Durst targets more converters with Tau 330 RSC E launch Durst, manufacturer of advanced digital printing and production technologies, has launched the Tau 330 RSC E UV inkjet single-pa...

January 21 2019

Durst targets more converters with Tau 330 RSC E launch

Durst, manufacturer of advanced digital printing and production technologies, has launched the Tau 330 RSC E UV inkjet single-pass press that will bring affordable digital production to increasing numbers of converters.

Specifically targeted at small and medium converters in the mid-tier market, the budget-priced new model – prices start from €350,000 – will be field upgradable to the full Durst Tau RSC high-speed press at full 8 colours and 78 linear meters/min (245 ft./min).

In line with Durst’s “Configure Your Digital Future” theme, the press is available in 330mm and 244mm print widths, offering 4 colours or 4 colours and white option in full-speed mode. The Tau RSC E benefits from Durst’s state-of-the-art RSC technology. Its native resolution of 1,200 x 1,200 dpi combined with its smallest drop size of 2pl provides photo-like quality.

Production capacity of 1,020 m² / hour is achievable with a printing speed of 52 m/min at full colour including white. High pigmented inks reduce ink consumption by up to 20% per sqm, optimising running costs to the lowest possible level.

All options from the Tau 330 RSC can be fitted to the new model, which include the chill roller, variable data printing or the external jumbo winders. The new machine runs at 52 linear m/min and can have up to 8 colour stations (CMYK-W-OVG). Fast, efficient, powerful and easy-to-use prepress Durst Workflow Label software is also offered.

Helmuth Munter, Segment Manager, Durst Label & Packaging Printing, said: “During the development of the Dust Tau 330 RSC E, a special focus was dedicated to the upgradeability and flexibility of the press. This is an important addition to the Durst Tau RSC family of variable, versatile, adjustable and configurable machine systems. Affordable digital label printing is now available to increasing numbers of converters and printers. We’re incredibly excited at the new opportunities that the new and budget-priced model will open up for increasing numbers of converters. Digital UV inkjet label printing is definitely here.”

API LAUNCHES RANGE OF PLASTIC-FREE HOLOGRAPHIC LAMINATES API Group has enhanced its range of Transmet™ products with the launch of new holographic designs. The range of 12 hologr...

January 15 2019

API LAUNCHES RANGE OF PLASTIC-FREE HOLOGRAPHIC LAMINATES

API Group has enhanced its range of Transmet™ products with the launch of new holographic designs. The range of 12 holographic patterns are available in API’s Transmet laminate, a plastic-free option for paperboard packaging, ensuring brand owners and designers have a sustainable packaging option without compromising on aesthetics.

Transmet has all the benefits of traditional metalised polyester cartonboard laminates, but without the film content, allowing it to be fully recycled through normal waste streams. The new Transmet holographic designs will allow brands to retain their stand-out shelf appeal, while also reducing their environmental impact.

Richard Burhouse, Marketing Director at API, said: “Over the last couple of years, we have experienced an uptake in demand for our Transmet plastic-free laminates as brands look for environmentally-friendly alternatives to create a fully recyclable end product.“It is more important than ever that we provide innovative solutions that consider both sustainability and shelf appeal. In an increasingly competitive retail environment, holographic and diffractive patterns can be used as an effective and eye-catching way for brands to strengthen their differentiation on shelf, delivering luxury effects that create a unique on-shelf identity. Our new holographic patterns will give brand owners and designers a wider variety of options to add visual impact to their product’s packaging and elevate brands to the next level.”

API Group has invested heavily in its Livingston plant in Scotland, consolidating its film, holographics and foil production under one roof to create a European technical centre of excellence.

Richard added: “As pioneers of Transmet, we like to push the boundaries and having brought together our films, foils and holographics expertise into one place, our customers are now able to enjoy the benefits of this effort. With unrivalled technology, industry experience and capacity, we are fully committed to continued development of packaging enhancement solutions that provide stand-out shelf appeal while being better for the environment.”

The designs will be available immediately and can be used across all approved board types.

AstroNova GmbH is expanding its Product Identification portfolio with the new digital, toner-based colour QL-300 label printer with five colours, including QuickLabel's white. The QL-300 also print...

January 07 2019

AstroNova GmbH is expanding its Product Identification portfolio with the new digital, toner-based colour QL-300 label printer with five colours, including QuickLabel's white. The QL-300 also prints high-UV-resistant "no-label-look" labels.

According to the company, the introduction of the QL-300 proves AstroNova is prepared to meet changing market requirements. The QL-300 is the first 5-colour CMYKW tabletop printer for printing R2R (roll-to-roll processing), AstroNova says.

The printer's capability of printing five colours with 1200 dpi resolution, including white, is a game-changer. Printing in white allows direct printing on coloured materials, such as black polyester or silver paper. This feature also ensures excellent readability when printing bar codes, even on transparent materials. The high scratch resistance of the print result extends the use of the QL-300 in all areas that demand the highest requirements such as the the chemical, cosmetic and e-cigarette industries.

The electrophotography printing system of the toner-based label printer uses a printing process in which the print image is transferred directly from a computer to the QL-300 without the need of time-consuming preliminary work. The print's high resistance to oils, solvents, water and UV-rays on virtually all materials, makes the QL-300 a universal label printer perfect for all applications.

