See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

Mactac expands roll label products with Lintec portfolio Mactac has announced the expansion of its roll label product offering with the addition of Lintec Corporation’s roll labe...

August 07 2018

Mactac expands roll label products with Lintec portfolio

Mactac has announced the expansion of its roll label product offering with the addition of Lintec Corporation’s roll label product portfolio.

Lintec, a comprehensive manufacturer of adhesive-related products and specialty papers, purchased the pressure sensitive adhesives manufacturer in 2016 to expand and strengthen its label business in North America. In order to better service customers, the two organizations are consolidating roll label sales activity and have started transitioning the first phase of the consolidation.

“We are extremely pleased with and confident in the transition of our product portfolio to Mactac,” says Kazuyoshi Node of Lintec USA. “Partnering with Mactac’s stellar sales team will truly help us better serve our customers.”

The addition of the Lintec products expands Mactac’s high performance film and adhesive product offering. Lintec products now being sold by Mactac, include:

- Cryogenic labelstocks for label applications requiring temperatures as low as -320 degrees Fahrenheit (-196 degrees Celsius).

- Security labelstocks for industrial and automotive tamper-evident solutions.

- Industrial labelstocks for extreme chemical and abrasion resistance.

- High adhesion labelstocks such as those that deliver strong adhesion to oil contaminated surfaces.

- Bubble-free labelstocks offering bubble-free application and resistance to outgassing.

- The products are designed for durable goods and industrial labeling applications, including power tools, appliances, electronics, compliance labels, and warning and instructional labels, as well as identification of test tubes and promotional labeling.

They are typically used to identify products, track or relay information, or instruct or warn consumers about a product’s proper usage.

“Lintec is a phenomenal organization and a true leader in adhesive product development,” says Kim Hensley, marketing manager, Mactac Performance Adhesives. “Above all else, Lintec is known for producing high-quality products, and Mactac is incredibly honored to have the opportunity to broaden our product portfolio with solutions from the best of the best.”

Massivit 3D Uses the Force of 3D Printing to Fulfil Teenager’s Dream with a Star Wars X-Wing Fighter Wheelchair Costume Massivit 3D, the leading provider of large format 3D print...

August 07 2018

Massivit 3D Uses the Force of 3D Printing to Fulfil Teenager’s Dream with a Star Wars X-Wing Fighter Wheelchair Costume

Massivit 3D, the leading provider of large format 3D printing solutions for visual communication, has unveiled the ‘world’s first’ 3D printed Poe Dameron X-Wing Fighter charity wheelchair costume at Comic-Con International (San Diego, July 19-22).

The costume was the vision of non-profit organization, Magic Wheelchair, and created for Star Wars fanatic, thirteen-year old Vedant Singhania. Companies who collaborated with Magic Wheelchair to make this project a reality include, Pixologic Inc, responsible for the design and modelling, Dangling Carrot Creative who 3D printed the costume with Massivit 3D donating the printing materials, and Monster City Studios who completed the assembly and finish.

Utilising the high print speeds and dual print heads of its Massivit 1800 3D Printer, Dangling Carrot Creative produced 50 individual costume pieces in just over two weeks. The 2.44m-high and 3m-long (8’ x 10’) spaceship provides Vedant with his very own Star Wars X-Wing fighter jet, crafted by some of the original Lucasfilm prop fabricators.

The Project Troopers

Magic Wheelchair provides bespoke costumes to kids with wheelchairs at no cost to their families. As part of Comic-Con’s special ‘Star Wars experience’ this year, and its partnership with Pixologic – the supplier of ZBrush digital sculpting software – Magic Wheelchair selected Vedant to receive the extraordinary 3D printed costume.

Paul Gaboury, 3D Product Development Manager at Pixologic, explains: “We connected with Magic Wheelchair realizing that our technology and modelling expertise could help them with the amazing work they’re doing for children in wheelchairs. After we designed the costume, Dangling Carrot Creative was the last piece to the puzzle. The company gave us the capability to 3D print life-size parts to help eliminate the need for molds or casting, saving considerable time and money.”

Commenting on Massivit 3D’s involvement in the project, Avner Israeli, CEO at Massivit 3D, says: “Together with our customers like Dangling Carrot, we’re constantly discovering new and exciting applications achievable with our 3D printing solutions for the entertainment market.

“This project has been an extraordinary opportunity to test the true value of our technology and to put young Vedant in the spotlight for the right reasons. There’s nothing quite so wonderful as bringing joy to a child.”

The costume was presented to Vedant at the Comic-Con International show on Saturday. He expressed his excitement and appreciation to all involved: “It’s mind-blowing. I didn’t expect the costume to be so big and I'm thrilled that it’s an X-Wing Fighter because I love Star Wars. I was really excited during the parade. I was so happy because all the people were taking pictures of me. It made me feel like a celebrity."

NESCHEN expands the colour range of the bestseller easy dot NESCHEN supplements its solvoprint easy dot colour range with the colours red, yellow, green, blue and a black variant. The ...

August 07 2018

NESCHEN expands the colour range of the bestseller easy dot

NESCHEN supplements its solvoprint easy dot colour range with the colours red, yellow, green, blue and a black variant. The company now offers its customers an extensive colour range for every design style, extending the easy dot range by the variants gold and silver.

