See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

HP will launch at FESPA a new rigid printer, the Latex R-series, that will feature a ‘newly formulated for rigid’ latex ink. First true hybrid HP ...

March 22 2018

HP will launch at FESPA a new rigid printer, the Latex R-series, that will feature a ‘newly formulated for rigid’ latex ink.

Today at ISA Sign Expo, HP Inc. announced the HP Latex R Series, HP’s first latex technology capable of printing on flexible and rigid materials with HP Latex Ink. The HP Latex R Series brings the most vibrant colors into the rigid printing world, and pioneers white ink capabilities with the introduction of HP Latex White Ink.

Equipped with a single, six-color ink set, the HP Latex R Series technology delivers unprecedented quality at speed, and is the first, true hybrid latex technology that merges HP’s renowned flexible printing capabilities into rigid printing.

The HP Latex R series brings unparalleled quality to a wide range of rigid materials, such as foamboards, foam PVC, cardboard, fluted polypropylene, solid plastics, aluminum, wood and glass among others. Unlike UV printing technology, which creates a thick layer of ink that completely covers the material and requires time to dry, HP’s water-based Latex Inks preserve the look and feel of the media, and delivers odorless prints that are both safe for the environment and the printer operator.

“The HP Latex R Series is remarkable for setting up new industry standards in quality and enabling Print Service Providers to produce stunning rigid and flexible prints,” said Joan Perez Pericot, General Manager, Graphic Solutions Business, HP Inc. “Our customers can expand their offering into new, high-value applications while also opening fresh creative ideas and concepts for sign and display that provide their users greater value.”

Tackling one of the industry’s most pervasive limitations in printing, HP’s White Latex Ink has an innovative system that recirculates the white ink – both within the ink delivery system and at the printhead – to avoid settling. It also has a unique storage system with automatic agitation for when the ink is not being used to minimize waste. For the first time, HP’s innovative White Latex Ink delivers glossy, high-quality “true white” that doesn’t yellow over time like traditional UV-based white ink does.

“White ink has been a consistent problem for the industry. Traditionally it uses bigger and heavier pigment particles that frequently clog printheads, or the opaque mixture becomes separated and settles to the bottom of the ink reservoir. Until now, physically shaking the reservoirs often has been the necessary solution,” said Thom Brown, Chief Inkologist at HP. “Through HP’s investment in innovation around chemistry and engineering, the white ink solution with the HP Latex R Series is an industry breakthrough.”

MUTOH INDUSTRIES LTD. a leading manufacturer of wide-format inkjet printers, affiliated with MUTOH HOLDINGS CO., LTD. today announced the new “PerformanceJet 2508UF”, Mutoh’s f...

March 22 2018

MUTOH INDUSTRIES LTD. a leading manufacturer of wide-format inkjet printers, affiliated with MUTOH HOLDINGS CO., LTD. today announced the new “PerformanceJet 2508UF”, Mutoh’s first true 4’x8′ UV-LED flatbed printer, will soon be released to the industrial printing market.

Prior to the formal launch, the “PJ-2508UF” will be exhibited at the ISA (International Sign Association) Sign Expo 2018, the largest sign and graphic exhibition in the US, to be held in Orlando, Florida, USA from March 22nd – 24th, 2018.

The PJ-2508UF is the latest performance model in flatbed printing with field upgradable head configurations of up to 8 sets. 4 sets of staggered print heads are installed as standard, achieving high-speed printing. In addition, the maximum resolution of 600x1200dpi and the latest printing technology, enables the PJ-2508UF to achieve high image quality and outstanding performance. The PerformanceJet is equipped with automatic media thickness detector supporting media up to 4 inches/100mm 50kg/m2 (92.15lbs./sq.yd).

The printer also comes standard with an automatic media registration pin system and a vacuum table with “blow-back” feature for easy handling and positioning of heavy media. The vacuum table is divided into four zones firmly fixing various media sizes and improving work efficiency.

The PJ-2508UF will expand a print shop’s production capability and product offerings such as promotional items, directional signage, awards, specialty, labels and packaging prototypes.

ABOUT THE PERFORMANCEJET 2508UF:

The features of the PerformanceJet 2508UF UV-LED flatbed printer include:

• Expandability: 4 print heads included as standard with the option to expand to 6 or 8 as your business grows.

• High-speed & High quality Printing

• Auto Media Thickness Detector: Automatically detects thickness of media and adjusts print heads for printing on substrates up to 4 inches thick.

• 4 Zone Vacuum Table: Firmly fixes various media sizes and improves work efficiency

• Automatic Media Registration Pin System and Vacuum Table with “blow-back” feature: make handling and positioning of heavy media easy.

• The Maximum Print Resolution: The maximum resolution of 600x1200dpi enables high image quality and outstanding performance.

• MUTOH UV-LED Hard Ink: Available4 or 6 colours (CMYK or CMYK, White & Varnish) with excellent durability and colour gamut, suitable for various media

• Static Elimination System: Standard system to enable printing on media vulnerable to anti-static electricity.

