See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

Lola Phillips, founder and managing director of Longina Phillip...

June 05 2018

Lola Phillips, founder and managing director of Longina Phillips Designs, discusses the part that Epson SureColor printers play in bringing their unique designs to the global fashion industry. Learn more about Epson SureColor for graphics here: http://bit.ly/2xmmF3C and for fabric here: http://bit.ly/2GXGcqr

SCREEN’S L350UV+LM VOTED ‘BEST LABEL PRINTER’ BY EDP Screen GP Australia is pleased to announce that the Screen Truepress Jet L350UV+LM (Low Migration inks) was...

June 05 2018

SCREEN’S L350UV+LM VOTED ‘BEST LABEL PRINTER’ BY EDP

Screen GP Australia is pleased to announce that the Screen Truepress Jet L350UV+LM (Low Migration inks) was awarded ‘Best Label Printer’ category by the European Digital Press Association (EDP) in its Annual Awards, presented during FESPA 2018, Berlin last month.

The EDP comprises twenty-one leading industry trade magazines, covering twenty-seven European countries, with an editorial focus on digital print processes. EDP’s total readership reach is more than half a million and winners are selected across several digital categories for quality and innovation in technologies for the printing industry. Criteria such as achievement, innovation, quality and costs are deciding factors.

The +LM version of the successful Truepress Jet L350UV label printer features a chill roller and newly developed low migration (low permeability) inks that offer unrivalled levels of functionality to food packaging label production. The UV curing of these special inks is accelerated using nitrogen gas bursts into the curing station.

Peter Scott, Screen GP Australia’s Managing Director says: “Since launching the original Truepress Jet L350UV inkjet label press in 2014, over 100 units have been shipped worldwide, with soon-to-be five in the ANZ region. We have accomplished this in close partnership with our label and CtP distributors Jet Technologies and Fujifilm NZ. Details of the latest New Zealand installation will be released shortly. With the L350UV+ and +LM models, Screen delivers industry-leading, reliable print speeds of up to 60 meters per minute, together with the option of gamut-expanding CMYKW plus orange inks and the unique low-migration inks for food applications.”

Scott continues: “We are naturally delighted to have won the EDP award for best label printer. To receive such recognition is an honour and further affirms our belief that we are leading the way in the development of inkjet solutions in the digital labels sector. Our R&D people continue to work extensively on innovation, productivity and customer-friendly applications.”

www.screenaust.com.au

Entries now open for the Konica Minolta National Specialised Print Awards 2018 Konica Minolta has announced that entries are now open for the National Specialised Print Awards 2...

June 01 2018

Entries now open for the Konica Minolta National Specialised Print Awards 2018

Konica Minolta has announced that entries are now open for the National Specialised Print Awards 2018. The awards celebrate exceptional craftsmanship in digital printing.

The 2018 awards will recognise the best work produced using Konica Minolta production print systems in five categories: books; brochures; embellishment; flat sheet; and labels. Entries will be judged by a panel of experts in October 2018.

Sue Threlfo, general manager, Production & Industrial Print, Konica Minolta said, “Now in its third year, the National Specialised Print Awards continue to go from strength to strength and are a great opportunity for our customers to showcase their extraordinary print work. These awards are our way of saying thank you to our customers for the outstanding work they produce using Konica Minolta production presses.

“This year we have included additional categories so customers can submit both embellished print jobs created on our MGI products and label print entries. We look forward to seeing how our customers push the boundaries with their Konica Minolta digital presses this year.”

State finalists will be flown to Sydney to attend the Konica Minolta National Specialised Print Awards event on the 18th of October. The National overall winner will be announced and will receive an exclusive trip to visit Konica Minolta’s Headquarters in Japan, including a tour of our Customer Experience Centre and R&D facilities

Entries close at 5pm on Friday, September 21. For more information or to enter, visit: https://www.konicaminolta.com.au/nspaawards

Océ Colorado Pops Up to Queensland Brisbane print service providers will be the first to get ‘up close and personal’ with the Océ Colorado next month w...

June 01 2018

Océ Colorado Pops Up to Queensland

Brisbane print service providers will be the first to get ‘up close and personal’ with the Océ Colorado next month when Océ Australia brings its Pop Up Showroom to Brisbane on the first stop of a planned multi-city tour.

The two-week event is designed to give decision makers, sales teams and production staff the chance to see the company’s ‘game-changing’ UVgel technology in action. Product and technical specialists will on hand to put their flagship Océ Colorado 1640 through its paces, at a time that suits customers and in a location that is a little out of the ordinary.

