See all the latest news from the Sign, Print, Graphics & Display Industries or simply browse any category from our menu. From Amazing Projects to Wide Format Digital Printing, Visual Impact Magazine has all the latest news and emerging technologies. To find out more join our newsletter and have all the latest news direct to your email.

Chooses SC80600 for ability to print and match reds and orange at speed Peak Digital is an Australian, family owned business with many ...

March 13 2018

Chooses SC80600 for ability to print and match reds and orange at speed

Peak Digital is an Australian, family owned business with many years of experience and expertise in all aspects of design, pre press, large format digital print, screen printing, signage and installation. They pride themselves on only using equipment that incorporates the very latest, environmentally friendly technology. Recently the company was looking for a new large format printer that could specialise in signage and décor. The printer they chose was Epson’s SureColor Solvent SC80600. The requirements the printer had to meet were, however, quite strict.

Peak Digital Director Andrew Robertson explained, “We strive to deliver high quality printing, personalised service, competitive pricing and a fast turnaround but the emphasis really is on quality. Peak Digital required a printer that could very accurately match reds and orange as closely as possible – a near match just wouldn’t be acceptable for our clients so this printer had to be very, very good. After viewing samples we made our minds up that the Epson SC80600 was the way to go. The SC80600’s ability to print either white or metallic silver was also a big contributing factor in our decision.”

The SureColor Solvent 80600 is designed to produce flexible high-value signage quickly, easily and at minimum cost. It suits a variable workflow with low to medium production volumes and can be used with a wide range of media including paper, canvas, film and vinyl. It suits an extended range of applications including large format photo and image printing, high-value high-impact indoor POS, durable outdoor signage, back-lit displays, window decorations, banners, vehicle wraps, wallpapers, surface finishes and labels.

Robertson continued, “The SC80600 incorporates Epson’s latest PrecisionCore printhead and UltraChrome Eco-Solvent ink technology. It produces durable prints that are bright and glossy with an unparalleled colour gamut and is designed to produce premium quality output, using minimum ink, with simple operation and fast job completion. The output speed and the ability of this amazing printer to so accurately colour match were unquestionably the main factors in our decision to purchase it.”

Peak Digital uses its new SC80600 to print vehicle signage, external shop signage, window and wall graphics with the printer getting a full daily workout, often seven days a week.

Robertson concluded, “The SC80600’s ability to print a much wider colour gamut means we are able to consistently and accurately match corporate colours, a major bonus for our customers. The machine also continuously runs unattended allowing operators to perform other tasks without the worry of checking the printer and despite its constant use, since we acquired it we have had no issues that have required technicians or operator intervention. Moving forward it’ll be hard to find a better large format signage printer than the SC80600 as the fact that we can so consistently meet customer demands in terms of colour matching and turnaround times makes it incredibly hard to beat and in my opinion the best printer in its class.”

For more on the Epson SC80600 click here

Andrew Broun joins the Graphic Art Mart Western Australia team with a comprehensive history in the signage industry spanning over 20 years. He has experience as a field service engineer, customer s...

March 13 2018

Andrew Broun joins the Graphic Art Mart Western Australia team with a comprehensive history in the signage industry spanning over 20 years. He has experience as a field service engineer, customer service representative and account manager. Andrew is excited by the opportunity to be part of a great company that is going places.

Q: I HAVE A MAC, CAN I USE IT TO RUN MY LASER? A: Yes, but there are some caveats. If you are lucky enough to own an Epilog Fusion M2 Laser then th...

March 13 2018

Q: I HAVE A MAC, CAN I USE IT TO RUN MY LASER?

A: Yes, but there are some caveats. If you are lucky enough to own an Epilog Fusion M2 Laser then these come with a dedicated Mac driver which can run your laser directly from your Mac computer without the need for any additional programs. If your machine does not provide a dedicated Mac driver then you still have a couple of options; (1) Boot Camp for Mac – after loading Windows on to your Mac you then have the ability to choose between running Windows or Mac OS when you first boot up. (2) Parallels for Mac – similar to Boot Camp however with Parallels you can run both Windows and Mac OS simultaneously so you don’t need to reboot each time you want to change between operating systems

Q: HOW DO I GET A MARK ON BARE METAL PLATES WITH MY CO2 LASER?

A: Commonly used materials like stainless steel and aluminium can be best marked with a CO2 laser by utilising one of the many different metal marking solutions available today to achieve a near permanent, high contrasting black mark. It is critical that the stainless steel or aluminium is raw and has no coating (make sure it doesn’t have a clear coat) and that the surface is clean and free from oils and grease before you apply a thin coat of the marking solution. Use a slow-to-medium speed and high power for best results when laser engraving. You will need to use a slower speed for aluminium. We recommend MarkSolid 114 Aerosol.

For anything to do with laser engraving, click on the link below.

Q: WHAT ARE THE BENEFITS OF HAVING MORE LASER POWER? A: Generally speaking, the more laser power you have the faster you can engrave or the thicker you ...

March 13 2018

Q: WHAT ARE THE BENEFITS OF HAVING MORE LASER POWER?

A: Generally speaking, the more laser power you have the faster you can engrave or the thicker you can cut. Keep in mind that not all materials require a lot of power – if you are only engraving materials like anodised aluminium or cast acrylic you do not need much power however if you plan on predominantly using your laser to cut then you’ll need to consider a suitable power depending on your specific application.

Q: HOW DO I KNOW WHICH DPI SETTING TO USE?

