, social, ethics and supply chain.

Renae Kezar, senior director, global sustainability at Avery Dennison said: “The Sustainability Procurement Program helps us to assess compliance and recognise high performing suppliers. In addition, EcoVadis has provided a straightforward method for discussion with our suppliers on topics of social and environmental awareness. It is not only about a “score” but we have dialogue around waste, increasing recycled content, the different certification schemes, and how to work together to improve the industry."

Canon Launches Océ LabelStream 4000 5-Color UV Inkjet and Flexo Hybrid Press Canon, a world-leader in imaging solutions, today launches the new Océ LabelStream 4000 serie...

August 07 2018

Canon Launches Océ LabelStream 4000 5-Color UV Inkjet and Flexo Hybrid Press

Canon, a world-leader in imaging solutions, today launches the new Océ LabelStream 4000 series, an industrial-scale UV inkjet press with optional flexo printing, embellishment and finishing units. With an industry-leading productivity range of 950 - 1672 sqm/h the press looks set to carve out a commanding presence in the growing label printing market.

The latest addition to the production printing portfolio underlines the Canon and Océ strategy to invest in growing industrial printing segments. Combining the virtues of UV inkjet printing with conventional technologies, this innovative label press delivers unrivalled value-add in terms of time, cost and value, enabling converters to select the best combination for any production requirement.

Christian Unterberger, Chief Marketing Officer & Executive Vice President Production Printing Products (PPP), outlines what makes the new label conversion solution special: “The Océ LabelStream is based on the inkjet DNA of Canon and Océ. With this comprehensive solution package optimized to benefit from current market dynamics, label converters can boost their profitability for short and medium job sizes, and amaze customers with labels of exceptional quality and customized messaging.”

The new press has a key role to play in the wider company strategy, as Crit Driessen, Vice President & Head of Digital Packaging PPP, explains, “Océ is keen to break into forward-looking markets, and industrial packaging printing offers excellent opportunities for new revenue streams. Digital products currently account for only a relatively small part of this market worldwide, but the share expected to grow rapidly. We are confident that market players will appreciate the Océ LabelStream’s productivity and customizing abilities as a way to add value to label printing.”

At its core the Océ LabelStream 4000 series is a 5-color UV inkjet press (CMYK and white) with a print speed of 48 m/min. It offers print widths of 330 mm (13”) or 410 mm (16”) and an optional performance mode of 68 m/min for less demanding print jobs. Providing a one-pass digital high opacity white of more than 80% at standard press speed the opacity of analogue printing technologies such as rotary screen and flexo can be matched.

Latest Xaar 2001 UV inkjet printheads with a resolution of 720 x 600 dpi and different quality modes guarantee the reproduction of fine details, smooth tones, vibrant color and solids on a wide range of standard label stocks including PP, PE, BOPP plus selected special substrates.

The system can be expanded to a full hybrid configuration with a custom mix of additional flexo, embellishment and finishing units turning it into a fully integrated single-pass label conversion line to meet various demands and budgets.

This mix of conventional and digital technologies enables fast, affordable production of high-quality self-adhesive labels – for example for fast moving consumer goods, cosmetics and pharmaceuticals. Along with the ability to deliver cost-efficient print-to-order run lengths to avoid overproduction digital printing offers an unbeatable advantage in this segment: customization. As more brands move to attract customers’ attention through customized packaging it is obvious that digital printing can add significant value to increase sales and enhance brand awareness.

The Océ LabelStream offers maximum flexibility and gives users the freedom to complete orders at short lead times: easy set-up and make-ready accelerate system availability. Production costs stay low, delivering a speedy return on investment.

Label converter will benefit from the best package in the industry based on Canon’s inkjet DNA. Innovative technologies integrated into comprehensive end-to-end solutions and supported by first-class global service and business consultancy will help to develop and grow a sustainable and profitable digital business.

Christian Unterberger is confident that the new Océ LabelStream will hit the mark: “The new Océ LabelStream 4000 series is the next step in advancing our market strategy. We plan to grow in the packaging market and ultimately play a leading role.”

Commercial availability of the Océ LabelStream 4000 series in Europe will be end of 2018.

Epson High-Speed Linehead Inkjet Multifunction Printers Receive ISO/IEC 15408 IT Security Certification Epson has acquired ISO/IEC 15408 certification for compliance with IEEE Std. 260...