This new range of colour foils is characterised above all by strong colour tones which create loud advertising messages on glass surfaces both in transmitted and incident light. The 100 µm PVC films are equipped with the special dot adhesive coating from NESCHEN. The structure of acrylate adhesive dots and air ducts running between them enables even inexperienced users to easily apply large motifs without bubbles and to subsequently correct the them. Solvoprint easy dot red, yellow, green, blue and black can be plotted and die-cut very well. The new colour films are therefore also ideal for e. g. lettering. In contrast to "normal" colour films, these coloured easy dot® media can be adhered quickly and easily. It does not require any drying time which would otherwise be urgently necessary for wet application. We recommend the application on the inside of the shop window which does not cloud the colour impression in any way.

Solvoprint easy dot can also be printed with (eco)solvent, latex and UV-curable inks if required. The new colour variants are now available in 137.2cm x 30m.

NUtec launches EFI GS & QS range of UV curable inks NUtec Digital Ink, a leading ink manufacturer producing water-based, UV curable and solvent printing inks, recently announced it...

August 07 2018

NUtec launches EFI GS & QS range of UV curable inks

NUtec Digital Ink, a leading ink manufacturer producing water-based, UV curable and solvent printing inks, recently announced its latest UV inks suitable for the EFI range of GS and QS printers.

NUtec’s Amethyst UV inks for EFI printers are available for roll to roll printers as the A50-RTR-EF or for hybrid printers as the A50-HYB-EF. Both ink versions offer superior colours, great reliability, excellent image quality and continued operating functionality.

The conversion from EFI original inks to one of the NUtec alternative inks is a smooth, hassle-free process due to NUtec’s specially designed bottle and adaptor. Developed in-house, the exclusive bottle design offers the unique ability to work across both 5 litre and 3 litre configurations for the GS and QS machines.

Neil Green, Sales and Marketing Director at NUtec notes, “EFI customers who have converted to our inks are particularly impressed with the colour and the physical properties of the inks especially as far as the adhesion and flexible attributes are concerned. These easy-to-install cost-effective UV inks, packaged exclusively for EFI printers, are fast gaining traction with satisfied customers around the world.”

NUtec’s alternative inks for the EFI GS and QS range of printers precede a comprehensive range of optimised UV inks soon to be launched by NUtec Digital Ink.

Quick and easy access to the Display & Visual team at Ball & Doggett. Ball & Doggett today announced the launch of a direct line and email address to support their growing

August 07 2018

Quick and easy access to the Display & Visual team at Ball & Doggett.

Ball & Doggett today announced the launch of a direct line and email address to support their growing

Display & Visual team around Australia.

Wide format customers can now call 1300 713 567 or email displayandvisual@ballanddoggett.com.au

to get direct access to a wide format specialist around Australia. This service is available from 8am to

5pm AEST, Monday to Friday.

Leigh Hooper, National Manager – Display & Visual states: “It’s vitally important for us to provide our

Display & Visual customers first class service and support. This service will allow us to provide our

customers with experienced product knowledge and technical support, live stock checks, the ability to

place and track orders, facilitate converting orders and manage general enquiries. We understand the

demands and pressures our customers face day-to-day, so we intend on providing them prompt,

reliable support and peace of mind.”

Recently, the company launched their website www.ballanddoggett.com.au which includes all of the

wide format media the company sells. From papers/boards, self-adhesive vinyl, synthetic, PVC Banner

to an extensive range of rigid substrates. Each product has a corresponding technical specification

sheet listing key data such as applications, features and material properties. To assist users with their

search, the filter function narrows down the large range by brand, machine type, category, application

and adhesive.

Ball & Doggett is Australia’s largest distributor of printable materials and consumables. For more than

100 years’ they have been selling the raw materials that turn big ideas into physical reality. With

offices in Victoria, New South Wales, Queensland, South Australia, Western Australia and Tasmania,

they are part of the OVOL Group owned by Japan Pulp & Paper, a company with a strong reputation,

trading history and global ties.

The new digitally printable HP Satin Wrapping Paper They say gift giving is an art, but with HP Satin Wrapping Paper, it means business! Print Service Providers can now cr...

August 07 2018

The new digitally printable HP Satin Wrapping Paper

They say gift giving is an art, but with HP Satin Wrapping Paper, it means business!

Print Service Providers can now create custom gift wrap with their HP PageWide XL, HP Latex or HP DesignJet Z series printers with little to no investment. Technology is making personalization widespread for a vast array of products and services. HP Satin Wrapping Paper allows consumers to personalize their gifts with photos, text and images for every occasion from Christmas, to weddings and birthdays, to Valentine’s Day and anniversaries. HP Satin Wrapping Paper provides a new profitable market opportunity.

Zach Ulivarri, General Manager of Color Reflections, Orlando, FL, believes there is a huge market for customizable wrapping paper. "We have tried in the past to emulate gift wrap, so having a product specifically designed for this application is really great and HP Satin Wrapping Paper runs beautifully on our Latex printers."

HP Satin Wrapping Paper provides excellent image quality at production speed. Not just for personal use either, HP Satin Wrapping Paper is perfect for corporate gifts, point-of-sale displays or posters. This recyclable*, FSC-certified* paper also meets environmental goals.