A: As a general rule you will want to use a mid-to-high dpi for engraving text or other items with fine details, and a lower dpi for photographs or large block-style objects. Again this is a general rule and you should experiment with the different settings to understand the different results you can achieve. The higher the dpi the more dots the laser will mark (basically more details) however this also increases the overall marking time. A lower dpi will provide for faster marking times but is not suitable for all jobs. One thing to keep in mind is that the lower the dpi you use the more laser power will be required in order to achieve the same depth/darkness of mark.

Q: WHAT IS THE BEST WAY TO REMOVE SMOKE RESIDUE AFTER LASER ENGRAVING?

A: If engraving wood you have a couple of options

(1) If the wood has been sealed/lacquered you should be able to remove most or all of the residues with a damp cloth, however, if the wood is raw you may need to use some fine sandpaper to remove the residue – we recommend having some 220 grit sandpaper on hand in case you ever need it

(2) Alternatively, you can be proactive and use a light to medium tack masking paper first and then engrave it into the wood, allowing the residue to settle on the mark instead of your part. Then after the job simply remove the mask to reveal your perfectly clean engraved design

For materials other than wood

(1) You can try using Isopropyl Alcohol (IPA) to clean away any leftover residue

(2) Another tip is to use the Bottom-Up engraving feature found in your print driver (a standard feature on Epilog Lasers). In standard top-down engraving, there can be a large amount of engraving debris generated and as that debris is pulled towards the exhaust ports at the rear of the machine, some of it will collect in the areas that have just been engraved. The Bottom-Up function reduces the amount of smoke and residue so that it is not dragged across freshly engraved marks. This feature is particularly useful for two-ply engraving plastics where you are engraving through a colour like red/blue/green into white underneath.

Regardless of the material you are engraving it is also a critical factor to make sure you have sufficient extraction otherwise the smoke and residue will hang around and settle on your material instead of being immediately sucked away after engraving.

Neopost, in partnership with HP is delighted to invite you to a series of power sessions designed to share the latest trends and opportunities that exist in the market to attract new ...

March 13 2018

Neopost, in partnership with HP is delighted to invite you to a series of power sessions designed to share the latest trends and opportunities that exist in the market to attract new customers and grow revenue from existing clients. There will be two groups (one morning and one afternoon) of each Power Sessions run at each location to ensure you don’t miss out.

Power of HP Latex Printing – Supported by HP

You will see the latest range of HP Latex printed applications available, receive free training and advice on best practice colour / RIP Management and get an exclusive insight into the innovative HP Signage Suite, an online portal that will increase customer demand.

Power of Print Finishing

These power sessions will demonstrate how you can grow revenue, keep abreast of the growing demands in embellishment and improve your bottom line by boosting productivity.

A morning tea, working lunch and afternoon tea will be served. FREE PARKING for all guests!

Attend any Power Session in any state and enter the draw to win a pass to our upcoming Ferrari Day, which also includes flights and accommodation!

*Terms & Conditions apply

For more information, please click here: VI Magazine eDM

To register, simply click here.

The Melbourne School of Design at University of Melbourne initiative for 2018 was to expose students to relative industry machinery and processes that they would potentially use as designers and...

