KernowJet KlearWipe is a clear PVC-free lamination film that offers durability and scratch resistance. Kernow Coatings has launched new dry-erase technology in the form of the company'...

October 29 2019

KernowJet KlearWipe is a clear PVC-free lamination film that offers durability and scratch resistance.

Kernow Coatings has launched new dry-erase technology in the form of the company's KernowJet KlearWipe. KernowJet KlearWipe is a clear PVC-free lamination film for dry-erase applications.

The product offers a thickness of 75µm, with a stiffness that makes it easier to apply. KlearWipe is durable and scratch resistant, as well, making it easy to handle and reassuring that it won't be damaged during lamination. KernowJet KlearWipe is highly transparent and comes with a special permanent adhesive to laminate over a plethora of prints, even UV-cured inks. It is available in widths up to 1,524mm.

The film has been tested with a wide range of water-based, solvent and acetone-based markers, and the product has been shown to pass all the tests. According to Kernow, there is no pearling of the inks when writing, and its erasability leaves no ink residue even after a long delay. Permanent markers can be cleaned off with alcohol without damaging the film, too. Dry erase surfaces can start to look tatty once they have been scratched and the ink imbeds inside the scratch. Due to its scratch resistance, KernowJet KlearWipe is an ideal solution for long term dry-erase surfaces.

This product is suitable for whiteboard and blackboard lamination for use in schools, offices, meeting rooms, convention centers. The material is compliant with the EN Standards: EN71-3 which is necessary for the safety of toys, and is therefore suitable for kids furniture, toys, child’s whiteboard, and more.

Esko, a leading provider of integrated technology solutions for packaging professionals, is giving users of its market-leading ArtiosCAD structural design software the opportunity to trial its inno...

September 24 2019

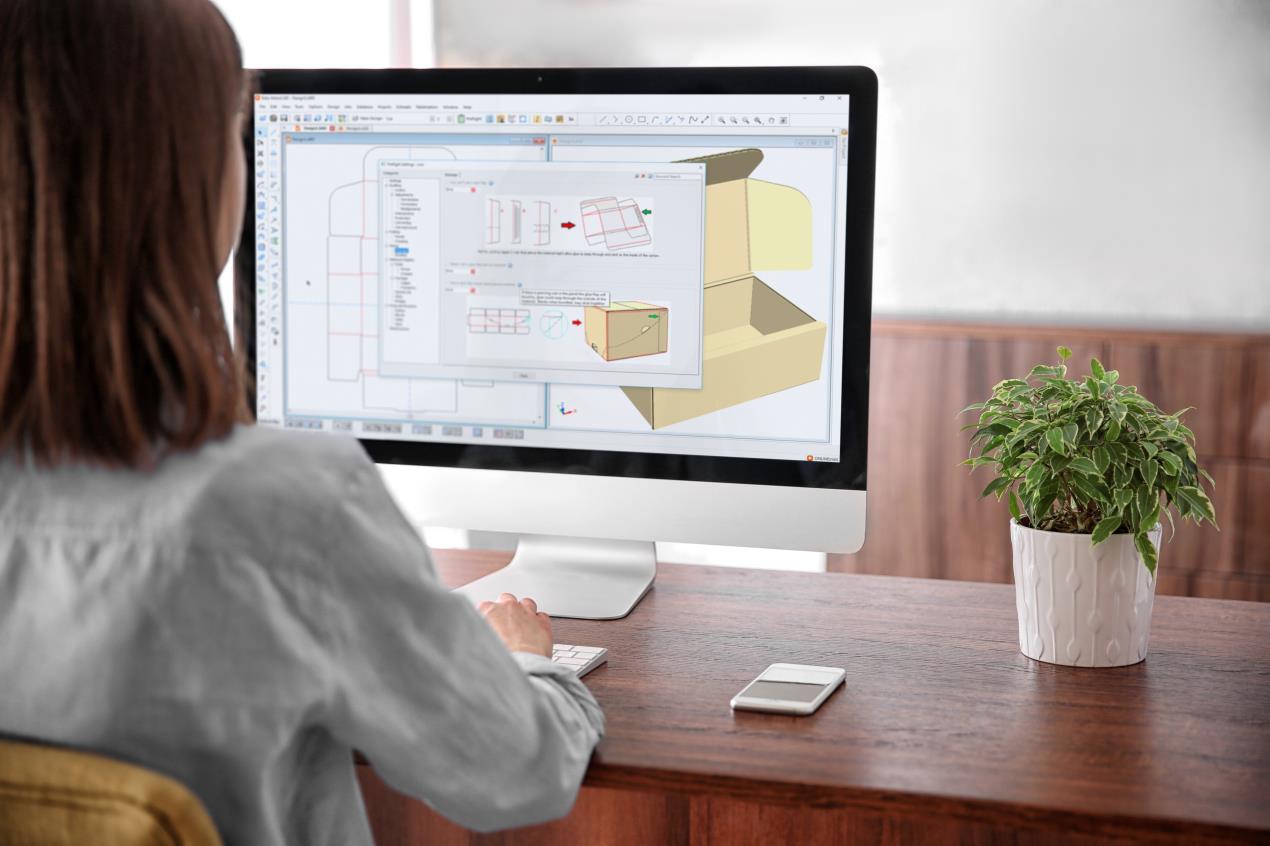

Esko, a leading provider of integrated technology solutions for packaging professionals, is giving users of its market-leading ArtiosCAD structural design software the opportunity to trial its innovative new preflight functionality in its latest release.

ArtiosCAD Preflight - ComputerArtiosCAD (18.1) users can now start using the breakthrough innovation for software-assisted quality control checks as a trial ahead of the full launch in early 2020. With unrivalled performance in CAD design for packaging and displays, the new preflight software delivers an even greater efficiency boost by saving users up to 15 minutes per design, eliminating the need for manual checks and standardizing design checks across a user group.

Specifically created to boost productivity for packaging structural designers, product development processes, virtual prototyping and die cut manufacturing operations, ArtiosCAD is a trusted tool with more than 23,000 users worldwide. “Best in class principles based on industry standards, including BOBST ABC guidelines, are now validated in ArtiosCAD to ensure accurate production-ready designs are established, reducing the iterative cycles between design and die making,” said Richard Deroo, Esko Product Manager. “Each design is checked to ensure it’s optimized for faster and more accurate waste removal during die cutting, and potential die cut production issues are now clearly identified earlier in the design phase.