XAAR and Stratasys in High Speed 3D print joint venture Xaar PLC is pleased to announce today that it will invest with Stratasys, a global leader in additive manufacturing, in a newly ...

August 07 2018

XAAR and Stratasys in High Speed 3D print joint venture

Xaar PLC is pleased to announce today that it will invest with Stratasys, a global leader in additive manufacturing, in a newly formed company, Xaar 3D Limited, to develop 3D printing solutions based on High Speed Sintering technologies.

Xaar 3D Ltd will leverage the natural synergies between Xaar and Stratasys, specifically Xaar’s technology relating to High Speed Sintering and industrial piezo inkjet printheads, along with the commercial and market expertise of Stratasys.

Xaar will hold 85% of Xaar 3D Ltd shares with Stratasys holding 15%. In addition, Stratasys has been granted an option to increase its ownership in Xaar 3D Ltd to a total of 30%. Xaar 3D Ltd will hold all of Xaar’s High Speed Sintering assets. The new company’s Board will be chaired by Xaar CEO, Doug Edwards.

Doug Edwards, Chief Executive Officer, Xaar

“We are delighted to launch our partnership with Stratasys. This joint investment in the development of 3D printing technologies reinforces the value created by our R&D and continues our plan to diversify Xaar’s business. We are also pleased to be working alongside a leader in the 3D printing space, who recognises the value of Xaar’s technology and expertise.”

Scott Crump, Chief Innovation Officer, Stratasys

“We are impressed with the Xaar team’s achievements to date. We believe that the complementary assets of Stratasys and Xaar will enable Xaar 3D Ltd to develop solutions that further address customers' additive manufacturing requirements for a broader range of production applications.”

Afinia Label unveils mid-run digital label printer Afinia Label, a manufacturer and distributor of industrial color label printing and finishing equipment, has announced the rel...

July 18 2018

Afinia Label unveils mid-run digital label printer

Afinia Label, a manufacturer and distributor of industrial color label printing and finishing equipment, has announced the release of the L701 Industrial Color Label Printer. The L701 is the newest addition to Afinia’s family of products. The L701 offers the speed and performance of Memjet in a new, smaller and more affordable configuration geared toward installations requiring multiple printers across several production lines or locations.

This full-color printer can print directly to inkjet-printable, diecut labels and tag stock. The L701 supports printing roll-to-roll, roll-to-cut – with the option of printing and presenting the label – and can accept fanfold stock for applications where space is at a premium. The L701’s five (CMYKK) 150ml capacity ink cartridges offer convenience and economy over smaller systems on the market, and can produce labels in full-color, with photo-quality, at print speeds up to 40 feet (~12 meters) per minute.

According to Afinia, the L701 has a lower price point, making it a more affordable option where multiple printers are required, and has the smallest footprint available of any production class color label printer currently available. “With the addition of the L701, Afinia offers the most comprehensive line of color label printers available today,” says Mike Atkins, National Sales Manager for Afinia Label. “The L701 has incredible print quality and speed, and it fits a perfect price point between the low volume, economy priced color label printers, and the high volume, production-level printers on the market. This combination of speed and economy will enable manufactures across many industries to implement full color label printing across multiple production lines.”

Nathan Daniel, EMEA Sales Manager for Afinia Label, is excited about how the L701’s purchase price will open the door to a new group of users. He says. “The low price point of the L701 allows those who, in the past, may not have been able to stretch their budgets to a higher yield printer, to take advantage of the many benefits gained by this print technology.”

The L701 is currently available through Afinia Label’s worldwide network of dealers. “We believe the L701 at this price point and size will enable companies to move away from buying printed labels. This will allow purchasers and packaging engineers the flexibility to more efficiently manage their label inventory without sacrificing the look of their brand,” concludes Atkins.

Fujifilm Launches High-Speed Samba Printbar System for Variable Inkjet Imprinting The Graphic Systems Division of FUJIFILM North America Corporation announces the release of the first ...

July 18 2018

Fujifilm Launches High-Speed Samba Printbar System for Variable Inkjet Imprinting

The Graphic Systems Division of FUJIFILM North America Corporation announces the release of the first product in its Samba Printbar System line, the Samba PS4300, for the commercial and packaging printing segments. The Samba PS4300 is a compact printbar system designed to be easily integrated into most existing print equipment or manufacturing process adding variable inkjet imprinting capabilities with unsurpassed print quality at revolutionary speeds.

This new printbar system adds an in-line digital printing option for a wide range of personalized or data printing applications including text, logos, QR and barcodes and graphics. The system integrates the ultra-reliable Samba Printhead technology paired with fit-for-purpose inks developed by Fujifilm. The Samba PS4300 has a print width of 1.6˝, with each printhead depositing billions of drops per second, delivering a native 1,200 dpi and speeds up to 1,000 feet per minute. The Samba PS4300 is available with up to four discrete printbars, depending on the customer and application requirements. Each printbar can be easily integrated into an existing offset press or manufacturing line and operated from a single controller.