March 13 2018

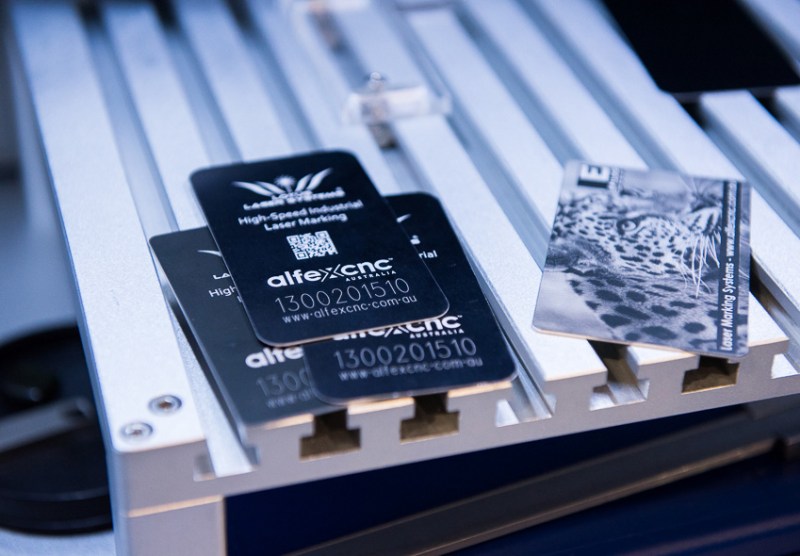

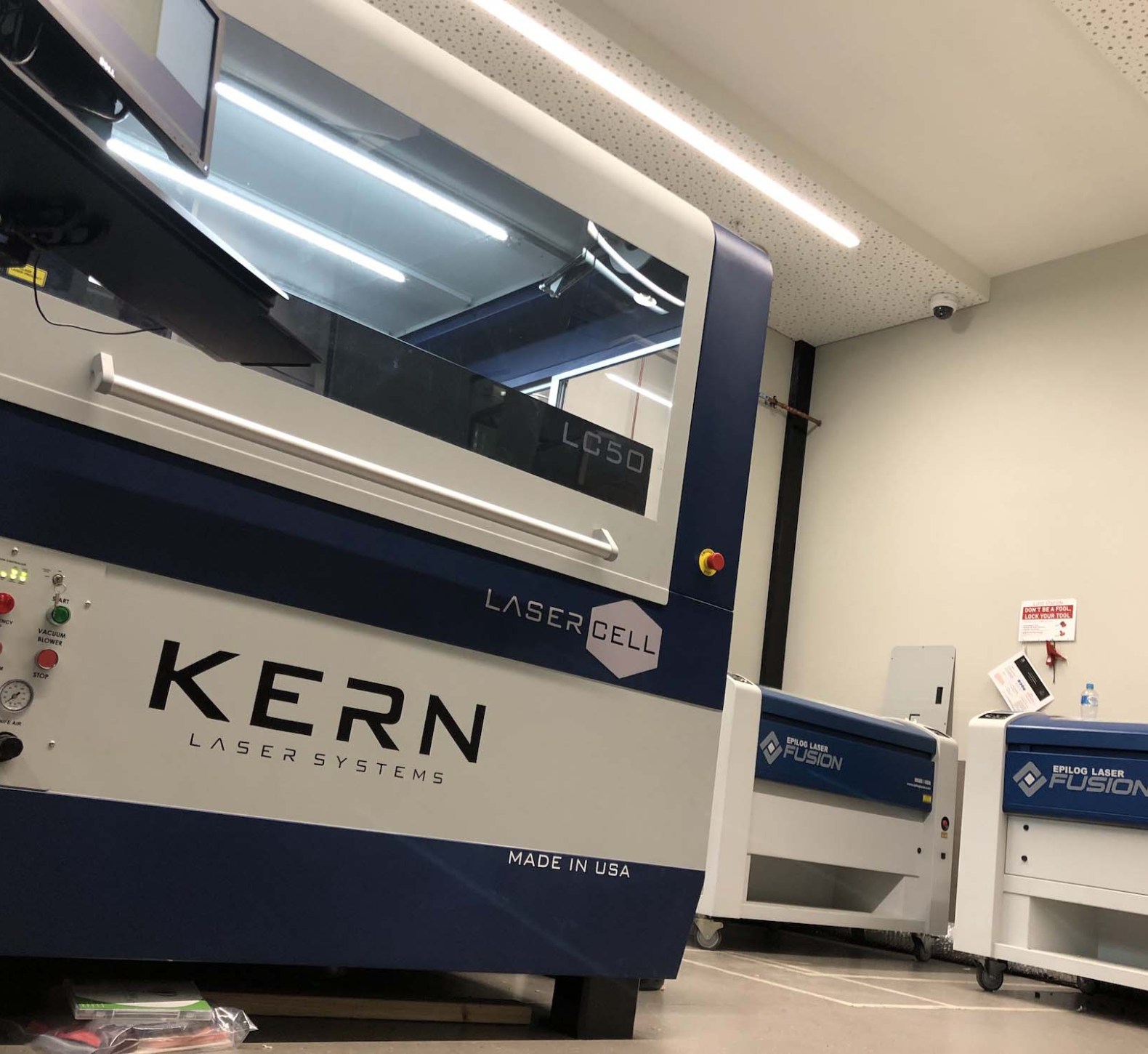

The Melbourne School of Design at University of Melbourne initiative for 2018 was to expose students to relative industry machinery and processes that they would potentially use as designers and architects after graduation. A complete laser cutting and engraving system that was safe to use in the classroom as well as flexible enough to have all the features needed inside a workshop meant the LaserCELL by Kern Laser Systems was the perfect solution.

Australia’s leading university, The University of Melbourne, is known to help graduates become thoughtful and skilled professionals. With their distinctive curriculum, the Melbourne Model, The University of Melbourne continues to seek ways to give students a wider understanding of the world beyond their degree.

Dr Jas Johnston, Manager of the Fabrication Workshop at the Melbourne School of Design, University of Melbourne, explained that the university wanted to expose students to relative industry machinery and processes that they would potentially use as designers and architects. “Industrial laser scale equipment was part of that initiative, to get the students hands-on in the industrial design field”.

Whilst their existing range of lasers allowed students to create projects made of plywood, MDF and acrylic, Dr Johnston and the University were looking for a solution that would allow students to cut and work with metal. “We find that once the students have access to the machinery and its capabilities, it opens up their creativity,” says Johnston.

The University required a laser system that was capable of cutting stainless steel, aluminium and other metals whilst still offer the ability to engrave and cut acrylic, plywood, MDF materials and also pipe/tube. This eliminated many vendors, especially when combined with the need for expert local support. “We felt confident with Kern and Alfex CNC Australia because of their commitment to supporting Australian customers. We got to speak with not only several members of the local team, but also Kern Laser Systems CEO Derek Kern, which you just don’t get with other companies.”

Issues with equipment usually stem from incorrect setup, which can lead to students to lack confidence in using the machinery again. “Having the Kern engineers come in from the USA and the local Alfex CNC engineers to set up the LaserCELL really boosted our confidence in knowing that the LaserCELL would be set up properly from the get-go and we would have expert support here in Melbourne.”

Another reason why we went with the Kern LaserCELL over other systems, is that it will still process all the other materials our students use. We needed the variety of materials as well as metals.”

The LaserCELL is perfect for educational settings due to the blend of performance and safety. The fully enclosed (Class 1) design is devised for high traffic areas such as University workshops and classrooms where safety is of the utmost importance”, said Christian Buhagiar, Business Development Manager of Alfex CNC Australia.

Now that students have access to industry machinery, Dr Johnston says their first project with the LaserCELL is an augmented reality workshop. The workshop will see students use the LaserCELL to cut flat sheets of metal to create hologram instructions. The LaserCELL will also be heavily used for Furniture Design projects.