“We know how hard it is for people to make time in their schedules to investigate new technologies at a corporate head office or showroom, so rather than expect the market to come to us, we’ve decided to bring the showroom and applications to the market in a convenient, interesting and fun way,” says Jane Cox, Business Development Manager – Graphic Arts for Océ Australia.

“At the Océ Colorado Pop Up Showroom, we’ll be opening early and closing late, taking visitors through the technology and running live demonstrations in a real-life environment. We’re even inviting you to bring your own job files in to be printed live, so you can see how much faster the Colorado can print your jobs and just how much you can save.”

The 64”, roll-to-roll Colorado is the first of the company’s printers to use its new UVgel technology, which Cox says brings together the flexibility, colour and vibrance of solvent with the safety and environmental benefits of legacy technologies. Unique in the space, it offers quite exceptional productivity and economy, creating plenty of interest for both small and large-volume producers.

“We can talk about the Colorado all day and tell you why we believe UVgel is the future of print, but it’s not until you see it in action that you really appreciate the advantages it can offer,” Cox says.

“The Pop Up Showroom gives you the opportunity to produce a range of applications produced on the Colorado, customised to your requests, so you can see for yourself the quality and versatility it offers. We will have our local team on hand to walk you through the process, break down the impact of the technology and crunch the numbers, to see how it can revolutionise your business.”

With staff on hand morning, noon and night and catering organised for each session, Cox says they hope business owners will not only make an appointment to come in and see the technology themselves, but take the opportunity to bring their whole team in for the event.

On its first outing, the Océ Colorado Pop Up Showroom will be popping up in Brisbane from July 16 – 27. Keep an eye out for the location to be revealed. All are welcome, but reservations are essential. Email jane.cox@oce.com to reserve an appointment at a time that suits you and your team.

3D projection mapping creates this Heavenly experience.

May 31 2018

Epson launches N6 Compact 6-Axis Robot and Hollow Force Sensor Epson has launched the new N6 compact 6-axis (vertically articulated) industrial robot and the SH250LH...

May 31 2018

Epson launches N6 Compact 6-Axis Robot and Hollow Force Sensor

Epson has launched the new N6 compact

6-axis (vertically articulated) industrial robot and the SH250LH, a new force sensor with a hollow design.

Epson’s N series of compact 6-axis robots perform tasks in tight spaces more efficiently than other robots because of a uniquely engineered “folding” arm. The N6 has a longer arm (1,000 mm) and can handle higher payloads (6 kg) than Epson’s previously released N2. The N6 is ideal for loading/unloading small electronic products and automotive parts into/from test equipment. It is also perfect for shelving/unshelving medical products and much more. It has a smaller installation footprint than earlier 6-axis robots and can reach a wider range of places, from the top shelf to the bottom. These features increase productivity and the efficiency with which factory space is used.

N6 Features

1. The unique arm structure and arm length give the N6 a small installation footprint while allowing it to reach high places.

Taking advantage of the N series’ folding arm design and a long (1,000 mm) arm, the N6 can access locations that are higher than those that can be reached by the N2 and by Epson’s 900-mm class 6-axis robots (the C4L and C8L). Users can exploit these features by laying out factory shelves and equipment vertically instead of horizontally to enable the N6 to use previously wasted vertical space.

Installation space (blue section) reduced by 75%

Even with an arm length of 1,000 mm, the N6 can reach objects at the same height as the C8XL, Epson’s 1,400-mm class 6-axis robot. Moreover, because the N6 can be installed closer to shelves and equipment than a 1,400-mm arm, the installation space can be reduced*2 by about 75%. In addition to installing the N6 in narrow spaces and inside equipment where robots previously would not fit, users have the freedom to consider more compact factory layouts.

2. Hollow arm provides storage space for cables and hoses

A hollow arm design is employed to allow cables and hoses to be routed through the centre of the arm at joints #5 and #6. Routing the cables and hoses to the end-effector through the arm reduces the risk of damage and disconnections that could occur if the cables and hoses were to get caught or pinched when accessing narrow openings to shelves or equipment. The robot can also be set up more easily because you no longer have to take into account the amount of wrist rotation (the wrist is the moving part between joints #5 and #6) when routing cables and hoses.

Conventional routing method

Cables and hoses routed to the end-effector through the arm

Like the arm, the optional new SH250LH force sensor also employs a hollow design, so cables and hoses can be neatly routed through the sensor as well as the arm.