“The Samba PS4300 is a game-changing, versatile device,” said Mike Barry, product marketing manager, FUJIFILM North America Corporation, Graphic Systems Division. “This unique product delivers added value to our current and potentially new customers. Most notably, the Samba Printbar Systems leverages reliable proven single-pass inkjet technology from Fujifilm to enable the addition of variable information that high speed and high quality digital print into a myriad of applications.”

The Samba PS4300 is designed to bring new capabilities to existing offset presses, flexo presses, mailing tables, and more, offering printers more value to their existing manufacturing platforms. Uptime on the Samba PS4300 is impressive, applying Fujifilm’s patented RediJet ink recirculation system, ensuring printbars are instantly primed, resulting in faster time to print, minimal material waste and improved reliability.

The Samba PS4300 is the first in a series of printbars Fujifilm will be launching in 2018. For more information on the Samba Printbar System line, go to www.fujifilminkjet.com/samba.

MACTAC LAUNCHES EASY TO USE JT 8300 DOT SERIES FOR SHORT TERM DECORATIONS Mactac, a leading brand of pressure sensitive graphic and decorative products from Europe, today announced the...

July 18 2018

MACTAC LAUNCHES EASY TO USE JT 8300 DOT SERIES FOR SHORT TERM DECORATIONS

Mactac, a leading brand of pressure sensitive graphic and decorative products from Europe, today announced the launch of the new JT 8300 Dot Series specially designed for short-term indoor advertising in Australia and New Zealand.

“Many frustrated employees of commercial spaces struggle to apply promotional graphics and we wanted to design an improved, easy-to-handle adhesive to solve this problem,” said Jordan Leach, business manager, Avery Dennison Graphic Solutions in Australia and New Zealand. “The Mactac JT 8300 Dot Series is the perfect choice for short-term promotions in commercial spaces as it offers quality in terms of creating striking designs without incurring extra costs related to professional installation.”

The Mactac JT 8300 Dot Series monomeric calendered PVC has a special dotted adhesive that allows fast application and removability while achieving a highly professional result. It has good adhesion power on glass, smooth flat surfaces as well as smooth door or painted surfaces and requires no water and application tools. It offers greater flexibility as it provides good printability on all main platforms.

This series is highly suitable for companies doing short term communication or advertising campaigns during festive seasons, or for discounts, promotional activities, product launches, exhibitions or trade shows.

With a reputation spanning over 50 years, Mactac products undergo strict quality control and are highly appreciated for their proven consistent product quality. Mactac has the strong backing of prestigious brands in areas ranging from architecture, interior design, signage and marking, transport to advertising.

www.mactacgraphics.eu

.png)

NUtec to introduce GBL-free solvent ink range Global supplier, NUtec Digital Ink is expanding its Diamond eco-solvent product offering with new GBL-free ink versions. This move s...

July 13 2018

NUtec to introduce GBL-free solvent ink range

Global supplier, NUtec Digital Ink is expanding its Diamond eco-solvent product offering with new GBL-free ink versions. This move supports NUtec’s new product strategy which includes the introduction of more environmentally and operator- friendly digital ink alternatives for its worldwide customers.

The Diamond GBL-free range will include the D10-GF-MS21 which will be chemically & colour matched to Mimaki® SS21 and designed as a back to back replacement, while the D10-GF-ESM will be chemically & colour matched to Roland Eco-Sol MAX™ inks.

A key feature of the GBL-free Diamond ink range is that no flushing or profiling will be required when converting from OEM inks. It will also be a low smell ink with excellent outdoor durability, superior abrasion and chemical resistance.

The Diamond range will provide excellent media compatibility across a broad range of self-adhesive and flexible substrates. All NUtec’s ink products are supported by NUtec Digital's Ink Delivery System Warranty.

NUtec also offers its customers a HAPs-free ink alternative through its Emerald range of Environment Responsible Product or ‘ERP’ inks. Both the Diamond GBL-free and the Emerald solvent ink ranges eliminates the use of controlled or restricted substances as defined in specific regions and countries.

Technical Director of NUtec, Paul Geldenhuys notes, “NUtec is continually working on alternative versions of traditional ink chemistries to ensure a healthier, cleaner environment for its customers. The Diamond GBL-free and Emerald ERP ranges are prime examples of these developments which are being welcomed by NUtec customers worldwide.”

For more information on the company, its products and its people, visit www.nutecdigital.com

.png)

Agfa Graphics announces the release of InkTune and PressTune software to reduce the production costs. These intelligent tools are part of Agfa Graphics’ ECO³ offering and gi...

July 10 2018

Agfa Graphics announces the release of InkTune and PressTune software to reduce the production costs.

These intelligent tools are part of Agfa Graphics’ ECO³ offering and give print houses complete control over all printing elements, from ink use to compliance with ISO, G7 and client-specific standards, while reducing production costs. Real-time data insights into print quality drive these capabilities, independent of printing technology and press manufacturer.

InkTune and PressTune are crucial elements of Agfa Graphics’ ECO³ program. In designing and creating solutions based on hardware, software and consumables, Agfa Graphics focuses on ecology, economy, and extra convenience (ECO³) to make prepress and printing operations cleaner, more cost-effective and easier to manage and maintain. The ECO³ solutions drive extra value to printing businesses.