The LaserCELL is Kern’s fastest and most productive machine to date and is compatible with Pipe Rotary, K-Vision Camera Registration and Metal Cutting options.

Our goal was to get students more access to machinery in the industry. With the Kern LaserCELL we’re confident that we’ll see new and innovative ideas in the classroom” said Dr Johnston.

We’re very proud of the relationship that Alfex and the team at Melbourne University have built over the years. It’s always a pleasure working with Jas, Sean and the guys, and we’re really excited to see them put the Kern LaserCELL to good work. There will no doubt be many impressive projects come from this new installation”, said Buhagiar.

For more information on the Kern LaserCELL and how you can use it in your organisation, call or email the team on 1300 20 15 10 or sales@alfexcnc.com.au today.

Orafol has released their latest trade catalogue and price list. You can view or download the guide by clicking here.

March 12 2018

Orafol has released their latest trade catalogue and price list. You can view or download the guide by clicking here.

Epilog Laser, the largest manufacturer of popular engraving and cutting systems, is excited to celebrate their 30th anniversary in 2018. The company plans to host an anniversary bash in the Denv...

March 07 2018

Epilog Laser, the largest manufacturer of popular engraving and cutting systems, is excited to celebrate their 30th anniversary in 2018. The company plans to host an anniversary bash in the Denver metro area on August 11 to celebrate their successes over the past three decades.

“As I look back on the past three decades I am incredibly proud of what we have accomplished as a company, but also humbled by the undying support we have received from everyone who touches this business – our employees and distributors, our customers and fans, our vendors and other associates – everyone we’ve met along the way has had some sort of impact,” said Steve Garnier, CEO and one of Epilog’s founding members. “The past 30 years have been an unforgettable journey filled with triumphs and challenges, growth, and innovation. I can’t wait to see what lies ahead for us.”

Epilog Laser got its start in 1988 when two Georgia Tech buddies – Garnier and John Doran, Epilog’s vice president of engineering – combined their talents to create the industry’s first small-format, computer-controlled laser engraving and cutting system.

Mike Dean, Epilog’s vice president of sales and marketing, came on board not long after and the trio set out to become game-changers in the engraving space. As the company has grown over the past 30 years, they’ve seen their lasers used in a wide variety of markets, from guitar customization to cabinetry design to medical device marking. The combination of industrial-quality engraving speeds and quality with an affordable price have allowed everyone from makers to engineers to artists to add lasers to their businesses and find real success.

“It has been and continues to be an amazing ride,” Garnier said, “and we’re so thankful to everyone who has taken it with us. We can’t wait to see what the next 30 years brings!”

For more information, visit www.EpilogLaser.com.

NZ Sign & Display Awards – Online entries are open, less than 57 days to go … The New Zealand Sign and Display Awards were created back in 1997 to encou...

March 07 2018

NZ Sign & Display Awards – Online entries are open, less than 57 days to go …

The New Zealand Sign and Display Awards were created back in 1997 to encourage and promote high standards of design and execution in all aspects of sign making and attain excellence in production. Therefore Acknowledging Excellence is the primary purpose of this event and so every year it receives hundreds of online entries from all over New Zealand which ensures that the overall standard of entries is high and competition for gold, silver and bronze medals is fierce.

Sign making in New Zealand is truly of a global standard – from the more traditional aspects of the industry such as brush lettering, gilding and airbrushing, through to the modern techniques that computerisation has brought to the craft, it is fair to say that we are blessed with some of the best, most creative, and most innovative craftsmen in the world. When judging takes place it is performed by a panel of three judges, one of whom is replaced each year to keep a fresh and current perspective. The judges are all previous winners of New Zealand Sign Awards and were chosen for their wide and varied experience within the industry

Register and upload today! The website is ready, so go check it out.

Pat Cybulski joins the company as National Sales Manager – Hardware Solutions, managing the company’s HP, Mimaki, Summa and ORALITE Traffic Printer sales channels. Nick Mawer...

March 06 2018

Pat Cybulski joins the company as National Sales Manager – Hardware Solutions, managing the company’s HP, Mimaki, Summa and ORALITE Traffic Printer sales channels.

Nick Mawer has been promoted to the role of Sales & Marketing Director – Reflective Solutions and Anthony Kioussis has moved into the focussed role of Sales & Marketing Director – Graphic Innovations.

Rob Kelly has been promoted to the role of National Business Development and Product Training Manager – Graphic Innovations.

“Having completed the acquisition and branch consolidation program of all five state-based ORAFOL distributors, ORAFOL Australia continue to invest heavily in the local market, with talent acquisition and advanced product training high on the agenda. Our national sales and customer services team now share over 350 years of industry experience, ensuring we’re equipped to deliver to customers the highest levels of technical and application-focussed support,” says Greg Nicholls, Managing Director, ORAFOL Australia.

United Franchise Group (UFG) is pleased to announce two decades of evolution and growth, as they celebrate the 20-year anniversary of the first

March 06 2018

United Franchise Group (UFG) is pleased to announce two decades of evolution and growth, as they celebrate the 20-year anniversary of the first Signarama location opening in Australia.

After launching in the U.S. more than 30 years ago, Signarama first expanded into Australia 20 years ago. Today there are 105 locations there with proven successes that include 22 Australian stores achieving “Million Dollar Circle” status in 2017.

“There have been many positive changes in the sign industry in the last 20 years that have helped our franchise locations succeed,” said Evan Foster, National Director for Signarama Australia. “The future promises to be even more exciting as we embrace new technologies and product lines to strengthen our network even more across the country.”