“Delivering quality control at the touch of a button, ArtiosCAD Preflight automatically analyzes structural design files and flags quality issues to avoid downstream errors and save time for converters,” said Richard. “The patent-pending software alerts designers to potential design issues before releasing the file to estimating or production, reducing errors and rework and boosting operational uptime and efficiency.”

Users of ArtiosCAD Preflight now have the option to join an exclusive online user group for this new feature enabling collaboration with peers and directly with the Esko R&D team on the benefits of preflighting structural design files, as well as developing ideas for future modifications to the software.

“We are working with a number of pre-release customers from our broad user base to shape the full release,” he said. “But it is already clear that this new addition to ArtiosCAD 18.1 can make a significant difference to the efficiency and operational performance of the packaging and display community.”

Graphic Packaging International has been a key pre-release customer for the software development. Elizaveta Roberts, Tactical and Manufacturing Design Senior Manager at Graphic Packaging International, said: “We’ve been running ArtiosCAD Preflight before a design goes to manufacturing. Some of the checks that are running have allowed us to save at least 10 minutes per design. Depending on how many designs we’re doing in a day that can really add up to big-time savings.”

New ArtiosCAD Preflight performs a number of quality control checks on structural design files including:

- Production checks to see if the design meets the requirements of the intended production assets

- Product quality checks to identify design features that can negatively affect the folding, gluing or stacking of the finished article.

- Die press performance assessments to assess any negative impacts on the operational speed of the die press

- File import checks to examine the structural integrity of imported designs to identify any anomalies that could impede production overall

Available to download from www.esko.com, ArtiosCAD Preflight is available as a trial until April 2020 for users who upgrade to ArtiosCAD 18.1. To find out more, please visit https://www.esko.com/en/products/artioscad/features/cad-preflight

Prism Inks and Graphics One are pleased to announce the introduction of its new GO FabriMate dye-sub ink to cotton technology. GO FabriMate will be exhibited for the first time during the Printing ...

September 24 2019

Prism Inks and Graphics One are pleased to announce the introduction of its new GO FabriMate dye-sub ink to cotton technology. GO FabriMate will be exhibited for the first time during the Printing United Show in Dallas, Texas October 23-25, 2019 in the Graphics One booth 2861.

According to Amir Ajanee, CEO and President, Prism Inks and Graphics One, “For many years sublimation has been limited to polyester substrates, with dye sublimation to cotton thought technically not possible. Over the past twenty-two months, we have been working to develop an innovative process for imaging dye-sub ink to cotton and have succeeded. The process uses standard dye-sub paper, is simple to use and is usable with virtually all EPSON piezo printers, including MicroTFP print heads. We are extremely excited to announce this breakthrough and to show it for the first time.”

Ajanee continued, “The feedback we have from our customers has been very exciting. We are expecting FabriMate applications to be wide-ranging and far beyond apparel to include automotive, interior decoration, furniture, soft signage, medical uniforms and much more. This technology offers incredible new capabilities.”

During the Printing United Show, Graphics One will be providing technology demonstrations on three different cotton and polyester systems including a complete letter-sized entry-level t-shirt system listing for $995, a complete 13”x 19” t-shirt system listing for $1,995 and a complete direct-to-fabric 24-inch for proofing purposes listing at $9,995.

FabriMate initial shipments are expected to start in November and will be available through the Graphics One distribution channel.

www.prisminks.com

French RIP and workflow software developer Caldera is set to release the latest version of its award-winning RIP software. Version 13 (V13) is coming to the market in October with a range of new fe...

September 24 2019

French RIP and workflow software developer Caldera is set to release the latest version of its award-winning RIP software. Version 13 (V13) is coming to the market in October with a range of new features, and several improvements to existing features. The new version will be showcased at a number of upcoming print conventions including SGIA/Printing United in Dallas in October, CPrint in Lyon next February, FESPA in Madrid in March, and ISA in Orlando in April.

A clear benefit of V13 is that users can expect to save significant amounts of time during prepress, reprinting, as well as saving on media in certain areas but also during mounting and installation in the field. The 5 main new features include Print&Cut Mirror, Tile Order, Caldera Jobs – Detailed View, Custom Annotations and Alpha-to-Spot.

Print&Cut Mirror has been designed to streamline mirror workflows, when printing the back side of backlit applications and for print-to-cut dye sublimation transfer applications. It allows printers to manage the mirroring of the image, the cut marks and the cut file directly from the RIP interface, resulting in prepress time savings. Tile Order allows users to choose the printing order of tiles to reduce onsite mounting time for large tiling jobs. Printing can be started from a corner of choice and the feature can deliver time savings on mounting times for building graphics, blueback posters and building wrapping.

Another new feature, CalderaJobs, makes managing large volumes of jobs and multiple printers more efficient. With the ability to archive, save or delete past jobs more effectively, users will save time spent searching for a reprint and have a clean view of all their work to date. The Custom Annotations feature allows printers to choose which information they print in the annotations, which results in saving media space and optimized data searching and pertinence. There is no more need to put the legacy Caldera standard or detailed information on textile applications and building wraps, saving both media and mounting time. The final innovation in this version is Alpha-to-Spot. This automatically converts files with transparent backgrounds into white channels in automated workflows, allowing for prepress time savings.

As well as the new features, V13 boasts a number of improvements to existing features. InkPerformer now offers a choice of V2 (Legacy) and V3 engines. The latter delivers ink savings of up to 30 percent, maintaining color quality with improved grey neutrality printing. New version Light Installers save time, while OS support has been extended to MacOS Catalina 10.15. V13 itself can be downloaded directly from CalderaDock, as can new ICC profiles and printer drivers. The new version sees updated Pantone Libraries, including 210 swatches in Pantone FHI Cotton TCX, and there’s a new 2xCMYK Print Mode, for finer prints with duplicated heads.

Vice President Marketing, Operations & IT Sébastien Hanssens says, ‘This new version of Caldera’s flagship RIP software has been developed to explicitly meet the needs of our existing users and to provide them with enhanced benefits across the full range of workflow and RIP functions. Printing with Caldera V13 is more efficient and cost effective than ever before, with a simplified user experience for valuable time savings.’

www.caldera.com

3M introduces an industry first – new 3M™ Wrap Films Series 2080 gloss films come engineered with a Protective Film Layer, allowing for easier installation. Further innova...

September 17 2019

3M introduces an industry first – new 3M™ Wrap Films Series 2080 gloss films come engineered with a Protective Film Layer, allowing for easier installation.