It can also print on various materials, from paper and metalised polyester to transparent materials. The transparent labels are more flexible and cost-effective compared to direct printing. Other effects for increasing customer motivation to buy a product are also possible such as bottle transparency.

The printer's high printing speed of up to 152 mm/s and printing widths of up to 126mm allow a wide variety of shapes and colour labels to be printed. The toner-based 5-coluor CMYKW printing system is also ideal for brand owners and packaging industry.

Nestlé has announced the creation of the Nestlé Institute of Packaging Sciences, dedicated to the discovery and development of functional, safe and environmentally friendly packaging ...

January 07 2019

Nestlé has announced the creation of the Nestlé Institute of Packaging Sciences, dedicated to the discovery and development of functional, safe and environmentally friendly packaging solutions. This is a step further to achieve the Company's commitment to make 100% of its packaging recyclable or reusable by 2025.

Nestlé CEO Mark Schneider said, "We want to be a leader in developing the most sustainable packaging solutions for our food and beverage products. To achieve this, we are enhancing our research capabilities to develop new packaging materials and solutions. Through this, we hope to address the growing packaging waste problem, in particular plastics. We aim to minimize our impact on the natural environment while safely delivering to our consumers healthier and tastier products."

The Nestlé Institute of Packaging Sciences, which is part of Nestlé's global research organization, will be located in Lausanne, Switzerland. It will employ around 50 people and include a state-of-the-art laboratory complex as well as facilities for rapid prototyping.

In close collaboration with the Company's global R&D network, academic partners, suppliers and start-ups, the institute will evaluate the safety and functionality of various sustainable packaging materials. Research focus areas will include recyclable, biodegradable or compostable polymers, functional paper, as well as new packaging concepts and technologies to increase the recyclability of plastic packaging. The new solutions will be tested in various product categories, before they are rolled out across Nestlé's global portfolio.

Nestlé Chief Technology Officer Stefan Palzer said, "Packaging plays a crucial role in helping us deliver safe and nutritious products to our consumers. The new Institute of Packaging Sciences will enable us to accelerate the redesign of our packaging solutions. Cutting-edge science as well as a close collaboration with globally leading academic institutions and industrial partners will deliver a pipeline of highly performing environmentally friendly packaging solutions."

Epson Launches TM-L90 Liner-Free Compatible Label Printer Epson Australia has launched its new TM-L90 Liner-free compatible label printer. The TM-L90 liner-free compatible label printe...

November 23 2018

Epson Launches TM-L90 Liner-Free Compatible Label Printer

Epson Australia has launched its new TM-L90 Liner-free compatible label printer. The TM-L90 liner-free compatible label printer delivers all the features you need to print liner-less "stay stuck" labels and is ideally suited for quick service environments such as coffee shops, delicatessens and restaurants, both quick and traditional service. Food operators can now easily identify customer orders on take away bags and boxes as well as use the labels to identify custom orders or label orders for delivery.

The addition of the TM-L90 liner-free compatible label printer expands Epson's line-up of reliable label and coupon printing solutions. Designed to print on both adhesive-backed media and thermal receipt media, the new TM-L90 liner-free label printer provides a flexible, hospitality-strength, liner-free labelling solution that improves efficiency while enhancing customer satisfaction.

The TM-L90 prints liner-free labels at a speed of up to 90mm/second and thermal receipts at up to 170mm/second at a crisp 203 x 203 dpi, supports variable length label output and accepts label rolls up to 102mm in diameter. The printer can easily be mounted in three ways (vertical, horizontal or wall-mounted) and offers additional benefits such as margin reduction options to reduce receipt size, automatic media type and paper width detection, sensor for auto cutting, and modified support rollers to minimise paper jams. Additionally, the TM-L90 liner-free label printer comes with a 12-month limited warranty and supports multiple interfaces, including serial, Ethernet, and powered USB.

TM-L90 Key Features

• Cost-effective liner-free label printing for QSRs and food service

• Special print options reduce paper usage by up to 30%

• Easy installation – 3 mounting positions

• Low power consumption reduces cost and environmental impact

• Standard 12 months RTB warranty

• Easy media switching between 40, 58 and 80 mm paper widths

The TM-L90 is available now from selected Epson resellers.

www.epson.com.au

NEW EYE CATCHING FOLDING CARTON WITH NANOTECHNOLOGY DECORATIVE ELEMENTS A new recyclable folding carton featuring advanced brand enhancement technology, has been launched by specialist...

November 23 2018

NEW EYE CATCHING FOLDING CARTON WITH NANOTECHNOLOGY DECORATIVE ELEMENTS

A new recyclable folding carton featuring advanced brand enhancement technology, has been launched by specialist Fresnels Inc.

First shown at Luxepack Monaco in October 2018, the design features innovative dynamic nanotechnology decorative elements, developed specifically to catch the eye and interact with customers in the retail drinks environment.

Incorporating enhanced levels of security features for added brand protection, the box has been produced from FSC certified paper over printed with a floral design before a clear, optically variable Peacock™ foil is applied via heated blind embossing. This ensures perfect register between the raised leaves and petals and the green to gold colour transformation imparted by the foil.

The same foil is also used directly on the white paper to create the letters ROSE - textured dies create an engraved effect to the lettering while adding security to the box - before a digitally created crest, using proprietary Cellini™ technology, is applied using silver metallised stamping foil.