Franchisees who started twenty years ago say their success has less to do with simply making and selling signs and more to do with building strong relationships with their valuable customers to help meet their needs.

“I opened my store in 1998 and we’ve gone from focusing on installers and simple signs to today’s world of multi-million dollar locations with experts in all fields of signage within our ranks,” said Ross Wade, Signarama Dandenong, Vic franchisee.

The same milestone is also being celebrated in New Zealand, where Master License partner, Grant Archibald now has 25 locations under the “Speedy Signs” name. Grant and his wife, Sarah were privileged to be able to meet with Prime Minster, Jacinda Ardern on the actual 20thanniversary date. Ms Ardern congratulated them on their success in creating the country’s largest network of sign companies.

“While the 20 years have passed quickly, I still remember the day we opened in Penrose, Auckland,” said Archibald. “Our eldest son was only a baby in our grand opening photos, and now, in a few more months, he’s getting married. The Penrose business as well as our other New Zealand locations continue to perform strongly -with no signs of stopping. We are now planning on opening another half dozen franchised locations in some of the smaller provincial centres like Gisborne, Napier, Wanganui and Timaru.”

The Signarama brand continues to grow worldwide with locations now in more than 60 countries and hundreds of new locations slated for opening in 2018 worldwide. Signarama consults with business owners to develop impactful signs, messaging, and marketing tactics that result in higher sales and increased business. To learn more about Signarama’s products, services and locations, go to signaramafranchise.com.au.

GJS today took the wraps off its new industry knowledge base* and Creator Com...

March 05 2018

GJS today took the wraps off its new industry knowledge base* and Creator Community, an online hub designed to support its digital decoration customers and provide a forum for people to connect, be inspired and share knowledge.

The launch of the GJS knowledge base continues GJS’ proud tradition of exceptional and industry-leading customer support and after-sales support and is designed to be a further value-add to support loyal GJS customers in an increasingly price-driven market.

The knowledge base already includes over 600 support articles and is driven by powerful heuristic search technology that enables creators to quickly and easily find the answers that they are seeking.

“Gone are the days of downloading a PDF document and misplacing it in the print room or fumbling through paper to find the times and temperatures needed to sublimate an item or instructions on how to operate and maintain equipment,” said Greg Stone, Managing Director, GJS.

The knowledge base also deeply integrates with the GJS website, providing powerful support options and assistance to customers from any page that they are browsing.

“Now, from any page on the GJS website and from within the knowledge base you simply type what you’re looking for in the help/search field and the relevant articles and help documentation will be presented to you. For example, if you’re looking for the time, temperature or pressure to sublimate our popular 11oz mugs you might enter ‘sublimate mug’ and several articles will be immediately available to you in the help window.” Greg added.

If accessed via the GJS website, the support articles open directly in the help widget giving creators access to all the information that they need without having to leave the page they might be browsing.

To help streamline the support experience, creators will only be shown articles relevant to the solutions and consumables that they have recently purchased.

“What this means is if you’re a creator who has one of our dye sublimation solutions and searches for ‘printer maintenance’ you’re not going to be shown a whole lot of articles relating to the maintenance of direct to garment printers,” Greg added.

In addition to the knowledge base, GJS today launched its Creator Community, a conversation hub that is designed to bring together Australia’s biggest collective of ‘digital decorators, photo-gift producers, garment customisation gurus and embellishment entrepreneurs.’

With existing topic areas such as dye sublimation, direct-to-garment printing, heat transfer vinyl, laser printers and doming, GJS hopes that these forums will become a place for valuable information sharing, networking and even shared business opportunities.

GJS customers can access the new knowledge base and Creator Community at: https://help.gjs.co and via the ‘Help’ widget on the bottom right corner on all pages of the GJS website when signed-in to their account.

*You’ll need a GJS.co account to view knowledge base content.

North Carolina State University researchers may have found a new way to print flexible (and stretchable) electronic circuits. In a recent study, researchers Yiwei Han and Jingyan Dong us...

March 05 2018

North Carolina State University researchers may have found a new way to print flexible (and stretchable) electronic circuits.

In a recent study, researchers Yiwei Han and Jingyan Dong used electrohydrodynamic (EHD) printing technology to create metallic conductors with sub 50 µm resolution that are not only electrically stable but also durable enough to stand up to hundreds of bending and stretching cycles.

The new fabrication method, published in the journal Advanced Materials Technologies, could be a window to next-generation electronics.

The researchers used EHD to print three different molten metal alloys onto glass, paper, as well as a pair of stretchable polymers. EHD is common in many manufacturing processes that typically use ink. This study was unique in that the researchers were direct printing metal alloys with melting points down to 60°C.

According to researcher Jingyan Dong, this method could reduce the cost of making high-resolution circuits, which could finally bring the price point low enough to employ the technology in commercial devices.

In tests, circuit conductivity survived 1,000 bend cycles and even remained viable after the conductors were stretched to 70% of tensile strain. When they did break, the conductors were easy to fix, because, given the low melting point, researchers could heat the area to ~70°C which enabled the metal to flow back together.

To demonstrate the technology, the researchers built a prototype touch sensor, but the team is now looking for partners to employ the method in electronic device markets, such as wearable sensors.

March 02 2018

Roland DG Australia, a leading provider of wide format inkjet printers and 3D devices, will this year mark a significant milestone in the industry, as it celebrates 30 years of business in Australia.