Further innovations in the new 3M™ Wrap Films Series 2080 include; better conformability for further ease of installation and an extended warranty of up to seven years* on vertical applications, to drive greater confidence and peace of mind for both installers and consumers.

New innovations in film technology are consistently being improved to achieve smooth and distinctive wrap designs. The patent-pending Protective Film Layer on gloss colours comes positioned over the top of the film’s surface to reduce the potential for surface imperfections, such as hazing or blotchiness. This remains in place during the installation and is removed easily once the film is applied to reveal a perfect finish. As a result, vehicle owners and installers will have the peace of mind that any scratches made to the Protective Film Layer will not transfer to the film itself, nor mar the look of the completed wrap. “The new 3M™ Wrap Films Series 2080 gloss films ensure both quality aesthetics and performance, and we’re excited to see the impact it has for installers and their customers.” said Janelle Pizzi, product marketer, 3M Commercial Solutions Division.

Simultaneously, the warranty backed by science means installers and consumers can have increased confidence that when wrapping a vehicle with 3M film, it will both perform during installation and uphold its striking appearance when maintained correctly.

The multi-layer cast, adhesive backed film will be first available in 41 colours, of which there are 6 new colours available to meet current consumer and trend demands, and all of which can be used with 3M™ Knifeless Tape.

For For more information on 3M™ Wrap Film Series 2080, please visit 3M.com.au/2080 or

3m.co.nz/2080.

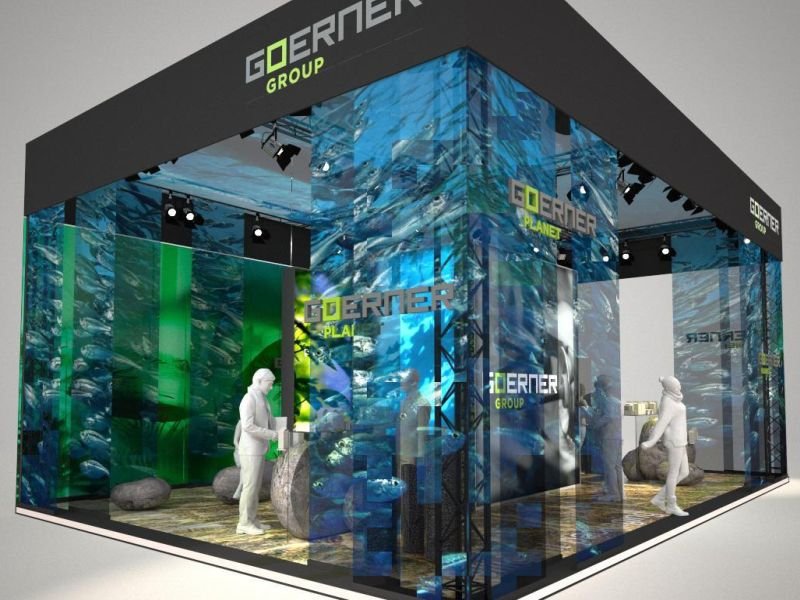

As a producer of cardboard packaging, the company's waste serves as the raw material for Goerner Formpack. At Fachpack, the company will present its newly developed GBfiber solution. F...

September 17 2019

As a producer of cardboard packaging, the company's waste serves as the raw material for Goerner Formpack. At Fachpack, the company will present its newly developed GBfiber solution.

Further development of the molded fiber technology and toolmaking was carried out in cooperation with a confectionery group in order to completely replace the plastic blister packs previously used with cellulose fiber products. The experiment was successful and GBfiber – the new brand of Goerner Bionics – meets various requirements, from an ISEGA certification for direct food contact and suitability for existing packaging systems.

GBfiber can be manufactured industrially and at costs that are absolutely comparable to the production of plastic blister packs. Wilhelm Siller-Goerner, the innovative mastermind at Goerner, says, “With GBfiber for the confectionery industry and greasy foods, we have developed an alternative to single-use plastics that is 100% environmentally friendly. There are also other sustainable approaches using other technologies and natural raw materials but they are often based on foods, such as potato starch. However, when it comes to economic efficiency, recyclability and sustainability, cellulose fiber and our molded fiber technology are currently ahead of the field.”

EFI announced the availability of important advancements in its latest version of Fiery® Color Profiler Suite – integrated colour management software that gives digital print producers mo...

September 17 2019

EFI announced the availability of important advancements in its latest version of Fiery® Color Profiler Suite – integrated colour management software that gives digital print producers more power than ever before to get colour right every time. Next generation EFI™ Fiery Edge™ colour profiling technology launching in the suite delivers out-of-the-box print quality and colour improvements in new Fiery digital front ends (DFEs). Plus, a host of new controls within Fiery Color Profiler Suite tune colour to meet customer preferences, such as features to intelligently boost colour and adjust shadow detail levels.

Fiery Edge profiles are available for selected new cut-sheet digital printers, as well as for many wide- and superwide-format printers that use EFI Fiery DFEs.

Expanded output controls

Users benefit from an increased array of advanced user controls. For example, a key element of the new Fiery Edge technology is the ability to control or manually select a black point that best matches the intent of the item being printed. This maximises the dynamic range of a print when the darkest printable colour is not a neutral black. Users can also control shadow detail levels to best represent a product’s or a subject’s characteristics.

Fiery Edge also gives print professionals the ability to define colour-to-black transitions for reduced image peppering, graininess, and smoother transitions, all of which is especially useful in colour-critical market segments such as photobook printing.

Prior to using Fiery Edge, Himanshu Pandey, owner of New Delhi-based Avantika Printers Pvt. Ltd., was unable to compete in that segment with his current printers. “The colours were not vibrant enough and the tonal values were not stable enough,” according to Pandey. “The colour control provided by Fiery Edge technology allowed us to use our printers to print photobooks containing various images of people and places. Fiery Edge literally opened the photo segment for us!”

Out-of-the-box enhancements

Users of Fiery Edge colour profiles will notice much smoother color transitions and blends right out of the box. They will also see more image detail, clarity, and depth. Plus, superior rendering of RGB reds and blues in Fiery Edge technology gives users a more-faithful rendering of RGB images.

“Fiery Edge colour profiling technology brings all the excellent results and controls to my Fiery cut-sheet printer customers that I’ve been relying on for several years to keep my Fiery wide-format inkjet customers happy,” said Rob Cawston, owner of Colour Consultancy Ltd. in Nottingham, England. “The smoothness of blends and extra image detail are the things that stood out as benefits of Fiery Edge just by using the default profiles and settings.