The new Fresnels technology meets the demand for eco-friendly packaging that can be recycled and is produced using manufacturing processes, which have minimum energy demands and environmental impact.

Foil technology is used to provide improved recyclability when compared with plastic laminates, while advanced digital origination technology allows covert markers and data to be incorporated into the packaging surfaces. These include Level 2 and 3 covert security features that can only be detected via hand held devices or forensic examination.

Dr Glenn Wood, COO of Fresnels Inc, said: “We are seeing mechanically produced fresnel lens effects as fascinating additions to packaging. However, the real prize is digitally produced images offering graphic designers much greater scope for creativity. We have also been successful in manufacturing these images as hot stamping foils suitable for high speed application to paper substrates.”

Fresnel Inc. President John Jones, said: “CELLINI™ has the appearance of moulded metal. It engages the eye and the touch by its raised appearance which renders the embossing of paper or carton unnecessary.”

Cellini™ and Peacock™ effects can also be supplied in label format to co-ordinate with the cartons. With headquarters in Connecticut, USA, Fresnels Inc. specialises in the commercialisation of optical microstructures and provides brand owners with high visibility packaging with dynamic effects, which are eco-friendly, highly secure and yet highly cost effective.

HP INTRODUCES WIDE TABLETOP PRINT ENGINE FOR DIRECT-TO-PACKAGE PRINTING HP Inc. has announced a new wide tabletop print engine for OEMs to design on-demand specialty packaging solution...

October 16 2018

HP INTRODUCES WIDE TABLETOP PRINT ENGINE FOR DIRECT-TO-PACKAGE PRINTING

HP Inc. has announced a new wide tabletop print engine for OEMs to design on-demand specialty packaging solutions.

The HP OEM Fixed Imager 1000 by HP Specialty Printing Systems (SPS) enables convenient in-plant or print service provider printing on a wide range of applications including gift and shopping bags, personalised gift boxes, shipping packaging, cartons, and envelopes. The highly versatile HP F1-1000 print engine introduces a 297.18 mm (11.7 inch) wide print swath, offering a large image area for colour printing on variable lengths of media.

“This wider print engine can deliver more elaborate on-demand color packaging and commercial printing applications for short-run, personalized direct to package printing. Brand owners can differentiate their packaging, shopping bags, envelopes to make their products stand out with color and personal messages,” said Annette Friskopp, general manager, HP Specialty Printing Systems, HP Inc. “HP opens extensive opportunities for OEM partners with a range of inkjet printing capabilities to meet fast-paced market needs.”

BALL AEROSOL PACKAGING LAUNCHES EYERIS® Aluminium aerosol customers traditionally have shied away from photo-realistic packaging designs because the graphics do not translate well ...

October 05 2018

BALL AEROSOL PACKAGING LAUNCHES EYERIS®

Aluminium aerosol customers traditionally have shied away from photo-realistic packaging designs because the graphics do not translate well to conventional offset printing. To overcome this limitation, Ball Aerosol Packaging is launching the highly anticipated Eyeris®, a proprietary high-definition printing technique.

For customers craving detailed graphics to bring products to life, Eyeris® printing is the solution to providing photo-realistic quality can designs without digital printing. This ground-breaking HD imagery spans 360 degrees of the can, creating premium product differentiation that engages consumers and elevates brands.

As the personal care industry continues moving toward more natural products, Eyeris® provides customers with the opportunity for the packaging to reflect this shift. Detailed life-like imagery, such as leaves, flowers and landscapes, can be printed on cans, allowing brands to stand out in today’s competitive retail market.

Jason Galley, Director of Global Innovation & Business Development for Ball Aerosol Packaging, comments: “We know the market is clamoring for inventive solutions to create standout packaging. There is such buzz in the industry for digital printing, and Eyeris® provides the perfect alternative to achieve similar results on aerosol cans. This unique technology will transform our customers’ ability to harness the increasing power of imagery and story-telling, truly representing the next generation of aluminum aerosol printing.”

Sato launches intelligent touchscreen label printer Sato, a global provider of auto-ID solutions that empower workforces and streamline operations, has launched the FX3-LX, a cloud-con...

October 05 2018

Sato launches intelligent touchscreen label printer

Sato, a global provider of auto-ID solutions that empower workforces and streamline operations, has launched the FX3-LX, a cloud-connected touchscreen label printer that can be operated without the need of a PC. It has been engineered with the needs of restaurants, retail, healthcare, manufacturing and logistics workplaces in mind.

Research shows that legacy hardware and outdated technology can have a major impact on worker productivity and competitiveness by impeding a collaborative workforce. Also, companies that are highly connected are far more likely to report a favorable market position than those with poor connectivity (57% versus 27%).

To address these concerns and more, Sato has designed the 3" FX3-LX label printer to be highly intuitive and customizable for increasingly tech-savvy businesses that expect a consumer-level user experience. With support for the Sato Application Enabled Printing (AEP) enterprise label printing platform, the printer enables apps specialized for various work environments that can be accessed intuitively as you would with a smart device.

The durable, portable device has a small footprint, allowing users to print labels anywhere they are required around the workplace.With its multi-lingual display and 7" TFT full-color touchscreen and ability to load original training videos, it gives operators on-demand insight into operational procedures to render training virtually unnecessary.

FX3-LX also supports the cloud-based maintenance service, SOS (SATO Online Services), allowing identification of issues before they cause downtime, visualization of printer status and asset management. This add-on service helps ensure stable operations and peace of mind for the user.

