Konica Minolta has launched AccurioLabel 230, the latest version in its digital toner press portfolio. AccurioLabel 230 builds on the AccurioLabel 190 press and is claimed to bring num...

June 04 2019

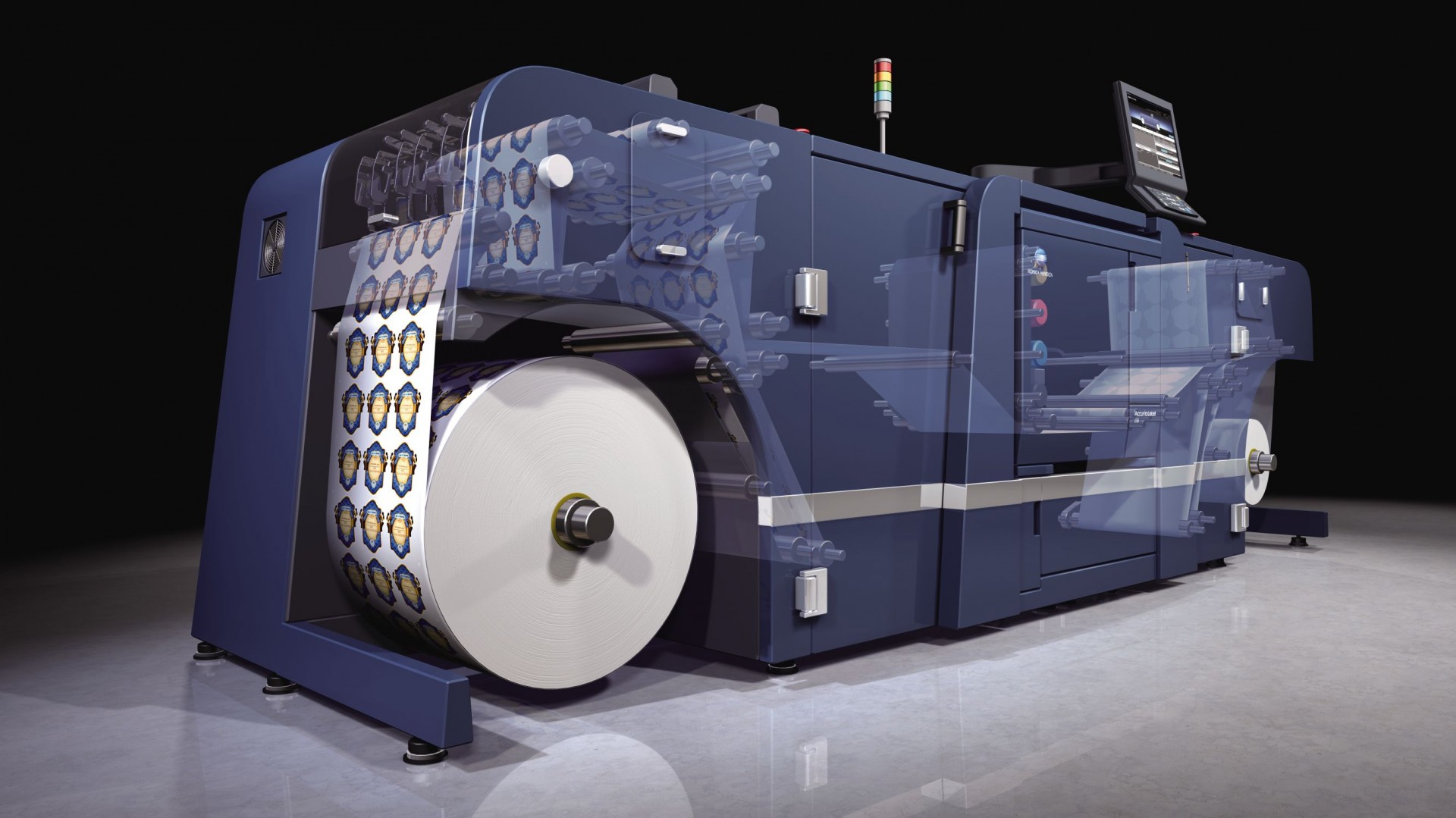

Konica Minolta has launched AccurioLabel 230, the latest version in its digital toner press portfolio.

AccurioLabel 230 builds on the AccurioLabel 190 press and is claimed to bring numerous benefits for customers including productivity, flexibility and stability. It has been built on the established Konica Minolta AccurioPress engine. It is targeted at small- and mid-range segments and is suitable for label printers, print providers, brand owners, packaging companies and commercial printers.

Enhancements available with the 4-color Konica Minolta AccurioLabel 230 include:

- Increased speed, at 23.4m/min and representing up to a 147 percent increase, with most coated/uncoated papers, PP and PET media now able to be printed at full speed;

- Productivity, with continuous highest quality 1200 x 1200 dpi print runs of up to 1000 meters able to be achieved without the need for recalibration; the time taken between jobs has also been eliminated, increasing productivity further;

- Overprinting, allowing printing of pre-printed media, for example overprinting of flexo white pre-printed on clear PP labels; and

- More accurate print registration, with a built-in speed detector for media feeding also cutting paper wastage.

Jon Pritchard, Industrial Print business unit leader at Konica Minolta Business Solutions (UK), explained: ‘With over 350 installations of the predecessor to the AccurioLabel 230, the core technology is proven worldwide. The AccurioLabel 230 is a robust and simple to operate/maintain concept that makes for the perfect entry-level digital label press, with productivity and print quality performance to match and exceed presses over three times the cost.

‘This is truly the most capable CYMK digital label press in the market, when considering performance and investment. Printers looking at entering the digital label market no longer have to compromise on media width, speed or quality. Whilst the AccurioLabel 230 has the price tag of an entry-level press, its performance and flexibility allow it to compete with the long-standing digital label presses in the market. If automation is required then the fully integrated inline semi rotary label finishing solution gives ultimate productivity advantage. The AccurioLabel 230 is the true no compromise entry-level label press.’

Shipments have already started for the new AccurioLabel 230 digital label press, which has been developed and manufactured in Europe with Danish firm Grafisk Maskinfabrik (GM).

AccurioLabel 230 will be officially shown in public for the first time at Labelexpo Europe 2019.

Afinia Label, a manufacturer and distributor of industrial colour label printing and finishing equipment, in conjunction with Sihl, Inc., are announcing the certification of BS 5609 (Section Three)...

May 28 2019

Afinia Label, a manufacturer and distributor of industrial colour label printing and finishing equipment, in conjunction with Sihl, Inc., are announcing the certification of BS 5609 (Section Three) from Smithers Pira for the L501 label printer, with pigment ink, when using PICOFILM O-60 White XM1 BOPP (polypropylene) label material.

Compliance with BS5609, the British Standard for pressure sensitive adhesive warning labels required for hazardous chemical containers shipped by sea, ensures labels stay intact, and remain legible. In the event of a maritime accident, durable labelling is crucial in keeping responders safe from injury and aiding in rapid containment and clean up of potential environmental hazards.

In order to meet this Section 3 standard, the specific printer, ink formula and label material must be tested. All aspects of the printed label, including ink, and label base material, must meet minimum durability benchmarks. This testing evaluates the permanence of the print through abrasion and submersion in salt water for a period of 90 days.

The Afinia Label L501 Duo Ink Color Label Printer’s ability to produce BS 5609-certified and GHS (Globally Harmonised System) labels keeps chemical manufacturers compliant with OSHA mandates. The consequences for failing to comply with these standards include significant fines, penalties and the possibility of irreparable damage to a manufacturer’s reputation.

Sihl offers a coated BOPP film for aqueous inkjet printing with PicoFilm O-60 white XM1 from the Facestock range for this purpose. Within the framework of the new GHS standards (globally harmonised system of classification and labelling of chemicals), the product is ideally suited for the labelling of hazardous goods transported by sea. It is characterised in particular by its high resistance to abrasion and water.

Mike Atkins, national sales manager of Afinia Label, says, “Afinia is pleased to offer a fully compliant solution to companies needing to properly and safely label products. The pigment-based inks used in the L501 along with certified materials have proven durability. The L501’s ability to print media up to 8.65" wide delivers flexibility for labeling small containers, industrial drums and everything in between.”