“I particularly like the new rendering intent option,” he added. “No more lengthy profile tweaking for customers that want more pop. Having all this control for toner now too is very welcome.”

“Getting the best colour and quality from any printer should be the goal for all print producers,” said John Henze, vice president of sales and marketing, EFI Fiery. “Whether it is taking advantage of the maximum gamut of a printer to give prints more colour, getting the most detail available to show a product at its best, or producing the smoothest colour transitions for photo-realistic images, these new capabilities will help print producers achieve the best results their print devices are capable of, therefore getting the most from their colour investments.”

Boosted colour to attract attention

Users can produce more colourful, vivid and dynamic-looking output in signage, point of sale, display and other applications because Fiery Edge technology brings the ability to boost colour with Fiery Intensify™ – a new rendering intent innovation that can increase colour and saturation while maintaining neutral grays and realistic skin tones. The new feature, which is part of Fiery Color Profiler Suite version 5.2, improves colour while at the same time maintaining balanced visual results – a difficult goal to achieve with other rendering solutions available on the market. Not only does this enable precise control of chroma, lightness and contrast levels, it also allows users to select the correct source profile for the best possible use of an output device’s gamut and dynamic range.

Fiery Edge technology also supports up to eight colour channels (CMYK+ 4 extra colours) further enhancing Color Profiler Suite’s ability to get the best possible colour out of any supported Fiery Driven™ printer, including those with gamut-expanding colorants such as orange, violet, blue, and green inks or toners.

The newest version of EFI Fiery Color Profiler Suite featuring Fiery Edge is available now from EFI and authorised EFI resellers. For more information about digital colour production printing using EFI Fiery technologies, visit www.efi.com.

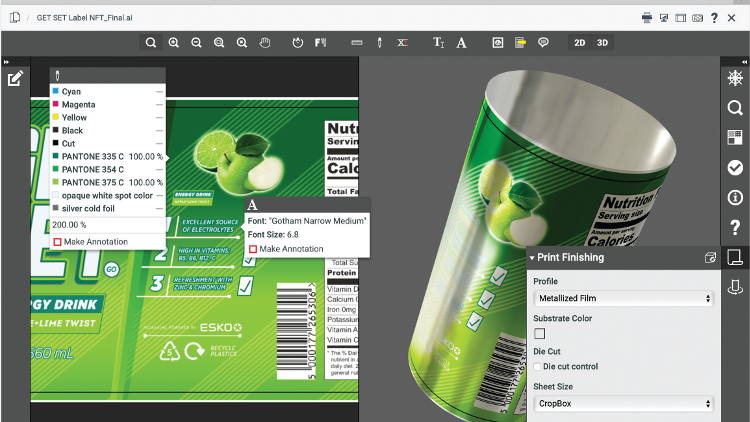

Share & Approve is a new and unique approval tool from Esko. The software runs as a service on Esko cloud architecture and enables users of Automation Engine to upload, share, annotate and appr...

September 10 2019

Share & Approve is a new and unique approval tool from Esko. The software runs as a service on Esko cloud architecture and enables users of Automation Engine to upload, share, annotate and approve packaging and labels jobs in 2D and hyper realistic 3D.

Esko knows that securing packaging job approvals can be a confusing process causing production delays and it’s often hard for the approver to envision their 2D design once finished. In today’s high speed and often pressured business environment, there is also no easy way to gather and interpret feedback from multiple stakeholders on a job, without significant time delays impacting the project.

The Esko Share & Approve software solution enables users to realistically visualise their pack in 2D and 3D and annotate the file with feedback in a single, centralised online tool. This new clarity reduces the amount of approval iterations and shortens the time required to get the job approved enabling brands and their supply chains to operate more efficiently and drive down time-to-market.

Karsten Daemen, Esko Product Manager, commented: “We are very happy to see approval loops finishing in a maximum of 8-9 days instead of a few weeks, which is typical of what happens in the industry today. We have also observed the number of job revisions decreasing from 8-9 to 3-4 with use of the software. With the speed and complexity of packaging management today, Share & Approve is going to make a tangible difference to our customers seeking to increase their speed to market.”

Users of Share & Approve can now instantly create 3D pack renders based on their actual 2D artwork, including special print effects and embellishments. The software has a super easy user interface enabling upload and set up in only four clicks and incorporates a range of unique packaging inspection tools for measurements, deep zooms and separations viewing, as well as barcode and braille reading.

Creating visibility on job management, Share & Approve provides a complete audit trail of operator actions and versioning, as well as increases approval rates up to 3x faster than traditional approval processes.

Jan De Roeck, Esko Marketing Director, added: “With Share & Approve designed as a cloud-based service, there is no IT overhead costs or efforts involved for our customers, compared to traditional on-premise solutions. There is no web deployment, no servers to maintain and keep up to date, no need to provide for data security and back-up scenarios and the uptime of the service is guaranteed."

HP introduces an innovative new banner material that offers a unique combination of durability and flexibility. Unlike other banner materials, HP Foldable Durable Synthetic Banner can be folded and...

September 10 2019

HP introduces an innovative new banner material that offers a unique combination of durability and flexibility. Unlike other banner materials, HP Foldable Durable Synthetic Banner can be folded and easily transported due to its thin, lightweight construction. Engineered with DuPont Tyvek material it is designed to produce tear-resistant, water-resistant, foldable maps, banners, and posters that can be grommeted and stitched. This versatile banner material is compatible with Original HP PageWide XL pigment inks, and HP Vivid Photo Inks and HP Bright Office Inks for HP DesignJet printers.

No longer just for technical documents, HP PageWide XL printers can produce brilliant banners radically faster than anything on the market—with low cost of operation.

www.HPLFMedia.com

- Push-to-Stop – greater automation, lower costs - Gang form creation with automatic optimisation - Plate Pilot supplies plates right on time as printing commences - Prinect...

September 10 2019

- Push-to-Stop – greater automation, lower costs

- Gang form creation with automatic optimisation

- Plate Pilot supplies plates right on time as printing commences

- Prinect supports hardcover book production

- SmartBi provides key lever for improving overall efficiency

- Case-based online support

- New functions for the packaging sector

Heidelberger Druckmaschinen AG (Heidelberg) is making it even easier for Prinect users to run their print shop with the new and partially cloud-based functions in the Prinect production workflow. “A growing number of Prinect functions are gradually migrating to the cloud. By taking out a subscription contract, customers can gain access to them as and when required and based on the benefits they offer,” says Jürgen Grimm, head of software solutions at Heidelberg. “The Prinect workflow thus forms the backbone of digitisation in print shops.”