Durst, has confirmed that Italy’s Italgrafica Sistemi will be the world’s first customer for the new

March 21 2018

Durst, has confirmed that Italy’s Italgrafica Sistemi will be the world’s first customer for the new Omet XJet. Powered by Durst, the integrated hybrid solution for a wide range of high-performance labels and packaging printing will be installed at its headquarters in Castelgomberto, in the province of Vicenza, in the early summer.

Together with Omet, the two companies are providing a complete hybrid print and finishing line to Italgrafica Sistemi that will offer an unlimited flexibility and a wide range of final applications with a consistent cost reduction. It chose the Omet XJet because of the ability for inline multi-process configurations that finalizes products in a single pass.

Italgrafica Sistemi is an €11m-turnover company with 50 employees who work two shifts. With 18 printing lines already running at Italgrafica Sistemi, the new Omet XJet provided through Lirma Print, a Durst and Omet distribution partner, is expected to replace two of the flexo lines as demands continue to increase for short-run, personalised technology in a single pass. It will open up new opportunities for cold foiling, printing on reverse and adhesives, as well as varnish and diecutting.

Francesco Niorettini, general manager of Italgrafica Sistemi, says the total cost of ownership and benefits to his customers were crucial in the decision-making. “This investment opens up a new world of opportunity,” he says. “It allows us to give far more choice to the market and produce so many more different types of labels for any kind of job. By including the Durst Tau, we will be able to broaden our portfolio by combining all the technologies together.

“What is also really important is to ensure that we retain the same high level and definitions produced with flexo and offset – and the Durst/Omet hybrid will enable this. Other factors in our investment decision included the 50% increase in speed, the low service and consumable costs, as well as the fact that both Durst and Omet have good reputations in the marketplace,” he adds. “We’ll be saving huge amounts of money and time. We expect a 20% saving in overall production costs and will benefit from faster start-up times, which will enable us to offer a wider product range. As one example for, say, a four-color job we expect to increase the productivity of the machine by 40% with faster setups. In addition, we will be saving around 70% in material waste by using digital.”

Helmuth Munter, segment manager, Labels & Package Printing at Durst, explains, “Italgrafica Sistemi is one of the increasing numbers of forward-thinking companies that are seeing the huge benefits of using the best technologies in a complete ‘all-in-one’ printing process. This ability to combine digital inkjet printing with conventional pre- and post press printing and finishing world, offers our future customers a highly cost effective solution.

“In addition, the feedback we received from our recent Durst Digital Days has also convinced us of how customers perceive future market opportunities to increasingly involve UV inkjet digital in flexible configurations or as a complementary technology. It’s the future.”

The jewel in the crown of the Durst and Omet partnership, the new Omet XJet is the new hybrid printing platform integrating Durst’s Tau RSC 330 digital inkjet system with Omet X6 flexo stations and converting units. Durst inkjet technology, together with Omet X6’s finishing and converting units, assure reliability and excellent results at every run, with the advantage of obtaining the final product in one single passage.

The Omet XJet hybrid broadens the opportunities for label printers thanks to its flexible configuration. Italgrafica Sistemi’s configuration provided through distribution partner Lirmaprint will feature an unwinder, two flexo units, the Tau 330 RCS, another two flexo units, a diecutting mono twin system, and a rewinder. The Vision automatic registration system is also included and the system has an option to print on adhesive, laminate and other applications to create coupons and special labels, including peel-back versions. It can be seen as three presses in one or used as a hybrid solution, flexo standalone or digital standalone, according to the length of the run or the level of personalisation required.

With the launch of the new AccurioPress 6136 series, Konica Minolta Business Solutions Austr...

March 21 2018

With the launch of the new AccurioPress 6136 series, Konica Minolta Business Solutions Australia introduces its new monochrome production print systems designed to increase customer profitability with enhanced productivity and increase capability to streamline automated workflows.

The affordable and cost-effective series consists of three models: AccurioPress 6136; AccurioPress 6136P; and AccurioPress 6120. Each delivers greater productivity to enhance job capacity, reliability and flexibility enabling operations to expand their monochrome print capabilities. As a successor model of the bizhub PRESS 1250e series, the AccurioPress 6136 series prints at an exceptional high speed of 136ppm on A4 and 78ppm on A3 sheets.

The Konica Minolta AccurioPress 6136 model can produce a monthly peak volume of up to 3.24 million A4 pages and offers the highest media flexibility in its class. It enables print providers to create more business opportunities by handling a wide range of essential digital printing applications.

The series supports various media types and weights, from 40 gsm up to 350 gsm, and the inclusion of Relay Unit (RU-518) facilitates the elimination of paper curl. There is an intelligent paper catalogue and optional envelope fuser creating greater media flexibility to provide ultimate performance. The addition of the dual side colour scanning on the AccurioPress 6136 and 6120, brings high speed scanning of up to 240opm, for high level archive and copy functions.

Automatic and real-time density and registration adjustment is delivered by the optional IQ-501, Intelligent Quality Optimiser that enables front-to-back registration, with image centring and zoom to enable the perfect sheet position at the press of a button when loading new media. This unique functionality helps eliminate operator set up time, reducing errors and waste.

The expanded range and finishing flexibility that can be included in these systems, with a vast number different configuration combinations possible, bringing professional finished print output at the press of the print button. These include Konica Minolta developed finishing as well as partnerships with market leading finishing companies such as Watkiss, GBC and Plockmatic.