In addition to its high-durability pigment inks, the L501 is compatible with dye inks that give labels maximum colour vibrancy. The L501 is best suited for small- to medium-sized print runs. It can print large labels with a media width up to 8.65" (219.7 mm) wide. The L501 uses separate CMYK ink cartridges that contribute to a lower cost per label, since only colours that are empty need to be replaced. It is also available in a fanfold-compatible version.

In-house printing offers opportunities to save time, save money and reduce waste. By printing labels in-house, it is possible to create clean, professional labels that are easy to modify. With in-house label printers, it is possible to design and create labels for different types of packaging that specific products require.

Labels give products their unique identity and influence the impulse to buy at the point of sale. Accounting for around 5% of the global print volume of approximately EUR 400 billion, today the lab...

May 22 2019

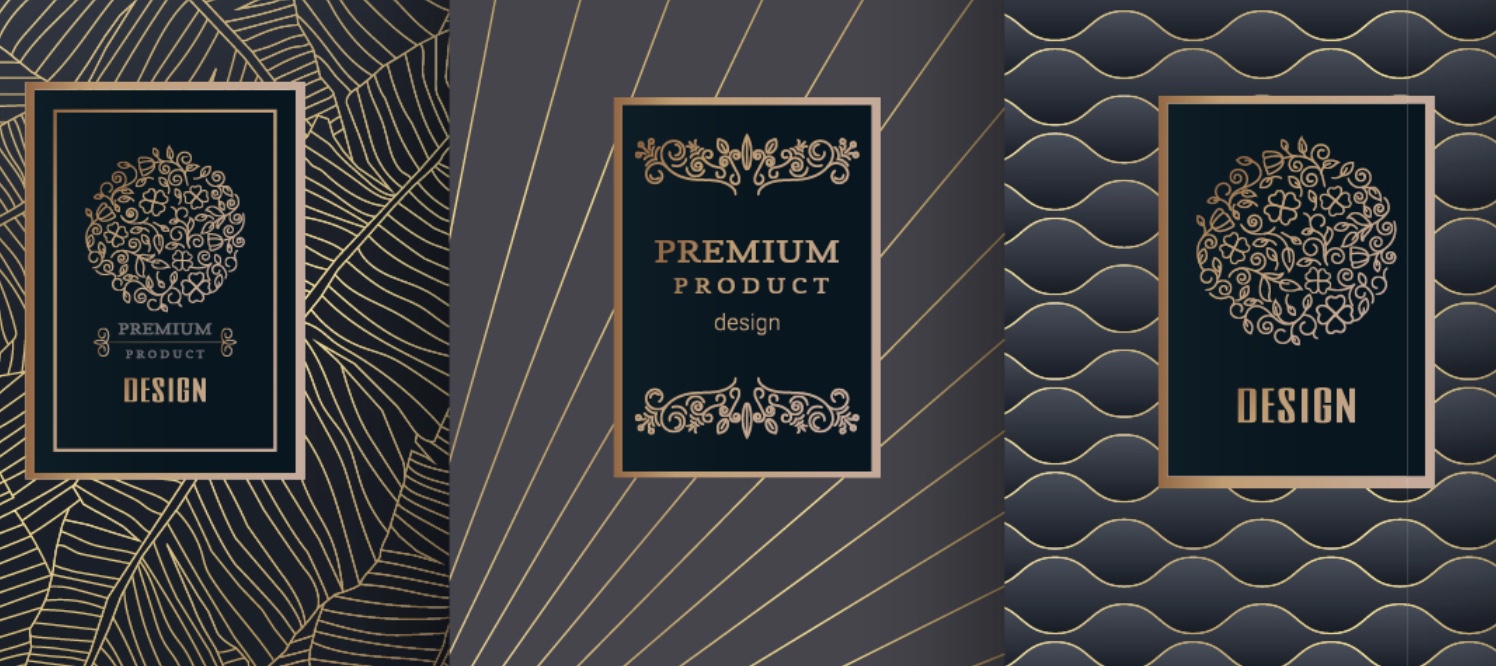

Labels give products their unique identity and influence the impulse to buy at the point of sale. Accounting for around 5% of the global print volume of approximately EUR 400 billion, today the label market has the greatest growth potential in the printing industry, and has evolved from a niche segment to a sizable industry over the last few decades. The associated knowledge base has also greatly increased hand in hand with this evolution, and today is differentiated on the basis of a remarkable variety of different printing technologies, applications, substrates and further consumables.

In the digital age it was just a matter of time before the stakeholders in this industry, in other words users, manufacturers, associations and market research institutes, bundled this knowledge and made it available on a digital platform. With immediate effect, the new knowledge portal in English for all things label printing can be found at https://label-experts.com. This expert forum was started as a joint project between Heidelberger Druckmaschinen AG (Heidelberg) and its subsidiary Gallus.

“Heidelberg’s strength lies in its knowledge of its customers and their issues,” explains Professor Ulrich Hermann, Member of the Management Board responsible for Lifecycle Solutions and Chief Digital Officer at Heidelberg. “This is where our future customer communication begins, not just with the product. Our customers in the label printing industry will be able to access exclusive expert knowledge with this platform presence. Only if we are able to prove to our customers that we understand the label printing industry, will our customers continue to place their trust in us for their most important investment decisions.”

According to Heidelberg: "In a highly dynamic environment, the requirements for label solutions are changing faster and faster nowadays. Following the trend of customisation, the market is increasingly demanding shorter runs as well as versioned and localised labels. Distinguishing features are becoming more and more important, thus the demand for just-in-time deliveries and labels with unusual embellishments is growing. For the latter, more and more creative formats are being found: labels as on-pack promotion deliver advertising messages in the smallest of spaces and can be broadened from a leaflet to a mini brochure. Special effects are produced using inks that light up in the dark or heat-sensitive inks that are visible within a limited temperature range. The wealth of variants is almost infinite. The variety of the applications is matched only by the multi-faceted nature of the content on https://label-experts.com. Awaiting users of this platform are newsletters, technical articles, the latest market research results, white papers, tips for their next investment, and much more."

You can register here: https://label-experts.com.

New collaboration with Avery Dennison and The Future Laboratory explores the implications of today’s trends on the future of label and packaging design Oegstgeest, Netherlands --...

May 21 2019

New collaboration with Avery Dennison and The Future Laboratory explores the implications of today’s trends on the future of label and packaging design