Push-to-Stop – greater automation, lower costs

Automatic planning in Prinect 2020 makes it even easier to optimise job sequences. Substrates, special colours, folding layouts, and much more are taken into account in digital planning and transferred directly to the Prinect Press Center, thereby reducing the changeover procedures that have to be carried out on the press. Operators no longer have to select and adopt jobs from the machine queue, which also reduces the scope for errors.

As of now, the Push-to-Stop concept is also supported in postpress

This means that appropriately configured folding machines can work through several jobs one after the other, with the status of work repeatedly reported back to the Prinect system. As a result, the productivity gains that Push-to-Stop has brought to the pressroom can now also be achieved in postpress.

Gang form creation with automatic optimisation

One major contribution that Prinect makes to lowering costs and driving up productivity relates to the creation of gang forms, with the gang server picking out jobs from a pool according to pre-set filter criteria and then using these criteria to optimize the compilation of appropriate gang forms on a fully automated basis. Any gang forms produced this way that do not satisfy these criteria are not forwarded to production, and are instead canceled and then combined with other jobs later on, provided an optimum gang form can be created.

Plate Pilot supplies plates right on time as printing commences

The new Prinect Plate Pilot works with the further improved Prinect Scheduler to automatically output plates so they can be placed on trolleys in the correct sequence and made available at the press in time for the planned printing slot. Operators can monitor this process via the Plate Pilot Widget of the Prinect Portal, which also allows them to intervene in the process as necessary. This solution puts an end to the tedious process of sorting printing plates and also avoids the damage and scratches that can otherwise occur.

Prinect supports hardcover book production

The production of bound (hardcover) books and other complex products involves a number of steps that go above and beyond the usual processes in commercial printing. The new version of Prinect supports the special workflow-specific features of book production in both production and MIS operations. With immediate effect, Prinect offers the option of factoring these steps into the fully automated costing of the book in Business Manager and then handing over to the Prinect production system for automatic processing.

SmartBi – cloud-based software provides key lever for improving overall efficiency

The cloud-based software Prinect SmartBi supports the analysis and use of data generated in print shops. After all, every activity, every production process, and every job generates data, but many companies either completely overlook the value and usefulness of this information or do not fully harness its potential. Prinect SmartBI helps print shops unlock and utilise this corporate and production data quickly and with ease, assisting Prinect users with the generation, filtering, preparation, and visualisation of their data.

New Prinect Portal becomes an efficient collaboration platform?Version 2020 of Prinect reinforces inter-company cooperation. For example, the Prinect Portal has been launched to meet the demand for a wide-ranging collaboration platform and can be used by print shop staff to establish efficient online communications both within their own company and with customers and suppliers.

New functions for the packaging sector

To support Push-to-Stop in the packaging sector, Prinect is offering a new function that allows customers to use the cutting tool as a criterion for optimising production planning. This ensures the same tool is not refitted several times over, thus significantly improving productivity and machine availability.

The cost savings and productivity gains achieved by using gang forms are also available to packaging print shops Working from an existing die cutting tool and filter criteria, gang forms are first created and then either kept or rejected depending on whether they satisfy pre-set criteria.

Prinect also offers a whole series of new functions for CAD. Having the option to set out all the parts of a packaging design in one drawing ensures the interdependencies between the individual parts can be taken into account accurately. This makes the design process easier and faster to complete.

When it comes to more complex packaging and displays, there is also the option of creating assembly instructions to make the items easier to build or set up.

What’s more, Prinect supports pillow box packaging, which can now be simulated as a 3D model and exported as an animated 3D PDF.

Context-sensitive online support

The launch of HTML-based online support gives users direct access from within the application to the current library of Prinect software documentation at all times, plus a growing number of explanatory videos. All this makes Prinect even easier to use.

Avery Dennison Graphics Solutions today introduced five new satin and gloss metallic colours incorporating vibrant pigments unique to their Supreme Wrapping™ Film portfolio. Thes...

August 27 2019

Avery Dennison Graphics Solutions today introduced five new satin and gloss metallic colours incorporating vibrant pigments unique to their Supreme Wrapping™ Film portfolio.

These new colours of Hope Green, Passion Red, Fun Purple, Wave Blue and Energetic Yellow offer vehicle owners in Australia and New Zealand exciting ways to show off their personality and originality.

“These bold new colours are designed to add a premium finish, enhancing contours and body work,” said Jordan Leach, Senior Business Manager for Avery Dennison Graphics Solutions in Australia and New Zealand. “With a prestigious metallic finish, the new colours reflect the latest trends in automotive paint. Customers can instantly transform their vehicles to the latest in fashion and style.”

With its high-quality performance, reliability and durability, these new colours feature the patented Avery Dennison Easy Apply RS™ technology, providing high conformability and repositioning capability for the most demanding wrapping applications. The new colours are now available at all authorised distributors. The Avery Dennison Supreme Wrapping Film portfolio boasts of more than 120 colours and finishes for car wraps. For the full range of Supreme Wrapping Film available, please visit graphicsap.averydennison.com.

Onyx Graphics, Inc., a leading software solution provider for the wide-format printing industry celebrating 30 years of innovation throughout 2019, announced today that its ONYX software is certifi...

August 20 2019

Onyx Graphics, Inc., a leading software solution provider for the wide-format printing industry celebrating 30 years of innovation throughout 2019, announced today that its ONYX software is certified for the HP Stitch textile printer line.

The HP Stitch S Series is the first widely available textile focused printing solution developed by HP.

HP’s RIP certification programme defines a comprehensive set of integration, compatibility and performance criteria aligned to the highest performance standards and the unique capabilities of HP printing technologies. The HP Stitch Certification is a process to differentiate HP partners who demonstrate conformance to these criteria in order to receive HP Stitch certification status.

For the new HP Stitch S Series printers, Onyx Graphics has designed the driver to include functionality for both direct-to-fabric printing and dye-sublimation transfer using paper or film. In addition, the ONYX driver provides a custom ICC build option preset specific to the HP Stitch as well as ONYX QuickSet options to simplify managing textile and dye-sublimation workflows. Combined with ONYX iccMAX v5 profiling found only in ONYX 19, users of the HP Stitch S300 and S500 printers have an easy way to achieve superior and consistent colour across their entire print production environment, as well as a simple way to automate complete textile print workflows.