“We’re delighted to introduce our cutting-edge FX3-LX to the market,” says Sato Holdings chief product planning officer Noriyasu Yamada. “As the user experience boundaries of personal and workplace tech become ever more blurred, we’ve created a next generation label printer that is user-friendly from the first use and offers operators a high degree of autonomy via easy database updates. We aim to further increase customer value with new IoT solutions to boost productivity.”

Yamada continues, “With the FX3-LX, we’ve worked hard to understand how we can empower workforces and streamline the operations of end users. The result is a universal device with simple cross-sector integration to improve Total Cost of Ownership (TCO) for Sato customers.”

The FX3-LX was recognized with the Red Dot Design Award 2017 for its minimalist design and practicality.

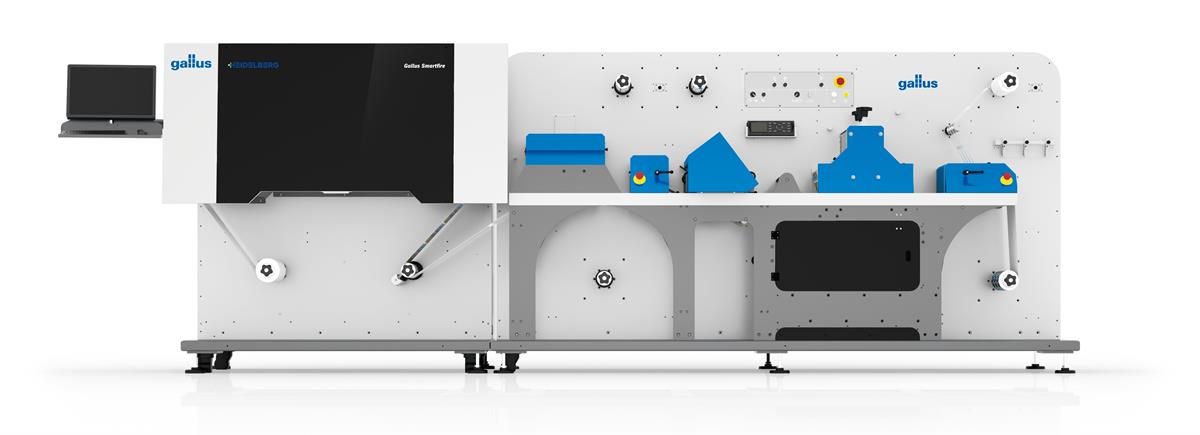

Gallus and Heidelberg unveil Smartfire digital label press In April 2018, Gallus and Heidelberg announced the completion of their full integration in North America. To highlight their ...

October 02 2018

Gallus and Heidelberg unveil Smartfire digital label press

In April 2018, Gallus and Heidelberg announced the completion of their full integration in North America. To highlight their commitment to the label industry and to show the combined strength of both companies with their aligned product portfolios, Gallus and Heidelberg are exhibiting together in Booth 6150 at Labelexpo Americas 2018.

At the show, Gallus’s new Smartfire digital label printing system is being unveiled to the North American market, and Heidelberg’s Omnifire 250 4D inkjet digital printer is available for demonstration. Respective market leaders in narrow-web and sheetfed offset printing, Gallus and Heidelberg now offer a complete print shop solution for label printers with reliable equipment, parts, service and consumables support – all from a single source.

Gallus’s vast portfolio includes the Labelmaster, the most cost-effective system in the industry. From the economical basic model to the fully equipped version, the Labelmaster is redefining conventional flexographic label printing; its modular design enables customers to configure the press to the needs of their business. On the digital side, Gallus’s Labelfire, an advanced hybrid inkjet system that was developed with Heidelberg and Fujifilm, is setting the standard for UV inkjet image quality with the lowest cost of production in its class. For high quality conventional flexo label production, customers can also rely on the Gallus ECS 340 for cost-effective label production and Gallus RCS 340, an extensively automated system for high-output label production.

On the offset side, Heidelberg has, for years, been a supplier to the label industry – most notably with their flagship press, the Speedmaster XL 106 with 41” sheet size, ability to print 18,000 sheets per hour, and optional UV, LE UV, and LED curing systems, which enable it to print on a variety of substrates, including synthetics. Customers can now also turn to Heidelberg’s Primefire 106, the first commercially available industrial inkjet digital printing system in the 70 x 100 (40”) format. Printed labels can be finished with the Heidelberg portfolio, which includes POLAR cutters and a variety of die cutters from Masterwork.

All Gallus-Heidelberg customers benefit from the specialist industry expertise of both companies along with Heidelberg’s established service network and extensive parts availability.

Gallus Smartfire

“The Smartfire focuses on new target groups who are looking for a low risk, easy entry into digital label printing,” explains Michael Ring, Head of Digital Solutions at Gallus. “Incorporating Memjet technology allows us to offer an inkjet printing press that produces labels with a quality of 1600×1600 dpi – while establishing a new, low investment price point in the market.”

The Memjet water-based inks and print heads mean that labels produced by the Smartfire are eco-friendly, with a minimal ecological footprint. Virtually “plug and play,” the Smartfire uses an ordinary power outlet, needs no exhaust equipment, is extremely compact, and does not emit VOCs (Volatile Organic Compounds), which makes it the perfect press for any work environment.