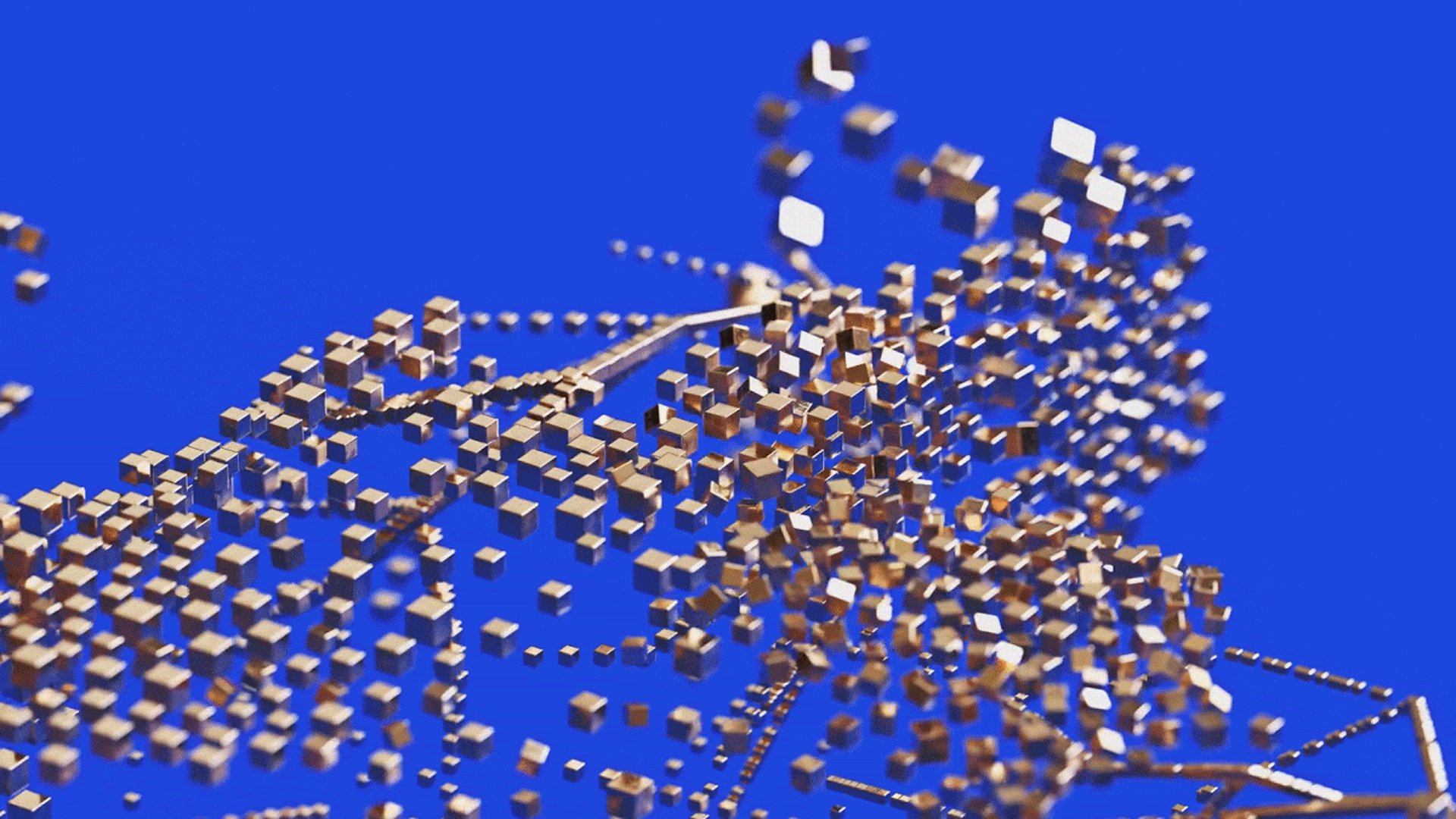

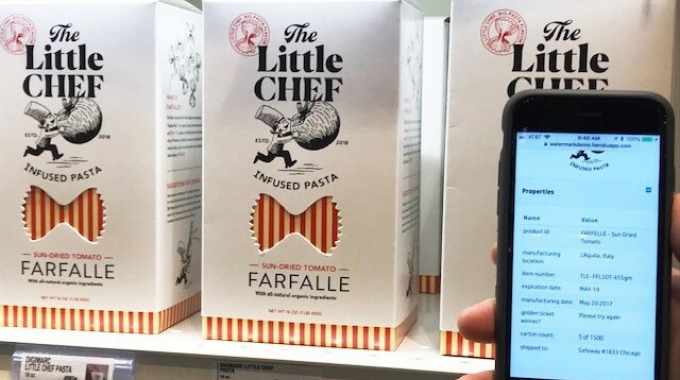

Oegstgeest, Netherlands -- May 8, 2019 — Avery Dennison announces a new original content series , authored by future forecasters, The Future Laboratory. The monthly online column, based on proprietary research, provides insights on global drivers, macro and micro trends and their impact on consumers, brands, and the label and packaging industry.

In the first release, available today, the renowned forecaster considers blockchain as a way to make labelling data more robust, information transparency more accessible, and ultimately empower consumers about their purchasing decisions.

“Product labels have many functions – to be eye-catching and attract attention on the shelf is one, but perhaps the most important function is to inform consumers. And yet in recent years, the data on labels has left many wanting. Almost half (48%) of consumers feel that they do not know enough about a product despite reading the label (source: Label Insight) ,” said researchers at The Future Laboratory.

In the new release , The Future Laboratory shows how blockchain, as a distributed digital ledger, can offer transparency beyond the label. “...Unlike any other digital database, a blockchain entry cannot be changed once it is logged, giving it a high-trust value,” they said. Blockchain-enabled products offer designers a chance to create engaging, immersive packaging that encourages customers to delve beyond the label and into a brand new world of transparency.

“When combined with emerging technologies, a product’s labelling can empower consumers about their purchase decisions, offering new levels of transparency,” said Amy White, vice president, communications and brand, Avery Dennison. “As material science and technology pioneers being up to date on these insights is essential .”

“As futurenauts, forecasters, and analysts of tomorrow, we seek out those places, portals, people, and processes that allow us a glimpse at what could be when designers, scientists, packing creatives, and material specialists mix and merge talent with insight, the obvious, with the counterintuitive. The team behind M_use, one of those platforms that we visit regularly, and Avery Dennison, sit within this category and culture,” said Martin Raymond and Christopher Sanderson, co-founders, The Future Laboratory.

Epson Australia has announced the launch of a new compact point-of-sale printer capable of receipt printing, slip printing and cheque processing in one unit, and offering improved reliability, usef...

May 07 2019

Epson Australia has announced the launch of a new compact point-of-sale printer capable of receipt printing, slip printing and cheque processing in one unit, and offering improved reliability, useful connectivity features and a very low total cost of ownership. Amongst other retailers, the TM-H6000V is aimed at shops and businesses that require cheque-processing facilities at point of sale, and want to print receipts with the same unit.

The TM-H6000V prints at speeds up to 350mm/s¹, offers faster cheque processing than its predecessor, has a faster auto-cutter, and offers a selection of other improvements that help businesses boost overall efficiency. It also helps minimise downtime with improved reliability.

The thermal printer is now effective for 200 km of receipts, while its auto-cutter is capable of three million cuts.

The printer is flexible enough to adapt to the demands of a modern retail environment, with new features including Server Direct Print (SDP) to permit web-based printing, as well as multiple interfaces for tablet and PC coexistence. ePOS-Print, ePOS-display and NFC tagging allow simple and quick tablet POS set-up, for businesses moving into tablet-based POS.

Designed with significant business critical improvements, the TM-H6000V multifunction hybrid printer supports advanced functionality to 'future proof' the product for many years to come.

In short the TM-H6000V helps businesses maximise the efficiency of their in-store printing so they’re constantly ready for the ever-changing world of retail.

TM-H6000V Key Features:

- Connect to multiple devices ― printer can be dynamically shared by legacy POS terminals, tablets and mobile devices, as well as cloud servers

- Triple-interface connectivity to future-proof growing businesses ― maximum flexibility with three options, including built-in USB and Ethernet2

- Less down time ― remote monitoring of the printer’s status and part life expectancy3

- Fewer service calls ― intuitive control panel with visual error notifications

- Designed for the cloud ― supports printing from Web-based applications utilising Epson's ePOS™ print technology; plus, utilise Server Direct Printing for online ordering support

- Distributed proximity-based printing ― through Epson’s Beacon support using BLE (Bluetooth® Low Energy)4; and, through NFC (Near Field Communication) technology for easy pairing with mobile devices5

- Advanced paper-saving functions for thermal receipts ― top-margin and character height reduction features help reduce paper usage by up to 47%6

- Reliability ― printhead reliability of 200 km and extended auto cutter life of 3 million cuts7

- Fast transaction times ― print speeds up to 350 mm/sec1, plus a high-speed auto cutter

- Fast check processing ― high MICR reader accuracy

1. Maximum print speed may not be achieved depending on the paper utilised, type of interface, data transmission conditions and combination of commands.

2. Built-in USB and Ethernet interfaces, with additional options of serial, parallel, Bluetooth and Wi-Fi interfaces

3. Requires customisation with third-party applications.

4. Requires the use of a beacon dongle connected to TM-H6000V printer via the USB-A port. Supports only Apple® iBeacon™ compliant format. The Epson-approved dongle is Laird model BT820.

5. NFC tag requires use of a device that includes an NFC reader, and may require additional software

6. Paper savings depend on the text and graphics printed on the receipt.

7. Rated printhead and cutter lives based on use of the following media only, with printer operated at room temperature and normal humidity:

Model KT55FA: Papierfabrik August Koehler SE

Model PD160R: Oji Imaging Media Co., Ltd.

Model TF50KS-Y: NIPPON Paper Industries Co., Ltd.

This new paper, made from grass, provides an eco-friendly label material for organic product brand owners. This label is usable on a wide range of product types (foodstuff, cosmetics, wine, pet foo...

April 30 2019

This new paper, made from grass, provides an eco-friendly label material for organic product brand owners. This label is usable on a wide range of product types (foodstuff, cosmetics, wine, pet foods) and is particularly suitable for labeling clothing.

