HP Inc. announced a 22mm wide-swath printhead for high-speed, high-resolution marking needs, including 1D and 2D bar codes, enabling brands to benefit from large-size codes ...

March 18 2018

HP Inc. announced a 22mm wide-swath printhead for high-speed, high-resolution marking needs, including 1D and 2D bar codes, enabling brands to benefit from large-size codes and characters for advanced product identification, anti-counterfeiting, and track and trace.

Manufactured by HP Specialty Printing Systems using HP Thermal Inkjet Technology, the new HP 22mm Printhead can be easily integrated into OEM printing systems and configured to specific applications.

The new HP 22mm Printhead supports a wide range of stitch-free product coding and marking applications for secondary packaging, including pharmaceutical labels and cartons, secondary box label replacement, as well as variable data printing.

“Product identification is used increasingly in manufacturing and supply chains to help brand owners protect products. Smart barcodes and more data-rich codes require high print quality,” said Annette Friskopp, general manager, HP Specialty Printing Systems, HP Inc. “HP is bringing advanced technology to protect products with the new HP 22mm Printhead and inks. This new, wider printhead offers better image resolution at higher speeds.”

The HP 22mm printhead achieves the highest level of bar code reading scores, readable from smartphones to a handheld scanner, required in product distribution and logistics . Additional benefits include:

• A 775ml ink supply cartridge can be connected to as many as four printheads at once, to meet production needs.

• Horizontal and vertical firing position provides flexibility for a range of applications.

• Fast printing speeds up to 150 m/min at 1200 x600 dpi

• The printhead can be replaced in minutes without specific operator training, allowing continuous production.

The new HP 22mm Printhead will be commercially available in the second half of 2018.

Additionally, HP announced its HP2580 ink for food and pharma packaging has received the European Printing Ink Association’s Good Manufacturing Practices (GMP) for Printing Inks for Food Contact Materials (2017).1

Here’s a great little video from Epilog Laser showing the versatility of their equipment to make spec...

March 18 2018

Here’s a great little video from Epilog Laser showing the versatility of their equipment to make specialised packaging products. Cardstock is a very versatile and popular material to use with the laser as it can be both cut and engraved. This sample club project features black cardstock that Epilog engraved and cut to create custom packaging for lightbulbs. By adjusting the speed, power and frequency settings on the laser, operators can etch text, cut out shapes, and even create perfectly perforated lines for easy folding and assembly.

S-One Holdings Corporation has launched S-One Labels & Packaging (S-OneLP), a new division focused on providing products, service, technical know-how and integrated produ...

March 18 2018

S-One Holdings Corporation has launched S-One Labels & Packaging (S-OneLP), a new division focused on providing products, service, technical know-how and integrated products to digital printers in the labels and flexible packaging market.

Through its LexJet and Utopia Digital Technologies divisions, S-One explained that it has developed a deep partnership with Michelman to serve the HP Indigo customer base with best-in-class primers for the past 12 years. S-One has recently signed agreements with flexible packaging specialists Toray America and Protect-all to create a comprehensive portfolio of packaging products designed to help label printing customers transition seamlessly into digital flexible packaging printing.

HP Indigo printers who currently purchase in-line, off-line and custom primers from S-One’s company, LexJet, will work with the S-OneLP team, effective March 1. Customers will have access to these products as well as a growing portfolio of specialty over-print varnishes and flexible packaging films, laminates, adhesives, paper-based substrates and more.

Ralph Giammarco, S-OneLP vice president, said: ‘Staying closely in tune with this market, we’ve discovered that our customers are looking for not only the best-performing products with lower minimums and improved lead times, but they are also searching for unwavering support and vital education as they expand into digital flexible packaging printing, which has seen exploding growth in the past year.

‘With S-OneLP, we’ve paired our exceptional primers sales team with product experts, market development specialists and the flex-pack industry’s top minds to lead this market forward.’

Giammarco added: ‘There are so many opportunities for HP Indigo print providers now, and with S-OneLP, we look forward to helping them master the world of digital label and flexible package printing.’

Now with major improvements to automation functions Epson Australia has expanded its digital label press lineup with the introduction of the new and improved SurePress®...