“The name says it all, the Smartfire is absolutely easy to operate via a self-explanatory touch panel,” says Ring. With this digital press, limited prepress skills are needed to create professional CMYK 4-color inkjet labels. Addressing the shortfall of other offerings in this space, a finishing unit is integrated into the press, where labels are laminated and cut, which means the Smartfire delivers finished die cut labels in one pass, ready for shipping.

Heidelberg Omnifire – Inkjet Personalization in the Fourth Dimension

Also available for demonstration in Booth 6150 at Labelexpo Americas will be the Omnifire 250 – Heidelberg’s “4D Printer,” which combines advanced Inkjet technology with high-precision robotics. The Omnifire 250 can personalize and customize most three-dimensional products. From a wine bottle to tumbler and beyond, the Omnifire gives customers the ability to change products over within seconds — providing shorter delivery times with on-demand printing.

“We think that the Omnifire is a great fit for the label market,” said Steven Calov, Product Manager of Omnifire for Heidelberg USA. “Most label printers are already creating customized labels for a variety of consumer products – with the Omnifire, they can take this same thinking and print a customized image direct to the object in many cases.”

Epson announces SurePress L-6534VW digital label press Epson has announced at Labelexpo the Epson SurePress L-6534VW digital label press. Joining the SurePress L-6034VW in the UV digit...

September 26 2018

Epson announces SurePress L-6534VW digital label press

Epson has announced at Labelexpo the Epson SurePress L-6534VW digital label press. Joining the SurePress L-6034VW in the UV digital label press line, the SurePress L-6534VW will offer three print speed modes from 49 feet per minute to 162 feet per minute (fpm). Epson will be demonstrating the new SurePress L-6534VW, as well as the SurePress L-6034VW and L-4533AW and workflow automation solutions with Wasatch RIP, at Labelexpo Americas in Chicago at Epson’s booth 5813.

“The SurePress L-6034VW set a higher standard for UV print quality,” said Mike Pruitt, product manager, Epson America, Inc. “Today we take our solution one step further by expanding the line to deliver faster print speeds compared to the previous generation; allowing prime label and packaging converters to fulfil demanding and varying portfolios more quickly – ultimately optimising productivity and efficiency.”

Designed for label converters investing in a digital label press for the first time or looking to expand production facilities with a reliable, easy-to-use press, the SurePress L-6534VW delivers three print speed modes to meet a range of converter needs:

mprint showcases mlabel GEN3 UV inkjet hybrid mprint gmbh of Baiersbronn, Germany is displaying its new generation of hybrid UV inkjet presses, the mlabel GEN3 at Labelexpo Americas 20...

September 26 2018

mprint showcases mlabel GEN3 UV inkjet hybrid

mprint gmbh of Baiersbronn, Germany is displaying its new generation of hybrid UV inkjet presses, the mlabel GEN3 at Labelexpo Americas 2018. Aside from the obvious facelift from GEN2, the machine incorporates several technological advances and additional modules.

The base machine has a standard mechanical width of 13" (330mm) but does not have to be outfitted with a print engine of the full print width from the beginning. This will allow a technology implementer to start with a lower cost system and expand the print engine in the future, adding capacity without having to purchase a new machine.

Aside from being equipped with CMYK+W, the machine shown at Labelexpo incorporates the Digital Metal Liner module – a fully digital foil embellishing unit, allowing printers to not only generate metallic effects on labels and packaging in a single pass, but also to customize these effects with every print. This state-of-the-art module was developed in cooperation with KURZ Transfer Products using their Digital Metal UV Ink technology and presents a technological milestone in digital printing. Especially suited for wine and spirit labels, cosmetics and other high value label and packaging applications, the seamless integration of foil embellishments into the digital workflow will give brand owners more possibilities to enhance their products.

Recycling of the inks used for purging and flushing the printheads is engrained in mprint’s concept and has not only a big environmental impact but also reduces ink cost by increasing ink utilization to over 99%. In adherence to the philosophy of mprint to adapt the machines to customers' requirements, the machines can be equipped with a vast array of color options of the digital print engine – CMYK+W+OV+G plus/or spot colors or spot varnishes, etc. – aside from analog options like flexo print stations, etc.

Through the introduction of the mlabel GEN3 series, mprint has advanced its standard UV inkjet narrow web machine portfolio to cover print widths from 4.25” – 12.75” (108mm to 324 mm) and single to multi-color (seven or more) by giving the customer all possible choices in initial price and future machine expansion. Custom machines with print widths of 17" (432mm) and above are also available.

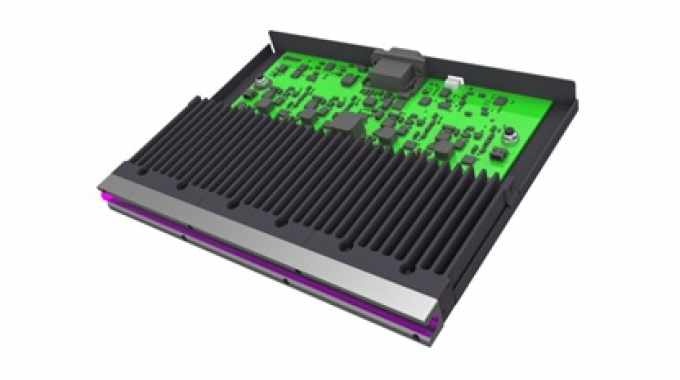

Phoseon introduces first passively cooled UV LED source Phoseon Technology has introduced FireEdge FE100, the first natural convection UV LED light source for industrial curing and wil...