The manufacturing process for conventional wood pulp uses 6,000 litres of water per ton – compared to 1 litre used in the production of this grass-based product; known under the reference 261. It has a permanent adhesive for small surfaces on a variety of substrates. This general-purpose adhesive is approved for direct foodstuff contact and has been awarded ISEGA Institute certification. As an option, AstroNova can also provide an acrylic dispersion adhesive, which is removable without leaving residue, from a variety of substrates.

The light brown colour of Grass paper means that a vintage-style label can be achieved without the need for additional processing.

Lintec Europe has introduced a range of easy-to-apply labelstocks featuring a ‘micro-canyon structure’ that prevents the formation of air bubbles beneath the label upon application.

April 23 2019

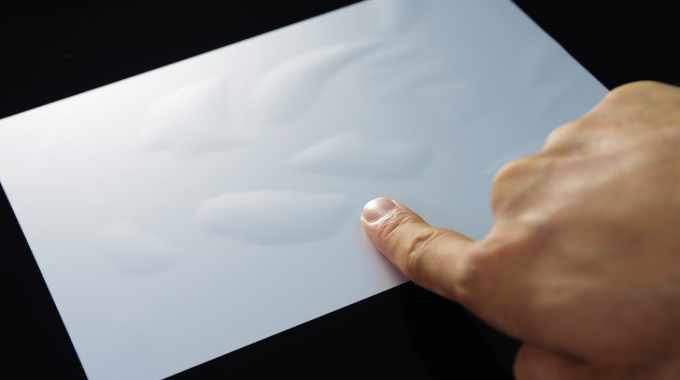

Lintec Europe has introduced a range of easy-to-apply labelstocks featuring a ‘micro-canyon structure’ that prevents the formation of air bubbles beneath the label upon application.

The labelstock is claimed to be particularly effective for information labels on home appliances or electronic devices, as well as large labels in the graphics market that require a high level of air-release performance. A UL-recognized product, the labelstock is also resistant to blistering caused by outgassing emitted by certain plastic surfaces.

‘The two key advantages of this product is that it is easy to apply and outgassing resistant,’ explained Soichiro Fujinaga, technical manager of Lintec Europe. ‘The labelstock features an innovative air release adhesive mechanism, facilitated by a specially designed textured adhesive surface that incorporates miniscule air channels, hence the name “micro-canyon”. As the label is applied to the surface, the air escapes via the channels, avoiding the formation of bubbles and resulting in smooth adhesion.’

Soichiro said the labelstock is also particularly effective for overcoming the problem of blistering caused by outgassing: ‘Blisters have long been a source of dissatisfaction as they are difficult to remove and they affect the visual presentation of a label. The cause of this phenomenon lies in certain plastics, such as polycarbonates, which emit gasses over time and under the influence of rising temperatures, leading to the formation of blisters under the label. Our product is the ideal countermeasure against this issue and removes the possibility of label delamination.’

With a UL969 certification, the bubble-free labelstock range is compliant with the safety standards issued by Underwriters Laboratories. ‘It is quite common to have products comply with UL Standards, and many home appliances are UL-approved,’ concluded Soichiro. ‘Certification is a responsibility we take very seriously at Lintec and a UL969 label means that our customers can be confident they are investing in a reliable product.’

A new selection of colour-shifting foils, which enable designers to develop eye-catching brand enhancing packaging, has been launched available by Fresnels Innovations. New ‘Scar...

April 23 2019

A new selection of colour-shifting foils, which enable designers to develop eye-catching brand enhancing packaging, has been launched available by Fresnels Innovations.

New ‘Scarab’, which reflects the iridescent colours of the eponymous beetle, and ‘Opal’, which takes its inspiration from the colour effects seen in mineral gem stones, follow the launch of the optically variable foil (OVF) Peacock stamping foil in 2018.

The latest foils will feature as part of a select range of eye-catching colour-shifting effects from Fresnels Innovations, designed to improve recyclable packaging through the use of stamping foil technology instead of inks.

Both are opaque foils but feature within their formulation either basic pigmentation (Scarab) or a reflective surface (Opal).Precision engineered to produce sophisticated optical elements, they deliver highly individual added-value packaging effects, which provide a striking visual appeal designed to catch the eye of consumers in the retail environment.

Unlike colour-shifting inks, which only change when tilted relative to viewing light, the foils also alter colour when rotated. When applied to curved surfaces, the full gamut of colour changes can be seen at a single glance.

Developed for high speed machine application and available for either hot stamping or cold transfer applications, each foil can be applied quickly and easily without the requirement for registration equipment.

COO Dr Glenn Wood said the new products will add novelty to packaging applications: ‘We are achieving similar colour changes to optically variable inks with our foils, thus providing branded packaging with customer engagement and visual effects previously found only on banknotes and other government security documents.’

Fresnels Innovations is working with a Taiwanese manufacturer of folding cartons to produce new eye-catching plastic free packaging, which is both 100 percent recyclable and FSC carton board certified.

Xeikon has announced a digital printing solution for pouches. This latest innovation has been developed for consumer goods markets – food, beverage, chemical and pharmaceutical industries. Th...

April 16 2019

Xeikon has announced a digital printing solution for pouches. This latest innovation has been developed for consumer goods markets – food, beverage, chemical and pharmaceutical industries. The digital process for printing on pouches responds to current trends, i.e. significant numbers of SKU’s, shorter lead times, and the rising popularity of pouches in store. Brand owners looking for shelf impact for their products are drawn to flexible pouches for their ability to stand, their light weight and their sustainability. Xeikon has simplified a key part of the overall production process to provide a fast turnaround solution.

Filip Weymans, Xeikon’s Vice President Marketing, says: “This is a prime example of what we call 'customer driven innovation.' By focusing on this application, we are supporting our customers’ requirements and also responding to the current trends in consumer preference. This development takes our digital production portfolio to the next level. With its technological expertise, Xeikon is ideally positioned to provide innovative digital processes.”

Pouches can be reasonably complex to manufacture because of the flexible nature of their multi-layers. It is essentially a laminated bag made from several layers of material that requires a number of different steps in production. Xeikon is helping to simplify the overall process to provide a fast turnaround solution. By firstly digitally printing the text and graphics on a thermal laminate, the outside layer of the pouch is prepared and ready for the next steps. A variety of different layers is then constructed by lamination with a series of barriers for protection before the pouch is finally put together in the manufacturing process. Xeikon’s digital printing solution offers the lowest possible complexity and the broadest lamination construction possible.

Marketers and brand owners see a lot of value in this kind of packaging for a variety of reasons, such as product presentation and functionality for the consumer. Pouches can also be sustainable: a pouch has a so-called "product-to-package" ratio of 35:1, which essentially means that it can carry up to 35 times its own weight, resulting in less energy consumption to produce and to transport. Pouches can have a variety of different shapes depending on size, end-use application and functionality. Many brands are transitioning from rigid types of packaging to more flexible versions such as pouches.

Digital printing with Xeikon’s dry toner technology has many advantages. It is not only the highest print quality on flexible substrates but there are also reductions in start-up costs and no job changeover costs. Importantly, the printer has the ability to print variable data information in both single and full colour. Xeikon’s digital dry toner technology allows JIT production, versioning and last minute adaptations on the fly. For busy print operations with a high volume and complex jobs looking to assess which process and technologies will give them an advantage, the crossover point for flexo and the digital process is at least 4000lm.

Weymans concludes, “Xeikon continues to develop new innovations for diverse markets to meet today’s challenging and fast moving world of consumerism. With our broad technology portfolio, we are in a perfect position to respond to current market trends and develop any solution required. Our digital printing solution for pouches utilises our dry toner technology, which comes with a guarantee for food safety. This technology also ensures consistency and an equal finish to offset (am screen) and to flexo when colour matching is required. With our aXelerate programme, our dedicated teams provide direct and personal training and support for our customers every step of the way. Xeikon is committed to providing only the very best products and services.”

Epson today announced a new high productivity, industrial UV Digital Label Press, the SurePress® L-6534VW, which will be on display at PRINT CHINA 2019 in Guangdong from April 9-13 at Epson&rsq...

April 09 2019

Epson today announced a new high productivity, industrial UV Digital Label Press, the SurePress® L-6534VW, which will be on display at PRINT CHINA 2019 in Guangdong from April 9-13 at Epson’s booth 1226 in Hall 1.