Image of the N6 and SH250LH

For additional information about Epson robots go to: http://global.epson.com/innovation/core_technology/robotics.html

Kodak Announces Plate Price Increase Kodak announced it will increase the price of Kodak offset printing plates globally. Plate prices will increase up to 9%.

May 31 2018

Kodak Announces Plate Price Increase

Kodak announced it will increase the price of Kodak offset printing plates globally. Plate prices will increase up to 9%.

The price of aluminum, the primary raw material used to manufacture printing plates, has increased dramatically in recent months. Despite internal cost reductions and improved operational productivity, the magnitude of rising aluminum prices can no longer be sustained by the company, as noted in Kodak’s Q1 2018 Earnings Conference Call.

John O’Grady, President, Print Systems Division, Kodak, explained, “With aluminum prices now reaching multi-year highs, it has become necessary to institute a plates price increase. While Kodak has worked diligently to reduce its own costs to lessen the impact of aluminum, the delta has become too great for us to bear, while maintaining our brand promise as a supplier of quality plates to the industry.”

“Looking to the future, we are exploring different business models to reduce the effect of aluminum volatility on our customers,” O’Grady added. “There are also measures that our customers can take to offset the increase in plate prices. Printers benefit from higher aluminum prices when they recycle their used plates, and many customers are saving additional money by switching to KODAK SONORA Process Free Plates to eliminate the costs of plate processing, including chemistry, water, and electricity costs.”

Details of the new pricing structure will be communicated to all customers and dealers across the world in the coming weeks.

Orafol has introduced a number of new printable films They are: - Orajet 3952F - a cast and highly transparent film with long-term durability and easy application.&...

May 31 2018

Orafol has introduced a number of new printable films

They are:

- Orajet 3952F - a cast and highly transparent film with long-term durability and easy application.

- Orajet 3851 - a digitally printable etched glass film for long term applications.

- Oracal 970 Premium Special Effect Cast - now with eight colours

- Oracal 351 - rose gold has been added and is available in 50 micron thickness.

- Oracal 7710 Fluorescent Premium Cast Plus - developed for application onto emergency services vehicles, this film comes in fluorescent yellow and red.

- Oraguard 244G Anti-Graffiti Film - UV resistant and can be cleaned without reducing its effectiveness.

Roland DG Celebrates 30 Years of Business in Australia Roland DG Australia has launched a new 30 Year Anniversary website to celebrate all things related to this milestone. The website...

May 31 2018

Roland DG Celebrates 30 Years of Business in Australia

Roland DG Australia has launched a new 30 Year Anniversary website to celebrate all things related to this milestone. The website includes a timeline of the journey of the company, case studies from some long-term customers, inspiring and useful applications videos, fun facts about what was happening in Australia and the world 30 years ago, as well as the latest promotions.

To help celebrate our 30 Year milestone, Roland DG is running a 'Buy and Win' promotion. Customers who have bought a participating Roland product to the value of over $5,000, have the chance to enter a competition to win their choice of one of the following products: EGX-350 Desktop Engraver, VersaLAM VL-1650TU Heat Assist Laminator, CAMM-1 GR-640 Vinyl Cutter, or the newly released LD-80 Laser Foil Decorator. To enter, simply tell us in 25 words or less why you chose your Roland.

Worldwide availability of Easy Cut Studio version 4.1.03. EasyCut Studio, the leading provider of vinyl cutting software solutions dedicated for the professional sign making and...

May 31 2018

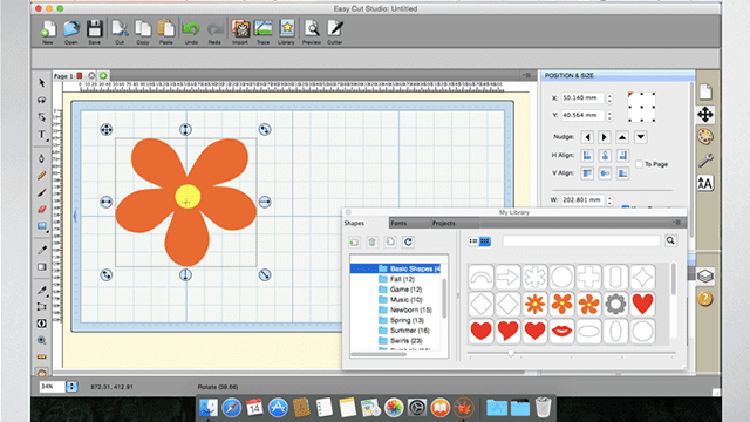

Worldwide availability of Easy Cut Studio version 4.1.03.