OpenAPI provides high scalability via a seamless interface between the AccurioPress 6136 series production printing devices and third-party solutions, and seamless integration with AccurioPro workflow solutions. It enables accounting, authentication or scan routing with applications such as YSoft SafeQ and Nuance eCopy Sharescan. A unified UI and remote panel operation help smooth set-up while operations can have maximum flexible control, which makes every day print work more efficient.

The new AccurioPress 6136 series is available now.

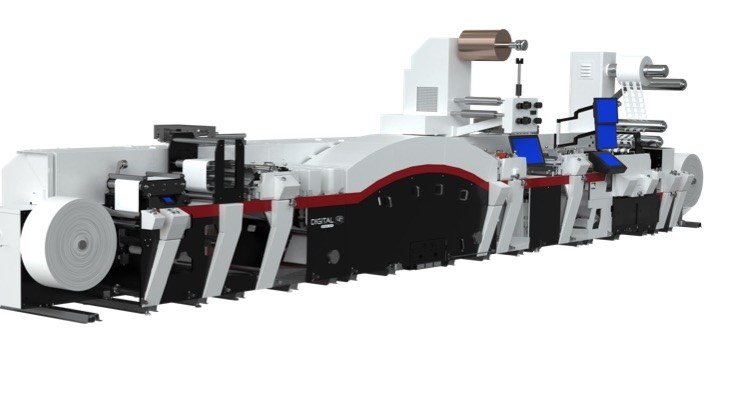

Label press manufacturer Mark Andy is continuing its commitment to hybrid printing with the announcement of a suite of enhancements to its Digital Series platform. The production-class digital s...

March 21 2018

Label press manufacturer Mark Andy is continuing its commitment to hybrid printing with the announcement of a suite of enhancements to its Digital Series platform. The production-class digital solution has been reimagined to bring greater levels of productivity and profitability to the modern converter. Building off the platform’s successes, Mark Andy says the latest true hybrid offering will take on the name Digital Series HD and combines flexibility of inline converting, high-resolution digital print, and best in class production capability.

Digital Series HD can be configured with 5 through 8 digital colors and can support integrated inline or future-proof near line converting options.This added flexibility enables Mark Andy’s portfolio of digital hybrid solutions to reach a larger percentage of the addressable market in terms of budget as well as unique application or workflow needs. The base roll-to-roll configuration is ideal for those just entering the production digital space. As their digital business expands, the modularity of the platform enables the shift to inline finishing to better utilize the high speed platform.

Expanded gamut now offered in a high-chroma ink set (CMYK + OVG) complements an existing richly pigmented white ink formulation, which delivers output comparable to rotary screen. Mark Andy product development reports the ink provides 3 times the opacity of flexo white and more than double that of conventional EP white, measured in excess of 80%. Digital white can be run without trade-off in speed at the platform’s standard of 240 fpm.

The most notable alteration to the Digital Series HD press comes in the form of the digital module. Once a flat table section, the new platform now showcases an arched IDS. The arch design accepts unsupported films and improves operator ergonomics, enabling quick and clean ink changeover. New print head technology housed in the module also matches the industry’s quality standard of 1200 dpi.

Digital Series HD also comes with further configurability in the way of 3 head cleaning options- manual, automatic, and semi-automatic. This variety translates to less downtime, improved head health and reduced costs for converters. Additionally, the platform now offers a more advantaged VDP tool in response to market demand for sophisticated personalization.

Digital Series HD is supported by Mark Andy’s industry leading web-transport system, maintaining production class speeds of 240 fpm. In addition to digital and converting flexibility, the press retains its limitless configurability of inline flexo options. All accessories available on the former Digital Series or Performance Series platform are supported by Digital Series HD, now and into the future.

When speaking to the new product developments, Tom Schelmbauer, VP of Engineering, Mark Andy, says, “The Digital Series platform was already incredibly successful, evidenced by our 2017 FTA Technical Innovation Award. Digital Series HD builds on these successes and delivers the highest quality, most productive hybrid solution on the market.” The product line extension also ensures every business has a digital growth path with Mark Andy. “Our users all have flexibility to upgrade their press as business continues to grow. We designed the press with modularity in mind because we understand demands are constantly changing. Mark Andy is prepared to tackle market shifts with our customers.”

For more technical specifications of the Mark Andy Digital Series HD, visit www.markandy.com/digitalseries.

Screen Graphic Solutions has seen cumulative shipments of its Truepress Jet L350UV inkjet label printing systems pass the 100-unit mark worldwide. The Truepress Jet L...

March 21 2018

Screen Graphic Solutions has seen cumulative shipments of its Truepress Jet L350UV inkjet label printing systems pass the 100-unit mark worldwide.

The Truepress Jet L350UV series was launched at the end of 2013, and has since been expanded to include: the Truepress Jet L350UV+, featuring enhanced productivity, thin substrate support and new orange ink; and the Truepress Jet L350UV+LM, which is compatible with newly developed low migration inks for the food packaging industry. These systems were launched at Labelexpo Europe 2017.