Established in 1988, Roland DG Australia Pty Ltd was one of the first international subsidiaries of Roland DG Corporation Japan. Since then, Roland DG Australia has grown to become a leading supplier to the Australian sign and display industry, and the 3D and Dental CAD/CAM markets.

“I would like to express our sincerest gratitude to all the customers who have supported the growth of Roland DG and Roland DG Australia,” said Hidenori Fujioka-san, Roland DG Corporation President. “Roland DG has continually valued the power of imagination, and has focused our efforts on developing digital technology that allows our customers to transform imagination into reality. Roland DG’s cutting machines and wide format inkjet printers have been widely accepted by the sign and display markets, and have contributed to propel forward our customers’ business around the world for more than three decades.”

John Wall, Director of Roland DG Australia, said: “We are very grateful for the support of our Authorised Dealers, partners and customers who have chosen to work with us over the past 30 years. Their contribution to our success cannot be overstated. We hope to continue to grow together for many years to come.”

As the company continues to evolve and diversify, developing new technologies and adding value for customers, remains a priority. In light of new products focusing on the personalisation market, as well as its 3D business under DGSHAPE Corporation, Fujioka-san commented: “Our mindset has always remained focused on the pursuit of creating added value for the customer based on our vision of ‘transforming imagination into reality,’ and will remain unchanged in the future.”

Throughout 2018, Roland DG Australia will mark this significant event in our history with our partners and customers with special offerings and an exclusive celebration event later in the year. Stay tuned for further announcements.

HEXIS announce the opening of a new subsidiary in Brisbane (Queensland), Australia. The launch of this subs...

March 02 2018

HEXIS announce the opening of a new subsidiary in Brisbane (Queensland), Australia. The launch of this subsidiary will reinforce the distribution of the HEXIS products, marketing and service on the Australian market. HEXIS products have been available in Australia for the last 16 years, thanks to their Melbourne-based distributor, Stickittome Australia Pty Ltd.

The opening of this subsidiary is in line with the HEXIS strategy to expand their worldwilde distribution network.

“HEXIS have been experiencing a consistent growth on the Australian market”, says Clément Mateu, HEXIS CEO. “We are convinced that the Australian market represents a substantial growth potential for our company and our local partners. Therefore we have considered that it was the right moment to invest locally.”

“The new HEXIS Australian subsidiary reflect our will to keep improving the quality of our service and the assistance to our customers and distributors in this area”, says Caroline Mateu, HEXIS President. “I am convinced that our presence in Queensland will help boost the local and neighbouring markets.

Establishment of sales office & warehouse in Brisbane

With 20 years experience in the print industry and an accounting background, HEXIS have entrusted Ian Parsonson with the management of this new subsidiary and the growth of HEXIS in Australia.

In terms of logistics, a brand new warehouse will hold a massive stock of the various HEXIS products, such as sign self-adhesive vinyls, printable media and laminates, wrapping films and PPF.

Customers and partners will also benefit from a dedicated sales dept. In addition, a HEXIS training centre will provide technical assistance and installation courses up to the HEXIS standard.

A reinforced cooperation between Hexis & Stickittome

The establishment of a new HEXIS subsidiary will also reinforce the partnership with their long-established distributor, STICKITTOME. A joint distribution policy will be implemented, allowing to strengthen the HEXIS brand image and the global offer.

“We are delighted to consolidate our partnership with Scott and Elisha Niven, they have been doing a brilliant job since 2001 to develop the HEXIS brand awareness in Australia”, says Sylvène Poncet, HEXIS Export Manager. “We shall work together in order to optimise the offer and the customer service. We wish to continue bringing innovative and bespoke solutions to our valued customers.”

For more information, please visit www.hexis.com.au

Mexico-based print service provider, Moti Digital 3D printed a towering, head-turning skeleton for the Mexican Festival of Light celebratio...

March 02 2018

Mexico-based print service provider, Moti Digital 3D printed a towering, head-turning skeleton for the Mexican Festival of Light celebrations in Guadalajara.

The four-day event explores how light and art work in perfect harmony and encapsulates the culture of Guadalajara. Moti Digital used its Massivit 1800 3D Printing Solution to create a model that would ‘wow’ visitors to the event and demonstrate the impressive capabilities of large format 3D printing technology.

Measuring at 8.40m (27.52ft) long and 3.60m (11.8ft) tall, the breath-taking skeleton was produced in just four days. The painted skeleton was positioned inside thePlaza Tapatía fountain pool and illuminated at night, where thousands of festival-goers were able to sit in its arms.The experience generated huge amounts of conversation and photos that featured prominently across social media platforms.

The lifelike skeleton will also feature at this year’s Festival del Día de los Muertos, taking place throughout Mexico from the 31st October.

Now with major improvements to automation functions Epson Australia has expanded its digital label press lineup with the introduction of the new and improved SurePress®...

March 01 2018

Now with major improvements to automation functions

Epson Australia has expanded its digital label press lineup with the introduction of the new and improved SurePress® L-4533A, a six colour aqueous resin ink machine and SurePress L-4533AW six colour plus white aqueous resin ink press.

Delivering high-quality labels and packaging at a low total cost of ownership (TCO), the easy-to-operate SurePress L-4533A/AW inkjet label presses are built for reliable, high-quality performance, making short-run label printing with accurate colour reproduction on a wide variety of substrates easy for label converters and commercial printers. The L-4533A/AW have also undergone significant developments to meet the growing demand for fast turnaround, with longer automated printing times, email alerts and minimal maintenance.