InkTune: cost savings plus quality boosts

Building on grey component replacement (GCR) technology, InkTune dynamically substitutes CMY inks with black ink. As an intuitive software solution that is fully integrated into the prepress workflow, InkTune uses Agfa unique technology such as Dynamic Ink Limit Control and Dynamic Device Link Generation to maximize ink reduction up to 30%, while maintaining color fidelity. The reduction of ink not only has a positive cost savings impact, it also increases overall production efficiency as the drying time is reduced. Furthermore, quality levels increase as rosette structures disappear and color deviations become less visible.

“InkTune eliminates the choice between the reduction of ink, time, and drying powder on the one hand, and high-quality prints on the other hand. Customers can achieve all these benefits through the software’s built-in intelligent adjustment of ink consumption. InkTune allows them to shorten press setup times, as well as to cut costs of all print-related resources, achieving the lowest total cost of ownership on the market. It is easily set up and requires no additional investment in training or hardware,” asserts Erik Peeters, Global Marketing Manager Software Solutions at Agfa Graphics.

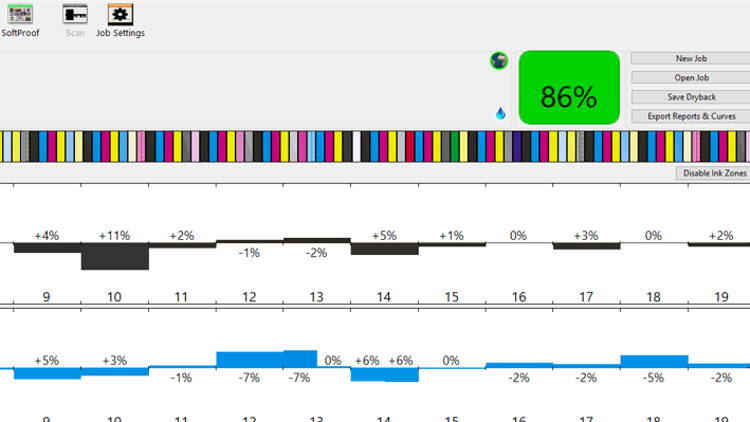

PressTune: a new benchmark in smart print process control

As a print production tool, PressTune drives consistency, productivity and the ability to print to exacting standards. As the required print quality standard is reached faster by means of dynamic ink density adjustment and a data-driven scoring mechanism incorporating dry-back compensation, make-ready times get reduced by up to 40% – which in turn leads to less waste.

Through intelligent analytics capabilities applied to print and color data obtained from the press, PressTune also reports in real time across printing technologies to each stakeholder, for full transparency of the print production process. It enables issue identification and optimized press maintenance scheduling. Even more, the solution’s easy-to-read dashboard makes it simple to generate print quality reports for brand owners in packaging and commercial print and allows for remote quality assurance.

“Together, PressTune and InkTune enable significant cost savings by reducing ink use, boosting quality and accelerating your production workflow,” continues Erik Peeters. “In fact, PressTune provides InkTune with the perfect foundation to optimize ink consumption by delivering quality consistence. Both PressTune and InkTune are central to our ECO³ offering, embodying sustainable innovation that focuses on ecology, economy, and extra convenience for the customer.”

Complementary solutions in action

Imprimeries et Editions Henry, a print house in Montreuil-sur-Mer with a 120-year history, recently worked alongside consultants from Agfa Graphics to take its print processes to the next level. Already relying on an Avalon system, Azura plates and Agfa Graphics’ Apogee workflow, the firm recently installed both PressTune and InkTune.

“PressTune and InkTune have enabled us to obtain a higher consistency throughout our print runs,” says Marc Henry at Imprimeries et Editions Henry. “We have reduced our make-ready times, we use less paper and ink, and we can adapt printer calibration curves according to paper, print job or customer-specific demands. Agfa Graphics’ solutions have brought us a more convenient way of working.”

Arrow Systems Unveils New finishing Unit Arrow Systems, Inc., a long time distributor of digital printing and finishing products, has released a new finishing unit to the market...

July 10 2018

Arrow Systems Unveils New finishing Unit

Arrow Systems, Inc., a long time distributor of digital printing and finishing products, has released a new finishing unit to the market. The Arrow Eco 300 is a tabletop blade finisher that can diecut up to 15” wide. The system features its own cutting software, as well as inline matrix removal.

“We believe this system has a place in the digital market as it fills a need for a low cost alternative to the blade and laser finishers we offer," says Shaan Patel or Arrow Systems, Inc. “The compact design allows it to be used with any roll-to-roll digital printer, and it can also be used for prepress sampling. It is an extremely economical way to get into diecutting your own labels”

The Eco 300 allows users to switch away from pre-cut media and use continuous media to be cut after printing, which can save users of small digital roll printers a lot of money. “Pre diecut media is extremely expensive, and having an option that allows you to cut your own media without breaking the bank is a nice option for brand owners to have," adds Patel.

AVERY DENNISON® “WRAP LIKE A KING” CHALLENGE OPENS FOR SUBMISSIONS Avery Dennison Graphics Solutions announced the opening of its annual “Wrap Like A King” ...