The new SurePress L-6534VW prints at speeds of up to 50 meters per minute for higher productivity, with improved reliability and usability. The new competitively priced SurePress UV inks comply with the European framework Regulation ((EC) No. 1935/2004) on Food Contact Materials (FCM).

The label press combines PrecisionCore® print heads around a central impression drum to provide outstanding image quality and precise colour to colour registration. With Epson’s proprietary Nozzle Verification Technology and automatic head maintenance, manual intervention by an operator is minimised. The SurePress L-6534VW uses low migration CMYK inks with a high opacity white as standard and includes an innovative in-line digital varnish for value added label production.

A high precision web feed system ensures substrate waste is minimal and provides consistent re-registration on a pre-printed roll. Together with a corona treater, web cleaner and ioniser the press provides versatility in print production. In addition, the new model offers faster full colour variable data printing and supports a wide range of label substrates for many different applications.

You can experience the latest in Epson Industrial UV inkjet technology at PRINT CHINA 2019 (April 9-13 2019, Booth 1226 Hall 1), PrintEx 19 (Sydney, August 13-16, 2019) and Labelexpo Europe 2019 (Brussels, September 24-27, 2019)

The new SurePress L-6534VW will begin shipping later in 2019.

www.epson.com.au

This involves reverse printing on the surface material and then using dry lamination to produce the packaging structure. This uses a specially developed water-based adhesive from Michelman to maxim...

April 02 2019

This involves reverse printing on the surface material and then using dry lamination to produce the packaging structure. This uses a specially developed water-based adhesive from Michelman to maximize bond strength between the dry toner inks and the packaging material.

Filip Weymans, vice president, marketing at Xeikon, noted that flexible packaging has been able to be produced using Xeikon’s presses for a while, when you consider products such as sleeves, wraparound labels and some paper-based products, but doing pouches opens up new potential revenue streams for its customers.

Weymans said: ‘This is a prime example of what we call “customer driven innovation”. By focusing on this application, we are supporting our customers’ requirements and also responding to the current trends in consumer preference. This development takes our digital production portfolio to the next level. With our technological expertise, Xeikon is ideally positioned to provide innovative digital processes.’

Xeikon has worked with UK printer CS Labels, a digital-only company, to develop dry toner pouch production. CS Labels has further developed its own in-house 6m-long converting line to allow it to produce converted flexible packaging.

Sihl has cooperated with various component manufacturers to develop Artysio. This has seen Sihl’s expertise in media for digital printing, combined with digital printing technology, create a ...

April 02 2019

Sihl has cooperated with various component manufacturers to develop Artysio. This has seen Sihl’s expertise in media for digital printing, combined with digital printing technology, create a system to allow local narrow web printers to produce small quantities in custom designs. Machine add-ons for converting and the packaging material from Sihl make this possible for narrow web printers.

In a video highlighting Artysio, the example of a car dealership group is used. Frey Automobile wants to produce herbal sweets with a unique design for each location for a company anniversary. The Artysio system is claimed to be suitable for the production of food-safe, high-quality flow-pack packaging that can be printed using environmentally friendly water-based inkjet printing. Frey Automobile is shown to benefit not only from efficient production, but in particular from ‘brilliant’ printing results. The food-grade barrier layer of the material with very good sealing properties guarantees a long shelf life for the sweets and prevents ink and undesirable substances from getting in.

Depending on the type of machine add-on, the narrow web printer can also package many other products, such as soaps for hotels, tea, biscuits, coffee beans and a variety of other items. Sihl supplies the appropriate material for a variety of packaging types.

In a statement, Sihl noted: ‘It‘s that easy to open up a broad new business segment for print shops, from which the car dealership group and many other customers such as start-ups, for example, can profit, who can have small packaging runs and customised solutions produced without sacrificing quality.’

Click here for more information.

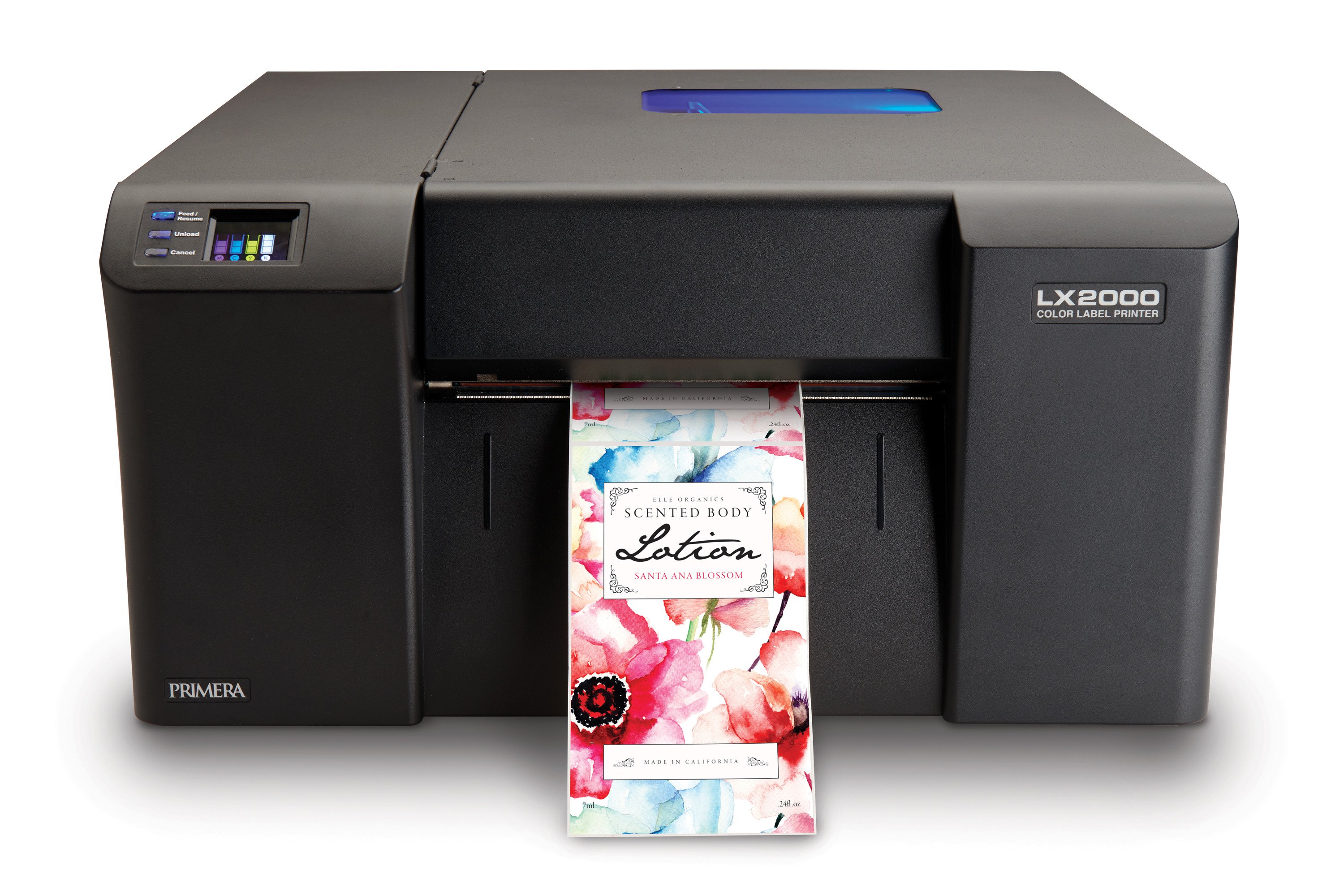

Primera Technology, Inc., a global manufacturer of specialty printers, has announced its new LX2000 colour label printer. LX2000 is Primera’s fastest-ever desktop colour printer, producing la...

March 20 2019

Primera Technology, Inc., a global manufacturer of specialty printers, has announced its new LX2000 colour label printer. LX2000 is Primera’s fastest-ever desktop colour printer, producing labels at speeds of up to 6” per second – about 25% faster than Primera’s best-selling LX900 colour label printer (for comparable print quality).

Large, separate ink cartridges for cyan, magenta, yellow and black keep the cost per label low. Other features include pigment-based ink for stronger resistance to UV light, chemicals and water, built in “pizza-wheel” cutter, viewing window to see label stock levels and wired Ethernet or USB 2.0 and wireless connection options.