September 26 2018

Phoseon introduces first passively cooled UV LED source

Phoseon Technology has introduced FireEdge FE100, the first natural convection UV LED light source for industrial curing and will show it at Labelexpo Americas 2018.

The FE100 UV LED curing lamp for digital inkjet pinning has no internal fan and is cooled passively through natural convection. A secondary application is edge curing during the manufacture of flat panel displays.

‘With its instant on/off and full intensity control, the FE100 enables precise finish control for digital inkjet pinning,’ said Ed Kiyoi, senior technical marketing engineer at Phoseon Technology. ‘And it’s extremely slim form factor makes it ideal for flat panel display edge curing.’

Using only ambient air for cooling, the FE100, which has an emitting window of 180x10 mm, eliminates the need for any external forced-air cooling system or chiller to remove heat from the UV source.

The FE100 joins the family of Phoseon FireEdge compact air-cooled UV LED light sources that minimize the distance required between inkjet heads, offer a simple, quick programmable logic controller (PLC) interface and provide high reliability and long life.

The FE100 will be available in the fourth quarter of 2018.

W&H furthers development of inkjet press for flexible packaging Windmöller & Hölscher (W&H), a specialist in machinery and systems for the manufacturing and conve...

September 12 2018

W&H furthers development of inkjet press for flexible packaging

Windmöller & Hölscher (W&H), a specialist in machinery and systems for the manufacturing and converting of flexible packaging, has developed an inkjet press concept that will allow the technology to be effectively used in this market.

W&H CEO Dr Jürgen Vutz explained: ‘We see a need in the flexible packaging market to use digital printing in addition to the established processes. This is driven by the need for faster time-to-market and very short order lengths.

‘However, the application of flexible packaging has very special requirements, for example regarding the adhesion of the ink to the film. As specialists in this market, we bring expert knowledge to offer answers to these challenges. First, by continuously advancing the established processes such as flexo and gravure printing. Second, by opening up the possibilities of digital printing for flexible packaging.’

W&H noted that while digital printing is already firmly established in the label and commercial printing sector, flexible packaging continues to be a challenge. An economical and stable digital printing process has yet to be developed, it noted.

To this end, W&H has now begun onboarding partners for its single-pass option, with Xaar providing the piezo inkjet technology upon which the W&H inkjet press is built This will see Xaar 5601 printheads used after successful performance tests. Xaar 5601 printheads use Xaar's new thin film piezo silicon MEMS technology, and offer very high resolution with over 5600 nozzles capable of jetting up to eight litres of fluid per hour. New innovations such as AcuDrp Technology allow complete control over greyscale drop ejection for perfect image quality. In addition, the Xaar 5601 incorporates TF Technology to maximise production up time, print quality and lifetime.

Hermann Veismann, general manager of the printing and finishing business unit at at W&H, commented: ‘We are delighted to be developing our latest system using the Xaar 5601. We saw an opportunity for digital printing in flexible packaging, driven by the need for faster time-to-market and very short order lengths, and aim to overcome the traditional difficulties in this area using our expert knowledge and outstanding new technology.’

Doug Edwards, Xaar CEO, stated: ‘This announcement is a significant milestone for Xaar. Windmöller & Hölscher is a major player in the flexible packaging machinery market and is renowned for placing innovation at the heart of its new product developments. I’m delighted that the Xaar 5601 has been selected for this new development on the basis of the printhead’s high performance.’

W&H has been conducting research in the field of digital printing for several years.

Sven Michael, head of the digital team at W&H, added: ‘We first collected practical requirements, evaluated technologies and tested new approaches. This has resulted in a machine concept that stands out from all existing approaches and provides our customers with added value. We are now implementing this with suitable partners. The new digital machine concept from W&H is characterized by higher quality and higher speeds.’

Vutz concluded: ‘High availability and usability in daily use are our top priorities. Our goal is to go to market with a functioning and mature digital printing machine that delivers on the promises of digital printing for flexible packaging as well.’

Xeikon announces new entry-level solution for digital label production Xeikon today announced an entry-level label printing and converting solution, offered at a price point that bring...

September 07 2018

Xeikon announces new entry-level solution for digital label production

Xeikon today announced an entry-level label printing and converting solution, offered at a price point that brings the lucrative label market squarely within reach for label converters of all sizes.

The Label Discovery solution consists of a Xeikon 3030, an entry-level web-fed digital label press and the new entryDcoat, a digital converting line that can be used inline or offline with the Xeikon 3030. The new solution will be featured at the company's booth at Labelexpo Americas, September 25-27, Rosemont, Illinois.

"Although digital label printing has become a fast-growing mainstream business, some companies are still reluctant to invest in the technology - either due to the cost or lack of a truly professional-quality entry-level solution," said David Wilkins, Xeikon's Vice President of Sales for the North American market. "The lower cost of the Xeikon Label Discovery solution enables these companies to embrace digital technology and capture a business potential that previously required a steep investment - the crucial business of producing short-run labels.