July 10 2018

AVERY DENNISON® “WRAP LIKE A KING” CHALLENGE OPENS FOR SUBMISSIONS

Avery Dennison Graphics Solutions announced the opening of its annual “Wrap Like A King” Challenge. This year’s vehicle wrap competition runs from July 9 through September 14, 2018, and it will again include Regional Wrap Kings, Continental Wrap Kings and the crowning of the “King of the Wrap World.”

Wrap installers from 53 countries across the globe can submit commercial, full print or colour change wrap projects to be judged to win thousands in prizes. The prize packages for 2018 are worth a combined total of over US$30,000, which will be spread out among Regional Wrap Kings, Continent Wrap Kings and the “King of the Wrap World.” Over 150 installers entered the Challenge in 2017.

“Australia and New Zealand have blown away the competition since the region was added to Wrap Like A King two years ago and we can’t wait to see even more astonishing creativity this year,” said Jordan Leach, business manager, Avery Dennison Graphics Solutions, Australia & New Zealand. “We look forward to once again demonstrating this region’s commitment to innovation on a global scale.”

Including Australia and New Zealand, the participating nations come from twelve geographic regions across Japan, South Korea, the United States, Canada, and Europe. Wrap installers in these regions will submit projects featuring Avery Dennison Supreme Wrapping™ Film, the Conform Chrome series, MPI 1105 Supercast Digital film or a combination of car wrap films to be evaluated against their regional peers by a panel of judges.

Wrap Installers can read the full official rules, judge bios and prize information and submit their entries on the “Wrap Like A King” Challenge site.

The 12 Regional Wrap Kings win almost US$2,000 worth of personalized marketing materials, Avery Dennison product, SEMA passes and more. They will go on to battle for royalty on their continents, North America, Europe, North Asia and Australia/New Zealand, and the overall winner will be chosen by the judges as the best in show and crowned the “King of the Wrap World” at the 2018 SEMA Show, October 30 - November 2, 2018 in Las Vegas, NV.

The “King of the Wrap World” grand prize package is worth almost US$5,000, with additional gift vouchers and exposure via the Avery Dennison website and web advertisements.

For more details of the Avery Dennison® Supreme Wrapping™ Film, please visit http://graphicsap.averydennison.com/en/home.html

Colorado Posters Popping Up Around Brisbane It’s not often you see one of the stars of the print industry plastered alongside music greats and some of the world’s be...

July 10 2018

Colorado Posters Popping Up Around Brisbane

It’s not often you see one of the stars of the print industry plastered alongside music greats and some of the world’s best-known products – but that’s exactly what’s happening in Brisbane at the moment, with a series of fun posters featuring (and printed on) the Océ Colorado 1640, popping up everywhere from bus shelters to underpasses.

The reason? Océ’s new Colorado Pop Up Showroom, that will pop up on James Street in New Farm, from July 16 to July 27. The event is set to draw visitors from around Queensland’s capital to see the Colorado and its game-changing UVgel technology, in action.

“Posters, of course, make perfect sense to promote the world’s fastest roll-to-roll printer, which can print 100 posters in 1 hour…for under $100,” said Jane Cox, Business Development Manager for Océ, when we caught up with her in the sunny city this week.

“Recent research found that 75% of print businesses surveyed expected their wide-format print volumes to increase in the coming 12 months, with the top growth prospects identified as banners, signs and posters.”

“The Océ Colorado can produce outdoor banners and posters like these at up to 159m2/hour. That’s a phenomenal speed, allowing businesses to tap into what we know are genuine growth markets with a solution that allows them to print more for less.”

The posters will be in Brisbane for a little while yet, with the Pop Up Showroom due to arrive on 16 July for two weeks. Appointments are booking fast, but there’s still time to reserve a spot to take a closer look at the new technology. For more information or to book your demo, go to www.oce.com.au/popup

Gallus unveils Smartfire digital label press in St. Gallen Gallus introduced its new entry-level digital label press. The Gallus Smartfire, poisitioned as a cost-effective digit...

July 10 2018

Gallus unveils Smartfire digital label press in St. Gallen

Gallus introduced its new entry-level digital label press. The Gallus Smartfire, poisitioned as a cost-effective digital solution and an ideal fit for a first-time digital adopter, complement's the Gallus Labelfire hybrid digital press.

The Smartfire had its official unveiling at the company’s headquarters in St Gallen, Switzerland. Powered by Memjet inkjet printing technology, the press allows converters to get into the digital space at a pricepoint of less than 150,000 euro. The press reaches speeds up to 9 m/min (25.5 fpm) on a 240mm web width (9 inches).

Gallus says the first Smartfire order will be shipped in September.

Michael Ring, head of digital solutions at Gallus, says the Smartfire is easy to use and an ideal "starter model" for digital labels. He said, “With the Gallus Smartfire, we are focusing on new target groups who are looking for a smart entry into digital label printing. The Memjet technology allows us to offer an inkjet printing press that produces labels with a quality of 1600×1600 dpi while still keeping the investment costs at a low level."

Printing in CMYK with water-based ink, the Smartfire features an in-line finishing unit with lamination, an integrated cutting plotter, and semi-rotary diecutter. The water-based ink the press uses translates to no VOCs being emitted during operation, thus removing the need for an exhaust system.