General Manager of the Business Division at Epson Australia, Craig Heckenberg said, “Everyone appreciated the success of the SurePress L-4033 series so we wanted to build on that with new products to meet the growing label and flexible packaging market demand for shorter runs and faster turnaround times. The L-4533A/AW do just that. Boasting even higher print quality, greater operator productivity and improved media versatility, the new printers boast more than 30 improvements over their predecessors. These improvements translate into users’ ability to print a wider range of applications, create more high value jobs and operate more cost efficiently.”

Specifically designed to improve productivity and increase efficiency, the SurePress L-4533A/AW offer advanced automated printing features, including up to eight hours of unattended printing, e-mail alerts and minimal manual cleaning. Offering the highest levels of reliability with all components built by Epson including the ink, printhead and controller, the L-4533A/AW feature versatile substrate support and print on off-the-shelf materials from 3.15-inches (8cm) up to 13-inches (33cm) wide and as thin as .00314-inches (0.08mm).

The SurePress L-4533A/AW also include upgraded microprocessors which improve processing speeds up to 80% compared to the outgoing models. The new digital label presses with variable drop size starting at three picoliters also include a new larger ink drop size, ideal for large solid colour backgrounds found on packaging.

More about the SurePress L-4533A/AW:

The Epson SurePress L-4533A/AW is designed to print prime labels and flexible packaging efficiently and profitably. Additional features include:

• High-quality labels – Epson MicroPiezo® inkjet technology and a wide colour gamut deliver colour matching and gradients required for branded prime labels and packaging

• Ease of operation – Automated printing allows a single operator to run multiple units at one time

• Remarkable reliability – All components are manufactured by Epson and supported by Epson service

• Low-cost turnkey solution – Training, workflow software and operational support included

• Competitive TCO – Automated printing, competitive ink price and minimal consumables

• Versatile substrate support – Prints on off-the-shelf flexo PS label materials, including uncoated, gloss and semi-gloss papers, film and supported or unsupported media

• Versatile data support – An ideal solution for text, barcode and image serialisation

• Industrial-quality inks – Seven-colour ink set (Cyan, Magenta, Yellow, Black, Orange, Green and White), durable, water-based, resin-coated pigment inks provide superior adhesion, produce a remarkable range of colours, and deliver water and abrasion resistance on most substrates

Availability

The Epson SurePress L-4533A/AW are available now. For additional information click here

Fujifilm Graphic Systems is pleased to announce the sale of the region’s first two Inca Onset X series UV flatbed printers to Active Display Group (Active) – one of Australia’s...

March 01 2018

Fujifilm Graphic Systems is pleased to announce the sale of the region’s first two Inca Onset X series UV flatbed printers to Active Display Group (Active) – one of Australia’s most awarded retail industry, POS, display and signage manufacturers. Active is part of the region’s largest brand management, advertising, PR and media group WPP AUNZ. WPP AUNZ is majority owned by WPP plc which has a primary listing on the London Stock Exchange and is a constituent of the FTSE 100 index. WPP plc is headed by notable advocate of print media, Sir Martin Sorrell.

This will be one of Fujifilm’s largest installations of its type in the Asia-Pacific region and features ABB Robotic Systems automation. These combined systems, to be installed at Active’s Mulgrave site, will be outstanding examples of digital wideformat productivity and, importantly, they are versatile and scalable systems that can grow with business needs, being highly automated with robotics.

Active’s Onset X3 is capable of printing commercial-quality up to 900m² per hr and features industry- leading printhead technology from Fujifilm Dimatix, Inc., a wholly owned subsidiary of Fujifilm Corporation. Both of Active’s Onset devices use the latest Dimatix R-class printheads which fire a standard 14pl ink droplet at billions of times per second. They will also be running the new Inca ‘tear-drop’ feature which allows droplet tuning from 11pl – 17pl, giving Active the capacity to further improve image quality and eliminate the need for additional light ink channels, which dramatically reduces the ink usage per square metre. This combined technology from Fujifilm and Inca Digital will be an impressive combination of quality and speed for the Australian-New Zealand market. The systems are due to be fully operational in early 2018.

Active’s second machine is an Onset X1 designed to be future-proof, like all Onset X series, thanks to Inca’s scalable architecture. This means that an Inca Onset-X purchased today is designed to grow with businesses into the future with in-field upgrades such as additional printheads and higher speeds.

Both of Active’s X series devices will be running robotic automation, allowing the company to maximise productivity by stacking higher stacks of printed sheets – something that was not previously possible with scissor-lift systems. This is of major benefit in terms of machine uptime, as other technologies increase the downtime due to pauses for stack changes. Added to this is the flexibility of being able to place proof-sheets for the operator to check during production, without having to interfere with the palletised job

Active’s General Manager of Operations, Stuart Gittus, comments: “As part of WPP AUNZ, Active is able to provide clients with an end-to-end path to purchase solution, seamlessly delivering one streamlined integration of experts. Because we offer the region’s most comprehensive suite of services from design, production & distribution through to merchandising and warehousing; we needed to look at our present and future needs including, but not limited to, growing volumes and shorter print runs.”

He continues: “Extensive due diligence was performed and, in the Inca Onset X series from Fujifilm, we found print speed at high quality will ultimately enable us to become even more competitive in a challenging market, whilst increasing our capacity for speed-to-market. Also, with the degree of automation, both machines can be run by a single operator.”

Fujifilm Graphic System’s National Sales Manager, Ashley Playford says: “Our thanks go out to Stuart and the whole team at Active for entrusting Fujifilm and Inca with their next production growth phase. We are truly excited for Active and can’t wait for their customers to experience the quality and speed to market that these two Onset X series systems will offer them.”