“LX2000 represents an entirely new product class in desktop label printing,” says Mark Strobel, Primera’s VP of sales and marketing. “With large ink tanks, we can offer an extremely competitive cost per label. Our print speeds rival printers that cost up to three times more. We have pigment ink that has far more resistance to water, chemicals and UV light. Print quality is superb. Add to that our wired Ethernet or USB 2.0 or wireless connection options, along with 8” print width and you’ve got everything most companies would ever need. With LX2000, there are only benefits and no compromises.”

Typical applications include product labels for coffee, wine, water, bakery, confectionary, meat, cheese and hundreds of other specialty and gourmet foods. LX2000 is also ideal for private labelling, test marketing, pre-press proofing and retail labelling.

With its pigment ink and Primera’s Tuffcoat Extreme PolyJet material, LX2000 has already passed Section 3, BS5609 testing. The testing included removal of print by adhesive tape, abrasion resistance and permanence of print evaluations under extreme conditions, including exposure to UV light and repeated salt spray and immersion. The material and printed images from LX2000 passed in all three categories.

Printer drivers are included for Windows Vista/7/8, along with Bartender Ultralite Software (for Windows) to format label designs, add bar codes, QR codes, etc. Most other popular graphic design programs for Windows can be used to design and print labels. A Mac driver is currently under development.

Qualified substrates include many different inkjet label materials, including Primera’s exclusive Tuffcoat Extreme white and clear polyester and white BOPP, as well as the new Tuffcoat Extreme PolyJet. Paper labels are also available in high-gloss, semi-gloss and matte finishes.

Label Image has invested in a Durst Tau 330 E UV inkjet press to support its ongoing commitment to operational growth and high quality customer service. Formed in 1986, the Australian company was a...

March 13 2019

Label Image has invested in a Durst Tau 330 E UV inkjet press to support its ongoing commitment to operational growth and high quality customer service. Formed in 1986, the Australian company was acquired by Nick and Emma Godwin in 2015. Since then they have made a number of improvements and investments focused on driving growth and maintaining a high level of service and support for their expanding customer base.

Today, Label Image is recognised for its innovative sales team, e-commerce shop front and digital printing systems. It challenges the market with new ideas and solutions developed from its understanding of customer needs. It executes environmentally astute print-on-demand solutions that reduce inventory and deliver shorter turnaround times.

The latest in digital inkjet technology was chosen to complement Label Image’s conventional label printing systems. Explains Nick: "We first assessed the basics of adaptability, reliability, quality and the opportunities offered to enhance their client offerings. The Durst Tau 330 E ticked all those boxes and more. Its productivity, print quality and colour consistency were stand out capabilities.

“During the extensive decision-making process the growth potential for Label Image was crucial. We considered the option of additional services and offerings but also wanted a return on investment (ROI) model that made sense and allowed us to scale up to meet future demand. We also recognised that having a lower capital cost press doesn’t always equate to a lower total cost of print.”

Emma continues: “The Durst Tau is remarkable at reducing media waste. We can print a press proof and rewind the media to the next label start point and immediately begin printing with no waste. This means the first label is a billable label, reducing waste and costs, something I have not seen on any other press to date. Nor have I seen this level of image quality on any other inkjet press.”

ROI was not the only consideration when investing in the Durst Tau 330 E. Important, too, was the broad range of media it could handle without the mess, cost or sourcing of primers or post coatings on materials. They range from direct thermal, cosmetic, food and beverage to industrial. In fact, it covers most commercial labels. Other convincers were the stunning white ink opacity achieved in the single pass print process reducing production time and operator flexibility.

Label Image’s single-pass direct printing Durst Tau 330 E has no blankets or transfer components that could compromise printed colour or densities. It is coupled with the Durst Workflow Label system including variable data printing, to deliver a consultative and creative approach. It has enabled Label Image to keep in-house fast turnaround and difficult jobs such as short and mid-sized run lengths, customised and personalised labels, multi SKUs, promotional and pilot applications.

It also includes back up and support from Durst and its Australian partner Photo Electronics Services (PES). Nick concludes: “Our experience with Durst and PES has been excellent both from a pre and post installation perspective. The installation was completed within a week and operators trained immediately after allowing us to transition into production sooner than expected.”

Helmuth Munter, Segment Manager, Durst Label & Packaging Printing, said: “It is great to see another company such as Label Image adopting our ‘Configure Your Digital Future’ approach by partnering with us to support their business growth aspirations and investigate new markets. We are delighted to be able to support their ambitious goals and help them expand their business reach.”

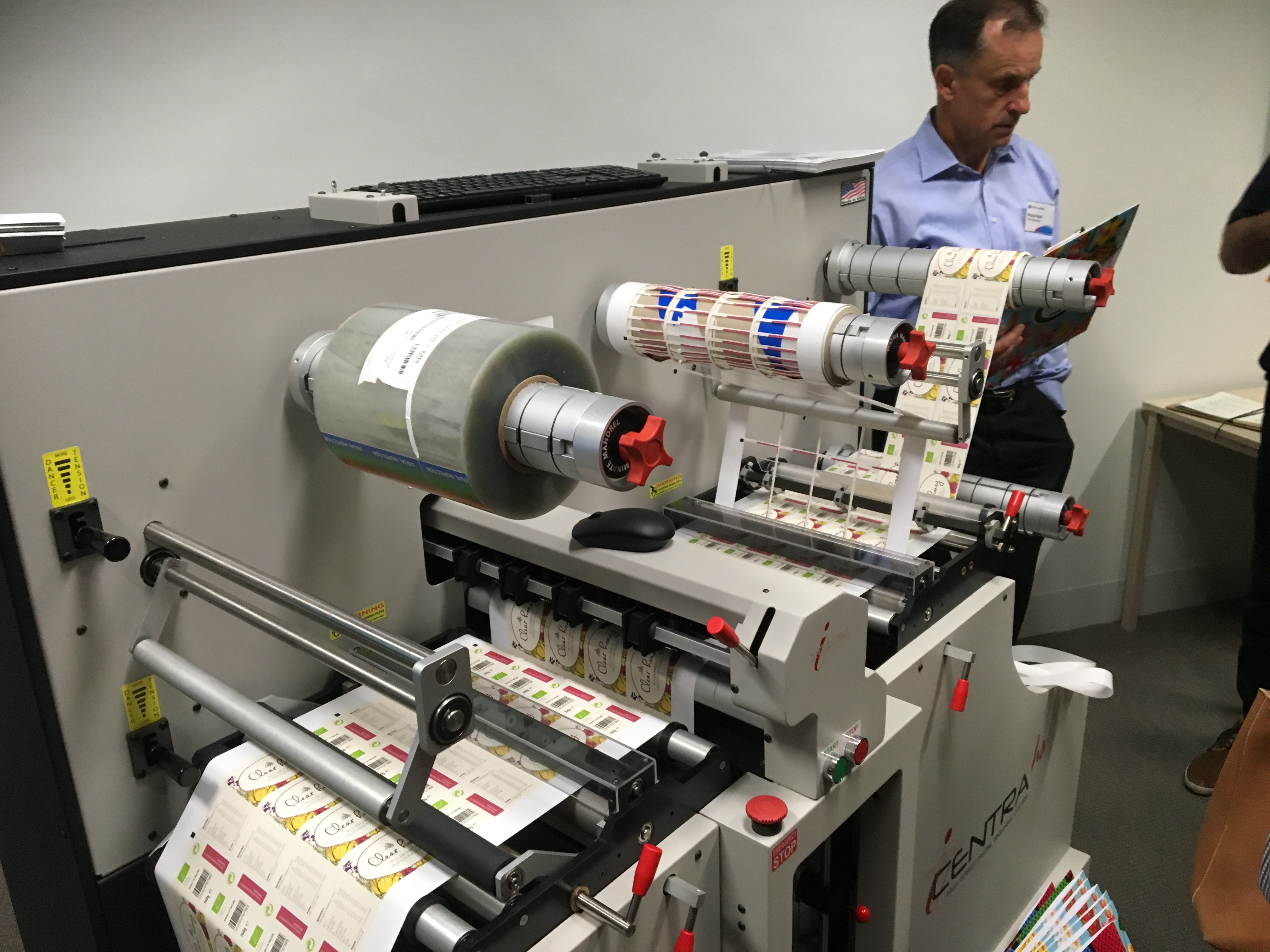

A full house of industry professionals enjoyed an inside look at the advantages of digitally printed label technology and support systems from Konica Minolta for short to medium run jobs.