The first was commercially released as a CMYK model at the end of 2013. In the spring of 2014, white ink was additionally released and in the following autumn, the JetConverter L350 digital label finishing line was added. Screen and Prati have also formed a collaboration to develop an interface between the Screen Truepress Jet L350UV series of digital label presses and the Digifast One modular digital converting line.

Following successful promotions in Japan, Europe and North America, Screen strengthened its showroom displays to create regular demonstrations in East Asian locations such as Singapore, Shanghai and Taiwan. These efforts have effectively contributed to a continuous increase in the number of installations throughout the East Asian region, the company noted.

Tsuneo Baba, Screen Graphic Solutions president, commented: ‘While we released the Truepress Jet L350UV digital label printing system at the end of 2013, the actual start of worldwide sales activities was around the spring of 2014, following the release of our white ink. I believe achieving shipments of 100 units in 3.5 years represents a good and stable pace, compared with our existing competitors.

‘The Truepress Jet L350UV was a late entry to the digital printing field. However, we have successfully differentiated ourselves in the market thanks to our well-established pre-press core technologies such as color matching and detailed reproduction of text and fine lines, as well as our product reliability and user-friendly designs promoted through the integration of software and hardware development.

‘Our efforts have resulted in high customer satisfaction, leading to strong repeat orders and customer-driven referral marketing. [We] will continue to develop products, sales and marketing programs, and support networks that quickly respond to market needs. We will also continue to listen to our customers’ opinions and build trusting relationships with these customers as a first priority.’

East Ryde, New South Wales, Australia DESCRIPTION At Konica Minolta, our goals are clear. We aim...

March 21 2018

East Ryde, New South Wales, Australia

DESCRIPTION

At Konica Minolta, our goals are clear. We aim to be a global company that is vital to society and an innovative company that is robust and constantly evolving. We are one of the leading suppliers of Industrial Print equipment in Australia. We are seeking a Technical Sales Specialist Industrial Print (IP) to provide national technical pre-sales support to our Regional Sales Specialists.

REQUIREMENTS

The role

In this varied and challenging role you will:

Desired skills

You will enjoy a collaborative environment where you will be supported and empowered to contribute your ideas and identify opportunities to develop our team and yourself.

BENEFITS

You will enjoy a collaborative environment where you will be supported and empowered to contribute your ideas and identify opportunities to develop our team and yourself.

Debuting in spring 2018, the Adamas solution demonstrates Agfa Graphics’ continui...

March 19 2018

Debuting in spring 2018, the Adamas solution demonstrates Agfa Graphics’ continuing commitment to eco innovation. Adamas brings robustness to a whole new level and offers every benefit of chem-free solutions. The most durable chem-free plate available on the market, Adamas boosts efficiency, both in plate throughput, as well as in run length, with optimal press performance, zero water and up to 75% less waste compared to similar products.

Maximising Efficiency and Eco-friendliness

Commercial printers seek cost efficiency and process optimization without compromising on performance. In Adamas, Agfa Graphics brings new technologies to the table that empower printers to deliver high-quality results in less time, and with less waste. To maximize performance, this highly sensitive plate was designed for use with Agfa Graphics’ dedicated Adamas clean-out units. Due to their eco-driven design, they can be simply cleaned with pH-neutral clean-out solution and zero water.

“When we designed Adamas, we kept every need of the most advanced commercial printers in mind. The result shows innovation on all fronts – increased durability, enhanced performance and responses to the biggest market trends, such as low-power curing inks,” asserts Iris Bogunovic, product manager for Thermal Plates. “Adamas is a testament to our ECO3 sustainable innovation drivers, which bring ecology, economy and extra convenience to our customers. With Adamas, commercial printers enjoy every advantage of chem-free printing, combined with new technology, ThermoLink, that takes press performance and process efficiency to new heights.”

ThermoLink: The Ultimate in High Performance

Agfa Graphics’ patented ThermoLink technology is at the heart of Adamas. Run lengths as long as 350,000 copies are no challenge for this durable plate. ThermoLink technology contributes to its chemical and mechanical robustness and optimum plate performance.

Superior Results, Run After Run

Adamas delivers superb results no matter the application, from commercial sheetfed and coldset to heatset printing. Even more, the plate is perfectly compatible with low-power curing UV inks. No matter how abrasive or demanding the conditions are, Adamas guarantees superior press performance and durability.

Mutoh Industries plans to launch the VJ-1638UR, a new 64˝ wide UV-LED inkjet printer for the commercial pr...

March 19 2018

Mutoh Industries plans to launch the VJ-1638UR, a new 64˝ wide UV-LED inkjet printer for the commercial print and sign & display markets.

The VJ-1638UR is specifically developed for roll-to-roll printing at an affordable price with the quality and performance of Mutoh’s current UV-LED printers. The staggered dual print head design and the dual UV lamps on the both sides of the print heads provide high productivity while also offering environmentally friendly features, such as UV ink that is VOC free, low energy consumption and odorless after curing.

Mutoh UV-LED ink provides a wide range of applications. In addition, Mutoh “Cool technology” reduces working temperature allowing printing on heat sensitive media. Varnish ink will contribute to your sign and display business by allowing spot varnish and multi-layer printing which is not possible with solvent printers.