Active has two other Fujifilm-supplied grand format printers at Mulgrave; a Uvistar 2 and a Uvistar Pro8 – both 5 metre wide roll-to-roll machines. Gittus says: “When the new Incas arrive, they will be printing a wide range of media including synthetic paper, art paper, screen board, fluted plastic and fluted cardboard for both Australian and global leading retailers and brands. He adds: “Fujifilm has been very proactive and lateral working with us to provide a solution to suit all our needs. Also, the technical information has been invaluable to the decision. It has been a pleasure working with Fujifilm and Inca.”

For more information, please visit http://www.fujifilm.com.au/powerofinkjet/platforms/robotics or www.Activedisplay.com.au

Active Display Group General Manager of Operations Stuart Gittus (r) with Shane Hanlon (c) and Ashley Playford (l) of Fujifilm Graphic Systems, with the Inca Onset X3 under installation

A fully robotised Inca Onset X3 similar to the ADG installation

Ricoh Asia Pacific is announcing another step in its journey to be the most innovative inkjet printing company in the world. ...

March 01 2018

Ricoh Asia Pacific is announcing another step in its journey to be the most innovative inkjet printing company in the world. Knowing that production printing businesses are continuing to ask more from digital print vendors, especially for inkjet solutions, Ricoh today announces the development of a new ink technology. This new ink will soon be brought to market as an additional option to current and future clients on the Ricoh Pro™ VC60000 continuous feed inkjet printing platform.

The direction Ricoh is taking with the new ink technology contributes to improving the wide-ranging capabilities of what is already an industry-leading production inkjet portfolio. Clients will benefit immediately and in the future because of Ricoh’s decades of experience in tuning print head technology, waveforms and ink chemistry. By using these new inks, clients will immediately see key advantages:

“Our clients have been very successful levering Ricoh’s production inkjet solutions in their businesses. They have also continued to partner with us in developing new technology that will enhance the solutions they have invested in, and offer them clear growth paths for the future,” said Eef de Ridder, Director, Commercial Printing of the Commercial & Industrial Printing Group, Ricoh Europe.

“The future of Ricoh’s business, and that of our clients’, is entwined in a shared opportunity to understand market requirements and the solutions required for business growth. Ricoh’s new inks are an excellent example of innovation addressing real world business opportunities through improved colour, faster production speeds, and enabling the use of common paper types in the commercial print space.”

For details on Ricoh’s full line of products, services and solutions for the production print market, please visit:

www.ricoh-ap.com

SCREEN Graphic Solutions Co., Ltd. has been honoured with a 2018 technology award by the Japanese Society of Printing Science and Technology (JSPST). The prize has gone to Screen’s...

March 01 2018

SCREEN Graphic Solutions Co., Ltd. has been honoured with a 2018 technology award by the Japanese Society of Printing Science and Technology (JSPST).

The prize has gone to Screen’s Truepress Jet520HD, a digital inkjet press that has become its flagship high-speed web model and, when running Screen’s new SC inks, can print directly on standard offset coated papers, without the need for any pre-treatment.

“This is a great recognition of Screen’s determination to bring high volume digital inkjet up to offset standards,” says Screen GP Austria managing director Peter Scott. “It comes six months after the 520HD and SC inks received the InterTech™ Technology Award presented by Printing Industries of America, at the Print 17 trade show in Chicago last September. The ability to print on offset coated stocks using inkjet brings down the barriers that have prevented quality offset printers from fully embracing digital. Paper costs have also reduced since standard offset stocks cost less than specially coated inkjet media, or pre-treating of offset papers.”

The JSPST presents the awards in February each year to recognise technologies that have made an outstanding contribution to the growth of the printing industry or to the development of applications for other fields. In making its selection, the JSPST considers points including the level of innovation, progress, marketability and expandability shown by each technology.

The Truepress Jet520HD is equipped with 1,200 dpi high-resolution inkjet printheads that effectively deliver the rich color gamut, texture, detail, vibrancy and depth required for high-quality publishing and commercial printing. The press enables the achievement of superior image quality approaching offset printing at industry leading speeds.

The specially developed SC inks enable the Truepress Jet520HD to print directly onto offset coated paper without any pretreatment or primer processing.This ability preserves the texture of surfaces while cutting lead times and costs. Thanks to these innovations, both products have been rapidly adopted by companies around the world for use in the publishing, commercial printing and direct mail markets.

Screen has previously won three JSPST technology awards; for its TaigaSPACE integrated prepress system, the PlateRite 8000 and 8600 thermal CtP recorders and original Truepress Jet520 high-speed roll-fed inkjet press.

Tsuneo Baba, President of SCREEN Graphic Solutions Co., Ltd., on being presented with the JSPST award commented: “ SCREEN is delighted to have been honored by the JSPST with one of its prestigious technology awards.

Until recently, specialized inkjet paper was the only choice available when using inkjet presses. However, we listened to calls from the market to be able to print directly onto standard offset coated paper and subsequently developed our award winning Truepress Jet520HD and SC inks.

Together these products deliver significantly improved cost efficiency and image quality that opens up a wide range of new applications in areas ranging from personalized direct mail to publishing and standard commercial printing. Our technical capabilities have allowed us to develop unrivaled propriety technologies and we are extremely grateful for this recognition of their advanced functionality and viability.

We plan to continue our work to create new business models that closely target the needs of our customers. It is our hope that the next-generation technologies developed as part of these efforts will make a major contribution to the ongoing expansion of the global printing industry.”