"The Label Discovery solution is a turnkey label production system that provides everything needed to offer an expanded range of services to their customers and to experience the benefits digital production can bring to their businesses. In addition to enabling an affordable entry into this lucrative market, the Label Discovery solution is a platform that can be field upgraded in terms of productivity as the business grows, ensuring long-term viability of the investment."

The Xeikon 3030 digital label press is a dry toner solution ideal for producing labels for a broad range of applications using standard flexo materials. This avoids the need to use specially-treated substrates, and eliminates the associated warehousing costs. Its five-color printing features CMYK and white or even a special spot or gamut-extending color. Changing toner colors on the system is relatively easy, a clear benefit of dry toner compared to other printing technologies. In addition, dry toner is recognized as the best technology for food labels in terms of food safety due to its non-toxic nature. Xeikon dry toner has also received FDA certification for both indirect and direct food contact with dry food, which is unique in the digital landscape.

The entryDCoat is a compact converting unit which consists of a varnish, die-cut and rewind station. To limit startup and tooling costs, the die-cut unit uses semi-rotary die-cutting technology. This ensures the lowest cost converting without loss of productivity while still delivering the well-known quality of conventional die-cutting. With semi-rotary die-cutting, costs can be reduced by as much as 50% with no need to acquire special tools and no setup time as required with conventional die-cutting.

Arrow Systems unveils new finishing unit Arrow Systems, Inc., a long time distributor of digital printing and finishing products, has released a new finishing unit to the market. The A...

September 06 2018

Arrow Systems unveils new finishing unit

Arrow Systems, Inc., a long time distributor of digital printing and finishing products, has released a new finishing unit to the market. The Arrow Eco 300 is a tabletop blade finisher that can diecut up to 15” wide. The system features its own cutting software, as well as inline matrix removal.

“We believe this system has a place in the digital market as it fills a need for a low cost alternative to the blade and laser finishers we offer," says Shaan Patel or Arrow Systems, Inc. “The compact design allows it to be used with any roll-to-roll digital printer, and it can also be used for prepress sampling. It is an extremely economical way to get into diecutting your own labels”

The Eco 300 allows users to switch away from pre-cut media and use continuous media to be cut after printing, which can save users of small digital roll printers a lot of money. “Pre diecut media is extremely expensive, and having an option that allows you to cut your own media without breaking the bank is a nice option for brand owners to have," adds Patel.

Mactac enters craft beer labelling market Officially announcing its entrance into the craft beer labeling market, Mactac Roll Label has launched a new line of all-temperature pressure-...

August 22 2018

Mactac enters craft beer labelling market

Officially announcing its entrance into the craft beer labeling market, Mactac Roll Label has launched a new line of all-temperature pressure-sensitive paper and film craft beer labels.

Designed to meet the needs of today’s craft beer brand owners, Mactac’s new craft beer labels are specially formulated with a variety of facestocks and finishes. With roughly 13 products available, Mactac offers semi-gloss, white and clear film options for bottle applications, as well as chrome films for cans.

“Craft beer packaging is all about shelf appeal, and today’s brand owners are trying to capture a certain look, with only seconds to persuade potential customers,” says Kim Hensley, marketing manager, Mactac Performance Adhesives. “Often, this means the labels on bottles and cans are just as important as the liquid inside. With a goal to stand out as much as possible at the point of sale, brand owners are seeking labels with special effects that give the perception of quality – such as varnishes, textures, the ‘no label look’ and specialty inks, in addition to vibrant, colorful labeling solutions.”

With nearly 60 years in the pressure sensitive adhesive business, Mactac has decades of experience and expertise in producing PS label solutions with a variety of specialty finishes and high-performance adhesive attributes.

Featuring the latest in Mactac’s all-temperature adhesive technology, the new craft beer label solutions are all designed with either Mactac’s industry-leading 640-AT acrylic adhesive or the company’s newest Chill AT hot-melt rubber adhesive. Both adhesives are ideal for cold and damp environments, as well as elevated temperatures. They also contain water resistance properties, maintaining adhesive integrity and aesthetic appeal if exposed to water or moisture.

Converters and printers alike will appreciate that Mactac’s craft beer label solutions allow short- and medium-run label jobs and are available under Mactac’s Precise Program, which allows customers to order less material for smaller runs – an extremely beneficial value-addition in the craft beer labelling market.

Mark Andy adds three new models to Performance Series line Mark Andy has introduced three new press models, P9E, P7E and P5E, to its Performance Series product line, as it seeks to mee...

August 16 2018

Mark Andy adds three new models to Performance Series line

Mark Andy has introduced three new press models, P9E, P7E and P5E, to its Performance Series product line, as it seeks to meet and support ever-evolving converter needs.

The P9E press is specifically designed for high-quality flexible packaging production. Available in web widths up to 26in (660mm), the flexo press is engineered as a production tool to print film, shrink sleeves, flexible packaging and foil lidding.

P9E is built standard with new servo-controlled impression adjustment, independent servo-driven anilox rolls and servo side adjust at print speeds up to 1,000ft/min. Ergonomic efficiency is at the forefront of the wider 22in and 26in web widths, which include plate cylinder loading support as well as an anilox and chamber drawer. Configured with Mark Andy AI, the Performance Series P9E offers advanced automation with automated registration and impression, job save, eight servo motors per station and a centralized control system. The enhancements reduce manual adjustments and associated downtime while meeting Industry 4.0 demands.

The Mark Andy AI package is intelligent and customized to unique business needs, curbing potential production bottlenecks.