The printer also comes standard with an automatic media registration pin system and a vacuum table with “blow-back” feature for easy handling and positioning of heavy media. The vacuum table is divided into four zones firmly fixing various media sizes and improving work efficiency.

The PJ-2508UF will expand a print shop’s production capability and product offerings such as promotional items, directional signage, awards, specialty, labels and packaging prototypes.

The VJ-1638UR is scheduled to be released sequentially in the U.S., Asia, EMEA. The release in Japan is planned for May.

Rowmark LLC introduces another great new contemporary product line with The Naturals, an authentic, nature-inspired, engravable 2 ply laminate featuring the textured look of marble, granite and ...

March 19 2018

Rowmark LLC introduces another great new contemporary product line with The Naturals, an authentic, nature-inspired, engravable 2 ply laminate featuring the textured look of marble, granite and wood.

Named the Best New Markable Material at the 2018 Awards and Personalised International Expo, The Naturals not only look like they came right from the outdoors, but they feel like it too.

And just like their real-life counterparts, The Naturals have a tough, exterior textured finish that will stand up to the elements.

The Naturals provide an authentic material options featuring the textured look of marble, granite and wood, that was created at the request of customers looking for a true representation of natural elements.

Easily fabricated with laser or rotary engravers and UV-LED printable, UV-stability and outdoor weatherability, The Naturals is a great option for customers looking for coordinating both interior and exterior signage. The modern look of this product will also appeal to customers who create craft, artistry, signage and wayfinding projects.

For more information about The Naturals contact sales@rowmark.com.au , phone 1300 023 370 or to request your sample piece click the following http://www.123formbuilder.com/form-3553412/Order-Rowmark-The-Naturals-Sample-Piece .

The engineering business of Uflex has launched Uflexo, an 8-color gearless CI flexo pre...

March 19 2018

The engineering business of Uflex has launched Uflexo, an 8-color gearless CI flexo press with a registered coating unit, in India.

The gearless printing machine has been made in partnership with Italy-based Comiflex, which assisted Uflex with technical expertise. It is made available in two models with a running speed of 300m/min and 400m/min respectively.

Featuring a user-friendly interface, the press features automated splicing, in-line slitting, quick changeover and reduced bouncing of plates. It has been built on a thick steel frame of 120mm to reduce vibrations in the press. Uflexo can be customized with 6-10 printing stations, with a desired web width of up to three meters.

The CI flexo press uses patented technology that reduces solvent consumption for cleaning the press to almost 10 percent. Gianfranco Nespoli of Comiflex explained: ‘This results in tremendous savings for converters. Other important feature that improve the efficiency of Uflexo is directly mounted servo motors without a gearbox. Further, auto color registration and correction ensures equal temperature around the CI drum is maintained for quality printing.’

Further explaining the functions of the specially designed unwinder, which is turret-based and self-loading, Sanjay Malik Sabharwal, executive vice president of the engineering business at Uflex, said: ‘Considering the gauge variation in flexible films, the unwinder has been designed to have two bull gears which are independently driven so as to achieve any amount of skew. This gives us the ability to handle any film with accuracy. Servo motors drive bull gears independently or in tandem giving them flexibility of skew.’

Uflexo can be operated using an iPad. The engineering business of Uflex is at the infancy stage of introducing Internet of Things (IoT) for this press,, which will not only enable it to see any potential problem on the press at the customer site but also enable them to offer preventive maintenance to customers.

Though the first press will be used by the converting business of Uflex, the engineering business has already received three orders – two for the Indian market and one for overseas.

Ajay Tandon, president and chief executive officer, engineering and new product development, Uflex, said: ‘Uflex always runs new machines developed in-house at its converting business to ensure it works fine before sending it to other customers. We complement converters businesses with new technology development.’

Uflex believes this press has a lot of potential in the Indian market as well as overseas owing to the increasing demand of packaging. ‘Printing on stretched films is likely to be a popular trend which will make this press very relevant in times to come,’ concluded Tandon.

HP Inc. announced a 22mm wide-swath printhead for high-speed, high-resolution marking needs, including 1D and 2D bar codes, enabling brands to benefit from large-size codes ...

March 18 2018

HP Inc. announced a 22mm wide-swath printhead for high-speed, high-resolution marking needs, including 1D and 2D bar codes, enabling brands to benefit from large-size codes and characters for advanced product identification, anti-counterfeiting, and track and trace.

Manufactured by HP Specialty Printing Systems using HP Thermal Inkjet Technology, the new HP 22mm Printhead can be easily integrated into OEM printing systems and configured to specific applications.

The new HP 22mm Printhead supports a wide range of stitch-free product coding and marking applications for secondary packaging, including pharmaceutical labels and cartons, secondary box label replacement, as well as variable data printing.

“Product identification is used increasingly in manufacturing and supply chains to help brand owners protect products. Smart barcodes and more data-rich codes require high print quality,” said Annette Friskopp, general manager, HP Specialty Printing Systems, HP Inc. “HP is bringing advanced technology to protect products with the new HP 22mm Printhead and inks. This new, wider printhead offers better image resolution at higher speeds.”