March 01 2018

Now with major improvements to automation functions

Epson Australia has expanded its digital label press lineup with the introduction of the new and improved SurePress® L-4533A, a six colour aqueous resin ink machine and SurePress L-4533AW six colour plus white aqueous resin ink press.

Delivering high-quality labels and packaging at a low total cost of ownership (TCO), the easy-to-operate SurePress L-4533A/AW inkjet label presses are built for reliable, high-quality performance, making short-run label printing with accurate colour reproduction on a wide variety of substrates easy for label converters and commercial printers. The L-4533A/AW have also undergone significant developments to meet the growing demand for fast turnaround, with longer automated printing times, email alerts and minimal maintenance.

General Manager of the Business Division at Epson Australia, Craig Heckenberg said, “Everyone appreciated the success of the SurePress L-4033 series so we wanted to build on that with new products to meet the growing label and flexible packaging market demand for shorter runs and faster turnaround times. The L-4533A/AW do just that. Boasting even higher print quality, greater operator productivity and improved media versatility, the new printers boast more than 30 improvements over their predecessors. These improvements translate into users’ ability to print a wider range of applications, create more high value jobs and operate more cost efficiently.”

Specifically designed to improve productivity and increase efficiency, the SurePress L-4533A/AW offer advanced automated printing features, including up to eight hours of unattended printing, e-mail alerts and minimal manual cleaning. Offering the highest levels of reliability with all components built by Epson including the ink, printhead and controller, the L-4533A/AW feature versatile substrate support and print on off-the-shelf materials from 3.15-inches (8cm) up to 13-inches (33cm) wide and as thin as .00314-inches (0.08mm).

The SurePress L-4533A/AW also include upgraded microprocessors which improve processing speeds up to 80% compared to the outgoing models. The new digital label presses with variable drop size starting at three picoliters also include a new larger ink drop size, ideal for large solid colour backgrounds found on packaging.

More about the SurePress L-4533A/AW:

The Epson SurePress L-4533A/AW is designed to print prime labels and flexible packaging efficiently and profitably. Additional features include:

• High-quality labels – Epson MicroPiezo® inkjet technology and a wide colour gamut deliver colour matching and gradients required for branded prime labels and packaging

• Ease of operation – Automated printing allows a single operator to run multiple units at one time

• Remarkable reliability – All components are manufactured by Epson and supported by Epson service

• Low-cost turnkey solution – Training, workflow software and operational support included

• Competitive TCO – Automated printing, competitive ink price and minimal consumables

• Versatile substrate support – Prints on off-the-shelf flexo PS label materials, including uncoated, gloss and semi-gloss papers, film and supported or unsupported media

• Versatile data support – An ideal solution for text, barcode and image serialisation

• Industrial-quality inks – Seven-colour ink set (Cyan, Magenta, Yellow, Black, Orange, Green and White), durable, water-based, resin-coated pigment inks provide superior adhesion, produce a remarkable range of colours, and deliver water and abrasion resistance on most substrates

Availability

The Epson SurePress L-4533A/AW are available now. For additional information click here

Innovia Films has added new down gauged grades to their Biaxially Oriented Polypropylene (...

February 22 2018

Innovia Films has added new down gauged grades to their Biaxially Oriented Polypropylene (BOPP) squeezable Rayoface™ label facestock range.

CZFA51 and WZFA51 are clear and white films respectively. These films offer customers the opportunity to save time and money for every step of the value chain if they switch from using PE85 to Innovia’s BOPP films. In addition, they gain a squeezable film with market leading clarity for ‘no-label’ look applications and perfect gloss for outstanding shelf appeal.

Richard Southward, Global Product Manager, Labels at Innovia Films states “We have researched the benefits that can be gained by switching from PE85 and they are substantial. As our films are thinner, the printer will get more square meters per reel, which means more printed labels per reel and increased up-time on press. It reduces the number of reels required by up to 60%, effectively decreasing the number of pallets and the storage space required by half. This results in less packaging and reel handling costs. The reduction in label material weight means that transport and logistics carbon footprint can be reduced by up to 45%. We believe this is an excellent opportunity to save time and money.”