“ONYX software certification by HP and its integration with HP’s first-ever textile printer defines quality and colour for textile and soft-signage print applications,” said Bryan Manwaring, Director of Product Marketing at Onyx Graphics, Inc. “HP Stitch S Series customers utilising ONYX software profiling and colour tools can feel confident in delivering fast, consistent quality output which can be automated at the click of a button.”

EasyCut Studio, a leading developer of vinyl cutter software programs, today announced the launch of its new edition of Easy Cut Studio. To be specific, it is Easy Cut Studio 4.1.0.7 which now supp...

August 12 2019

EasyCut Studio, a leading developer of vinyl cutter software programs, today announced the launch of its new edition of Easy Cut Studio. To be specific, it is Easy Cut Studio 4.1.0.7 which now supports ability to design in vector and cut the design with a Mutoh Kona, Mutoh SC, Gerber FasTrack, or Liyu SC-A vinyl cutter. Exclusive Print and Cut Technology allows you to print designs to a colour printer and then cut them out with your Mutoh cutter.

Easy Cut Studio is one of the most popular and widely trusted vinyl cutting applications for Mac and Windows. support for all the latest as well as legacy cutting plotters. The software packed with a large selection of tools and features for designing and laying out all types of signs, decals, lettering, posters, and graphic artwork to be cut out using a vinyl plotter. You can also open bitmap graphics or scan logos and convert them into cuttable vector graphics. With countless features and advanced cutting settings, Easy Cut Studio will make your sign design and cutting tasks a pleasure while increasing quality and productivity!

Since it has been a while since Easy Cut Studio 4.1.0.7 was released, an update was pending. According to the engineers working on the product, the update took a while since they wanted to deliver the best-possible results. The team claims that over 200 different cutting plotters were tested. The team even visited a number of cutting plotter manufacturers and talked to different engineers to understand their pain points. All of this helped the developers come up with a one-stop vinyl cutting software with exceptional results and increase your productivity.

Easy Cut Studio v4.1.07 includes the following new features and bug fixes:

What new in version 4.1.07:

1. Added support for Liyu SC-A, TC-A, TC-AA and HC-AF Series;

2. Added support for Mutoh Kona and Mutoh SC series cutters;

3. Added support for Gerber FasTrack cutting plotter;

4. New Mutoh Kona plotter driver including support for Mutoh 4 point cropmarks for Print and Cut jobs;

5. Added cut selection only and mirror options for Rabbit cutter;

6. Fixed a problem with cutting with Silhouette CAMEO 3;

7. Fixed a problem with editing nodes after cutting the design;

8. Other stability improvements and small bugs fixed.

To learn more about Easy Cut Studio 4.1.0.7, please visit https://www.easycutstudio.com/

Pricing and availability:

Easy Cut Studio version 4.1.0.7 comes with Lifetime License at a starting price of $59.95 USD. This software is available for both Windows and macOS platforms. You can get a free trial of Easy Cut Studio from the official website. Since Easy Cut Studio offers a free lifetime upgrade on its products, the existing users of Easy Cut Studio 4.xxx can upgrade to version 4.1.0.7 easily.

With increasing demand for more sustainable, recyclable and environmentally responsible products for print, signage and display applications, Australian media supplier Rojo Pacific has announced th...

August 06 2019

With increasing demand for more sustainable, recyclable and environmentally responsible products for print, signage and display applications, Australian media supplier Rojo Pacific has announced the addition of new ‘clean and green’ Kavalan printable coated textiles to its existing extensive range.

It was a couple of years ago now that Rojo Pacific’s John Wright really started to notice a surge in the number of enquiries his company was receiving about eco-friendly materials which could be used as an alternative to PVC coated fabrics and vinyls.

With the launch of the Kavalan range at PrintEx19 in Sydney next month, Wright says he’ll be the first in Australia to provide print, sign and display businesses with a genuinely viable answer: a high quality, cost-effective and completely PVC-free alternative for everything from banners and flags, to backlit panels, wall and even window graphics.

“PVC composite fabrics are fantastic performers, but they do have a reputation for being complex and expensive to recycle,” Wright concedes, “and the properties of PVC are simply not necessary for every application.”

While not quite as durable as PVC for heavy duty or outdoor use, Wright says Kavalan, from international specialist textile manufacturer, TAYA Canvas, provides an ideal alternative for indoor or sheltered applications, interchangeable graphics for marketing campaigns, or shorter-term outdoor use – and can then be recycled after use.

“Kavalan is lightweight, totally PVC and phthalate-free, biodegradable and 100% ‘clean and green’,” Wright says, explaining that the range – which was launched at FESPA 2017 – replaces the usual PVC film coating with a unique, eco-friendly corn starch coating to create a reliable print-receptive layer.

“These materials can be used with UV, Latex or dye-sublimation inks for outstanding print quality and then, at the end of their useful life, they can be recycled without the use of solvents. Disposal is easy on the environment too – Kavalan can be incinerated without releasing harmful chemicals – in fact, we know of companies that are putting it into their ‘waste-to-energy’ stream – and if it goes into landfill, its water-based PA coating is fully biodegradable.”

Rojo is bringing five of the Kavalan products to Australia and all will be on show on the Kavalan stand at PrintEx19. Sunlight, is a grey-backed semi-block-out, weldable material for front-lit signage including banners, roll-up displays, display frame systems and exhibition graphics. It can be printed with direct or transfer dye-sublimation, UV or Latex printers and comes in widths up to 5m.

Moonlight is a 200gsm coated fabric for backlit applications like lightboxes or banners, Butterfly is a two-sided banner fabric with a block-out core for high-impact double-sided banners and roll-up displays, and Gecko is a high-end fabric for wall or ceiling applications. All share a common maximum width of 5m and have been designed for large format digital UV and Latex printing.

Completing the range is Spiderweb, a 300gsm mesh banner material, which is ideal for window signage. It can also be printed with UV or LX inks, and has a maximum width of 3.2m.

“We’ve been working with TAYA for 15 years as their exclusive Australian agent for signage and industrial grades of PVC coated polyester fabrics and other specialised textiles, so we know them well and understand the quality of their R&D, their innovation and their manufacturing processes,” Wright says.