The HP 22mm printhead achieves the highest level of bar code reading scores, readable from smartphones to a handheld scanner, required in product distribution and logistics . Additional benefits include:

• A 775ml ink supply cartridge can be connected to as many as four printheads at once, to meet production needs.

• Horizontal and vertical firing position provides flexibility for a range of applications.

• Fast printing speeds up to 150 m/min at 1200 x600 dpi

• The printhead can be replaced in minutes without specific operator training, allowing continuous production.

The new HP 22mm Printhead will be commercially available in the second half of 2018.

Additionally, HP announced its HP2580 ink for food and pharma packaging has received the European Printing Ink Association’s Good Manufacturing Practices (GMP) for Printing Inks for Food Contact Materials (2017).1

Eastman Kodak has reported financial results for the fourth quarter and full year 2017, delivering net earnings for the year of $94 million on revenues of $1.5 billion and continued growth in ke...

March 18 2018

Eastman Kodak has reported financial results for the fourth quarter and full year 2017, delivering net earnings for the year of $94 million on revenues of $1.5 billion and continued growth in key product areas.

Highlights Include:

2018 Guidance

“2017 was a year of investment in our strategic growth priorities which bodes well for the future,” said Jeff Clarke, Kodak CEO. “We also eliminated several business initiatives while continuing to reduce cost and drive greater efficiency in the company. We enter 2018 with a stronger growth profile and more productive operations.”Revenues for the full year 2017 were $1.5 billion, down 7% from 2016. The revenue decline was driven by volume and pricing declines within the company’s commercial print business and volume declines in the company’s consumer inkjet and industrial film and chemicals businesses.

The company’s cash balance was $344 million at the end of 2017, compared with $434 million at the end of 2016. The company used cash to invest in strategic growth businesses, fund working capital needs, meet legacy cash obligations and service and prepay debt.

“Our use of cash in 2017 included meaningful investments in the Ultrastream inkjet platform, Flexcel NX packaging, Sonora X plates, advanced materials and brand licensing which will contribute to growth,” said David Bullwinkle, Kodak CFO. “In the fourth quarter of 2017, we reprioritized our investments to focus on shorter payback periods and reduced costs which will improve our ability to generate cash in 2018 and beyond.”

Print Systems Division (PSD), Kodak’s largest division, had Q4 revenues of $261 million, a 6% decline compared with Q4 in 2016. Operational EBITDA for the quarter was $16 million, compared with $39 million for the same period a year ago. Print Systems Division had full-year 2017 revenues of $942 million, a 7% decline compared with 2016. Full-year Operational EBITDA was $58 million, a decline of $48 million compared with the prior year. The decline was due primarily to industry pricing pressures, higher aluminum costs and an overall commercial print industry slowdown.

PSD’s environmentally-advantaged Kodak Sonora Process Free Plates had continued strong performance, delivering 21% year-over-year growth in unit sales. Sonora Plates now account for 19% of the division’s total plate unit sales.

Enterprise Inkjet Systems Division (EISD), including the Kodak Prosper and Kodak Versamark businesses and the investment in Ultrastream inkjet technology, had fourth-quarter revenues of $39 million, down from $43 million in the same period in 2016. Operational EBITDA was $3 million, an increase of $1 million compared with the fourth quarter of 2016.

For the full year 2017, EISD revenues were $144 million, compared with $166 million in 2016. Operational EBITDA for the full year 2017 increased by $21 million from 2016 to $5 million in 2017. The results reflect the positive impact of cost control actions and continued strong growth in Prosper annuities.

The company continues to invest in the development of Kodak Ultrastream, the next-generation inkjet writing system, which is scheduled for launch in 2019.

Flexographic Packaging Division (FPD) includes Kodak Flexcel NX systems and plates, as well as other packaging businesses, such as analog flexographic plates and letterpress plates, proofing products and services. Revenues for Q4 were $41 million, up $7 million compared with the same period a year ago. Operational EBITDA for Q4 was $10 million, an improvement of $3 million compared with the fourth quarter of 2016.

For the full year 2017, revenues were $145 million, compared with $132 million in the prior year, or a 10% improvement. Full-year Operational EBITDA of $31 million is an improvement of $7 million compared with the prior year.

Flexcel NX products continue to deliver strong growth. Year over year, Flexcel NX plate volume increased 13% for the quarter and 17% for the full year. The division continues to invest in new product development and infrastructure, including a total investment of $16 million to build a plate manufacturing line.

Here’s a great little video from Epilog Laser showing the versatility of their equipment to make spec...

March 18 2018

Here’s a great little video from Epilog Laser showing the versatility of their equipment to make specialised packaging products. Cardstock is a very versatile and popular material to use with the laser as it can be both cut and engraved. This sample club project features black cardstock that Epilog engraved and cut to create custom packaging for lightbulbs. By adjusting the speed, power and frequency settings on the laser, operators can etch text, cut out shapes, and even create perfectly perforated lines for easy folding and assembly.

Siegwerk, an international suppliers of printing inks for packaging applications and labels, and Agfa Graphics, a supplier in prepress offset and inkjet print, have entered i...

March 18 2018

Siegwerk, an international suppliers of printing inks for packaging applications and labels, and Agfa Graphics, a supplier in prepress offset and inkjet print, have entered into a strategic alliance for digital packaging inks.