August 07 2018

Epson High-Speed Linehead Inkjet Multifunction Printers Receive ISO/IEC 15408 IT Security Certification

Epson has acquired ISO/IEC 15408 certification for compliance with IEEE Std. 2600.2™-2009*1 for its high-speed WorkForce Enterprise linehead inkjet multifunction printers (MFPs), including the WF-C20590, WF-C20590a, WF-C17590 and WF-C17590a.

IEEE Std. 2600.2™-2009 is an international standard that specifies information security criteria for MFPs. MFP security can be comprehensively strengthened by providing standard-compliant security functionalities such as user identification and authentication, access control, data overwrite, network protection, security management, self-test, and audit logs.

ISO/IEC 15408, also called Common Criteria (CC), is an international standard for the independent and objective evaluation of security measures in IT products and systems to determine whether those measures are properly designed and implemented.

Epson is committed to providing its customers with products that offer robust information security along with unbeatable performance and usability.

Epson SurePress L-4533A/AW receives 91% Pantone coverage certification The Epson SurePress L-4533A/AW digital label press comes the news that the press has been evaluated and approved ...

August 07 2018

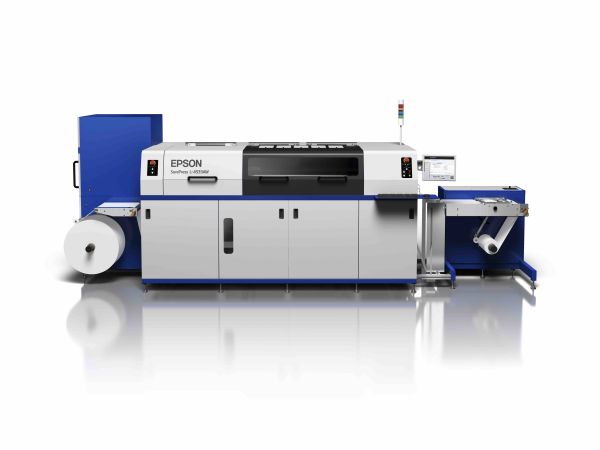

Epson SurePress L-4533A/AW receives 91% Pantone coverage certification

The Epson SurePress L-4533A/AW digital label press comes the news that the press has been evaluated and approved by Pantone for its capability to achieve 91 percent of the PANTONE Solid Coated colours within delta E of 1.5 CIEDE2000.

The Epson SurePress L-4533A/AW is certified to reach its full Pantone coverage capabilities when used in conjunction with the Avery Primax 250TC/S692N/BG40W/BW6033B PS label media and Epson ink.

L4533 MainUnit 001a 002The 91 percent coverage certification is so wide that Epson regularly uses the XCMYK input profile versus GRACoL®, the industry’s current standard, and SWOP profiles made for earlier generations of pre-digital six colour equipment. The L-4533 uses a 4-colour work flow with the RIP and the press determines the orange and green automatically, saving time, simplifying the operation and improving the day to day accuracy of the jobs. In a rapidly changing printing and packaging landscape, this certification helps underscore Epson’s commitment to helping converters and their customers create engaging colour labels.

According to a study by the Journal of Experimental Psychology, colour helps people store images more efficiently than colourless scenes, showing that colour labels are more memorable and consequentially recognisable. Studies by CCIColor – Institute for colour Research also show that between 62 and 90 percent of people’s subconscious judgment at initial viewing of a product is based on colour alone3, further pushing the need for greater colour achievability in the label market. The expanded colour selection allows owners of the Epson SurePress L-4533A/AW to address more applications, such as flexible packaging with photographic images.

ID Products, a company that specialises in labels, screen printed overlays and more, has been using the SurePress L-4533A/AW to create nutrition labels, craft beer labels, pharma labels, and more. Adding this press into its production workflow has expanded ID Products’ customer base as well as its reach into new and exciting market verticals. With its wide colour gamut and precision, the SurePress L-4533A/AW has reinforced ID Products’ foundation on delivering perfect and consistent quality, enabling the business to meet their customers’ high expectations for colour accuracy and dependability.

“Our business has been built on providing perfect and consistent quality, and we measure colour at the beginning, middle and end of runs with multiple light sources. I can say, the SurePress results have exceeded my expectations – colours are consistent time and time again,” said Luke Philippas, director of manufacturing and engineering, ID Products. “Using the SurePress, we are able to re-run jobs from months ago with little to no colour adjustment. This is not the first digital technology we have put into production, but it is the best.”