Kavalan will ideally complement the conventional products in the company’s trusted ROFAB and ROTEX ranges and, like KATZ paper-based display board and other products Rojo has debuted in Australia, reflects the company’s commitment to innovation, sustainability and ‘world’s best practice’ operation.

“The Kavalan launch is in line with the Business as Best Practice commitment we made in 2013 – that ‘where we can make better choices, we will,” Wright says.

“We are a family company and we are absolutely dedicated to doing what we can to safeguard the future by incorporating life cycle thinking into every aspect of our daily business activities. So, when we are sourcing new products, we are not just looking for higher quality materials that deliver better performance and reliability, but also for sustainability. Kavalan answers those criteria.”

Kavalan will be showcased by Rojo Pacific on the Kavalan stand, Stand L20, at PrintEx19, at the Sydney Showground, Sydney Olympic Park from 13-16 August. The full range is available through Rojo Pacific and its distributors throughout Australia. For more information, call +61 3 9872 1000 or email sales@rojopacific.com.au

Digital ink manufacturer, NUtec recently announced its latest UV-curable ink optimised for the HP® Scitex FB 500, 550, 700 & 750 series of printers. The Amethyst A50-RIG-FB is ...

July 29 2019

Digital ink manufacturer, NUtec recently announced its latest UV-curable ink optimised for the HP® Scitex FB 500, 550, 700 & 750 series of printers.

The Amethyst A50-RIG-FB is a premium quality UV ink for rigid applications designed for superior media adhesion and optimised for use on the HP Scitex FB printers.

The A50-RIG-FB formulation is optimised for rigid substrates using conventional UV lamp curing and features a superior colour gamut for bright, vivid images.

Offered in a 2.5L box container for colours and a 1.7L container for white, the A50-RIG-FB ink can be used on a large variety of rigid substrates including glass and ceramics for indoor decoration, without the need for primers. Provided the inks are used in regular applications, using suitable substrates, these printed images will last for up to 24 months.

NUtec Digital Ink products are supported by NUtec Digital's Ink Delivery System Warranty giving customers peace of mind when converting to NUtec inks.

Neil Green, NUtec Sales and Marketing Director notes, “The development of the A50-RIG-FB ink for HP FB printers shows NUtec’s commitment to offering our customers world class alternative inks. Our latest NVC-free, UV-curable ink offers excellent adhesion and flexibility coupled with great all-round printing reliability. “

“This ideal combination of adhesion, flexibility and reliability is creating many new and exciting business and application opportunities for those converting to our inks,” concludes Green.

For further information visit www.nutecdigital.com or email info@nutecdigital.com.

The most popular sign-making and cutting plotter software program for Windows and Mac. Now drivers for over 500 plotter models. New York and BeiJing, China, Today, EasyCut Studio, a le...

July 24 2019

The most popular sign-making and cutting plotter software program for Windows and Mac. Now drivers for over 500 plotter models.

New York and BeiJing, China, Today, EasyCut Studio, a leading developer of vinyl cutter software programs, today announced the launch of its new edition of Easy Cut Studio. To be specific, it is Easy Cut Studio 4.1.0.7 which now supports ability to design in vector and cut the design with a Mutoh Kona, Mutoh SC, Gerber FasTrack, or Liyu SC-A vinyl cutter. Exclusive Print and Cut Technology allows you to print designs to a colour printer and then cut them out with your Mutoh cutter.

Easy Cut Studio is one of the most popular and widely trusted vinyl cutting applications for Mac and Windows. support for all the latest as well as legacy cutting plotters. The software packed with a large selection of tools and features for designing and laying out all types of signs, decals, lettering, posters, and graphic artwork to be cut out using a vinyl plotter. You can also open bitmap graphics or scan logos and convert them into cuttable vector graphics. With countless features and advanced cutting settings, Easy Cut Studio will make your sign design and cutting tasks a pleasure while increasing quality and productivity!

Since it has been a while since Easy Cut Studio 4.1.0.7 was released, an update was pending. According to the engineers working on the product, the update took a while since they wanted to deliver the best-possible results. The team claims that over 200 different cutting plotters were tested. The team even visited a number of cutting plotter manufacturers and talked to different engineers to understand their pain points. All of this helped the developers come up with a one-stop vinyl cutting software with exceptional results and increase your productivity.

Easy Cut Studio v4.1.07 includes the following new features and bug fixes:

What new in version 4.1.07:

1. Added support for Liyu SC-A, TC-A, TC-AA and HC-AF Series;

2. Added support for Mutoh Kona and Mutoh SC series cutters;

3. Added support for Gerber FasTrack cutting plotter;

4. New Mutoh Kona plotter driver including support for Mutoh 4 point cropmarks for Print and Cut jobs;

5. Added cut selection only and mirror options for Rabbit cutter;

6. Fixed a problem with cutting with Silhouette CAMEO 3;

7. Fixed a problem with editing nodes after cutting the design;

8. Other stability improvements and small bugs fixed.

To learn more about Easy Cut Studio 4.1.0.7, please visit https://www.easycutstudio.com/

Pricing and availability:

Easy Cut Studio version 4.1.0.7 comes with Lifetime License at a starting price of $59.95 USD. This software is available for both Windows and macOS platforms. You can get a free trial of Easy Cut Studio from the official website. Since Easy Cut Studio offers a free lifetime upgrade on its products, the existing users of Easy Cut Studio 4.xxx can upgrade to version 4.1.0.7 easily.

Drytac has announced the global availability of Polar Chrome, an innovative reflective film perfect for the creation of eye-catching graphics in a range of environments. Drytac - a lea...

July 23 2019

Drytac has announced the global availability of Polar Chrome, an innovative reflective film perfect for the creation of eye-catching graphics in a range of environments.

Drytac - a leading international manufacturer of self-adhesive materials for the large format print and signage markets - has added Polar Chrome to its popular Polar range to give even more options to print professionals, advertising bureau and retailers who want to make an impact with their displays.

Polar Chrome is a 75 micron (3 mil) reflective satin silver PET film that catches the light for a stunning finish. Thanks to its compatibility with eco-solvent, solvent, latex and UV printing technology and availability in rolls up to 60" wide, it is ideal for a wide variety of applications such as billboards, exhibition graphics, POS displays and public transport advertisements.

Its three-year indoor and two-year outdoor durability makes it perfect for interior signage and high-impact outdoor signs, with a two-year warranty providing extra reassurance. Furthermore, Polar Chrome is a great choice for the production of ultra-reflective labels.