EasyCut Studio, the leading provider of vinyl cutting software solutions dedicated for the professional sign making and sign production processes, has announced the launch and worldwide availability of Easy Cut Studio version 4.1.03. the latest version of Easy Cut Studio includes many new vinyl cutters supported, like Mutoh ValueCut Series, Fenta, Roland GS and etc.

In addition, The new version features enhanced SVG support , Text to Outlines conversion capabilities, and the ability to work on multiple layers at once among its improvements.

Complete layout, design, text and production features for all of your sign making needs, Easy Cut Studio is the top-of-the line sign design & cutting software for macOS and Windows on the market today. Includes professional cutting tools to design, print and cut all types of graphics. Comes with many features for fast cutting. It supports many popular vinyl cutting plotters of well-known brands. Fully compatible with Windows 10 and the latest macOS 10.13. New cutting plotter drivers are being added continuously in Easy Cut Studio.

Easy Cut Studio v4.1.03 includes dozens of new features including the following:

Added support for Mutoh ValueCut Series;

Added support for Fenta SL440, SL740 and SL1320 vinyl cutters;

Added support for Roland GS cutter;

Fixed FCM batch convert error;

Fully compatible with the latest macOS 10.13.4.

Other improvements and bug fixes.

Pricing and availability:

Easy Cut Studio version 4.1.03 is compatible with both macOS and Windows. The upgrade is available to all current Easy Cut Studio users at no charge. New users can get all the features and updates for $59.95 ($10 off) for a limited time with lifetime free upgrades.

Agfa introduces the Jeti Tauro H3300 New from Agfa Graphics is the Jeti Tauro H3300 LED printer. Building on the Jeti Tauro H2500 LED, the hybrid workhorse is capable of printin...

May 27 2018

Agfa introduces the Jeti Tauro H3300

New from Agfa Graphics is the Jeti Tauro H3300 LED printer. Building on the Jeti Tauro H2500 LED, the hybrid workhorse is capable of printing on media up to 3.3m wide at speeds up to 453m²/h, and is designed for 24/7 operation. It is convertible to enable different degrees of automation.

“Those who opt for automation will have fully automated multi-board loading and unloading up to four boards, reducing idle time and increasing production efficiency even more,” said Reinhilde Alaert, marketing product manager of sign and display at Agfa Graphics. “Its extreme speed becomes even more apparent in the roll-to-roll version, which is capable of handling heavy master rolls in single or dual-roll mode for a wide variety of flexible media. With the Jeti Tauro H3300 LED, we can offer the highest possible level of both quality and productivity, thanks to a brand-new vacuum table and Agfa-patented vacuum belt design that keep print media perfectly flat under the print shuttle, guaranteeing precise dot positioning and accurate media transport.”

The Jeti Tauro’s image vividness is created to last, even when subjected to harsh outdoor weather conditions. Due to the high pigment load of Agfa-made inks and Asanti’s ink saving algorithms, ink consumption per square meter is the lowest on the market. The result is an ideal balance between quality, productivity and cost of ownership.

“Among other benefits, LEDs are durable – they generate consistent light output throughout their lifespans of about 10,000 hours,” says Reinhilde Alaert. “Also, the Agfa-developed and manufactured UV-curable inks match perfectly with the spectral emission of Tauro’s LED lamps. This guarantees deep instant curing and delivers dry output, outstanding adhesion on a broad media range, good scratch resistance, perfect color stability, etc.… The fact that the Jeti Tauro H3300 LED relies fully on this technology is truly unique – it’s one of the engine’s many strong suits. Not only that, this hybrid UV inkjet workhorse is capable of producing visually stunning prints on media up to 3.3 m wide at speeds up to 453 m²/h, able to keep going 24/7 and convertible to enable different degrees of automation. It truly is one of a kind.”

Extreme Productivity. Extreme Quality.

Agfa’s printing solutions stand out because of their use of specially-formulated UV LED inks, which are suitable for a wide variety of rigid and flexible substrates. In combination with the company’s Asanti workflow and color management software, these inks produce award-winning prints with the largest color gamut and superior adhesion and durability.

In addition, Agfa Graphics’ patented Thin Ink Layer technology guarantees the lowest ink consumption per square meter on the market, thanks to the inks’ high pigment load, and the unique color management capabilities of Asanti.