Noted during the event was the Smartfire's ease of use, as well as its training and parts accessibilty. Training and the installation process takes place in just one week's time, it was noted, and the complete all-in-one label converting solution features all parts field-replaceable by Heidelberg within 48 hours. Press is ideal for short runs as well as ultra-short runs, Gallus says.

Additional benefits include a compact footprint and low power requirements – only a standard outlet is needed.

HP expands HP Latex R Printer Series portfolio Today, HP Inc. expanded its hybrid HP Latex R Printer Series with the R1000 Printer for rigid and flexible printing. Designe...

July 10 2018

HP expands HP Latex R Printer Series portfolio

Today, HP Inc. expanded its hybrid HP Latex R Printer Series with the R1000 Printer for rigid and flexible printing.

Designed for a variety of hybrid applications including signage and displays, the growing portfolio offers choice, value, and versatility while featuring innovative technologies including HP Latex Rigid Printing Technology and HP Latex White Ink.

“Print service providers are looking at new ways to increase production and expand applications by investing in innovative print technologies such as rigid and white ink to embrace all the possibilities of print,” said Joan Pérez Pericot, General Manager, HP Large Format Graphics Business, HP Inc. “The new introduction to our HP Latex R Printer Series delivers a versatile and innovative print solution for medium-sized businesses to unlock print opportunities and drive growth.”

The current portfolio includes the HP Latex R2000 Printer, designed for large-signage printer service providers (PSP) who require workflow efficiency and sustained production. With the debut of the HP Latex R1000 Printer, HP is adding depth to offer maximum value in one device. Designed for growing businesses with investment and space constraints, the versatile printer offers a single set of inks for a wide range of flexible and rigid media including applications for retail, outdoor signage, window graphics, events and exhibitions, and decorations.

The new printer comes with three liter-ink cartridges, compared to the larger model with five liters, and is designed to accommodate materials up to 1.64 meters/64 inches wide and up to 5 cm/2-inches thick while the R2000 prints up to 2.5-meters/98-inches wide and up to 5-cm/2-inches thick.

The HP Latest R1000 enables:

• High image quality and vibrant colors: HP Thermal Inkjet Printheads and redesigned HP Latex Inks achieve vibrant color gamut on rigid while preserving media gloss and feel with no smell1.

• Printing in white without barriers: HP Latex White Ink delivers the glossiest white2 on transparent and colored media and achieves no waste between white print jobs. The removable HP Thermal Inkjet Printheads can be stored in an offline rotating chamber and automatic maintenance makes white like any other color, including automatic recirculation and nozzle checks.

• Durability and versatility: HP Latex Overcoat3 adds durable and flexible water-based ink for high adhesion and scratch resistance while lower curing temperatures allow for wide media versatility.

• Efficiency: Productive belt workflow enables customers to handle print peaks in-house and meet short deadlines with up to 57 sqm per hour (614 sqf per hour) with up to 60 kg/150lb rolls for flexible printing.

• Smarter printing: Proactive and preventive services via HP Smart Services maximize uptime and helps avoid costly operating mistakes with automatic maintenance, smart vacuum, and assisted loading.

SATO LAUNCHES COST-EFFECTIVE, ECO-FRIENDLY LABEL SOLUTION SATO, a global leader in the development of Auto-Identification and labelling solutions has launched an environmentally...

July 10 2018

SATO LAUNCHES COST-EFFECTIVE, ECO-FRIENDLY LABEL SOLUTION

SATO, a global leader in the development of Auto-Identification and labelling solutions has launched an environmentally responsible direct thermal linerless labelling solution with lower total cost of ownership.

The groundbreaking pressure-sensitive label technology with specially formulated release coating and optional perforated tear lines removes the need for a release liner. This results in measurable benefits for businesses that are considering switching to a sustainable labelling alternative.

Detlev Mueller, General Manager DACH and CEE at SATO commented: “No liner waste equates to lower transportation, storage and waste disposal costs. Businesses who switch to SATO linerless labels can dramatically reduce their carbon footprint and improve safety standards for their employees – there is no risk of injury through slippage, for example, if the backing liner is taken out of the equation.”

Mueller continues: “And perhaps most appealing to European businesses looking for a viable eco-friendly solution in line with today’s global trends, linerless labels include up to 40% more labels per roll than labels with a backing liner. It really is a win-win situation for both the company and the environment.”

SATO self-adhesive linerless labels are compatible with SATO industrial and portable printers such as SATO’s flagship CLNX Series and its recently launched mobile PW2NX Series. The solution is suitable for a wide range of applications such as price markdowns, shipping labelling and shelf-edge labelling for industries including retail, healthcare and warehousing.

In addition to the standard linerless label, SATO offers the StripeStikTM label as a complementary addition to the range for retailers. StripeStik is an innovative linerless-on-linerless labelling solution for grocery and non-grocery retail that offers enhanced security and the ability to mark-down products multiple times.

SCREEN’S ‘DIGITAL EVERYWHERE’ THEME FOR IGAS 2018 Sydney, July 4th 2018 - With Japan’s IGAS trade fair set to open on July 26th, SCREEN is taking a very ...