Mark Andy identified increased demand for shrink and pouches, coupled with larger volumes of shorter run lengths, as making P9E a ‘profitable platform’ for short run flexible packaging production.

Jeff Cowan, business development director at Mark Andy, said: ‘Mark Andy has over 800 Performance Series installed worldwide. We continue to develop flexible printing solutions that allow our customers to evolve as their job mix changes. The Performance Series P9E is an extension of our commitment and solves the pain points narrow web converters are facing plus the growing demand for shrink.’

The Performance Series P7E has been engineered to allow converters to expand into new markets, targeting entry-level film and extended content applications. P5E is designed to increase converter profitability for the simplest to most complex label applications.

Cowan added: ‘The P5 and P7 have been best-selling models in the Performance Series line, based primarily on the versatility and productivity. The release of the P5E and P7E demonstrates updated servo architecture allowing for tighter registration and a complete redesign of the converting options all focused on providing a better operator experience.’

All three of the new presses deliver an updated ProLED system with air cooling and modular recirculation dryers, both offering sustainability benefits. The machines are equipped with Mark Andy Thread-It technology, which simplifies press webbing for operators and is claimed to be three times faster than traditional webbing methods. Additional press options include Digital Plus Screen, a digital inkjet replacement for rotary screen printing as well as QCDC-SR (Quick Change Die Cut Semi Rotary) adding advanced capability to flexo equipment that is also available on Mark Andy digital hybrid technology.

The Performance Series P7E and P5E are available now for order, with the official unveiling of the Performance Series P9E at Labelexpo Americas 2018.

HP One Package Workflow Suite HP Inc. announced the HP One Package workflow suite for PageWide Industrial corrugated presses, the industry’s first ecosystem for digital corrugate...

August 09 2018

HP One Package Workflow Suite

HP Inc. announced the HP One Package workflow suite for PageWide Industrial corrugated presses, the industry’s first ecosystem for digital corrugated printing. HP One Package offers software and solutions from HP and partners to help converters maximize the flexibility of digital production.

HP One Package workflow streamlines submission and preparation of orders, allowing converters to take advantage of an array of digital value-added possibilities, including solutions for brands’ consumer engagement and piracy protection using variable data, imagery and unique ID serialization. One Package’s production management and automation software also enhances operational performance and optimizes the supply chain.

The suite supports a range of industry third-party workflow solutions, including MIS and pre-press, HP’s powerful print servers, color management tools, and PrintOS cloud-based management applications. HP One Package complements HP’s growing portfolio of corrugated digital presses, including the HP PageWide C500 press for post-print and HP PageWide T1190 for pre-print.

“HP is revolutionizing corrugated printing with digital flexibility, offering high-volume productivity, food-safe inks, and now a sophisticated and integrated workflow solution to drive corrugated jobs from order to fulfillment,” said Eric Wiesner, General Manager, PageWide Industrial division, HP Inc. “Whether converters adopt a strategy for digital pre-print or digital post-print, HP One Package provides an integrated set of solutions for end-to-end productivity.”

HP One Package allows converters to unlock the potential of digital print, while integrating HP digital presses into existing production and business workflows. In addition to HP’s own workflow components, HP selects and qualifies partners and integrates these products. HP One Package workflow suite includes:

HP workflow solutions

Afinia Label unveils mid-run digital label printer Afinia Label, a manufacturer and distributor of industrial color label printing and finishing equipment, has announced the release of...

August 07 2018

Afinia Label unveils mid-run digital label printer

Afinia Label, a manufacturer and distributor of industrial color label printing and finishing equipment, has announced the release of the L701 Industrial Color Label Printer. The L701 is the newest addition to Afinia’s family of products. The L701 offers the speed and performance of Memjet in a new, smaller and more affordable configuration geared toward installations requiring multiple printers across several production lines or locations.

This full-color printer can print directly to inkjet-printable, diecut labels and tag stock. The L701 supports printing roll-to-roll, roll-to-cut – with the option of printing and presenting the label – and can accept fanfold stock for applications where space is at a premium. The L701’s five (CMYKK) 150ml capacity ink cartridges offer convenience and economy over smaller systems on the market, and can produce labels in full-color, with photo-quality, at print speeds up to 40 feet (~12 meters) per minute.

According to Afinia, the L701 has a lower price point, making it a more affordable option where multiple printers are required, and has the smallest footprint available of any production class color label printer currently available. “With the addition of the L701, Afinia offers the most comprehensive line of color label printers available today,” says Mike Atkins, National Sales Manager for Afinia Label. “The L701 has incredible print quality and speed, and it fits a perfect price point between the low volume, economy priced color label printers, and the high volume, production-level printers on the market. This combination of speed and economy will enable manufactures across many industries to implement full color label printing across multiple production lines.”

Nathan Daniel, EMEA Sales Manager for Afinia Label, is excited about how the L701’s purchase price will open the door to a new group of users. He says. “The low price point of the L701 allows those who, in the past, may not have been able to stretch their budgets to a higher yield printer, to take advantage of the many benefits gained by this print technology.”

The L701 is currently available through Afinia Label’s worldwide network of dealers. “We believe the L701 at this price point and size will enable companies to move away from buying printed labels. This will allow purchasers and packaging engineers the flexibility to more efficiently manage their label inventory without sacrificing the look of their brand,” concludes Atkins.