This supreme level of quality, combined with the stellar productivity that results from a combination of high-speed printing with a range of automation options, is at the core of Agfa Graphics’ EXTREME campaign, which is reflected in its slogan: ‘Extreme Productivity. Extreme Quality.’ All of these benefits are embodied by Agfa’s latest pride and joy, the Jeti Tauro H3300 LED.

Andretti Autosport wins with ONYX Thrive Watch how ONYX RI{ software products help Andretti Motorsport.

May 27 2018

Colordyne Technologies launches laser finishing system Colordyne Technologies, a digital labels and packaging equipment manufacturer, has introduced the 2800 Series Mini Laser, ...

May 27 2018

Colordyne Technologies launches laser finishing system

Colordyne Technologies, a digital labels and packaging equipment manufacturer, has introduced the 2800 Series Mini Laser, an off-line or near-line finishing system. The new addition to Colordyne's suite of solutions marks the first of the company's finishing-only product offerings.

The 2800 Series Mini Laser features the same reliable finishing technology as Colordyne's 2800 Series Mini Laser Pro. It laminates, laser diecuts and removes matrix waste in a single pass. This solution is ideal for accompanying roll-to-roll digital printers, such as the 2600 Series Mini Press, to complete the short run, custom label and tag production process.

"Other companies sell digital label and packaging equipment. We sell digital label and packaging solutions," says Andrew Matter, president of Colordyne Technologies. "We have brand owners and private label manufacturers using our digital printers that typically source pre-diecut material from outside vendors because they do not have the space or resources to manage a multitude of dies. We wanted to provide a solution for these customers to bring label finishing in-house to take full control of their label production."

The 2800 Series Mini Laser is suitable for finishing labels off-line or near-line, and it can create custom diecut blank labelstock for use on digital benchtop solutions. Since it uses a laser for diecutting instead of traditional rotary or blade cutting, it can produce more jobs in less time, with lower consumable costs, the company says. The laser technology eliminates the need for expensive dies and knives, making it a more cost-effective solution long term.

The 2800 Series Mini Laser offers a max cut width of 7.87" and a max cut length of 47.24" with speeds up to 60 fpm. It allows users to easily and affordably execute complex cuts in any quantity to create custom labels.

Like Colordyne's digital print systems, the 2800 Series Mini Laser features an intuitive and visual user interface that allows operators to make cutting adjustments on-the-fly. Transitioning from one cut to another is completed quickly with its built-in job library that allows users to save and reopen diecuts on-press. Setup times between jobs are nearly eliminated compared to traditional finishing.

"Every product we engineer has our customers in mind," adds Matter. "We decided to offer the 2800 Series Mini Laser for companies that do more than labeling such as brand owners and private label manufacturers. There was a gap in the market for this type of application, so we stepped in to fill it."

The 2800 Series Mini Laser can fit anywhere from a press warehouse to an office, thanks in part to its compact size and low level of noise. While this solution is user friendly enough for companies new to packaging production to operate, it laminates and cuts with the precision needed for converters.

CONNECTED PRODUCT WITH NFC AND AR REACTS TO CUSTOMERS’ MOOD Multi-Color Corporation and Talkin’ Things are the first Internet of Things packaging platform providers ...

May 27 2018

CONNECTED PRODUCT WITH NFC AND AR REACTS TO CUSTOMERS’ MOOD

Multi-Color Corporation and Talkin’ Things are the first Internet of Things packaging platform providers to combine Augmented Reality (AR) and NFC technology to create a unique customer experience in connected product that will help boost its sales.

This label demonstrates how advanced smart packaging can be by interacting with the consumer via AR facial recognition and incorporates dynamic scenarios dependent on users’ emotions.

The smart label produced by MCC becomes a trigger, no additional marker has been implemented to launch an AR experience. When the customer scans the smart label with a mobile app, the skull presented on the label engages into interactive dialogue with the consumer. The face recognition feature detects if the customer is happy or sad and customises the next part of the dialogue. Variable AR scenarios are also launched depending on answers provided to questions asked by the skull.

"Thanks to our labelling production capabilities and Talkin’ Things technology combined with creative services, we are able to offer our Clients a brand new solution that will completely transform a product and change the way end-customers interact with it.” -praises Craig Miller, President of NA CPG at Multi-Color.

Additionally, NFC smart label applied to the bottle’s neck provides a proof of purchase solution for 2-stage communication with end-customers. It recognises when the product has been opened to provide different messages to the customers. "With our technology it is also possible to provide completely new experience with AR technology before and after the purchase.” - said Marcin Pilarz, CEO at Talkin’ Things.