Squeezable films are popular with Brand Managers, especially in the Home & Personal Care sector. Labels produced from these films maintain their consistency and quality throughout the life of the container on which they are applied, whatever format they are.

Southward adds “The added bonus is that they are also food contact compliant under FDA and EU regulations and offer game-changing branding impact with their unprecedented clarity.”

HP Inc. has expanded its labels and packaging portfolio with what the company say are solutions to drive printing and converting toward more flexible, productive and profitable digital printing ...

February 21 2018

HP Inc. has expanded its labels and packaging portfolio with what the company say are solutions to drive printing and converting toward more flexible, productive and profitable digital printing of any application. Among its new solutions include the HP Indigo 6900 digital press for labels and packaging and HP PageWide C500 Press for mainstream corrugated production.

“The expansion follows the largest packaging deal ever for HP Indigo with ePac. Our customers are growing fast across all segments and are experiencing massive success. They are leveraging HP technology to innovate and deliver on brands’ evolving needs,” comments Santi Morera, global head of graphics solutions business, HP Inc. “These new technologies we are launching are needed now more than ever and will allow our customers to be more productive.”

The new HP Indigo 6900 digital press increases the addressable label market while offering higher revenue per meter, including:

Additionally, the high-performance HP Production Pro for Indigo Labels and Packaging is now included in the HP Indigo 6900 and rolling out this year to HP Indigo’s entire Labels and Packaging portfolio. Featuring five times faster RIP power and the Esko Color Engine, the powerful Digital Front End provides extensive productivity and scalability for continuous digital production, to allow converters to scale and manage their digital production across multiple presses and multiple sites, increase the number of jobs per day, and shorten delivery cycles.

Pack Ready Laminator commercially available

For the HP Indigo 20000 flexible packaging press, the HP Indigo Pack Ready Laminator is now commercially available. A pioneering technology, Pack Ready Lamination allows for immediate time-to-market of HP Indigo digitally printed flexible packaging by eliminating the use of adhesives. The Pack Ready Laminator is manufactured and supplied by Karlville.

Extended capabilities for the HP Indigo 30000

The HP Indigo 30000 Digital Press offers converters an opportunity to build new profitable businesses that leverage cost-effective short runs and added value long-run production. The new capabilities and improved performance include:

Digilinck, a folding carton converter based in Deinze, Belgium, is adding a second HP Indigo 30000 digital press. “The Folding cartons market is changing and our customers expect speedy delivery and lower inventory levels. The HP Indigo 30000’s high flexibility and offset matching quality allow us to seize this opportunity and build a new profitable digital business, offering short turnaround-time and economic production of short-run healthcare packages,” says Vincent Oosterlinck, Owner, Digilinck. “Since installing the press, our business grew by 66% in the last three years.”

Addressing the corrugated packaging market

HP also announced that Kiwiplan, a leading MIS/MES software solutions provider for corrugated and rigid packaging, will be fully integrated, keeping the HP PageWide C500 presses running at optimum capacity, while helping customers to save time and costs through production and supply chain efficiency.

Five customers in Europe and the US have already purchased the groundbreaking PageWide C500 Press for direct-to-board post-print corrugated production. The first unit will ship next month.

Utilizing HP’s high-performance single-pass Thermal Inkjet technology, the HP PageWide C500 provides a cost-effective digital alternative for offset lamination and flexo production. The press delivers offset quality direct-to-board with mainstream productivity on both coated and uncoated papers, delivering packaging with vibrant graphics that preserves even the finest details.

The HP PageWide C500 utilises HP CV150 Water-Based Inks, which contain no UV-reactive chemistries. These true water-based inks allow corrugated converters to print primary and secondary food-related packaging without an additional barrier.2 This robust and trusted solution enables compliance with the most stringent global food safety regulations and industry guidelines.

Durst, manufacturer of advanced digital production technologies, together with OMET, manufacturer of printing and converting machines, have strengthened their collaboration with the introduction...

February 15 2018

Durst, manufacturer of advanced digital production technologies, together with OMET, manufacturer of printing and converting machines, have strengthened their collaboration with the introduction of the new OMET XJet.

Powered by Durst, the integrated hybrid solution for a wide range of high-performance labels and packaging printing guarantees flexibility and cost savings.