March 12 2019

A full house of industry professionals enjoyed an inside look at the advantages of digitally printed label technology and support systems from Konica Minolta for short to medium run jobs.

Held at the Printing Education Centre at Victoria’s Holmesglen Tafe, presenters from Konica Minolta, in conjunction with software and systems providers XMPie and PrintIQ, talked about the advantages of the AccurioLabel 190 label press, online ordering and data management systems and integrated production software. Guests also got a look at the iTech CENTRA HS finishing system.

A series of five speakers gave presentations in their area of speciality, taking guests on the journey from the moment an order is placed online, to the point at which the final product receives specialist finishing.

The first presenter was Enda Kavanaugh, Asia Pacific Sales Manager, XMPIE. Enda talked about the ability of variable data to increase the value of a label by enhancing the emotional connection to the final recipient. Campaigns such as personalised Vegemite and Nutella labels demonstrated the success by which variable data label printing can bolster the perceived value of the final product, something that customers will willingly pay for.

“Personalised packaging is worth 40 per cent more,” said Enda. “We’ve seen this happen with the Vegemite and Nutella campaigns. If a jar of Nutella is $6, I can add a personalised label to it and can sell it for $12. There is significant emotional content that can be created by the label if you make it available to the person.”

Next to present was Adrian Fleming, Global Sales Director, PrintIQ. Adrian detailed the PrintIQ process showing which print device will give the best profit margin for a specific job (including all variables), and the benefits this delivers for estimation and quotes, as well as streamlining the whole production process.

David Cascarino, National Manager Industrial Print, Konica Minolta, presented the benefits of the AccurioLabel 190 for short and medium run variable digital label printing. Released in 2016 at Konica Minolta has sold 300 units worldwide with 10 currently in operation in Australia.

“The AccurioLabel 190 has certainly found a niche in the marketplace because of the wide range of applications and industries that it caters for,” said David. “We are talking about labels for the liquor and beverage industries, industrial products and medical labels because we have got FDA compliance.”

“The AccurioLabel 190 is 1200 x 1200dpi capable, meaning image quality is equal to our sheetfed presses. “The printer supports a 330mm web at a print rate of 18.8mpm, and due to the use of dry toner, no pre-coating is required giving it the ability to print on a wide range of stocks.”

The Konica Minolta AccurioLabel 190 is indeed an impressive machine. The capabilities and growing demand for variable data printing is well documented, so too the growing trend of shorter and medium-run label production. With its advanced capabilities it is easy to see why the AccurioLabel 190 is in demand.

Following David was Joseph Brown, Sales Executive, QLM, who spoke to attendees about the iTech CENTRA HS label finishing system. The machine is a high-speed, roll-to-roll digital converting system that allows users to laminate, die cut, strip and slit custom labels in one production pass. Joseph detailed the advantages of the system and how, with minimal training, and operator could be very proficient with this easy to use technology.

Completing the event was Paul Ross, Program Manager at the Holmesglen Tafe print centre. Paul commended Konica Minolta for the company’s complete support of the centre, and the technology and training support they had provided.

Paul stated that the program was designed to cater for all aspects of the industry, not just digital print, and had seen an increase in the number of students currently enrolled.

“We’ve had an increase in the number of people wanting to do the course,” said Paul. “We currently have 17 people in one group, with 25 more waiting to do the second course starting in May. Students come here for four days each week, with one day a week being spent in work experience with companies looking for apprentices or an employee and that go on to full time employment,"

There was certainly a lot to be learned from the presentations, and very interesting to see how the whole production process works seamlessly for greater efficiency, waste minimisation and profit maximisation.

For more information about the Konica Minolta AccurioLabel 190, please visit here.

AstroNova, Inc. has announced that its Product Identification group has launched the QuickLabel QL-300, a new product the company says is world’s first 5-colour, toner-based tabletop printer ...

February 06 2019

AstroNova, Inc. has announced that its Product Identification group has launched the QuickLabel QL-300, a new product the company says is world’s first 5-colour, toner-based tabletop printer designed specifically for production label printing.

The QL-300 goes beyond the traditional 4-colour (cyan, magenta, yellow and black) printing process by adding white toner, giving customers the ability to print white and CMYK in 1200 dpi (dots per inch) high resolution in a single pass. The benefit of toner EP (electrophotographic) technology includes label print that is durable, water-fast and UV resistant.

The QL-300 expands printing labels from traditional white or light-coloured materials to also include transparent/clear, black, Kraft paper, metallic silver and gold coloured label materials. The AstroNova Materials Research Lab has tested and approved a wide variety of label materials, from economical to premium, that are compatible with this printer.

The addition of white toner expands the creative labelling opportunities for industries such as personal care, cosmetics, food and beverage, beer and wine, chemical, e-liquids and many others.

QuickLabel’s newest printing solution is being unveiled at WestPack, which takes place today through Thursday at the Anaheim Convention Centre. Visitors to the AstroNova booth (#5439) will be able to view live demos of the QL-300 along with the expansive product lineup from both the QuickLabel and TrojanLabel AstroNova business units.

“In 1994, we introduced the world’s first tabletop digital colour label printer. Now 25 years later we’ve achieved another major industry breakthrough with the QL-300 that can print full colour plus white,” said AstroNova President and CEO Greg Woods. “Unlike office machines, the QL-300 was developed from the ground up as a full-production label printer in a compact tabletop footprint that easily adapts into the print workflow of any business.”

The QL-300 prints label widths ranging from 1.0” to 5.0” and features roll-to-cut or roll-to-roll operation. With a built-in automatic cutter that allows for single-pass printing, label waste is eliminated. The QL-300 also includes a free license to CQL Pro, QuickLabel’s advanced labelling software that allows users to effortlessly design, manage and print their own labels.

“Because AstroNova is the only full solution provider in this industry, we are also releasing today an updated version of CQL Pro, our industry-leading design software, to support the QL-300 and a broad range of new label media types,” Woods said. “By tightly integrating the operation of our hardware, software and supplies, customers are assured of optimal results and outstanding labels.”

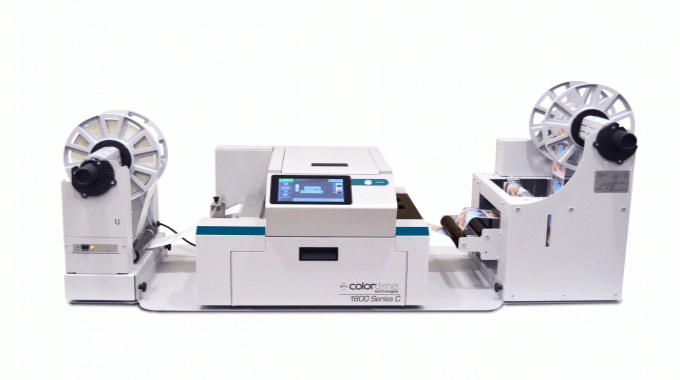

Colordyne Technologies, a manufacturer of full colour digital inkjet label and tag printers, has released an enhanced entry-level label printer, the 1800 Series C. The addition to Colordyne's suite...

February 06 2019

Colordyne Technologies, a manufacturer of full colour digital inkjet label and tag printers, has released an enhanced entry-level label printer, the 1800 Series C. The addition to Colordyne's suite of products provides brand owners and private label manufacturers with affordable and versatile in-house label and tag printing capabilities.

The 1800 Series C is a continuous printer for on-demand short run label and tag production. The press features a flat, unobstructed printing path and redesigned printhead maintenance station. These press enhancements eliminate the need to break the web to clean the printhead during runs, increasing run lengths and improving print quality.

"Colordyne's newest system provides additional features that customers have been looking for in our entry-level benchtop solutions," says Taylor Buckthorpe, director of sales at Colordyne Technologies. "This includes an on-press job library that allows brands to better manage their label inventory on-demand, eliminating the need to manage a stock of pre-printed labels and reducing waste from unused label inventory."