The contract signed between the two companies includes a business transfer from Agfa Graphics to Siegwerk of a selected OEM customer list, access to know-how, intellectual property and services in the domain of UV curable digital inkjet inks for the single pass packaging and labels industry.

‘This strategic alliance is a perfect fit for both of us,’ said Tom Cloots, director industrial inkjet Agfa NV. ‘Packaging and label printers are increasingly attracted by the performance and quality of the Agfa inks that are used in a wide variety of printing systems. With this deal, we allow Siegwerk to extensively leverage on our strong network with OEM print head and equipment manufacturers as well as on our know-how and intellectual property in the domain of UV curable digital inks for packaging. At the same time, Agfa continues to focus on the other domains of the growing industrial print segment where Agfa has stronger market access potential.’

‘With this deal we are bridging the best of two worlds. While we will continue to rely on Agfa’s existing strong collaboration with OEMs and print head manufacturers, we will be able to offer our packaging market access and application know-how to these new partners,’ said Matthieu Carni, director business unit Inkjet Siegwerk.

Both companies will work together to ensure a handover of business without any interference for the customers of both companies. Agfa will continue to manufacture on behalf of Siegwerk for several months to support a smooth transition for the customers. After the transition period, Siegwerk will produce the new inks and varnishes according to the highest quality and safety standards at its own inkjet manufacturing center in Annemasse, France. With its global commercial network, Siegwerk then will be able to offer its new UV inkjet portfolio to customers worldwide.

S-One Holdings Corporation has launched S-One Labels & Packaging (S-OneLP), a new division focused on providing products, service, technical know-how and integrated produ...

March 18 2018

S-One Holdings Corporation has launched S-One Labels & Packaging (S-OneLP), a new division focused on providing products, service, technical know-how and integrated products to digital printers in the labels and flexible packaging market.

Through its LexJet and Utopia Digital Technologies divisions, S-One explained that it has developed a deep partnership with Michelman to serve the HP Indigo customer base with best-in-class primers for the past 12 years. S-One has recently signed agreements with flexible packaging specialists Toray America and Protect-all to create a comprehensive portfolio of packaging products designed to help label printing customers transition seamlessly into digital flexible packaging printing.

HP Indigo printers who currently purchase in-line, off-line and custom primers from S-One’s company, LexJet, will work with the S-OneLP team, effective March 1. Customers will have access to these products as well as a growing portfolio of specialty over-print varnishes and flexible packaging films, laminates, adhesives, paper-based substrates and more.

Ralph Giammarco, S-OneLP vice president, said: ‘Staying closely in tune with this market, we’ve discovered that our customers are looking for not only the best-performing products with lower minimums and improved lead times, but they are also searching for unwavering support and vital education as they expand into digital flexible packaging printing, which has seen exploding growth in the past year.

‘With S-OneLP, we’ve paired our exceptional primers sales team with product experts, market development specialists and the flex-pack industry’s top minds to lead this market forward.’

Giammarco added: ‘There are so many opportunities for HP Indigo print providers now, and with S-OneLP, we look forward to helping them master the world of digital label and flexible package printing.’

HP PrintOS Print Beat delivers efficiency, flexibility and productivity across Dashing Group’s HP Latex, Scitex and Indigo presses HP today announced that

March 14 2018

HP PrintOS Print Beat delivers efficiency, flexibility and productivity across Dashing Group’s HP Latex, Scitex and Indigo presses

HP today announced that Dashing Group, an Australian print, technology and design business, has become the first in the Asia Pacific and Japan (APJ) region to deploy HP PrintOS Print Beat across HP’s large format, industrial and Indigo digital print platforms.

A print optimisation solution in HP’s cloud-based print production operating system, Print Beat is operating on Dashing Group’s four HP Latex production printers, two HP Scitex industrial presses, and three HP Indigo sheet-fed digital presses.

“Since its launch at drupa in 2016, print service providers of all sizes have begun connecting to PrintOS to simplify production and get the most out of their HP presses and printers,”said Jeremy Brew, Application Specialist – Large Format, HP South Pacific. “Australian businesses have been among the earliest adopters as they look to continue improving operations while protecting their margins. Dashing Group is leading this movement, and we expect its success will encourage many others around the world to follow suit.”

As a provider of large and small format prints for Australia’s biggest retail brands, Dashing Group needed a solution to manage its high print volumes by simplifying and automating the production process. Having chosen HP as its primary supplier of large format and digital presses, the decision to implement PrintOS was straightforward.

“At Dashing Group we have seen growing demand for highly customised prints as customers look for new ways to stand out from the crowd. But while projects have become more complex, lead times are shrinking,” said Paul Wilcockson, Chief Operating Officer, Dashing Group. “Having one platform to help us automate our print production and manage any number of jobs from submission to delivery has allowed us to not only keep up with demand, but offer a level of service no other print service provider can. The fact that PrintOS came at no extra cost has been an added bonus.”

For Dashing Group, the standout feature of HP’s PrintOS system is the ability to generate real-time data on press performance through PrintOS Print Beat. As one of 13 PrintOS applications, Print Beat offers both historical and near-real-time data on volume, utilisation and maintenance to track printer and site performance.