The jewel in the crown of the Durst and OMET partnership, the new OMET XJet, is being officially presented to more than a 100 customers from across the globe at Durst’s Digital Days at its Italian headquarters in Brixen, northern Italy. The three-day event is dedicated to the best digital label and packaging printing solutions.

The OMET XJET is the new hybrid printing platform integrating Durst’s Tau 330 digital inkjet system with OMET X6 flexo stations and converting units. It can offer an unlimited flexibility and a wide range of final applications with a consistent cost reduction thanks to the in-line multi-process configuration. Durst inkjet technology together with OMET X6’s finishing and converting units like cold foil, hot foil, lamination, varnishing, die-cutting and slitting assure reliability and excellent results at every run, with the advantage of obtaining the final product in one single passage.

The OMET XJet is powered by Durst Tau RSC, the high-performance UV inkjet printing press featuring 330 mm (13”) print width with maximum print speed of 78 linear meters/min (245 ft./min) at 1200 x 1200 dpi resolution. Thanks to its eight color stations (CMYK+W+OVG) with new designed high pigmented inks it delivers outstanding print quality with 98% pantone color gamut coverage.

The hybrid solution broadens the opportunities for label printers thanks to its flexible configuration. It can be seen as three presses in one as it can be used as hybrid solution, flexo stand-alone or digital stand-alone according to the length of the run or the level of personalization required. This concept can help optimize production time and costs, getting faster ROI and open new market opportunities.

Helmuth Munter, Segment Manager Labels & Package Printing at Durst comments: “We are very pleased to partner OMET in the launch of this highly professional hybrid printing solution. It combines the best technologies of both, the digital inkjet printing and conventional pre- and post press printing and finishing world, offering our common future customers a highly cost effective and complete “all-in-one” printing process.”

Marco Calcagni, OMET Sales and Marketing Director, added: “We managed to create a complete Made-in-Italy printing solution that meets the market trends of personalization, just-in-time deliveries and final product variation, but also maintaining all the capabilities of a conventional press. I believe that Durst is the right partner for such a challenging project because they have deep knowledge and the best digital inkjet technology acknowledged by the international market.”

For more information, click here http://printing.omet.com/en/

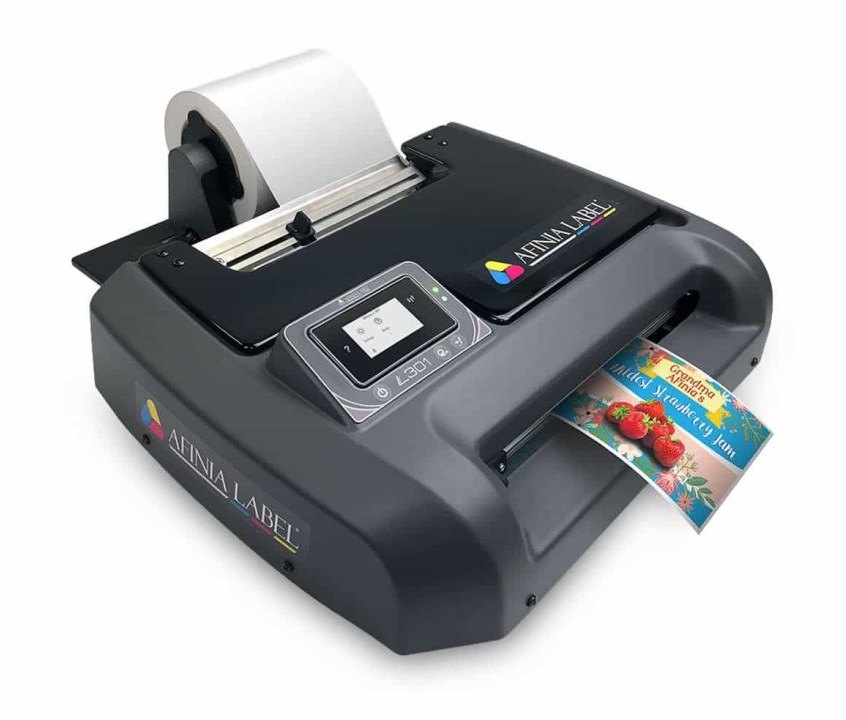

Afinia Label has released the L301 Color Label Printer: a compact, full-color inkjet printer, capable of up to 4800 dpi ph...