Talkin’ Things provided NFC technology, creative concept and artworks for Augmented Reality and software development. The smart labels were produced by Multi-Color.

More info:

www.talkinthings.com/black/

EFI Raises the Bar in Soft Signage with New, In-line VUTEk FabriVU Print and Sublimation Product EFI has unveiled its new fabric soft signage printer with in-line sublimation, t...

May 27 2018

EFI Raises the Bar in Soft Signage with New, In-line VUTEk FabriVU Print and Sublimation Product

EFI has unveiled its new fabric soft signage printer with in-line sublimation, the EFI™ VUTEk® FabriVU® 340i. This advanced, aqueous dispersed dye-sublimation printer features a new platen and extraction system that enables in-line heat press sublimation directly from the printer.

EFI customers gain greater convenience and value with this new offering, as it is available at a price that is less than the cost of a comparable printer and heat press purchased separately. Plus, the combined printer/heat press system uses less floor space than would be required with separate printing and sublimation stations.

The new offering continues a track record of innovation and customer success worldwide with VUTEk FabriVU aqueous dye-sub printers – a best-in-class technology based on EFI Reggiani’s 70+ years of innovation in textile printing.

“We are excited by the continued advances of our soft-signage portfolio,” said Ken Hanulec, vice president of marketing, EFI Inkjet. “Our new in-line innovation for this product line creates direct-to-fabric prints that are immediately ready for finishing or shipping. By combining two major production steps into one continuous process our customers can drive greater throughput and take full advantage of the rapidly growing soft signage and fabric printing market.”

“EFI has just sold our very first VUTEk 340i printer,” Hanulec added, “and it has taken us to a significant milestone, as it is the 100th VUTEk FabriVU aqueous soft-signage printer sold worldwide.”

A milestone achievement at CoverUp Ltd

Dublin, Ireland-based CoverUp Ltd is the first company to purchase the 340i model printer. The company chose the 133-inch (340-cm) wide device to take its soft signage capabilities to the next level of quality and productivity.

“We were looking to increase our soft signage printing capacity with a reliable printer with inline fixation,” said CoverUp Operations Director Anthony Byrne. “We flew to EFI Reggiani in Italy to see one of the very first VUTEk FabriVU 340i demos, and found the printer to be a significant upgrade in terms of image quality, productivity and reliability compared to our existing fabric printers. The addition of this latest technology from EFI is going to give us a significant competitive advantage in our marketplace.”

The new printer provides the high quality of EFI VUTEk FabriVU aqueous dispersed dye-sub printing with sublimation completed in-line at fast production speeds. Customers who occasionally need to print to transfer paper and then sublimate offline can utilize a special direct-to-paper mode on the 340i model for printing only.

In addition to the new VUTEk FabriVU printer, EFI’s exhibit at FESPA, in hall 2.2, stand B30 of Messe Berlin, will include technologies from the company’s leading portfolio of VUTEk LED inkjet and Reggiani industrial textile digital printers – all driven by the latest EFI Fiery® digital front end systems. The exhibit also will feature EFI Optitex®, a leading integrated 2D/3D software platform for apparel and soft goods applications; the EFI Midmarket Print Suite for end-to-end signage and graphics business and production management; and MarketDirect, EFI’s new customer communication platform software.

For more information about EFI products, visit www.efi.com.

Esko and Asahi partner to streamline flexo platemaking Esko and Asahi are partnering to improve overall equipment effectiveness (OEE) in flexo platemaking through the combinatio...

May 27 2018

Esko and Asahi partner to streamline flexo platemaking

Esko and Asahi are partnering to improve overall equipment effectiveness (OEE) in flexo platemaking through the combination of their respective technologies.

Stephan Doppelhammer, business development manager at Asahi Photoproducts Europe, explained: ‘In our fast-paced and rapidly evolving industry, efficiency, waste reduction and speed to market are critical.

‘By partnering with Esko, we bring together solutions from two world-class companies to create a faster, more efficient and more consistent workflow in flexographic platemaking. Esko Equinox is ideal for converting separations to fixed palette printing, while Esko’s Crystal technology reduces the number of platemaking steps required and is making the process more consistent. By adding Asahi’s AWP water washable plates with Clean Transfer Technology to the mix, Asahi and Esko customers can take OEE to a brand new level of efficiency while boosting print quality and reducing their environmental footprint.’