Designed for prime label converters and commercial printers, the Epson SurePress L-4533A/AW is an easy-to-operate, six or seven-colour inkjet digital label press for high-quality, short-run label printing. Delivering exceptional print and colour quality, as well as innovative features, the SurePress L-4533A/AW allows printers to expand their service offerings.

“Pantone’s certification of the SurePress L4533A/AW underscores the wide colour gamut this digital label press delivers to converters,” said Mike Pruitt, product manager, Epson America, Inc. “With the increasing demand for vibrant colour labels, this certification further shows that Epson is able to provide a solution to enable businesses to create brilliant and vivid colour labels while delivering high-quality results.”

www.epson.com.au

Fujifilm launches getFIT Jet Press comparison App Fujifilm has launched getFIT, a new comparison tool to show the savings printers can make by investing in a Jet Press 720S. getFIT is ...

August 07 2018

Fujifilm launches getFIT Jet Press comparison App

Fujifilm has launched getFIT, a new comparison tool to show the savings printers can make by investing in a Jet Press 720S. getFIT is a web-based app for potential customers to discover the economic benefits of the Jet Press compared with offset printing. Based on a printer’s specific jobs and requirements, getFIT can estimate the ink usage as well as the cost and speed of printing on both the Jet Press and an offset press, providing a real-life comparison with existing offset printing equipment.

The getFIT tool allows Jet Press sales specialists to process a variety of print files that represent a cross-section of work, as well as entering existing offset costs, to evaluate, job by job, which would be best run on a Jet Press.

Mark Stephenson, Product Manager, Digital Printing and Press Systems, Fujifilm Graphic Systems EMEA, comments: “The Jet Press 720S is transforming an increasing number of businesses across Europe and beyond, but in our discussions with printers, initially they often don’t believe just how much the Jet Press can save them, whether that’s in terms of cost, time or ink usage. This new comparison tool will help us provide a realistic indication of just how much they can save, as it is based on their real-life job requirements. We showcased getFIT at our recent open days at the Fujifilm Advanced Print Technology Centre in Brussels and feedback from visitors was very positive, with a number of prospective customer scenarios showing great results.”

Fujifilm distributors and partners, such as Camporese Macchine Grafiche in Italy, are also seeing the benefits of the app. Director, Enrico Camporese explains: “This is an amazing tool, hugely appreciated by our customers. It allows us to very clearly demonstrate to offset printers the true potential of investing in a Jet Press and the transformative affect it can have on their businesses.”

Printers looking to explore the savings they can make with a Jet Press 720S should visit www.imagineinkjet.com and submit a request for Fujifilm to get in touch.

Fujifilm launches new printbar system The Graphic Systems Division of Fujifilm has announced the release of the first product in its Samba Printbar System line, the Samba PS4300, for t...

August 07 2018

Fujifilm launches new printbar system

The Graphic Systems Division of Fujifilm has announced the release of the first product in its Samba Printbar System line, the Samba PS4300, for the commercial and packaging printing segments. The Samba PS4300 is a compact printbar system designed to be easily integrated into most existing print equipment or manufacturing processes, adding variable inkjet imprinting capabilities with enhanced print quality at high speeds.

This new printbar system adds an inline digital printing option for a wide range of personalized or data printing applications including text, logos, QR and bar codes and graphics. The system integrates the ultra-reliable Samba Printhead technology paired with fit-for-purpose inks developed by Fujifilm.

The Samba PS4300 has a print width of 1.6”, with each printhead depositing billions of drops per second, delivering a native 1,200 dpi and speeds up to 1,000 fpm. The Samba PS4300 is available with up to four discrete printbars, depending on the customer and application requirements. Each printbar can be easily integrated into an existing offset press or manufacturing line and operated from a single controller.

“The Samba PS4300 is a game-changing, versatile device,” says Mike Barry, product marketing manager, Fujifilm North America Corporation, Graphic Systems Division. “This unique product delivers added value to our current and potentially new customers. Most notably, the Samba Printbar Systems leverages reliable, proven, single-pass inkjet technology from Fujifilm to enable the addition of variable information that high speed and high quality digital print into a myriad of applications.”

The Samba PS4300 is designed to bring new capabilities to existing offset presses, flexo presses, mailing tables and more, offering printers more value to their existing manufacturing platforms. Uptime on the Samba PS4300 is impressive, the company says, applying Fujifilm’s patented RediJet ink recirculation system, ensuring printbars are instantly primed, resulting in faster time to print, minimal material waste and improved reliability.

The Samba PS4300 is the first in a series of printbars Fujifilm will be launching in 2018.