January 31 2018

Afinia Label has released the L301 Color Label Printer: a compact, full-color inkjet printer, capable of up to 4800 dpi photo-quality prints. This product expands Afinia Label’s existing line of industrial full-color label printers, and it is designed to address the needs of smaller organizations requiring professional looking labels in lower volumes.

“Bringing professional label printing in-house with the L301 allows brand owners the flexibility they need to grow,” says Mike Atkins, Afinia Label’s national sales manager. “Instead of ordering high minimum quantities of labels from a third party, they can now print the labels they need, when they need them. The L301 also opens the door to seasonal product labeling and private labeling on behalf of their customers.”

The L301 is based upon an HP thermal inkjet printing platform that prints labels up to 6” wide (or up to 8.5” wide, with an optional unwinder). Its small footprint, ease of use and quiet operation make it suitable for any desktop environment. It prints in vivid, optimized color (up to 4800 x 1200 dpi), creating a professional label that catches the eye of potential customers. It’s compatible with a wide range of media.

The L301 is now available worldwide through Afinia Label resellers; along with the Memjet-powered L801 Label Printer, the DLF-1100 Digital Label Finisher, and the DLP-2000 Digital Label Press.

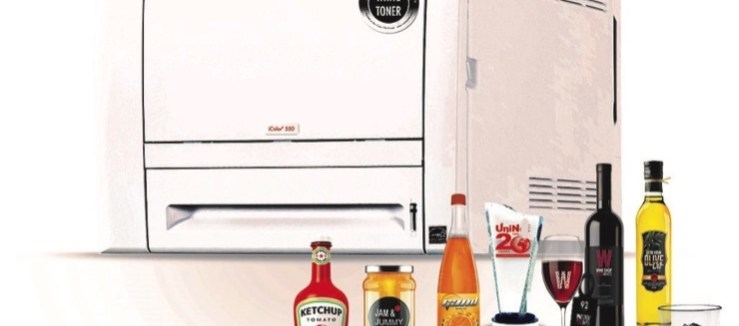

UniNet, an OEM of on-demand digital print technology, has launched its newest transfer printer at the Imprinted Sportswear Show, which took place January 19-21, in Long Beach, CA, USA Th...

January 31 2018

UniNet, an OEM of on-demand digital print technology, has launched its newest transfer printer at the Imprinted Sportswear Show, which took place January 19-21, in Long Beach, CA, USA

The iColor 550 is a multi-purpose printing solution for transfer production of garments, labels, stationary, banners, hard surfaces, marketing customisation and more. The versatility of this new printer allows users to create heat transfer prints with white overprint, right side reading with white underprint, and regular CMYK prints without white. The iColor 550’s capabilities can be further enhanced using UniNet’s specialty toner upgrade kits which includes fluorescent, clear, security, and dye sublimation toners.

Also being presented is the new iColor SmartCut software, which allows users to easily print and press oversized images onto apparel and hard surfaces. This ground-breaking application turns any iColor 500, 550 and 600 transfer printer into a tabloid ‘plus’ capable machine, allowing for the splitting and splicing of one graphic across two printed transfer sheets for pressing onto large items.

Afinia Label, a manufacturer and distributor of industrial color label printing and finishing equipment, has released the ...

January 18 2018

Afinia Label, a manufacturer and distributor of industrial color label printing and finishing equipment, has released the L901 digital color label printer, powered by the Sirius print engine from Memjet.

The L901 is the newest printer to join Afinia Label’s broad family of label printing and finishing solutions. The L901 gives companies the ability to run a full-color digital label printer inline with a finishing or application system without complications related to mid-job printhead maintenance. This industrial digital label printer can produce full-color prints with excellent image quality at speeds of up to 12″ per second. Photo-quality images and exceptionally-crisp text and bar codes are printed at up to 1600 x 1600 dpi via Memjet’s Sirius print engine. Five high-capacity 250mL ink cartridges (CYMKK) offer a low ink cost per label.