With sites across Sydney and Melbourne, PrintOS Print Beat has allowed Dashing Group to promote better, faster decision-making, work flow planning and resource allocation. Flexibility has also been key, as PrintOS Print Beat is available through a web browser and mobile app.

“When you travel as often as we do, it’s important that we’re able to monitor the fleet’s performance and efficiency from any location,” said Wilcockson. “On multiple occasions, PrintOS Print Beat has allowed me to access real-time data from halfway across the world, so it’s reassuring to know we can monitor our print production from anywhere, at any time.”

The PrintOS Print Beat dashboard can also be displayed onscreen, beside each printer, to give operators a near-live feed on how each device is performing and how it is tracking against current targets and past performance. According to Wilcockson, this benchmarking feature has introduced the unexpected benefit of friendly competition in the print room.

More information on HP PrintOS and Print Beat is available at: http://www8.hp.com/au/en/commercial-printers/floater/printos.html

Pozitive sign & graphic supplies, a leading supplier of machinery and consumables for the print, sign and display industries, is pleased to announce they have been appoint...

March 14 2018

Pozitive sign & graphic supplies, a leading supplier of machinery and consumables for the print, sign and display industries, is pleased to announce they have been appointed as the exclusive Australian dealer of the state-of-the-art the F Series range of flatbed cutting tables from Summa.

“At Summa, we believe in the values of reliability, high-quality solutions & impeccable customer service,” says Wim Maes, Chief Commercial Officer – Executive Director. “We want these values to reflect in our partners. As the exclusive Summa F Series partner in Australia, we have no doubt that Pozitive will represent these values perfectly. Together, we will provide the Australian market with high quality Summa solutions and dedicated customer service from Pozitive. Summa looks forward to fulfilling the customers’ needs for an excellent finish, which only a Summa product can provide.”

The Summa F Series is the most versatile flatbed cutting system on the market. An award-winning solution, the Summa F Series is ideal for producing innovative signage, displays, samples, packaging applications and more.

Features include:

. Multifunctional head that holds up to three modules at one time

. Powerful tangential module that offers 10kg vertical force with a wide range of matching tools

. Pneumatically driven media advance clamps to hold materials down for continuous operation

. Automatic barcode recognition identifies the job to obtain the necessary cutting data

. Safety pack laser system that surrounds the table and controls the motion area

. Automated depth control (ADC) simplifies tool, knife or bit changes for optimal cut quality

. Available in four sizes, ranging from 160cm x 120cm up to 265cm x 305cm

“Pozitive has a long history supplying and servicing the Summa cutters to the Australian market,” says Philip Trumble, Managing Director, Pozitive sign & graphic supplies. “It was the very first cutter I used when I was introduced to the industry at 16 years old! Over the next 25 years I have seen first-hand the quality and durability of the product, so it’s an honour and privilege for Pozitive to be appointed as the Exclusive distributor of Summa’s versatile flatbed cutting systems.”

A Summa F Series F1612 flatbed cutter will be available for viewing and testing at Pozitive’s state-of-the-art demonstration centre at Eastern Creek, NSW. Guests can also view a wide range of equipment and consumables that Pozitive represents exclusively in the Australian market.

For further details about the Summa F Series range, please visit https://www.summa.eu/f-series

ABOUT POZITIVE

Pozitive sign & graphic supplies is an Australian family owned industry leader in the supply of UV flatbed printers, eco-solvent printers, CNC routers, laser cutters and engravers, dye sublimation textile printers and hardware, software and consumables for the sign making, screen printing, graphics, display and commercial printing industries. With over 25 years experience, Pozitive has established a reputation for excellence, offering expert advice, equipment, service and support. Their mission is to supply the very best machinery, powered by the very best consumables and always to exceed the expectations of their clients.

Media Contact

Andrea Georgiadis / Marketing Manager

E: andrea@pozitive.com.au

T: +62 2 9648 5588

Sydney March 14th, 2018 – As of February 1st Starleaton completed the acquisition of the Uniscreen Australia business. Established in 2004, ...

March 14 2018

Sydney March 14th, 2018 – As of February 1st Starleaton completed the acquisition of the Uniscreen Australia business. Established in 2004, the Australian arm of the Uniscreen group is primarily focused on supplying sublimation papers and inks.

Early this year Starleaton completed talks with Uniscreen Owner and CEO Ross Clarke to take over their Australian distribution. Over the last few weeks the Starleaton team have been undergoing extensive training on the new range to begin the immediate introduction to their customers.

In particular they are excited to gain access to the Coldenhove sublimation papers. CEO Ben Eaton says: “Coldenhove are the industry leaders and inventors of digital sublimation transfer printing papers, so to be able to add their range to our current offering is a real bonus for us. With the Epson F-series, EFI FabriVu, and Georg+Otto Friedrich fabrics already covering the direct to fabric market for us, a quality transfer paper was the missing link.”

Starleaton will also continue to supply the full range of Kiian inks and Transmatic heat presses.

Existing customers of Uniscreen Australia should see a seamless transition to Starleaton, and the range will be introduced to Starleaton’s existing customers over the course of the coming months.

About Starleaton