INDUSTRY PARTNERS ANNOUNCE EDUCATION LIAISON POSITION Visual Connections, the Australian Sign & Graphics Association (ASGA) and Re-Engineering Australia announced today the appoint...

August 07 2018

INDUSTRY PARTNERS ANNOUNCE EDUCATION LIAISON POSITION

Visual Connections, the Australian Sign & Graphics Association (ASGA) and Re-Engineering Australia announced today the appointment of AusSIP as its Industry Education Liaison Manager.

The newly created national role is to help increase awareness of the opportunities in our industry to schools, TAFES and universities and strengthen ties between industry and schools in order to promote career opportunities within the sector.

The longer-term goal of the appointment is to influence enrolments in print, sign and graphic apprenticeships, increase school-based apprenticeships and to create a greater awareness of the industry as a viable career alternative for students.

The role would work closely with two industry associations – the Australian Sign and Graphics Association and Visual Connections as well as our partner, REA (Re-engineering Australia). The focus of both associations is to promote and grow the industry for our members with particular emphasis on education and training within the broader print, sign and graphics area.

AusSIP has been chosen due to its experience in working at local, national and international levels to raise educational and industry opportunities, both at strategic and operational levels. AusSIP has the demonstrated experience, skill sets, networks, capacity and passion to increase awareness and opportunities in the Print, Sign and Graphics industry nationally.

Mitchell Mulligan, President Visual Connections welcomed the appointment “Visual Connections members are thrilled to allocate funding towards this vitally needed position. The need to promote the industry to younger entrants and to continue to build talent and career pathways has never been greater and we look forward to contributing to a stronger talent pool for our customers in the future”.

Michael Blazek, President ASGA, says the appointment has been made with the strong affirmation of the Association’s members. “For too long the most visible of all trades has remained invisible to parents, students and the wider education community. It is an exciting industry, which offers a mix of skills, imagination and initiative. We look forward to working closely with AusSIP in promoting increased industry awareness and opportunities for youth across Australia”.

Kodak Introduces Predictive Ink and Plate Usage Service for PRINERGY Cloud Kodak announced its new Decision Analytics Software-as-a-Service offering for KODAK PRINERGY System, a soluti...

August 07 2018

Kodak Introduces Predictive Ink and Plate Usage Service for PRINERGY Cloud

Kodak announced its new Decision Analytics Software-as-a-Service offering for KODAK PRINERGY System, a solution designed to optimise the use of consumables on press, helping offset print service providers realise new sources of savings. This new ground-breaking service will automatically analyse and predict ink usage on press, enabling printers to improve efficiencies, lower costs and reduce risk.

The Decision Analytics - Ink and Plate Usage Service allows PSPs to base their business and labor planning, job quoting and consumable purchasing decisions on their own historical and predictive usage data. The ability to monitor results by plant, press, product and/or job, will allow them to uncover business insights quickly and meet customer requirements while reducing manufacturing costs. Commercial PSPs will be able to quote jobs more accurately ensuring a competitive edge without sacrificing profit margin. Packaging Printers and Converters will benefit from inventory controls for process and spot inks, whereby they can reduce hazardous waste disposal expenses and inventory carrying costs.

Decision Analytics Ink & Plate Usage Service Benefits Include:

- Macro Level Business Intelligence. Gain business insight by viewing historical and predictive ink consumption by company, division, plant location, press, product type and/or job.

- Reduced Labor Costs - Optimize manufacturing planning to allow highly skilled employees to focus on other important job activities.

- Improve Accuracy in Job Quoting - Efficiencies gained from understanding historical ink consumption allows estimating to be much more precise. This opens the door to be more competitive when quoting new work without sacrificing profit margin.

- Reduce Inventory Carrying Costs for Consumables. Ability to move to an on-demand model, reducing the cost and risks of carrying excess inventory. Purchase or mix just the right amount of ink you need to print a job and not a drop more.

- Minimise Hazardous Waste. Reduce surplus ink supplies and the associated disposal costs.

Drive Step Change Growth. Knowledge is power. Utilize historical data to lower costs, reduce risk and increase profitability.

“KODAK’s Ink and Plate usage service opens the door for granular visibility into the actual costs of manufacturing for printers. It affords them the unique ability to optimize the manufacturing process and reduce costs, which ultimately leads to amplified profitability,” said Allan Brown, Vice President and General Manager of Kodak’s Unified Workflow Solutions. “This unprecedented innovation for the commercial and packaging print industry will redefine operational efficiencies and drive step change growth for our customers.”