“The Afinia Label L901’s redesigned printhead servicing and cleaning station allows this printer to be run inline with finishing equipment, label applicators, label dispensers and unwind/rewindunits,” says Mike Atkins, national sales manager for Afinia Label. “This new design eliminates the need to cut the web in order to clean or cap the printhead, making it suitable for in-plant integration with other machines. The L901 gives users the ability to print and apply labels in full color, with variable data, on demand. This, combined with full color, photo-quality resolution, high print speed, and low cost of operation, make the L901 the perfect color label printer for medium- to high-volume labeling applications.”

For print houses, the L901 helps offload smaller jobs and proofing, eliminating the need to tie up large flexo or digital presses for those tasks. Additionally, the L901’s user interface was designed to be intuitive and easy to use, so there is no need for a specialized technician.“

Many companies would like the ability to automatically print and apply labels on the production line,” says Atkins.“Some achieve this now with single-color thermal label printers, but they are limited to simple text or bar codes. The L901 offers a new and better way to print and apply full-color labels on demand. This could eliminate the need to purchase pre-printed labels, which greatly improves productivity while driving down packaging costs.”

SCREEN GP Australia has announced that it will introduce two more ’mini’ digital label presses into Australia in 2018, under the Trojan brand name. As with the existing Trojan-made p...

December 20 2017

SCREEN GP Australia has announced that it will introduce two more ’mini’ digital label presses into Australia in 2018, under the Trojan brand name. As with the existing Trojan-made press sold under the Screen name – the Truepress Jet L250AQ, the new presses will also be available through Jet Technologies, Screen GP’s channel partner for narrow web digital presses.

The Trojan T2-C is a desktop label printer that performs like a bigger machine. Using Memjet printhead technology, it runs at up to 18 metres per minute with a maximum print width of up to 223mm across a 250mm web. It can print on pre-diecut or continuous label reels, for offline finishing.

Peter Scott, managing director of Screen GP Australia says: “The Trojan T2-C has proper web feed and take up with tensioning and yet fits any size print department due to its compact desktop footprint. Ink supply can be either by internal 250ml cartridges or, for higher productivity, external 2 litre tanks. At either 1600 x 1600dpi or 1600 x 800 dpi, the image quality is superb.”

The other new label press from Screen and Jet is the Trojan T4, an all-in-one label press line with top class inline finishing. Print speed, resolution and width is the same as for the T2-C but the T4 is a 1200Kg floor-standing unit with very robust printing, laminating, die-cutting, slitting and rewind for an end-to-end solution.

Scott says: “It’s a mini-marvel unlike any other solution for short-run and variable versioned labels. The engineering standard is first class and the die-cutter can be fully or semi-rotary and used alone to create die-cut blanks or to finish labels from another press. Best of all both the T2-C and T4 are fully supported by Screen GP’s local engineers and Jet Technologies’ expertise.”

He concludes: “We now have a complete range of digital label presses from desktop 18 metres per minute to high-end UV at 60 metres per minute, which I believe is the most complete line-up of such presses available and fully supported in Australia.”

Sun Chemicals has released a guide called ‘Brighter Ideas for Labels’.

November 20 2017

The portfolio of materials is designed to reduce packaging falsification and tampering in the pharmaceutical sector. The ne...

October 19 2017

The portfolio of materials is designed to reduce packaging falsification and tampering in the pharmaceutical sector.

The need to protect the safety of pharmaceutical products has risen in recent years, and Avery Dennison has developed a portfolio of materials designed to reduce packaging falsification and tampering in the pharmaceutical sector.

“Drug counterfeiting is a major global problem. Patient safety is compromised by product manipulation and substitution, and manufacturers can experience damage to their brand image, sales and revenue,” explains Gabriela Gregor, Avery Dennison’s project manager for pharmaceutical labeling. “Our products can change the game in protecting patient safety and safeguarding manufacturer reputation.”

One key product range in the portfolio is the Tamper-evident Seal Range, which, when combined with newly formulated adhesive S799P, makes tampering with cartons more difficult, and eases compliance with the EU Medicine Directive 2011/62/EU, which is designed to prevent “falsified medicines” from entering the legal prescription supply chain, and also applies to some over-the-counter products.