Gateway Packaging, a high-end printer and packaging converter, and the largest pet food packaging provider in North America, recently restructured its entire platemaking process with Asahi Photoproducts technology as the core element.

Tharrin Akers, the company’s pre-press manager, commented: ‘When running the Asahi AWP Clean Transfer plates, we were able to run the press at a 17 percent higher speed – 1,640ft/min – and only had to stop for plate cleaning once. And that only required cleaning two plates, consuming 20 minutes.

‘The result was a total production time of 7.2 hours instead of 11 hours in the past and an astonishing 53 percent improvement in OEE over our previous process.’

Gallus has developed Smartfire, a new digital label printing system designed as an affordable option for short runs. Debuting at the Gallus Innovation Days event on June 26-28, ...

May 27 2018

Gallus has developed Smartfire, a new digital label printing system designed as an affordable option for short runs.

Debuting at the Gallus Innovation Days event on June 26-28, 2018 in St Gallen, Switzerland, Smartfire is described as being, ‘designed for constantly changing short runs and furthermore represents an affordable solution for any label printer who is interested in going into digital label printing.’

Other technologies to be shown at Gallus Innovation Days 2018 are to include: Gallus Labelfire, equipped with a fully integrated screen printing unit; Gallus Labelmaster Advanced with automatic transverse and longitudinal register control; Gallus RCS 430 with flying imprint and fast UV ink drying thanks to a UV booster; and Gallus ECS 340, featured with web shifting for the manufacture of multilayer labels.

On top of that, the Gallus screen printing department will be presenting the whole production process of a Screeny A-Line printing plate, from screen exposure with the new Phoenix UV LED exposing system by Heidelberg, to the development of a new automated washing and drying system by Gallus Screeny, to the final assembly of the ready-to-print screen printing plate.

Heidelberg equipment presentations will cover in-mold printing with the rotative die-cutter Speedmaster XL 160-DD, and 3D printing with the Omnifire 250. Cerm will introduce new mobile features for its business management software.

Additionally during Gallus Innovation Days 2018, Gallus and Heidelberg experts will be showing how digitization will change the label business and how the two companies are going to jointly support their customers in ‘mastering this paradigm shift’.

HP Showcases Multi Jet Fusion 3D Printing Applications, Announces Expanded Partnerships HP‘s Multi Jet Fusion technology has been spreading to every corner of the industry...

May 27 2018

HP Showcases Multi Jet Fusion 3D Printing Applications, Announces Expanded Partnerships

HP‘s Multi Jet Fusion technology has been spreading to every corner of the industry as the company cements partnerships all over the world. This week in Barcelona at the HP Innovation Summit, HP announced additional collaborations that will see the technology further utilized by some industry heavyweights, as well as highlighting several of the applications in which Multi Jet Fusion is already being used to change how things are made.

“The digital transformation of the $12 trillion manufacturing industry is changing the game for the world’s designers, product developers, manufacturing and supply chain professionals, creating massive opportunity for the 3D printing ecosystem,” said Ramon Pastor, General Manager of Multi Jet Fusion, HP Inc. “In collaboration with our customers, we are proud to reinvent the way the world designs and manufacturers and to drive innovative new applications made possible with HP Multi Jet Fusion. Whether it’s helping the Swiss Guard protect the Vatican or reinventing what can be done for an entire industry like orthopedics, the possibilities are endless.”

Protolabs was one of HP’s original partners when Multi Jet Fusion technology was initially launched, and now the service bureau is upgrading its seven HP Jet Fusion systems to industrial HP Jet Fusion 4210 systems in order to meet growing demand for production-grade 3D printing. Applications in which Protolabs has already been using the technology to help customers include specialized packaging, such as a promotional series of Black Panther masks put out by Pepsi. In addition, Protolabs used MJF to help customer Stream Lion Design to solve a combustion turbine issue, 3D printing a modal hammer to survey engines in the field and double the speed of data collection.

“The demand for 3D-printed production applications continues to grow and HP’s Multi Jet Fusion technology is furthering our ability to deliver our customers industrial-grade parts quickly and cost-effectively,” said Vicki Holt, president and CEO, Protolabs. “By expanding the capacity of our HP Multi Jet Fusion services and installing printers in the United States and Europe, we are meeting the needs of our global customer base and demonstrating that geographically distributed, on-demand production is a reality today.”

Materialise was another early MJF partner, and has been using eight HP Jet Fusion 4200 3D printers. Now Materialise and HP have joined with RSPrint to scale an end-to-end solution for the production of personalized 3D printed insoles. Through RSPrint, FitStation powered by HP uses customer data to design custom insoles, which are then 3D printed on Materialise’s Jet Fusion 3D printers.