July 10 2018

SCREEN’S ‘DIGITAL EVERYWHERE’ THEME FOR IGAS 2018

Sydney, July 4th 2018 - With Japan’s IGAS trade fair set to open on July 26th, SCREEN is taking a very digital theme with ‘Digital Everywhere,’ to be held at Tokyo Big Sight in Ariake, Tokyo.

Working examples illustrating the possibilities available with a digital printing business will be presented. This will include many items not possible with standard offset or flexo/gravure label printing, including mixed and small lot on-demand books, variable direct mail, security tickets, food packaging labels and shrink-wrap labels for beverages.

At the core of Screen’s stand is the EQUIOS workflow solution platform, which drives its range of Truepress Jet digital presses and can also interface with offset CtP for longer runs and mixed offset/digital production.

The main product highlights are:

Truepress Jet520HD + SC Inks

The star of the show will be Screen’s Truepress Jet520HD high-speed inkjet press, running SC wide-gamut inks that enable digital printing onto standard offset coated stocks.

The excellence of the 520HD + SC ink combination led to them receiving twin prizes in the US and Japan: a 2017 InterTech Technology Award from Printing Industries of America (PIA) and a 2018 technology award from the Japanese Society of Printing Science and Technology (JSPST).

Newly improved drying functions have further increased print speeds to 75 meters per minute even on offset coated papers. Attendees will have the opportunity to see a production solution built around EQUIOS that is linked from its front end, through to digital print and on to a cut and stack system provided by postprocessing experts Tecnau. Also demonstrated as a pilot on the 520HD, will be six-colour wide-gamut digital printing using SC inks.

Truepress Jet520NX

The high-speed (150 metres per minute) Truepress Jet520NX supports a wide variety of applications including the creation of direct mail, transactional print, books on-demand, cheques, lottery tickets and educational study guides tailored to individual learning levels. The system will be used in a demonstration that includes the installation of an extra ink printhead (provisional exhibit) compatible with functional inks such as MICR and ‘invisible’ to show the Truepress Jet520NX’s high value- added capabilities.

Essentially a CMYK full-colour variable content printer, the CMY printheads can be ‘parked’ when printing mono only, which saves ink. Print resolution is up to 600 x 1200dpi.

EQUIOS and EQUIOS Online

EQUIOS powerful workflow will be on display at the SCREEN stand. This solution platform forms the core of the digital inkjet presses exhibited by SCREEN at IGAS as well as the printing solutions enabled by the latest CtP technologies. EQUIOS promotes process automation from data submission right through to postprocessing and also links to production presses to create hybrid workflows that allow it to integrate seamlessly into production lines.

The exhibit will also include the debut of EQUIOS Online Version 5, the latest edition of the platform’s Web portal system. The package includes new user authorization

functions that have been upgraded to accommodate the major changes made to the interface in the previous version, as well as improved plate inspection functions.

Truepress Jet L350UV+LM and Cartes GE361L die-cutter

The Truepress Jet L350UV+LM will make its Asia-Pacific regional debut at IGAS 2018. The high-end digital label press enables a significantly expanded range of applications including food packaging labels and shrink-wrap labels for beverages. It is also compatible with SCREEN’s low migration inks featuring reduced odour and is equipped with a nitrogen purge mechanism that accelerates UV curing.

A laser die cutting machine from Cartes will also be on display as a postprocessing solution. Technologies newly developed by Cartes are highly effective for overcoming the issue of white edges generated during die cutting. The system’s capabilities will be introduced in a demonstration of high-speed cutting using variable data.

Local Screen GP Managing Director Peter Scott says: “We look forward to warmly welcoming all IGAS visitors from Australia and New Zealand. Although the theme is ‘Digital Everywhere,’ Screen will also show latest developments in CtP and other products not yet available in our market. The venue is stunning and of course Tokyo night life after work is legendary. It’s well worth the visit.”

Stephen Green joins Epson to lead Document Solutions Business In a move that clearly furthers and bolsters their commitment to the market, Epson Australia has appointed industry specia...

July 10 2018

Stephen Green joins Epson to lead Document Solutions Business

In a move that clearly furthers and bolsters their commitment to the market, Epson Australia has appointed industry specialist Stephen Green as business manager for document solutions, a role which sees him now lead the company’s Document Solutions business.

Green joins Epson bringing with him a rare wealth of experience in the printing industry having previously enjoyed success in senior leadership roles with Oce, Kodak, Ricoh, EFI and Fuji Xerox.

Green said, “Epson’s focus and ambition in the A4 and A3 office print space is unparalleled in the market right now. It’s also a very good fit with my background and experience so I’m delighted to be joining the strong team at Epson Australia at such an exciting time. Epson’s value proposition resonates incredibly well in this market and that will only continue to grow.”

Green’s appointment is the latest by Epson which demonstrates the importance it places in building and cementing its enterprise print business.

Epson Australia’s commercial division general manager Craig Heckenberg said, “Steve’s appointment is a major plus for Epson. He has excellent experience in document solutions and proven success in building business and relationships with clients, the channel and the overall market. He also joins us at a time when Epson is investing more heavily than ever before in high speed, high efficiency, low power consumption business inkjet technology solutions so the future is looking very bright indeed.”