New Polar Chrome features Drytac's advanced clear permanent acrylic adhesive which makes the installation and repositioning of graphics easy, while removal is quick and clean with no sticky residue.

Shaun Holdom, Global Product Manager at Drytac, comments: "We're delighted to launch Polar Chrome, a new product perfect for truly engaging displays and signage. This bold reflective film has already been used to create incredible effects by our network of trusted distribution partners, especially when teamed with clear UV ink to create textures with depth and special effect finishes. We're looking forward to seeing our customers' incredible designs using Polar Chrome."

Drytac's popular Polar range also includes Polar Burst, a satin reflective PVC film perfect for window graphics and Polar Grip vinyl, designed for rough surfaces and permanent printed signs even in extreme weather conditions.

For more information on Drytac's other products and services please visit www.drytac.com

SAi, the leading provider of software solutions for the signmaking, digital printing and CNC machining industries, has announced a significant upgrade to its flagship EnRoute CAD/CAM software. EnRo...

July 23 2019

SAi, the leading provider of software solutions for the signmaking, digital printing and CNC machining industries, has announced a significant upgrade to its flagship EnRoute CAD/CAM software. EnRoute 6.1 meets the various needs and budgets of users across multiple industries and is accessible to existing subscribers of EnRoute software.

EnRoute 6.1 includes half a dozen new efficiency-enhancing tools to boost CNC routing capabilities for CNC woodworking, signmaking and millworking companies, as well as nested-based manufacturing users. These new features span improved previewing options, comprehensive job statistics and greater cutting control.

They include:

- The newly introduced Backplot tool which simultaneously generates four preview angles and contains detailed cut statistics. It now also incorporates colour code for the text in the file, making it easier to identify what is included on the output file.

- The Group Order function, which allows subscribers to not only select the order in which they want the objects to be cut but saves this to a group which can be copied. This allows users to dramatically reduce their design time and maximise throughput.

- Job Statistics, which deliver improved information of cutting time. By providing realistic production times and job estimates, users can optimise throughput.

- The Order by Line option. By drawing a simple line on screen, users can quickly select the order of the parts to be cut, providing them with superior cutting control.

In addition, EnRoute 6.1 subscriptions include new and useful time-saving features*. Among these are a new Hot Folder option which ensures that once a part is outputted from EnRoute 6.1, it is automatically saved in a predefined (hot) folder created by the user, ready to be cut. This reduces the time required to save each part and decreases the risk of manual errors.

Also, introduced to create toolpaths for cutting complex geometries, is the new Drag Knife tool which uses a motion-controlled knife that dictates the direction of the blade. This provides new and advanced functionalities to users of entry-level CNC machines without the large capital investment of a premium cutter.

SAi’s many different options enable users to access the exact productivity and design tools required for their needs. For those seeking a comprehensive design-to-output workflow, EnRoute Complete comprises the full spectrum of tools. EnRoute Fabrication offers a haul of tools tailored to users operating plasma, waterjet and laser CNC machines within the metal fabrication industry, while EnRoute Designer provides users with access to standard production tools at an entry-level price.

For further information, please visit: www.ThinkSAi.com or contact:

With the launch of the new jetscript Metal VPG 1018, Mitsubishi HiTec Paper has unveiled a metallic silver gloss inkjet paper, developed for water-based inkjet printing. It is particularly suitable...

July 15 2019

With the launch of the new jetscript Metal VPG 1018, Mitsubishi HiTec Paper has unveiled a metallic silver gloss inkjet paper, developed for water-based inkjet printing. It is particularly suitable for self-adhesive label applications, as well.

According to Mitsubishi HiTec Paper, the results on the metallic glossy inkjet labels were only previously possible using a metallic film. Jetscript Metal VPG 1018 is a pure fiber-based paper product with a metallic mirror finish and a transparent, microporous inkjet coating for excellent printing performance.

The main features are:

- 110 gsm

- metallic-silver mirror finish

- high print density

- fast drying

- suitable for water-based inkjet printing (dye and pigment inks)

- compatible with latex inks

- optimum performance in the self-adhesive production process (handling, labelling, matrix removal)

This makes jetscript Metal VPG 1018 suitable to produce eye-catching labels in the cosmetics, beverage or food industry, as well as personalised wrapping paper, high-quality advertising panels and displays.

Scodix, the world’s leading provider of digital enhancement solutions for the graphic arts industry, today announces the launch of Scodix Studio W2P solutions, unlocking new profitable digita...

July 15 2019

Scodix, the world’s leading provider of digital enhancement solutions for the graphic arts industry, today announces the launch of Scodix Studio W2P solutions, unlocking new profitable digital enhancement applications for web-to-print businesses and further value-added, customised products for consumers.

The new Scodix Studio W2P solutions integrate seamlessly into all major existing web-to-print workflows, making digital enhancement automatic for even the most demanding web-to-print jobs. With the substantial value increases made possible by digitally enhancing products, the new software unlocks significant new avenues for profit for web-to-print businesses operating in both the B2B and B2C sectors.

Enhancement design files are sent to Scodix Studio W2P which automatically processes the data and directs it to a Scodix Ultra press. By off-loading and automating file pre-processing, the software service boosts the utilization and productivity of Scodix Ultra Digital Enhancement Presses and the entire workflow. With the advanced Scodix Studio W2P solutions, MIS integration is also enabled to strengthen the automation process, further saving time, reducing human intervention and increasing efficiency.

Implemented at over 20 customer sites across North America and Europe, Scodix Studio W2P solutions are already proven to be robust, trusted and valued solutions – even in the most demanding peak seasons. Early users report invaluable business differentiation following easy application of the software.

For complex jobs Scodix Studio W2P enables a market-leading array of nine premium, attention-grabbing print enhancements to be included. Applications include Scodix Foil™, Scodix Sense™, Scodix Glitter™, Scodix VDE™, Scodix Braille™, Scodix Crystals™, Scodix Cast&Cure™, Scodix Metallic and Scodix Spot™, high-quality UV coating and glitter. In addition, the software offers a host of features ideal for web-to-print businesses.

Scodix CEO Adina Shorr concludes, “We see web-to-print as a key market for Scodix. The Association for Print Technologies predicts a compound annual growth rate in the sector of 5.7 percent until 2023, so there’s clear opportunity for our customers to leverage. Scodix digital enhancement provides a perfect solution for differentiating businesses from the competition and keeping customers returning for products that truly change the business. The new Scodix Studio W2P provides the perfect tool for fully automated workflow for this space.”