Belgian service bureau ZiggZagg has also jumped on the MJF train, investing in six HP Jet Fusion 4210 3D printers. ZiggZagg serves a variety of customers across industries including medical, consumer goods, industrial and automotive. According to CEO Stijn Paridaens, the company also plans to purchase an additional five Jet Fusion 3D printers by the end of the year.

IAM 3D Hub, an organization that brings together private companies, public entities, and R&D organizations to integrate and coordinate 3D printing activities around the world, has installed eight HP Jet Fusion 4200 systems and is also working with HP to expand educational and training opportunities and offer business mentoring.

“IAM 3D Hub shares HP’s vision to accelerate the adoption and development of 3D printing technologies for industrial production, and provide expansive education and training opportunities to grow the market,” said Aintzane Arbide, General Secretary, IAM 3D Hub. “HP’s leadership has already helped us move the needle across our various programs specific to technology innovation. The advanced capabilities of Multi Jet Fusion allow organizations to completely rethink their approach to product engineering and design, complex workflows, and advance the future of their manufacturing processes.”

At the summit, HP also showcased several of the applications in which customers have been using Multi Jet Fusion technology, such as 3D printed helmets worn by the Vatican’s Swiss Guard, lightweight bicycle helmets produced by Sculpteo for customer Syncro Innovation, and an ankle foot orthosis 3D printed by Crispin Orthotics.

Koenig & Bauer Announces New Measurement and Control Technology for Sheetfed Offset Presses With QualiTronic NextGeneration, Koenig & Bauer is launching a revolutionary ...

May 27 2018

Koenig & Bauer Announces New Measurement and Control Technology for Sheetfed Offset Presses

With QualiTronic NextGeneration, Koenig & Bauer is launching a revolutionary package of innovations for its inline measuring systems on Rapida sheetfed offset presses. QualiTronic NextGeneration provides a foundation for the restructuring of all inline measurement functions and a platform for further developments in the future. As already successfully implemented with regard to mechanical press components and software, a modular principle enables identical system hardware to be used for a variety of applications. Users can now combine:

New: swissQprint Generation 3 swissQprint once again provided a surprise at FESPA 2018. The Swiss developer and producer of high-end large-format printers presented a new genera...

May 27 2018

New: swissQprint Generation 3

swissQprint once again provided a surprise at FESPA 2018. The Swiss developer and producer of high-end large-format printers presented a new generation of machines – five of them, in fact: Nyala 3, Impala 3 and Oryx 3, together with the speed models Nyala 3S and Impala 3S. Each of these LED flatbed printers has the accustomed add-on features, which now include an extended roll to roll option that was also shown for the first time at FESPA.

Adriano Gut, swissQprint product manager, explains: "Mechanical refinements make these new systems even more stable and precise than their predecessors." Given that this is what these Swiss products are already known for, here is perfection being taken to a whole new level. Gut adds: "Among other things, we have completely redesigned the architecture of the print head carriage." A new control system also contributes to the advances and to increased user-friendliness, this being evident in many details such as control and regulation of the vacuum effect. However, the new control system is mainly present as a foundation for future developments, some of which swissQprint already showed in Berlin.

Nyala 3S and Impala 3S are designed for high-output operations: Nyala 3S delivers up to 370 m²/h, Impala 3S up to 317 m²/h, with remarkable print quality in view of their pace. The new high-performance models cleverly combine print density and speed. High-quality POS items, displays, posters, banners, backlit and other similarly demanding media are the classical applications. The maximum productivity level extends to print products intended for viewing at a distance, such as mega posters, banners and wraps for buildings under conversion.

swissQprint is introducing an extended roll to roll option as part of printer generation 3. A new spreading roller smooths material before it reaches the print bed in order to prevent wrinkles and resulting crashes. Meanwhile, carbon brushes on the spreading roller dissipate static charge from the material, aiding precise droplet placement. In combination with LED curing, the new roll to roll option increases the variety of materials by making it easy to process delicate and heat-sensitive media. This solution includes another variant: the dual roll option for printing two widths of material in parallel, doubling productivity at a stroke.

With the new generation, swissQprint is offering even more finely granular solutions than before: the individualised systems can just as effectively meet the needs of a lettering operation as they can in the case of a large print shop or an industrial enterprise. The generation 3 models will be available from August 2018 via the swissQprint distribution network.