The job library can be accessed through the 1800 Series C's on-press touch screen user interface. The touch screen improves the user experience by providing quicker access to frequently used printer functions, such as: printhead maintenance, job setup, media settings and more. Additionally, the user interface was designed to be easy to use, so operators of any skill level can run and maintain the printer.

"Companies are looking for a solution to affordably print smaller label quantities in a just-in-time business model," says Buckthorpe. "The 1800 Series C gives brand owners and private label manufacturers the opportunity to bring high-quality label printing in-house. These companies are increasing their productivity, expanding marketing capabilities and improving customer satisfaction."

The 1800 Series C can run in multiple modes, including: print-to-cut, fanfold and roll-to-roll, when used with optional unwind and rewind attachments. The 1800 Series C prints in full colour (CMYKK) using a single Memjet water-based dye printhead and ink set. The press can print at a premium resolution of 1600 x 1600 dpi and run at speeds up to 60 fpm.

The Gallus Labelfire E 340 features CMYK plus digital white, and is intended to provide a different entry point to those looking to produce lowest cost, digital, finished labels in a single pass on...

February 05 2019

The Gallus Labelfire E 340 features CMYK plus digital white, and is intended to provide a different entry point to those looking to produce lowest cost, digital, finished labels in a single pass on an industrial platform.

Launched in 2016, the Gallus Labelfire 340 is an 8-colour digital production system combining UV inkjet printing with in-line embellishment and converting. The inkjet system, co-developed with Heidelberg, features state-of-the-art, 1200 dpi inkjet heads from Fujifilm. Gallus Labelfire E 340 features the same 1200 x 1200 dpi image quality, without orange, violet and green inks.

Gallus stated that the new model can be configured based on the current needs of the customer to provide the lowest cost of entry when it comes to getting started with digital hybrid label printing. The whole system is integrated into Heidelberg’s Prinect print media workflow. Those customers who purchase the five-colour Labelfire will have the ability to upgrade to eight colours and add further embellishing options including screen, cold foil, additional flexo, as the need arises or their business grows.

Michael Ring, head of digital solutions at Gallus, said: ‘We have many customers who want to get into digital hybrid printing, but do not need the complete high-end, fully featured configuration that an 8-colour Labelfire provides. This new 5-colour version allows them to get started in the digital arena but still provides the flexibility for expansion in the future while protecting their initial investment.’

Gallus Labelfire E 340 is available worldwide immediately. Deliveries are expected to start in April.

The labelstock supplier has collaborated with both wineries and converters to develop more than 150 substrates. Avery Dennison has responded to market demand, developing more than 150 ...

January 29 2019

The labelstock supplier has collaborated with both wineries and converters to develop more than 150 substrates.

Avery Dennison has responded to market demand, developing more than 150 constructions specifically engineering for wine and spirits. The company has gone directly to wineries and converters to troubleshoot current customer problems and ideate new ideas.

“The Avery Dennison Wine and Spirits portfolio offers inspiration through classic, premium materials enabling brands to stand out on shelf,” says Vanita Marzette, senior product manager - wine and spirits. “Wine materials cross both wine and spirits, as well as craft beer, because these areas are all following the trend towards premiumisation. We are also seeing more unique/textured facestocks that work across segments. The wine materials offer the added benefit of being able to stand up to ice buckets and condensation.”

To meet demand, Avery Dennison is launching three new collections for its wine portfolio. The Sensorial collection will feature new Ruby Velvet and Black Velvet facestocks. According to Marzette, Avery Dennison’s Sensorial collection adds the senses of touch, sound and even smell to the label. The Sensorial Collection offers label surfaces that feature a soft touch, textured or patterned papers. Some materials offer subtle sounds as fingers move across the surface. Meanwhile, hand-selected trees are used to fashion wooden labels that deliver a delicate, natural scent.

The new Black collection will include Laid Epic Black and Night Skye facestocks. “Black really is the new black, helping a brand to deliver a message of premium, quality content,” says Marzette. “The Black collection is a broad portfolio that reflects dependable quality to deliver outstanding shelf appeal. Materials include structured surfaces, thick to thin facestocks and a choice of different shades. Converters will appreciate the fact that they no longer have to print twice to create a rich, even black label with no white edges and stable hot foiling.”

Finally, the Luminous line, featuring Snowbound White, includes labels that glitter, sparkle and shine to stand out on the shelf.

In addition, Avery Dennison is adding to its sustainability portfolio with Grape Touch, which is made of 15% grape waste sourced from wine production – and Estate Label No. 14, a 100% post-consumer-waste (PCW) paper material that maintains colour and strength, even when wet.

“These products help tell a brand’s sustainability story while delivering performance and shelf appeal that result in sales,” adds Marzette. “Sustainability resonates with many consumers, and that story goes beyond production.”

The wine label goes beyond the facestock, too. Avery Dennison has developed multiple adhesives that are optimised for wine labels–and its customer service team works diligently to pair the right materials and adhesives with a customer’s desired application.

“We offer a range of adhesives that are formulated to work well in ice bucket, heavy condensation environments,” says Marzette. “Our technical resources put our adhesives through a range of testing before they launch, and all of the results can be found in our wine and spirits collateral and data sheets.

“We list all of our service offerings and support programs in our wine and spirits collateral to make it easy for customers to find,” Marzette adds. “Additionally, we have customers service, application consultants and technical leads available to help customers find the right materials for them. We also have our engineered solutions team available to help source and find a material if we don’t have what a customer is looking for.”

Plus, the Avery Dennison Concept lab is comprised of designers that work closely with other designers, converters, brands and agencies in the wine and spirits space to help bring their vision to life.

In the future, Avery Dennison expects to see continued premiumisation and a trend toward more unique facestocks that create pop on the shelf. Marzette adds that brands can create more engagement with their customers by opting for intelligent and interactive labels. Requests will continue for inkjet-optimised materials, too.

And, as is seen in the Luminous collection, a different range of colours will be utilised to further appeal to millennials.

Digimarc has introduced a new serialised packaging offering combining Digimarc Barcode and HP Link, which can provide every printed object with a unique identity and offers a cost-effective option ...

January 29 2019

Digimarc has introduced a new serialised packaging offering combining Digimarc Barcode and HP Link, which can provide every printed object with a unique identity and offers a cost-effective option for tackle supply chain problems.

HP and Digimarc offer consumer brands and their digital print providers the ability to apply a serialised global trade item number (SGTIN) on packaging to track and protect a package through the supply chain and at point-of-sale (POS) in retail environments.

It is claimed this new capability will help to combat product counterfeiting and piracy, currently estimated by Frontier Economics and the International Chamber of Commerce to reach $4.2 trillion USD by 2022.

Assigning SGTINs to individual items means that two otherwise identical units of the same product are uniquely identifiable, making it possible to track and trace for brand protection and product origination.

Digimarc Barcode is an advanced visually imperceptible code that can be serialised during printing on HP digital presses of product packaging, retail labels, point-of-purchase (POP) displays and other print output. It is reliably and efficiently scanned by enabled consumer phones, associated mobile devices, retail barcode scanners and computer vision systems.

With HP Link, Digimarc Barcode can carry an SGTIN, the combination of a GS1 GTIN and a unique serial number of up to 12 digits. This provides each package with a unique identity and the ability for consumer brands to track and trace a package or product at the item level through the supply chain all the way to point-of-sale. HP Link offers a security serialisation option including Digimarc Barcode and a toolset that integrates with existing enterprise resource planning (ERP), manufacturing, scanning, distribution and digital printing systems.

By monitoring scanning behaviour and tracking data, the HP Link platform automatically identifies suspicious behaviour, including diverted packages. Cloud-based product and tracking information can be applied throughout the supply chain through to the end consumer.

Heidi Dethloff, vice president of marketing at Digimarc, said: ‘Traceability initiatives are being fuelled by product fraud, recalls, regulatory compliance and the need for greater transparency across the supply chain. This new digital capability from HP allows brands to free-up their package design real estate, while also leveraging the full benefits of variable data printing for connected, customised, personalised and serialised packages.’

Marvin Gross, head of emerging solutions, HP Graphics Solutions Business, said: ‘With HP Link and Digimarc Barcode, consumer brands can protect their brand, track products from origin-to-destination, provide personalised content and coupons, and other benefits. Our solution can integrate with enterprise systems to manage inventory at the unique item level as well as enable faster and easier forms of checkout, including traditional, mobile and self-checkout.’